No Products in the Cart

Picking the right schläuche für gasflaschen is a massive deal for safety and keeping things running smoothly, particularly in places like labs or industrial plants where there’s no room for error. Think of the hose as the lifeline for your entire gas setup; the wrong one can lead to dangerous leaks, contaminated gas, or a catastrophic failure.

Selecting a hose for a gas cylinder isn't like buying a simple accessory. It’s a core component that guarantees the safe and efficient movement of vital—and often hazardous—gases. A bad choice doesn't just put your operations at risk; it threatens the safety of your team and your entire facility. The fallout from a mismatch, like using a standard rubber hose for cryogenic liquid nitrogen, can range from poor performance to a truly severe accident.

This guide will walk you through the non-negotiables you need to consider to make a safe, informed decision. It all boils down to four main pillars of hose selection:

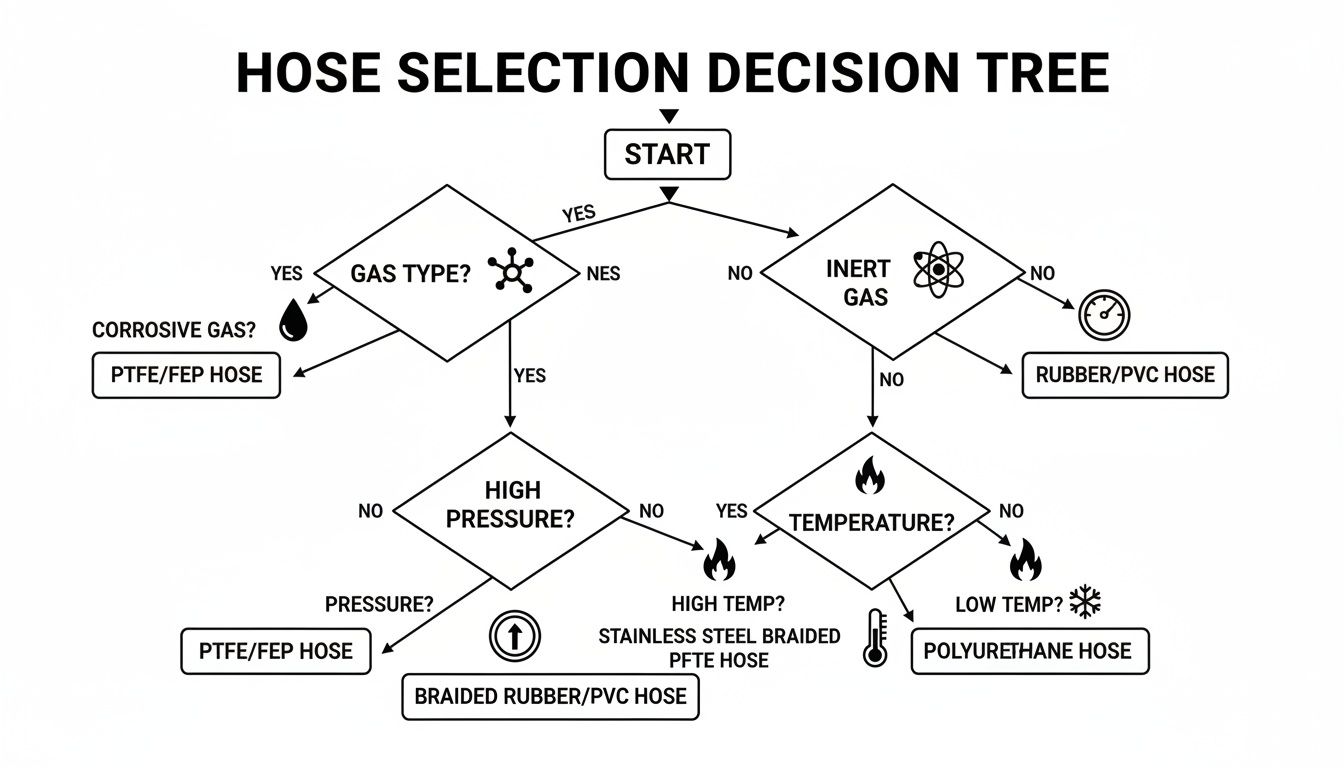

This simple decision tree shows how these key factors steer your choice right from the start.

As you can see, the journey always begins with the gas type. Chemical compatibility is the absolute, non-negotiable starting point for safety.

To make this even simpler, here's a quick reference table for some common scenarios.

This table offers a snapshot of how different applications dictate hose requirements. It's a great starting point, but always cross-reference with your specific gas data sheets and system parameters.

| Application | Primary Gas Type | Key Hose Requirement | Relevant Standard |

|---|---|---|---|

| Welding & Cutting | Acetylene, Oxygen | Flame resistance, high pressure | EN 559, ISO 3821 |

| Laboratory/Analytics | High-Purity Gases | Low permeation, chemical inertness (often PTFE-lined) | N/A (Application-specific) |

| Medical Gas Supply | Medical Oxygen, N₂O | High purity, cleanliness, specific colour-coding | EN ISO 7396, HTM 02-01 |

| Cryogenic Transfer | Liquid Nitrogen (LN₂) | Extreme low-temperature flexibility, vacuum insulation | EN 12434 |

| Industrial Processes | Hydrogen, Ammonia | High pressure, material compatibility, robust build | ISO 10380, EN 14585 |

| BBQ/Leisure | Propane, Butane | Low pressure, flexibility, weather resistance | EN 16436 |

Think of this table as a cheat sheet. It helps you quickly narrow down the field before you dive into the finer details of materials and connectors, which we'll cover next.

It's tempting to search for a one-size-fits-all solution, but in the world of gas handling, that's a dangerous fantasy. Every application is a unique cocktail of chemical, thermal, and mechanical stress.

A flexible rubber hose that’s perfect for a low-pressure propane BBQ would become brittle and shatter in an instant if you tried to run liquid nitrogen at -196°C through it.

A gas hose is never just an accessory; it is an engineered component integral to the safety and integrity of your entire gas delivery system. Overlooking its specifications is like building a strong bridge but using weak bolts to hold it together.

On the other hand, a heavy-duty, corrugated stainless steel hose designed for high-pressure or cryogenic work would be complete overkill—and needlessly stiff—for a simple, low-pressure airline. Getting the trade-offs right is the key.

By carefully weighing each factor, you ensure your chosen schläuche für gasflaschen strikes the right balance of flexibility, durability, and resistance. This puts you on solid ground for a safe and reliable operation and prepares you for the next step: a deeper dive into the specific materials and standards that govern these critical components.

A gas hose might look simple from the outside, but it’s a sophisticated piece of engineering. Think of it as a specialised artery, built with one job in mind: to move high-pressure or intensely cold cryogenic gases safely from point A to point B.

Its construction is layered for a reason. The innermost tube acts as the slick, non-reactive pathway for the gas. The reinforcement layer is the powerful muscle, handling the immense pressure. And the outer cover is the tough skin that shields everything from the outside world.

Choosing the right materials for these layers is everything. The right combination determines whether the Schläuche für Gasflaschen will perform flawlessly, whether it's feeding a high-purity gas to a sensitive lab instrument or transferring liquid nitrogen at bone-chilling temperatures.

Every proper gas hose is built around three core layers, each playing a vital role:

Once you understand this layered approach, it becomes clear why there’s no such thing as a "one-size-fits-all" gas hose. The specific materials used in each layer define the hose's capabilities and limitations.

The material you need hinges entirely on the gas you're handling, along with the pressures and temperatures involved. Let's walk through the most common players on the field.

Rubber hoses are the dependable workhorses of the gas industry. They’re flexible, durable, and don't break the bank, which makes them a go-to choice for common industrial gases like compressed air, nitrogen, and propane.

But not all rubber is created equal. Nitrile, for example, holds up well against oils, while EPDM is excellent at resisting weather and ozone, making it perfect for outdoor use. In the German market, rubber hoses are a dominant force, accounting for a massive 40.93% revenue share. This shows just how essential they are as reliable Schläuche für Gasflaschen across countless industries.

When you need brute strength and the ability to handle extreme temperatures—hot or cold—corrugated stainless steel is the undisputed champion. Its metal construction means gases can't permeate through it, making it ideal for aggressive, corrosive, or high-purity gases.

For cryogenic work, a corrugated stainless steel hose isn't just an option; it's a necessity. Its unique ability to stay strong yet flexible at temperatures dipping as low as -196°C is crucial for safely handling liquid nitrogen.

For jobs that demand this kind of extreme performance, you can find out more about our specialised cryogenic hoses.

You probably know it by its brand name, Teflon™. PTFE is a high-performance polymer famous for being incredibly non-reactive. Its super-smooth, non-stick inner surface is perfect for high-purity applications, like in laboratories or pharmaceutical production, where even the slightest contamination is a major problem.

Thermoplastic hoses are a lightweight and often more flexible alternative to rubber. PVC is a solid choice for its chemical resistance, while polyurethane is prized for its exceptional resistance to abrasion, often outlasting rubber in physically demanding environments.

To make sense of these options, it helps to see them side-by-side. The table below breaks down the key characteristics of each material to help guide your decision.

| Material | Temperature Range (°C) | Pressure Rating | Best For (Gas Types) | Key Limitation |

|---|---|---|---|---|

| Rubber (EPDM) | -40°C to 100°C | Low to Medium | Inert gases, Propane, Air | Can degrade with certain chemicals |

| Stainless Steel | -200°C to 450°C | Very High | Cryogenic liquids, High-purity, Corrosive gases | Less flexible than rubber |

| PTFE | -70°C to 260°C | Medium to High | High-purity, Reactive, Corrosive gases | Can be less flexible and more costly |

| Thermoplastic | -20°C to 60°C | Low | Air, Water, Some chemicals | Limited temperature and pressure range |

Ultimately, the best hose is the one that’s perfectly matched to its specific job. Using this comparison as a starting point will help ensure you select a material that provides both safety and performance.

Choosing the right schläuche für gasflaschen is about more than just picking the right material. It’s about understanding two invisible but powerful forces that can make or break your setup: pressure and temperature. Get these wrong, and a hose that should last for years could fail in an instant. Ignoring them is like driving over a bridge without checking the weight limit—the consequences can be catastrophic.

Let’s break down these critical specs, so you can see exactly how to read pressure ratings and understand why temperature extremes—from the heat of a welding workshop to the biting cold of cryogenics—are so crucial to your hose's integrity.

Every gas hose is rated with a Maximum Allowable Working Pressure (MAWP). This isn't a friendly suggestion; it's the absolute ceiling for safe, day-in, day-out operation. Think of it like the red line on a car's tachometer. Pushing past it, even for a moment, puts immense stress on the hose's reinforcement layers and courts a dangerous burst.

A simple rule of thumb is to pick a hose with a MAWP that is significantly higher than your system’s peak operating pressure. This buffer is your safety margin, accounting for any unexpected pressure spikes or surges that can happen on the job. Never cut this corner. The small cost of a higher-rated hose is nothing compared to the price of an accident.

A hose’s pressure rating is a hard limit, not a flexible guideline. Exceeding the MAWP compromises the structural integrity of the entire assembly, turning a controlled gas transfer into an uncontrolled hazard.

Of course, proper pressure management involves the whole system, not just the hose. Keeping a constant eye on your setup with a reliable instrument is fundamental to safety. If you need pinpoint accuracy, check out our guide on selecting a high-quality pressure gauge.

The need for high-pressure gas handling is growing across the board. Take Germany's gas cylinder market, for instance. Valued at USD 313.51 million in 2024, it's expected to climb to USD 515.80 million by 2032. This surge, highlighted by Data Bridge Market Research, is largely driven by high-pressure cylinders used in critical applications like cryogenic storage—fuelling the demand for tough, reliable schläuche für gasflaschen.

Temperature is pressure’s silent partner. Extreme heat or cold can completely change a hose material's physical properties, messing with its flexibility, strength, and ability to hold pressure.

When you're dealing with cryogenic liquids like liquid nitrogen (LN₂), which sits at a frosty -196°C (-321°F), you're facing challenges that standard hoses just can't handle. This is where specialised engineering becomes non-negotiable.

The biggest issue is thermal contraction. As materials get incredibly cold, they shrink. If a hose and its metal fittings shrink at different rates, the seal between them will fail, causing a serious leak. On top of that, most common materials become as brittle as glass at these temperatures.

This is exactly why cryogenic hoses are almost always made from corrugated stainless steel. This material is engineered from the ground up to:

For cryogenic work, choosing the right schläuche für gasflaschen isn't just about performance—it's about making the safe transfer of these volatile liquids possible in the first place.

Choosing the right material and pressure rating for your schläuche für gasflaschen is only half the battle. The final, critical piece of the puzzle is creating a perfect, leak-free connection. This is where connectors and safety standards come in, acting as a universal language to ensure parts from different manufacturers can work together safely.

Think of it like this: the connector is the handshake between your gas cylinder, the hose, and your equipment. If that handshake is off—if the threads don't match or the seal is wrong—the entire system is compromised. Getting this right isn't just a good idea; it's absolutely non-negotiable for safety and operational integrity.

In Europe, and especially in Germany, gas cylinder connections are meticulously standardised to prevent dangerous mix-ups. This is by design. You can't, for example, accidentally hook up a hose meant for an inert gas to a flammable gas cylinder. The main standard you'll run into is DIN 477.

This standard assigns unique connector types to different gases or families of gases based on their properties. It's a clever safety feature that uses physical incompatibility as the first line of defence against misuse.

For instance, the connector for an oxygen cylinder (DIN 477-1 No. 9) is physically different from the one for a hydrogen cylinder (DIN 477-1 No. 1). You simply cannot interchange them. The lesson here is to always check the cylinder valve outlet and make sure your hose connector is an exact match.

Beyond just the physical fit, European standards give you a solid guarantee of quality, safety, and performance. When you see a hose marked with an EN (European Norm) or ISO (International Organization for Standardization) standard, it means it has been put through its paces and rigorously tested for its intended use.

These certifications are your proof that the schläuche für gasflaschen you’re using is fit for purpose and has passed tough tests for pressure, material composition, and durability.

A safety certification is more than just a label on a hose; it's a documented promise from the manufacturer that the product meets established safety benchmarks. Relying on uncertified components is a gamble with potentially severe consequences for both personnel and equipment.

Let's dive into a few of the most important standards you're likely to see.

The importance of these standards is highlighted by the dominance of cylinders in the German industrial gases market, where they hold a commanding 45% market share. Cylinders are the backbone of gas delivery for biobanks, hospitals, and biotech labs where a safe, portable supply is essential. This heavy reliance on cylinder-based systems makes high-quality, certified hoses a critical link in the supply chain. You can explore more about this market dynamic from Vyansa Intelligence.

By getting to know these connector types and safety certifications, you can confidently pick a hose that not only fits perfectly but is also proven to be safe and reliable for your specific job. It turns the selection process from guesswork into a methodical, safety-first approach.

Moving from the technical specs on paper to the real world, proper installation and routine checks are the absolute bedrock of safe gas handling. It's simple: a correctly installed hose is a secure and efficient one. Regular inspections catch potential failures before they turn into dangerous incidents. Don't think of this as a chore—it's essential preventative maintenance for a critical part of your system.

This checklist breaks everything down into clear, actionable steps. Follow these guidelines for every single schläuche für gasflaschen you install or look after. Doing so will massively reduce risks, extend the life of your equipment, and ensure a safer environment for everyone.

Before you even think about making a connection, a thorough visual check is non-negotiable. Hoses can get damaged during shipping or just by being moved around, and installing a compromised one is a risk you just can't take. A few moments spent here can prevent a major failure down the line.

A clean connection is a safe connection. Debris in the threads can prevent a proper seal, leading to slow, undetectable leaks. Always ensure both the hose fittings and the cylinder valve are immaculate before assembly.

Getting the installation technique right is crucial. You're aiming for a durable, leak-free seal without putting any unnecessary stress on the hose or its connections.

The goal here is a tight seal without going overboard and over-torquing the fittings. That's a surefire way to damage the threads or the sealing surfaces.

Once it's installed, your very next step is a leak test. This isn't optional. It’s the only way to confirm your connections are sound before you put the system into service. A simple soap and water mixture works perfectly as a leak detection solution—it will bubble up at the site of any escaping gas.

Regular inspections are the most effective thing you can do to maintain safety. Set a consistent schedule—maybe monthly for high-use systems, quarterly for others—and keep an eye out for these signs of wear and tear.

By working through these checks systematically, you can confidently manage the safety and reliability of every single schläuche für gasflaschen in your facility.

Even with the best installation and inspection routines, things can still go wrong with your schläuche für gasflaschen. Knowing how to spot and fix these problems quickly isn't just about efficiency—it's fundamental to keeping everyone safe. The good news is that most issues have simple causes and straightforward solutions, as long as you know what to look for.

Think of this as your field guide to the most common hose troubles. By understanding the root of the problem, you can not only sort out the current issue but also prevent it from happening again down the line.

A gas leak is the single most critical problem you can have, and it demands your immediate attention. Leaks almost always pop up at connection points, but they can occasionally appear somewhere along the body of the hose itself.

Physical wear and tear is the number one reason hoses fail before their time. Kinks and abrasion are particularly nasty because they compromise the hose's structure, creating dangerous weak spots.

A kink in a gas hose is like a fold in a piece of paper—even when you straighten it out, the weakness is there forever. Never trust a hose that's been sharply creased. That spot is now primed to burst under pressure.

Hoses carrying cryogenic liquids like liquid nitrogen have their own unique set of challenges to deal with, all of which can impact performance and safety.

Even after going through a detailed guide on schläuche für gasflaschen, it's natural to have a few specific questions pop up. This section is designed to give you direct, practical answers to the most common queries we hear, building on the safety and operational concepts we've already covered.

Think of this as your go-to reference for clearing up any final doubts. Getting these details right is absolutely essential for the long-term safety and smooth running of your entire gas delivery setup.

There’s no single, hard-and-fast rule here. A hose's lifespan really depends on what it's made of, the type of gas flowing through it, the conditions it's used in, and what the manufacturer recommends. The best approach is to get into a routine of regular inspections—say, monthly or quarterly, depending on how heavily it's used.

However, a hose needs to be replaced immediately if you spot any signs of wear and tear. Keep an eye out for:

For high-stakes applications, many organisations don't wait for visible damage. They set a fixed replacement schedule—every five years, for example—no matter how the hose looks. This proactive method is the gold standard for keeping risks to a minimum.

Absolutely not. This is a highly dangerous practice that you should avoid at all costs. Hoses are carefully engineered with specific material compounds that are chosen for their chemical compatibility with certain gases. Using the wrong hose can cause the material to break down quickly, leading to leaks or even a violent chemical reaction.

Think of it this way: you wouldn't use a garden hose for petrol, and the same logic applies here with much higher stakes. An inert gas hose used for an oxidiser like oxygen could fail catastrophically.

Always dedicate a specific hose to a single gas or a compatible group of gases. This simple step prevents dangerous chemical reactions and cuts out the risk of cross-contamination—something that's especially crucial in high-purity lab or medical settings where gas integrity is everything.

The main difference comes down to the materials and construction needed to handle incredibly cold temperatures. A standard rubber or polymer hose will become as brittle as glass at cryogenic temperatures and would simply shatter if bent or knocked.

Cryogenic hoses, which are typically made from corrugated stainless steel, are built specifically to stay strong and flexible at temperatures as low as -196°C (-320°F)—the boiling point of liquid nitrogen. They are often built with vacuum insulation to reduce heat transfer from the surrounding air. This is a crucial feature that slows down how quickly the cryogenic liquid turns back into a gas during transfer, making the whole process safer and more efficient.

At Cryonos GmbH, we specialise in providing state-of-the-art cryogenic solutions, including certified hoses designed for the safe handling of industrial gases and biological samples. Explore our comprehensive portfolio of equipment and accessories built for reliability and safety at https://www.cryonos.shop.