No Products in the Cart

At its core, copper vacuum insulation is a powerful thermal barrier that brings together a vacuum space and a copper lining to massively cut down on heat transfer. This is the technology that excels at keeping cryogenic liquids, like nitrogen, incredibly cold by fighting off heat from the outside world. It’s really the go-to solution for any work where stable, ultra-low temperatures are an absolute must.

Picture an invisible yet incredibly strong thermal shield, silently protecting priceless assets from the constant threat of heat. That’s exactly the job of copper vacuum insulation in the high-stakes world of cryogenics. Trying to manage extreme cold is a non-stop battle, as heat is always trying to sneak in and ruin carefully controlled environments.

This technology is the frontline defence against that problem. It acts like a fortress, protecting everything from irreplaceable biological samples in a biobank to huge shipments of industrial gases. The survival of these materials hinges entirely on keeping temperatures locked in, often below -150°C.

Over the course of this guide, we’re going to walk through every aspect of this vital technology. The goal is to give professionals who rely on total cryogenic integrity a clear roadmap, breaking down complex ideas into practical, real-world knowledge.

Here’s a taste of what we'll cover:

Choosing the right insulation isn't just a small technical detail—it directly impacts your operational efficiency, costs, and the safety of your most critical assets. A vessel with better insulation means you’ll use less liquid nitrogen, which cuts down your running costs significantly over the equipment's lifespan. For anyone working with sensitive biologicals, better insulation translates to longer holding times and a much bigger safety net against temperature swings.

The effectiveness of a cryogenic storage system is fundamentally tied to its ability to combat heat transfer. Copper vacuum insulation provides one of the most robust defences against thermal ingress, making it a cornerstone of modern cryogenic engineering.

This guide is all about giving you the knowledge to make smarter decisions. By really understanding the science behind the technology and knowing how to weigh up different options, you can choose and maintain the equipment that truly forms the backbone of your cryogenic work. To get a head start on the containers themselves, you can learn more about the different types of cryogenic vessels and their applications. Having this foundational knowledge is the key to ensuring your valuable materials are secure for the long haul.

To really get a feel for the protective power of copper vacuum insulation, you have to look at the three scientific principles working in concert. It isn't just one feature doing the heavy lifting; it's a trio of thermal defences that create an incredibly effective barrier against heat.

Each piece of this puzzle plays a unique and vital role in hitting the stable, ultra-low temperatures that cryogenic applications demand. When you break down the technology, you find a clever system designed to fight heat transfer on every front. Let's dig into the vacuum, the copper layer, and the specialised getters that keep everything working flawlessly for years.

The first and most fundamental layer of defence is the vacuum itself. Heat gets around in three ways: conduction (through touch), convection (through moving air or liquid), and radiation (through waves). The vacuum’s main job is to put a dead stop to the first two.

Think of it like a busy motorway packed with cars, where each car is a molecule carrying heat energy. By creating a vacuum between the inner and outer walls of a cryogenic dewar, we’re essentially emptying that motorway, removing almost all the cars. Without those molecules to ferry heat across the gap, both conduction and convection are brought to a screeching halt.

By pulling over 99.9% of the air molecules out from the space between the walls, a high-quality vacuum creates a near-impassable barrier for convection and conduction. It forces heat to find another way in.

This powerful isolation is the foundation the whole system is built on. It’s a simple concept with massive implications for thermal management, but it's only the first piece of the puzzle. There’s another, more sneaky form of heat that still needs to be dealt with.

Even in a perfect vacuum, heat can still travel as thermal radiation. This is the same energy you feel from the sun or a warm fire, and it doesn't need any molecules to move. This is where the "copper" in copper vacuum insulation becomes the hero of the story.

A thin, highly polished layer of copper is applied to the inner wall facing the vacuum space. The easiest way to picture this layer is as a near-perfect mirror, but for heat instead of light. Its one job is to reflect thermal radiation straight back out before it can warm up the cryogenic contents.

This property is known as low emissivity. Materials with low emissivity are terrible at both emitting and absorbing radiant heat. Copper is exceptional at this, reflecting up to 97% of incoming thermal radiation. It works just like an emergency space blanket, which reflects your body heat back to keep you warm. In a dewar, the copper reflects ambient heat away from the precious cold liquid inside.

This reflective shield is the key advantage that sets copper-enhanced systems apart from standard stainless steel vacuum insulation. While stainless steel also has low emissivity, copper is significantly better at the job, giving you a measurable performance boost that directly translates to lower boil-off rates.

The final piece of this puzzle is a small, often hidden component called a getter. Despite its tiny size, its role is absolutely critical for the long-term integrity of the insulation. Over many years, a tiny amount of gas molecules can slowly escape from the vessel's own metal walls—a process called outgassing—or seep in through microscopic imperfections.

If you just let this happen, these stray molecules would gradually ruin the vacuum, allowing convection to creep back in and compromise the vessel's performance. The getter acts as a molecular sponge, permanently trapping these rogue gas molecules as soon as they appear.

This three-pronged defence is what makes copper vacuum insulation so effective. To put it all together, here's a quick summary of the core principles at play.

Core Principles of Copper Vacuum Insulation

| Mechanism | Principle | Analogy |

|---|---|---|

| Vacuum | Eliminates heat transfer via conduction and convection by removing air molecules from the space between the inner and outer walls. | Removing all the cars from a motorway so nothing can travel along it. |

| Copper Shielding | A low-emissivity copper layer reflects up to 97% of incoming thermal radiation, preventing heat from radiating across the vacuum gap. | A heat mirror that bounces radiant energy away from the cold contents. |

| Getter | A reactive material that absorbs stray gas molecules from outgassing or leaks, preserving the integrity of the vacuum over its entire lifespan. | A molecular sponge that soaks up any contaminants to keep the vacuum pure. |

These elements are what make the system work so well:

Together, these three components—the vacuum stopping convection, the copper reflecting radiation, and the getter preserving the vacuum—create a thermal shield that is incredibly difficult for heat to penetrate. This sophisticated, multi-layered approach is precisely why copper vacuum insulation is the gold standard for demanding cryogenic applications.

The science behind cryogenic insulation is fascinating, but for professionals in labs and industry, what really counts are the results you can measure. When we talk about the real-world performance of copper vacuum insulation, we’re moving past theory and into the hard numbers that define efficiency, safety, and operational costs. These figures aren't just specs on a data sheet; they're the vital signs of a cryogenic vessel's ability to protect its precious contents.

This is where the physics translates directly into performance you can bank on. Two key metrics have become the gold standard for judging any piece of cryogenic storage or transport equipment: the K-value and, most critically, the static evaporation rate.

To make the right choice for your needs, you have to speak the language of thermal efficiency. The metrics used in cryogenics are precise and standardised for a good reason—they allow you to make direct, apples-to-apples comparisons between different insulation types and vessel designs.

Here are the essential terms you’ll need to know:

A low boil-off rate is the hallmark of a superior cryogenic vessel. For example, a high-performance dewar might have a boil-off rate as low as 0.10 litres per day. A less efficient model, on the other hand, could lose several times that amount, dramatically driving up your operational costs over the long term.

Understanding these figures is non-negotiable. They are tested and certified under strict industry standards, especially for medical and transport applications where failure is not an option. To get the full picture, you can learn more about the complete parameters for quality assessment of cryogenic equipment in our detailed guide.

While manufacturers provide static boil-off rates based on lab conditions, how your equipment performs day-to-day can be affected by several environmental and handling factors. Think of the certified numbers as a baseline; your daily practices play a huge role in getting the most out of your investment.

It's a bit like the stated fuel efficiency for a car—your actual mileage varies based on how you drive. In the same way, a cryogenic vessel's thermal performance is influenced by:

By keeping these variables in check, you can ensure your equipment performs much closer to its optimal, lab-certified specifications. At the end of the day, investing in a system with superior copper vacuum insulation pays for itself through a lower total cost of ownership, driven by less cryogen consumption and the peace of mind that comes with longer, safer holding times for your critical assets.

Choosing the right insulation for a cryogenic system is a major decision. It directly affects performance, running costs, and even the safety of your assets. While a few different methods can fight off heat transfer, copper vacuum insulation really stands out as a powerful and well-rounded solution.

To really get a feel for its strengths, it helps to see it side-by-side with other common technologies, namely standard stainless steel vacuum insulation and multi-layer insulation (MLI). Each approach has its place, but comparing them makes it clear why copper vacuum insulation is so often the go-to choice for demanding work, like in laboratory biobanks or for transporting liquid nitrogen.

The most straightforward comparison is with standard stainless steel vacuum insulation. Both technologies are built on the same foundation: using a vacuum to stop heat transfer through convection and conduction. The real difference—and where the copper layer provides a huge performance boost—is in how they deal with thermal radiation.

Think of it this way: both systems get rid of the "air" that carries heat, but the copper lining acts as a much, much better heat mirror.

So, while a standard stainless steel vessel does a decent job, adding that copper shield gives copper vacuum insulation a clear, quantifiable edge in thermal efficiency.

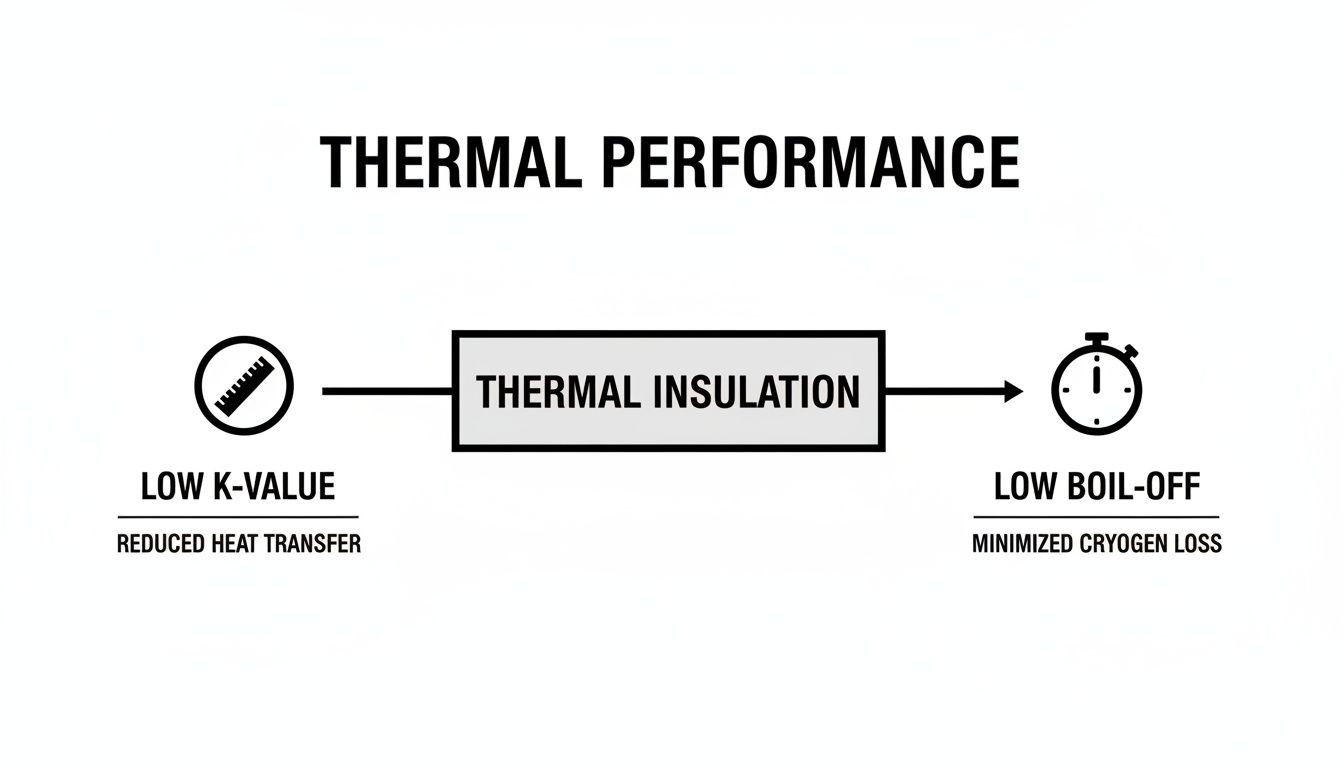

The diagram below shows exactly what this technology is designed to achieve.

As you can see, the goal is a low K-value (thermal conductivity). This directly translates to a low boil-off rate—the ultimate benchmark for cryogenic efficiency.

To put things into perspective, let's compare these methods in a simple table. This helps clarify the specific role each technology plays in the world of cryogenics.

| Insulation Type | Primary Mechanism | Best For | Key Limitation |

|---|---|---|---|

| Copper Vacuum Insulation | Vacuum + Radiation Shielding | Lab, medical & industrial storage; transport | Higher initial cost than basic insulation |

| Stainless Steel Vacuum | Vacuum only | General-purpose, less critical applications | Less effective against radiant heat transfer |

| Multi-Layer Insulation (MLI) | Multiple Radiation Barriers in Vacuum | Aerospace, research where max performance is vital | Complex, delicate, and high cost |

Ultimately, the choice comes down to balancing performance needs with practical considerations like durability and budget.

Another high-performance method is Multi-Layer Insulation (MLI). You'll often see this in very specialised fields like aerospace or particle physics experiments. MLI is essentially a high-tech thermal blanket made of many thin, reflective layers separated by a vacuum.

MLI is incredibly effective, but it comes with a different set of trade-offs when you compare it to the robust simplicity of copper vacuum insulation.

For the vast majority of lab and industrial uses, copper vacuum insulation hits the sweet spot, offering an ideal mix of top-tier performance, toughness, and value. MLI is powerful, but it can be more fragile and complex than what's needed for everyday cryogenic storage.

Here’s a breakdown of how they compare:

The market backs this up. There's a projected surge in demand for vacuum insulated systems in industrial and research settings. For example, the global vacuum insulated pipe market is expected to climb from USD 1.3 billion in 2025 to USD 2.1 billion by 2035. Germany's market is a great example, showing strong demand in biotech and pharma with a projected 5.9% CAGR, outpacing other major European markets. You can read the full research about vacuum insulated pipe market trends to see how this growth highlights the real-world value of tough, dependable vacuum insulation in essential industries.

The theory behind copper vacuum insulation is one thing, but where it truly shines is in the vital work it supports every single day. This isn't just a product feature; it's the technology that enables breakthroughs in medicine, high-stakes research, and critical industry. In these fields, perfect temperature stability isn't a luxury—it's the absolute bedrock of success and safety.

From the building blocks of life to the gases that power modern manufacturing, high-performance insulated vessels are the first line of defence against thermal damage. They solve problems that standard insulation simply can't touch, making them indispensable tools for modern science and industry.

In medicine and life sciences, the integrity of biological samples is everything. A tiny temperature fluctuation can wipe out years of research or render a life-changing treatment completely useless. This is where the sheer reliability of copper vacuum insulation becomes non-negotiable.

Think about these critical environments:

For these applications, maintaining the chain of custody isn't just a logistical exercise—it's an ethical and regulatory mandate. The reliability that comes with advanced vacuum insulation is a core part of ensuring samples are viable and safe from the moment they are stored to the moment they are needed.

This level of performance lets scientists focus on the science, not on worrying whether their equipment will fail them.

Step outside the lab, and you'll find copper vacuum insulation is a workhorse in industries that depend on cryogenic gases. Here, the challenge isn't just preserving tiny samples, but safely and efficiently transporting and storing massive volumes of liquid gases. The economic and safety stakes are enormous.

These vessels are essential for:

The demand for these high-performance systems is on the rise, mirroring a wider industrial push for greater efficiency. Take Germany, a powerhouse in industrial tech, which holds a major share of the European market for vacuum insulated pipes. This is driven in part by ambitious national targets, like the German Energy Agency’s goal to boost energy efficiency by 30% by 2030. This kind of commitment fuels the need for advanced thermal solutions like copper vacuum insulation. You can find more details in this report on the European vacuum insulated pipe market on marketdataforecast.com.

Whether it’s a single vial in a research lab or a multi-tonne tanker on the motorway, this technology provides the performance needed to protect valuable assets, guarantee safety, and drive progress forward.

Choosing equipment with copper vacuum insulation is a major decision, one that affects both your budget and how securely you can run your operations. Getting it right from the start and following a solid care routine will pay for itself over and over, keeping your critical assets safe for the long haul.

This isn't just about ticking boxes on a spec sheet. It's about taking a hard look at what you actually need, finding a supplier you can count on, and sticking to a maintenance schedule to get the most out of the vessel's performance and lifespan.

The first step to picking the right vessel is to map out your operational needs in detail. A vessel that’s too big is just a way to waste liquid nitrogen, but one that’s too small can seriously disrupt your workflow and even create safety risks.

Start by nailing down these key factors:

Think of a strong supplier relationship as your best insurance policy. Knowing you have expert technicians and spare parts on call gives you long-term peace of mind and protects your initial investment.

Once you have a few options, think about the total cost of ownership. A vessel that costs a bit more upfront but has a much better boil-off rate will save you a fortune in liquid nitrogen over its lifetime, often making it the smarter financial choice.

Taking good care of your equipment is non-negotiable for protecting the integrity of its copper vacuum insulation. Simple, regular checks and proper handling can stop small problems from turning into catastrophic failures, protecting the vessel and whatever's inside it.

Just follow this straightforward maintenance checklist:

As we wrap up this deep dive, it's worth tackling some of the practical questions we often hear from professionals about using and owning equipment with copper vacuum insulation. Getting these points clear can help firm up your understanding and give you complete confidence when choosing or looking after your critical cryogenic vessels.

These are the questions that come up time and again from labs, biobanks, and industrial teams who count on flawless cryogenic performance every single day.

A top-tier cryogenic vessel is built to hold its vacuum for a very long time—often a decade or even more. The real-world lifespan really boils down to the quality of manufacturing, the integrity of the seals, and how well the internal getter material does its job of mopping up stray gas molecules over the years.

A long warranty on the vacuum, say five years, is a great sign that you're looking at a well-built, reliable unit. You can also keep an eye on the vacuum's health with simple visual checks. Frost appearing on the outside of the vessel is the classic early warning sign that you might have a vacuum loss.

While the initial price tag for a vessel with copper vacuum insulation might be a bit higher than a more basic alternative, it nearly always works out to a lower total cost of ownership. The secret is its fantastic thermal efficiency, which directly translates to a much lower boil-off rate for liquid nitrogen.

What this means for your budget is that you spend far less on replacing cryogen over the vessel's lifetime. These ongoing operational savings deliver a strong, and often quick, return on your initial investment—especially in situations where protecting the integrity of your samples is non-negotiable.

Fixing a compromised vacuum is a highly specialised job, not something that can be handled in a typical lab or out in the field. The process demands industrial-grade vacuum pumps, special ovens, and tightly controlled conditions to properly re-evacuate the insulation space and bake out any moisture or contaminants.

If you even suspect your vessel has lost its vacuum, it's vital to get in touch with the original manufacturer or a qualified service expert right away. Trying to fix it yourself isn't just ineffective; you could cause permanent damage to the vessel and create serious safety hazards. A professional assessment is the only safe and sensible way forward.

At Cryonos GmbH, we provide cutting-edge cryogenic solutions built on decades of technical expertise and a solid commitment to long-term reliability. See our complete range of ADR-licensed and medically certified vessels at https://www.cryonos.shop.