No Products in the Cart

Dry ice is simply the solid form of carbon dioxide (CO₂). What makes it so unique is a property called sublimation. Unlike regular ice that melts into a puddle, dry ice transforms directly from a solid into a gas at a bone-chilling -78.5°C (-109.3°F).

Because it never turns into a liquid, it leaves behind zero residue. This powerful, clean cooling capability has made it a true cornerstone of modern cold-chain logistics and countless industrial processes.

Dry ice might look straightforward, but its behaviour is rooted in some fascinating physics. That process of sublimation—jumping straight from solid to gas—is what truly sets it apart from water ice. Think of how a puddle evaporates on a hot day; dry ice does something similar, but instantly and at an incredibly low temperature, completely skipping the liquid phase.

This unique trait is precisely where its value lies. Since it doesn't melt, there's no risk of water damage or contamination. This makes it the perfect choice for shipping sensitive materials like pharmaceuticals, biological samples, and high-end foods. The thick, white fog it creates is just pure, gaseous CO₂, which is heavier than air and sinks, producing that famous visual effect you see in theatres and at events.

Grasping sublimation is the key to understanding why dry ice is so important in industry. This single characteristic delivers several massive advantages:

These properties are so effective that the demand for dry ice is constantly on the rise. In 2022, the European market, with Germany leading the way, was valued at around USD 139 million and is expected to climb past USD 217 million by 2030. This growth is fuelled by industries that can't compromise on clean, efficient, and reliable cooling. You can find more details on the European dry ice market at businessmarketinsights.com.

At its core, dry ice is a transportable, high-density form of extreme cold. It’s not just frozen gas; it’s a tool that enables industries to maintain precise temperature control without the mess or limitations of traditional coolants.

The science that governs these extremely low temperatures is fascinating. To explore this field further, you can get a deeper understanding of what is cryogenics in our detailed article.

The visual below shows a block of dry ice actively sublimating, releasing that classic dense fog of carbon dioxide gas.

This image perfectly captures that transition from solid to gas. It shows why dry ice is so effective for creating atmospheric effects while also being a powerhouse cooling agent. This unique dual-purpose nature is why it’s used everywhere from Hollywood sets to critical supply chains, where the Herstellung von Trockeneis (production of dry ice) must meet incredibly strict standards for purity and density.

Turning invisible carbon dioxide gas into a dense, solid block of dry ice is a fascinating feat of engineering. The industrial production of dry ice is a precise, multi-stage process that masterfully manipulates pressure and temperature to force a change of state. It all starts not in a freezer, but with a highly pressurised liquid.

The primary raw material is liquid carbon dioxide (LCO₂), typically stored on-site in large, insulated bulk tanks. These tanks are kept under high pressure to prevent the LCO₂ from turning back into a gas. Interestingly, this LCO₂ is often a byproduct captured from other industrial activities, like ammonia production or fermentation, making its sourcing a clever form of industrial recycling.

Before anything else, this LCO₂ must be impeccably pure. For food or medical-grade applications, a purity of 99.9% or higher is non-negotiable. The liquid is carefully filtered and purified to remove any trace moisture, hydrocarbons, or other contaminants that could compromise the final product's quality.

At the heart of dry ice manufacturing is a scientific principle known as the Joule-Thomson effect. It sounds complex, but you’ve likely seen it in action.

Think about what happens when you use an aerosol can. As the pressurised contents escape through the small nozzle, the can gets noticeably cold. That’s the Joule-Thomson effect. Dry ice production simply harnesses this principle on a much larger and more powerful scale.

The process is a rapid sequence of events:

This rapid expansion is the magical moment where liquid CO₂ transforms into a solid state. It’s not a slow freezing process like making water ice; it's an instantaneous conversion driven purely by physics, turning pressurised liquid into an extremely cold solid snow in the blink of an eye.

The table below breaks down these core stages of production, showing how liquid carbon dioxide is methodically converted into solid dry ice.

| Stages of Industrial Dry Ice Production |

| :--- | :--- | :--- |

| Stage | Process Description | Key Principle |

| 1. Sourcing & Purification | Liquid CO₂ is stored under pressure and filtered to achieve high purity (e.g., 99.9%). | High-quality input is essential for a high-quality output, especially for food and pharma grades. |

| 2. Expansion & Solidification | High-pressure LCO₂ is released into an atmospheric pressure chamber, causing rapid expansion and freezing. | The Joule-Thomson effect causes an instant temperature drop, converting about half the liquid into solid CO₂ "snow". |

| 3. Compression | The newly formed CO₂ snow is compacted under immense hydraulic pressure. | This step increases the density and stability of the dry ice, forming it into usable blocks or pellets. |

Each step is critical for ensuring the final product meets the density, purity, and form factor required for industrial use.

This freshly created CO₂ snow is soft and has a low density, which isn’t very practical for handling or transport. The final, crucial step is compression. Here, immense force is applied to transform this fluffy snow into the dense, usable forms of dry ice that industries depend on.

This is where specialised equipment like block presses and pelletisers take over. A powerful hydraulic ram descends into the chamber, compressing the CO₂ snow with extreme force. This compaction process squeezes out any remaining gaseous CO₂, fusing the snow particles into a solid, cohesive mass.

The final shape of the dry ice depends on the machine's die plate:

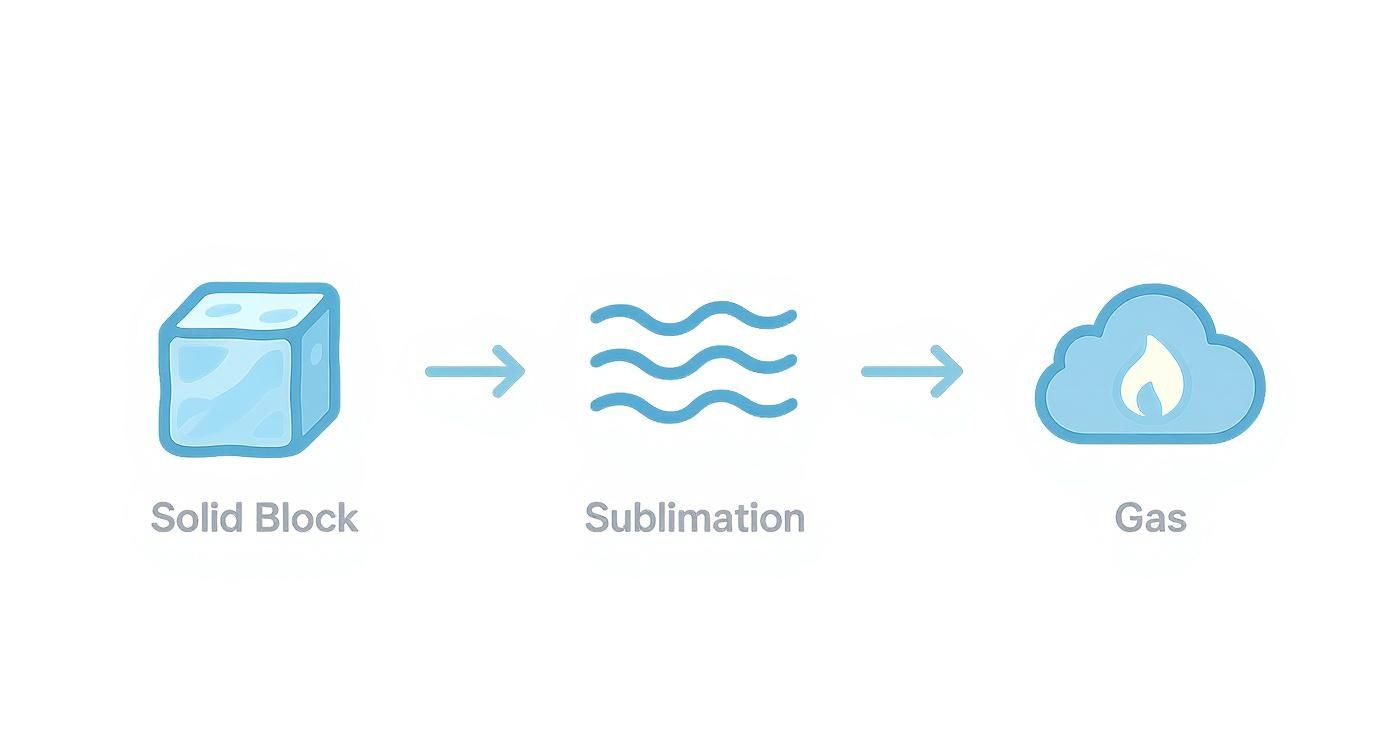

The illustration below shows the simple yet powerful process of sublimation, where the final solid block turns directly into gas.

This direct transition from solid to gas is what makes dry ice a "clean" coolant—it leaves no liquid residue behind. This property is fundamental to its use in sensitive cryogenic industrial processes.

Germany’s dry ice market is currently seeing a significant shift, driven by technology and sustainability, especially within its large pharmaceutical and food sectors. To comply with EU environmental goals, German companies are increasingly focused on producing dry ice from recycled CO₂ sources. This aligns with regulations like the EU Emissions Trading System (EU ETS), which are designed to reduce carbon footprints—a key trend in a European dry ice market valued at USD 89.39 million and growing steadily.

Behind every pellet and block of dry ice, there's a whole system of specialised machinery working hard to turn liquid CO₂ into a solid coolant. The journey of Herstellung von Trockeneis (making dry ice) starts long before you see that iconic white fog. It all begins with the most fundamental piece of kit at any production facility: the storage tank.

These aren't just any old containers. They are massive, heavily insulated, and highly pressurised vessels built to hold liquid carbon dioxide (LCO₂) under the exact conditions needed to stop it from turning back into a gas. Think of them as giant, industrial-grade thermos flasks, keeping the raw material stable and ready to go. From these tanks, the LCO₂ is piped to the real workhorses of the plant.

After the rapid expansion turns LCO₂ into fluffy CO₂ snow, that snow has to be compacted into a dense, useful form. This is where two main types of machines take over, each designed to make a specific format of dry ice for different jobs.

First up, we have the dry ice pelletizers. These machines work a lot like a high-powered extruder. The CO₂ snow is fed into a chamber and then squeezed through a die plate—a thick steel plate full of holes of a specific size. As the snow is forced through, it gets compacted into small, uniform pellets.

The other key piece of equipment is the dry ice block press. Instead of extruding snow, this powerful machine uses a massive hydraulic ram to compress a large amount of CO₂ snow inside a chamber. The pressure is immense, fusing the snow particles into a single, high-density block. These blocks are the undisputed champions of long-lasting cooling.

The form of the dry ice isn't just about shape; it directly impacts its performance. A big, dense block has a much lower surface-area-to-volume ratio than the same weight in pellets, which means it sublimates much, much slower. That makes blocks the go-to choice for long-haul shipping.

This ability to tailor the final product is what allows manufacturers to meet the needs of so many different industries, from food processing to pharmaceutical logistics.

A modern dry ice production facility is more than just presses and pelletizers. To keep things running smoothly, safely, and continuously, you need a whole network of supporting equipment. This integrated system is what makes high-volume output for industrial clients possible.

Some key supporting components include:

Taken together, this whole ecosystem of machinery—from the initial storage tank to the final insulated container—forms a complete production line. Every component is meticulously designed to handle the extreme cold and unique properties of dry ice, ensuring a reliable supply of this incredibly versatile industrial tool.

When you’re dropping a few pellets of dry ice into a punch bowl for a spooky party effect, the quality standards are pretty relaxed. But when that same dry ice is responsible for keeping life-saving vaccines stable or flash-freezing food products, there is absolutely no margin for error. Not all dry ice is created equal, and for critical industries, quality control during the Herstellung von Trockeneis is everything.

The path to top-tier dry ice starts right at the source. For any application in the food, pharmaceutical, or medical fields, only food-grade dry ice will do. This isn't just a fancy label—it's a strict standard that demands the liquid carbon dioxide used in production has a minimum purity of 99.9%.

This high level of purity is crucial. It guarantees the final product is completely free of any potential contaminants like hydrocarbons, moisture, or other unwanted residual gases. Even trace amounts of these impurities could easily compromise the integrity of the products being cooled, leading to spoilage, contamination, or a loss of effectiveness.

To make sure these demanding standards are met, manufacturers depend on rigorous testing protocols. Organisations like the International Society of Beverage Technologists (ISBT) have set out clear guidelines for beverage-quality CO₂, which have become the go-to benchmark for producing food-grade dry ice across Europe.

Constant testing confirms that the CO₂ consistently meets these purity requirements. This involves sophisticated lab analysis designed to sniff out any undesirable trace elements, ensuring that every single block or pellet is safe for both direct and indirect contact with food, beverages, and sensitive biological materials.

But quality isn't just about what you can't see. It also comes down to physical properties that have a direct impact on performance, and none is more critical than density.

Think of it like this: you have two ice cubes that weigh the same. One is a solid, clear block, and the other is light and airy, like a tightly packed snowball. The snowy one will melt far more quickly simply because more of its surface is exposed to the air. The very same principle applies to dry ice.

A denser block of dry ice sublimates—turns from a solid directly into a gas—at a much slower rate than a less dense one. This longer lifespan is absolutely vital for applications like long-haul shipping, where a stable temperature has to be maintained for days on end. A higher-density block delivers a more dependable, longer-lasting cooling solution, making sure the cold chain remains unbroken from start to finish.

The density of dry ice is a direct outcome of the compression stage during its manufacturing. By carefully controlling the hydraulic pressure applied to the CO₂ snow, producers can tailor the final product's density to meet a client's specific needs for longevity and cooling power.

Producers can fine-tune this final step to create products with distinct characteristics:

Ultimately, a commitment to quality in the Herstellung von Trockeneis is a promise of reliability. From sourcing ultra-pure CO₂ to fine-tuning the physical properties of the final product, every step is geared towards delivering a safe, effective, and consistent cooling tool that critical industries can depend on, no questions asked.

Working with a substance colder than an Antarctic winter requires more than just a bit of caution—it demands strict discipline and specialist knowledge. Dry ice, with its surface temperature of -78.5°C (-109.3°F), is an incredibly powerful tool, but it comes with three primary hazards that have to be managed with absolute precision.

Getting a handle on these risks is the first step toward a safe working environment. The dangers are direct and significant. First, there's severe frostbite from skin contact, which can damage tissue in seconds. Then, there's the risk of asphyxiation as the solid sublimates into CO₂ gas, pushing oxygen out of confined spaces.

Finally, you have the danger of explosive pressure if dry ice is ever sealed in an airtight container. The good news is that every single one of these hazards is completely preventable with the right protocols in place.

Direct contact with dry ice is a definite no-go and calls for the right Personal Protective Equipment (PPE). Your standard work gloves won't do a thing; the extreme cold will pass straight through them.

Here's the mandatory safety gear you'll need:

Proper PPE turns a potentially hazardous job into a routine, safe procedure. For a deeper dive into the risks associated with super-cooled substances, our guide on the hazards of cryogenic liquids offers some valuable insights.

As dry ice sublimates, it lets off a huge volume of carbon dioxide gas—a single kilogramme of solid dry ice creates about 541 litres of CO₂ gas. In a room without good airflow, this gas can quickly replace the oxygen, creating a serious risk of asphyxiation.

Because of this, you must always ensure constant and adequate ventilation when handling or storing dry ice. This can be as simple as opening doors and windows or using mechanical ventilation systems in an industrial setting. Never, ever store dry ice in unventilated spaces like cellars, cold rooms, or inside the main cab of a vehicle.

The cardinal rule of dry ice storage is simple: never use an airtight container. The pressure from sublimation will just keep building until the container ruptures or explodes with violent force. Always use a purpose-built, insulated container designed to vent the gas safely.

Shipping dry ice safely is governed by strict regulations to protect everyone involved, from the handlers to the general public. For transport purposes, dry ice is classified as a hazardous material, specifically as "Miscellaneous Dangerous Goods" under Class 9, UN 1845. This classification comes with specific labelling and packaging rules.

Key transport requirements include:

Sticking to these protocols isn't just best practice; it's a legal requirement under ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) and other international transport codes. With a huge chunk of European dry ice consumption happening right here in Germany for industrial and pharmaceutical use, strict adherence is absolutely vital for the entire supply chain. You can discover more insights about the European dry ice market on snsinsider.com.

Even after getting a handle on the basics of Herstellung von Trockeneis, you’ll likely still have some practical questions. People often wonder about the different types of dry ice, how to store it properly, and what its real-world impact is. Let's tackle some of the most common queries to help you use dry ice safely and get the most out of it.

One of the biggest points of confusion is the difference between food-grade and industrial-grade dry ice. While both are just solid CO₂, where they come from and how they're made sets them worlds apart.

The real distinction comes down to the purity of the source CO₂ and how clean the production facility is. Food-grade dry ice is made using beverage-quality liquid CO₂, which has a purity level of 99.9% or higher. It's produced in facilities that follow strict food safety protocols, ensuring it's completely free from contaminants. That’s why it's safe for things like flash-freezing food or creating those cool fog effects in high-end cocktails and dishes.

Industrial-grade dry ice, on the other hand, might be produced using CO₂ captured from various industrial sources that aren't as pure. It's perfectly fine for jobs like abrasive blast cleaning or shrink-fitting metal parts—basically, any application where it won’t touch food or medical products.

You can't stop dry ice from sublimating, but you can definitely slow it down. The trick is to insulate it as well as you can while still allowing the CO₂ gas to escape safely.

Here’s how to extend its lifespan:

It’s natural to wonder if making dry ice is bad for the environment. The answer isn't a simple yes or no, but it's more positive than you might think. The process of making dry ice is just a physical change of state; it doesn't create any new CO₂.

The key point is that the vast majority of carbon dioxide used for Herstellung von Trockeneis is a captured byproduct from other industries, like ammonia plants or fermentation facilities. This is essentially a form of carbon recycling. It takes CO₂ that would have otherwise been vented into the atmosphere and gives it a second, useful life.

The environmental footprint of dry ice isn't from the CO₂ itself. It's tied to the energy needed for compression and the logistics involved. The good news is that the industry is moving towards using more recycled CO₂ and energy-efficient equipment, making the whole process much more sustainable.

The main environmental factors are the energy consumption of the production plant and where that energy comes from. A facility running on renewable energy will obviously have a much smaller carbon footprint. In short, making dry ice is a valuable way of putting captured carbon to good use.

The price of dry ice isn't fixed; it shifts based on several economic and logistical factors. If you understand what drives the cost, you'll see why prices can vary so much between different suppliers and regions.

Here are the main things that affect what you pay:

Ultimately, the cost reflects a complex supply chain that has to manage a product with an extremely short shelf life, all the way from the plant to your doorstep.

At Cryonos GmbH, we know that solid cryogenic solutions are the backbone of your operations. Our state-of-the-art storage and transport vessels are designed to integrate perfectly with dry ice workflows, protecting the integrity of your sensitive materials every step of the way. Explore our complete range of cryogenic equipment at https://www.cryonos.shop.