No Products in the Cart

Navigating the rules for transporting gas cylinders in Germany, often referred to as Transport Gasflaschen Vorschriften, really boils down to getting to grips with the European ADR agreement. These aren't just arbitrary rules; they cover every detail, from how cylinders are secured and labelled to the specific training drivers need, all to ensure these pressurised materials get from A to B safely.

Moving gas cylinders, whether for a lab, a hospital, or an industrial site, is a job that comes with a serious set of safety protocols. These regulations are a carefully designed framework to prevent accidents. After all, we're talking about materials under high pressure that can be flammable, toxic, or even cause asphyxiation. The first step to doing it right—and keeping everyone safe—is understanding the core principles.

At the heart of Germany's regulations for moving dangerous goods by road is a comprehensive European-wide agreement. This gives us a standardised set of rules that apply across dozens of countries, making cross-border transport much more straightforward and consistently safe.

The one regulation you absolutely must know is the ADR (Agreement concerning the International Carriage of Dangerous Goods by Road). Think of the ADR as the definitive rulebook for transporting hazardous materials on European roads. Germany has woven the ADR directly into its national law, which means following it is mandatory for almost all commercial transport of gas cylinders in the country.

The entire point of the ADR is to minimise risk. It does this by standardising procedures for everyone in the transport chain, from the person dispatching the cylinders to the driver behind the wheel. This system ensures that a cylinder of nitrogen leaving a facility in Hamburg is handled with the exact same care and documented in the same way as one arriving in Munich.

Key areas the ADR covers include:

Failing to stick to these Transport Gasflaschen Vorschriften has consequences that go far beyond a fine. An improperly secured or unlabelled cylinder is a direct threat to the driver, the public, and any emergency services that might have to respond to an incident. A mistake that seems minor, like forgetting a valve cap, could lead to a catastrophic leak if that cylinder takes a tumble in the back of the van.

The regulations are built on a simple premise: a well-informed and prepared transporter is a safe transporter. Every label, every document, and every securing strap is a piece of a larger safety system designed to protect lives and property.

This guide will break down these complex rules into clear, actionable steps. By understanding the 'why' behind the ADR and how Germany applies it, you can go beyond just ticking boxes and build a genuine culture of safety in your operations. In the sections that follow, we'll dive into the specifics of labelling, securing your cargo, documentation, and the important exemptions that might apply to you.

Imagine the chaos of shipping a package across Europe if every country had its own unique, complex rules for hazardous materials. That's exactly the nightmare scenario the ADR (Agreement concerning the International Carriage of Dangerous Goods by Road) was created to prevent. For anyone dealing with Transport Gasflaschen Vorschriften in Germany, the ADR is the single most important rulebook.

The ADR creates a unified, predictable set of regulations for transporting dangerous goods. This ensures safety standards are the same whether a truck is rolling through Berlin, Paris, or Warsaw. For Germany, the ADR isn't just a good idea—it's the law. It’s written directly into national legislation like the Gefahrgutverordnung Straße, Eisenbahn und Binnenschifffahrt (GGVSEB), making it legally binding for everyone.

The ADR neatly sorts all dangerous goods into classes based on the main hazard they pose. If you're transporting gas cylinders, you need to be intimately familiar with Class 2 Gases. But it doesn't stop there; this class is broken down even further to get specific about the type of gas you're handling.

Getting this classification right is the first step, and it dictates everything that follows—from the labels on the cylinder to the type of vehicle you can use and the paperwork you need.

The main subdivisions you'll see in Class 2 are:

This system is essentially a universal language of safety. A glance at the label tells anyone handling the cylinder exactly what kind of primary risk they're dealing with, no matter where they are in Europe.

Once a gas is classified, it gets its own unique four-digit UN number. Think of it as a specific ID card for that substance. For example, compressed oxygen is always UN 1072, and liquid nitrogen is UN 1977. This number has to be front and centre on the cylinder's label and on all transport documents.

The UN number is the key that unlocks all other ADR requirements. From this single number, you can determine the correct hazard labels, packaging instructions, and any special provisions that apply to the transport of that specific gas.

Simply put, without the right UN number, you can't move forward with compliance. It's the bedrock of the entire safety system, giving logistics staff, drivers, and emergency crews a clear, unmistakable reference point.

While the ADR provides the international blueprint, the enforcement happens on the ground, at a national level. In Germany, the GGVSEB is the legal muscle that translates ADR requirements into German law. It empowers authorities like the Bundesamt für Güterverkehr (Federal Office for Goods Transport) to carry out roadside checks and hand out penalties. This integration makes sure the Transport Gasflaschen Vorschriften are treated as firm legal duties, not just suggestions.

The world of gas regulation is anything but static, as recent events have shown. After the 2022 energy crisis, Germany's natural gas imports dropped from 5,000 petajoules in 2021 to 3,524 petajoules. In a direct response, the German government ordered storage facilities to be at 95% capacity by November 1st, 2022. This had a ripple effect, directly impacting the transport and storage rules for pressurised gas containers across the country. You can read more on how Germany's gas sector changed. It's a powerful reminder of how quickly transport logistics must adapt to new rules, making a solid grasp of the legal framework absolutely essential.

Think of a gas cylinder's label as its passport. Without it, the cylinder is going nowhere safely or legally. These markings are the first line of defence in preventing accidents, instantly telling handlers and emergency responders exactly what’s inside and how to manage the risks.

Under the German Transport Gasflaschen Vorschriften, this visual communication isn't just a good idea—it's non-negotiable. Without clear markings, a harmless nitrogen cylinder could be mistaken for a flammable one, creating a recipe for disaster. ADR regulations are built to eliminate that ambiguity.

The markings on a gas cylinder are a universal language. Every compliant cylinder will have critical information displayed on a shoulder label and permanently stamped into the metal itself.

The most immediate visual cue is the hazard diamond, or placard. This tells you the primary danger at a single glance.

Along with the hazard diamond, you'll find the four-digit UN Number. This is a unique identifier. For example, UN 1977 always means liquid nitrogen, and UN 1072 is always compressed oxygen. This number, paired with the Proper Shipping Name, is the core identifier used in all transport documents.

Proper labelling is more than a box-ticking exercise; it's a fundamental commitment to safety. It ensures every single person who handles that cylinder, from the loading bay to its final destination, has the information they need to do their job without incident.

To give you a clearer picture, here’s a quick breakdown of the hazard labels for common gases you might encounter.

This table outlines the primary hazard placards required for different types of gases transported under ADR rules.

| Hazard Class Division | Description | Label Symbol | Common Gas Examples |

|---|---|---|---|

| 2.1 | Flammable gases | Flame (red background) | Hydrogen, Propane, Acetylene |

| 2.2 | Non-flammable, non-toxic gases (may be oxidising) | Gas cylinder (green) | Nitrogen, Helium, Argon, Carbon Dioxide, Oxygen* |

| 2.3 | Toxic gases | Skull and crossbones | Chlorine, Ammonia, Carbon Monoxide |

*Note: Oxygen also requires a secondary 'Oxidising' hazard label (Division 5.1).

This is just a snapshot, but it shows how the system is designed for quick, unambiguous hazard identification.

The cylinder's physical history is also stamped right into the metal shoulder. Gas cylinders, or Gasflaschen in Germany, are serious pressure vessels, often holding gases up to 300 bar. This stamped data—manufacturing info, inspection dates, nominal pressure—is a permanent record of the cylinder's life and capabilities.

A perfect label on a damaged cylinder is completely useless. The physical condition of the cylinder is just as critical as its markings. Before any cylinder is loaded for transport, a quick visual inspection is an absolute must.

Pay special attention to valve protection. The valve is the cylinder's Achilles' heel. A sharp knock can snap it clean off, turning the cylinder into an unguided, high-pressure rocket. It’s a terrifying prospect, and easily preventable.

Before moving any cylinder, always check:

Finally, scan the cylinder body. Look for deep rust, major dents, or any tell-tale signs of a leak like a hissing sound or frost building up around the valve (a classic sign of a cryogenic liquid leak). Any cylinder that fails this simple check stays put. Period.

Performing these basic but vital checks is a cornerstone of operational safety. If you want to dive deeper, you can explore our comprehensive guides on cryogenic safety protocols. Following these packaging and marking rules isn't just about compliance—it's about making sure everyone gets home safe.

Getting the labels and paperwork right is half the battle, but it's the physical act of securing gas cylinders where safety really hits the road. An unsecured cylinder can quickly turn into a high-pressure projectile in an accident. This is why German regulations, heavily guided by ADR, put such an immense focus on Ladungssicherung—the art and science of securing a load properly.

Getting the labels and paperwork right is half the battle, but it's the physical act of securing gas cylinders where safety really hits the road. An unsecured cylinder can quickly turn into a high-pressure projectile in an accident. This is why German regulations, heavily guided by ADR, put such an immense focus on Ladungssicherung—the art and science of securing a load properly.

This goes way beyond just tying things down. The goal is to create a single, stable block of cargo that moves as one with the vehicle. You have to counteract the forces of accelerating, braking, and turning to make sure every cylinder ends its journey in the exact same spot it started.

To secure a load effectively, you first have to understand the forces you're up against. A sudden stop can launch a loose cylinder forward with terrifying force. To stop this from happening, ADR rules demand that cylinders are secured against any movement.

There are a few approved ways to do this, and the best method often depends on your vehicle and what you're transporting. The trick is to pick an approach that is both compliant and practical for your daily operations.

If you move cylinders often, investing in specialised gear is a no-brainer. For example, a purpose-built AC trolley for liquid cylinders doesn't just make it safer to move them around your facility; it can also be securely anchored inside a vehicle, creating a rock-solid base for transport.

The vehicle itself is a critical piece of the safety puzzle. You can't just use any old van, especially if you're dealing with gases that are flammable or could cause asphyxiation.

The single most overlooked vehicle requirement is proper ventilation. A tiny, slow leak of an inert gas like nitrogen in a sealed van can displace oxygen. This creates a deadly, invisible trap for the driver who opens the doors.

Adequate ventilation is mandatory. This can be as simple as having roof vents or keeping windows slightly open to ensure fresh air is constantly circulating and dispersing any potential leaks. For flammable gases, the risk is even greater, as a gas build-up could create an explosive atmosphere.

When your load exceeds the exemption limits (like the 1000-point rule), your vehicle needs to be clearly marked. This means displaying plain orange plates on the front and back. These plates are a universal warning to emergency services that you're carrying dangerous goods, which helps them respond correctly if there's an incident.

ADR also requires a specific set of safety equipment to be on board at all times. This isn't a list of helpful suggestions—it's a legal requirement under the transport gasflaschen vorschriften.

Essential Vehicle Safety Kit:

This kit makes sure the driver is equipped to handle a minor issue and can safely secure the scene while waiting for professional help to arrive.

Getting your gas cylinders physically secure for the journey is one thing, but true compliance with transport gasflaschen vorschriften is just as much about the paperwork and the person behind the wheel. Think of it like a pilot's pre-flight check. The plane can be in perfect shape, but it’s not going anywhere safely without a flight plan and a qualified pilot. For gas transport, your documentation and driver certification are just as critical.

These pieces aren't just bureaucracy. They ensure that if something goes wrong, emergency responders know exactly what they're dealing with, and the driver has the training to react properly. It’s a complete system of safety and accountability that travels with the cargo.

For almost any commercial shipment of gas cylinders, a specific document called the Beförderungspapier must be in the vehicle. This isn't your average delivery note. It's a highly detailed declaration that gives a complete, unambiguous picture of the hazardous goods on board.

This document is the official record of your shipment, clearly spelling out the contents and their associated risks. ADR regulations are very strict here, requiring specific, standardised information to eliminate any guesswork.

Every transport document absolutely must include:

The Beförderungspapier is the very first thing authorities will ask to see during a roadside inspection. If it’s missing, incomplete, or inaccurate, you're looking at a serious compliance failure that can lead to on-the-spot fines and major delays.

You can have all the right equipment, but the human element is arguably the most crucial part of the safety chain. It’s the driver who has to use those tools correctly. That's why the ADR framework demands specialised training for anyone transporting dangerous goods above certain quantities.

In Germany, this certification is known as the ADR-Schein. It's solid proof that the driver has passed a government-approved course covering everything from hazard identification and emergency responses to firefighting and correct loading techniques. An ADR-certified driver isn’t just delivering goods; they're a trained safety professional.

Generally, the ADR-Schein becomes mandatory once your load exceeds the thresholds of the "1000-point rule" exemption. For any business moving significant quantities of gas on a regular basis, making sure all drivers hold a valid certificate is a non-negotiable part of operations. This isn't a one-and-done deal, either. The certification involves an initial course and then regular refresher training to keep it valid, ensuring knowledge never gets stale.

The gas cylinder market is a massive industrial pillar, valued globally at USD 7.8 billion back in 2025. Here in Germany, sectors like construction and infrastructure keep the demand for on-site gas supplies consistently high, giving the market a steady foundation even as the country shifts towards renewables. You can find more details in the gas cylinder market forecast on futuremarketinsights.com. This persistent demand just goes to show how vital it is to maintain a skilled, properly certified workforce to handle these essential—and hazardous—materials safely day in and day out.

Full, by-the-book ADR compliance isn't always necessary every single time you move a gas cylinder. Thankfully, the German regulations (transport gasflaschen vorschriften) include a few crucial exemptions. These are designed to make life easier for those handling smaller quantities in specific situations, saving businesses and individuals a lot of hassle and expense.

Getting your head around these provisions is the key to working both efficiently and legally. They exist because the rules rightly acknowledge that moving one cylinder for a job is a world away from hauling a full truckload. The most common and useful of these is the "1000-point rule".

The 1000-Punkte-Regel is probably the most valuable exemption you'll find in the ADR framework. It allows you to transport limited quantities of dangerous goods without needing a fully kitted-out ADR vehicle or a driver holding a special ADR certificate. For tradespeople, labs, and small businesses, this rule is a real game-changer.

The whole system is based on points. Every gas is assigned a "Transport Category" (from 0 to 4) based on its hazard level, and each category has a point multiplier. The goal is simple: as long as the total points for everything on your vehicle stay below 1,000, you fall under the exemption.

To figure out your total, you just multiply the amount of each gas (in kilograms or litres) by its multiplier. For example, a common gas like Argon (UN 1006) is in Transport Category 3, which has a multiplier of 1. That means you could carry up to 999 litres before the full weight of ADR rules applies.

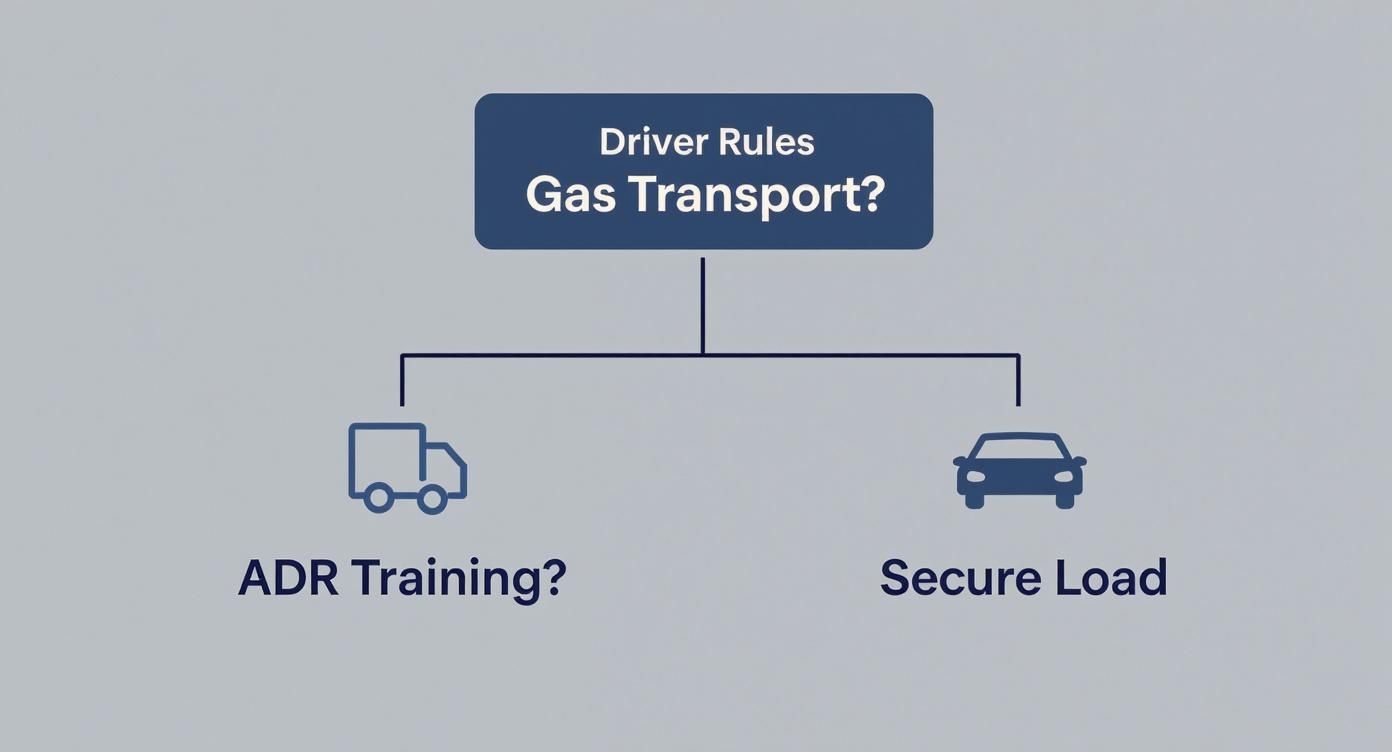

This flowchart makes it much simpler for drivers to see what's required of them.

As you can see, it draws a clear line between commercial transport, which often needs full ADR training, and private transport, where the absolute priority is always on making sure the load is properly secured.

As you can see, it draws a clear line between commercial transport, which often needs full ADR training, and private transport, where the absolute priority is always on making sure the load is properly secured.

Let's walk through how to calculate your points for a mixed load. The table below provides a clear, practical example of how you'd work out whether you're under that magic 1000-point limit.

| Gas Type (Example) | UN Number | Transport Category | Multiplier (Points per kg/litre) | Example Calculation |

|---|---|---|---|---|

| Nitrogen, compressed | UN 1066 | 3 | 1 | 10 x 50-litre cylinders = 500 litres. 500 x 1 = 500 points. |

| Oxygen, compressed | UN 1072 | 3 | 1 | 4 x 50-litre cylinders = 200 litres. 200 x 1 = 200 points. |

| Acetylene, dissolved | UN 1001 | 2 | 3 | 1 x 40-litre cylinder = 40 kg. 40 x 3 = 120 points. |

| Propane | UN 1978 | 2 | 3 | 2 x 11 kg cylinders = 22 kg. 22 x 3 = 66 points. |

In this scenario, you'd add everything up: 500 + 200 + 120 + 66 = 886 points. Because the total is safely under the 1,000-point threshold, this load is exempt from the requirements for an ADR-certified driver and vehicle placarding. For a deeper dive, our guides on the transport of nitrogen have more specifics.

The 1000-point rule isn't the only way out of full ADR compliance. A couple of other key exemptions exist that simplify the transport gasflaschen vorschriften for certain users.

Crucial Takeaway: No matter which exemption you use, your basic duty of care never goes away. You are always legally responsible for securing cylinders properly, making sure they aren't leaking, and keeping the vehicle well-ventilated.

These exemptions are incredibly helpful, but you have to apply them correctly. Get it wrong, and you could be facing serious safety risks and legal penalties.

When it comes to the practical side of transport gasflaschen vorschriften (gas cylinder transport regulations), a lot of specific questions pop up. Let's tackle some of the most common ones we hear from businesses and individuals every day.

Good news for your weekend BBQ or camping trip – the answer is generally no. Transporting a single gas cylinder for your own private use, like a propane bottle, is usually exempt from the full scope of ADR regulations. This exemption is strictly for individuals, not for commercial activities.

That said, you still have a duty of care. You must make sure the cylinder is properly secured in your vehicle so it can’t roll around. The valve needs to be shut tight, the protective cap should be on, and it's always a smart idea to keep the car well-ventilated.

For many small businesses, the '1000-Point Rule' is an absolute game-changer. It's a limited quantity exemption under ADR that lets you move smaller amounts of dangerous goods without needing a fully ADR-trained driver or a vehicle with orange warning placards.

Every type of gas falls into a 'Transport Category' with a specific point multiplier. As long as the grand total of points for all the dangerous goods on your vehicle stays under 1000, you can use the exemption. It’s perfect for tradespeople, mobile technicians, or labs that only need to shift a few cylinders at a time.

A word of caution: even when you're under the 1000-point threshold, the basic safety rules never go away. You are always legally required to secure your load properly, check that cylinders aren't leaking, and ensure your vehicle has enough ventilation.

From what we've seen over the years, the most frequent—and most dangerous—mistakes are often the simplest ones. Nailing these fundamentals is the key to safe transport.

Here are the top errors to watch out for:

At Cryonos GmbH, we know that getting your transport right is non-negotiable. Our ADR-licensed cryogenic vessels and expert team are here to make sure your operations meet the highest safety and compliance standards. Take a look at our solutions at https://www.cryonos.shop.

Article created using Outrank