No Products in the Cart

An ultralow temperature freezer is a highly specialised piece of lab equipment, engineered to store sensitive biological materials at temperatures plummeting between -40°C and -86°C. Think of it as a biological time capsule. Its one job is to press pause on cellular activity, preserving everything from vaccines and enzymes to precious genetic material for years without any degradation.

A standard kitchen freezer or even a typical lab freezer sits around -20°C. A ULT freezer, however, creates an environment so intensely cold that it effectively halts nearly all biological processes. This isn't just about keeping things frozen; it's a precision tool designed to stop the clock on molecular decay.

Without this capability, the delicate structures of RNA, DNA, proteins, and living cells would break down in a matter of hours or days. Long-term research and much of modern medicine would be completely impossible. The core purpose of these units is to protect the viability and integrity of invaluable—and often irreplaceable—biological samples.

Even at standard freezer temperatures, there's enough residual enzymatic activity to cause damage over time. Ice crystal formation is another big problem, as these sharp crystals can literally shred delicate cellular structures.

Dropping the temperature down to -86°C effectively vitrifies the water inside cells. This process prevents the formation of large, damaging ice crystals and completely shuts down the enzymatic reactions that would otherwise degrade the sample.

The primary goal of an ultralow temperature freezer is to push samples below their "glass transition" temperature. This is the point at which biological processes are so slow they are considered to be stopped, ensuring long-term stability and sample integrity.

This level of cold is absolutely critical for applications that demand perfect preservation. Whether you're safeguarding the building blocks of new vaccines or storing stem cells for future therapies, the ultralow temperature environment provides the stability needed for major scientific and medical breakthroughs.

Achieving these conditions requires advanced engineering that goes far beyond simple refrigeration. The science behind this deep cold is fascinating, and for those interested, you can explore more about the principles of cryogenics and how they apply to modern technology.

A few key features clearly distinguish a true ultralow temperature freezer from any other cold storage solution. Here's a quick rundown of what defines these powerful machines.

| Feature | Typical Specification | Why It Matters |

|---|---|---|

| Temperature Range | -40°C to -86°C | This is the defining capability, enabling the long-term preservation of the most sensitive biological materials. |

| Insulation | Vacuum-insulated panels (VIPs) combined with high-density foam | Superior insulation minimises heat entering the chamber, ensuring temperature stability and improving energy efficiency. |

| Sealing System | Multi-point gaskets and reinforced door latches | Creates an airtight seal to prevent ambient air and moisture from getting in, which would otherwise lead to frost build-up. |

| Cooling Technology | Two-stage cascade refrigeration system | This powerful, dual-compressor system is necessary to efficiently reach and reliably maintain ultralow temperatures. |

| Monitoring & Alarms | Digital display, audible/visual alarms for temperature deviations, power failure | Provides constant oversight and immediate alerts if conditions drift, protecting invaluable samples from being compromised. |

These components all work together to create a highly stable, secure environment. It's this combination of raw power and precision engineering that makes the ultralow temperature freezer a cornerstone of any modern research or clinical lab.

Getting a freezer down to the brutal cold of -86°C is a serious engineering challenge. Your standard kitchen freezer, with its single compressor, just isn't built for that kind of work. To hit those ultralow temperatures, freezers rely on a much more powerful and clever system to methodically pull every last bit of warmth out of the insulated chamber. The most common and proven method is what’s known as a cascade refrigeration system.

Think of it like a two-person relay race where the baton is "heat" and the finish line is outside the freezer. The first runner grabs the heat and runs as far as they can before getting tired. Then, a second, fresh runner takes the handoff and carries the heat the rest of the way out. That’s a cascade system in a nutshell—two independent refrigeration circuits working as a team to achieve what one alone cannot.

This whole process is a fascinating dance between physics and highly specialised components, all working together to ensure your priceless samples stay perfectly stable for years on end.

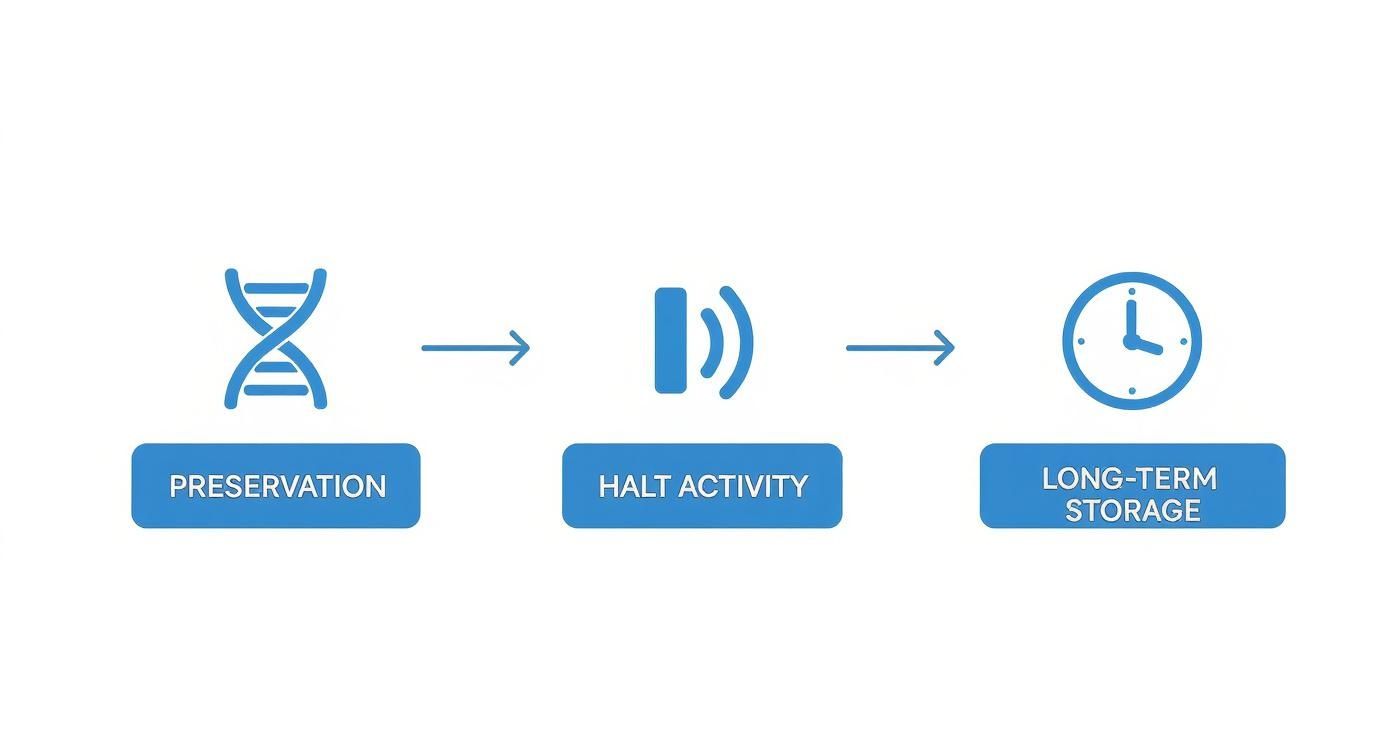

The diagram below really gets to the heart of why this technology is so critical. It’s not just about making things cold; it's about stopping biological time.

As you can see, the ultimate goal isn't just freezing. It’s about completely halting molecular activity to make sure sensitive biological materials can be stored reliably for the long haul.

It all starts with the first refrigeration circuit, which is often called the "high-temperature" stage. This part of the system works a lot like a regular freezer, using a high-pressure refrigerant such as R404a. Its main job isn't to cool the freezer cabinet itself, but to get the second stage nice and cold.

First, a compressor squeezes the refrigerant gas, making it very hot. This hot, high-pressure gas travels through condenser coils where a fan blows the heat out into the room. As the gas cools, it turns into a liquid. This liquid then shoots through an expansion valve and into a heat exchanger, which causes its temperature and pressure to drop dramatically.

This heat exchanger is where the magic happens. It’s the handoff point in our relay race. The first circuit absorbs heat from the second circuit, which causes its own refrigerant to warm up, turn back into a gas, and head back to the compressor to start the cycle all over again.

Now, the second "low-temperature" circuit jumps into action. This circuit uses a specialised, very-low-pressure refrigerant like R508b or R170, which is designed to work in extremely cold conditions.

This refrigerant gets pre-chilled by the first stage in that critical heat exchanger. From there, it moves through its own expansion valve and into the evaporator coils that line the freezer's inner walls. As this super-chilled liquid evaporates back into a gas, it sucks a massive amount of heat out of the chamber, pulling the internal temperature down toward that target of -86°C.

The now-warmed gas from the second stage then goes back to its own compressor, gets re-pressurised, and flows back to the heat exchanger to be cooled down by the first stage once more, completing its loop.

This two-step "cascade" is the secret sauce. The first circuit creates a moderately cold environment that gives the second, more specialised circuit the boost it needs to reach the ultralow temperatures required for long-term sample preservation.

Of course, even the most powerful cooling system is useless without top-notch insulation. Modern ULT freezers use a combination of high-density foam and vacuum insulated panels (VIPs). These panels offer incredible thermal resistance without being thick, maximising the usable storage space inside while keeping room-temperature air from creeping in.

A rock-solid door seal is just as important. Most units feature multiple gaskets and even heated seals to create a perfect, airtight closure. This prevents ambient air from sneaking in and causing frost, which would force the compressors to work harder and risk temperature stability. The design principles here share some DNA with even more advanced systems; you can learn more about how cryogenic freezers work in our detailed guide on that topic.

While cascade systems are the long-standing industry standard, other technologies are starting to make their mark. A notable example is the Stirling engine. Instead of using compressors and refrigerants, a Stirling engine uses helium gas and a piston in a closed-loop system with almost no friction.

These systems are known for being remarkably energy-efficient, needing less maintenance because they have fewer moving parts, and running much quieter. For modern labs looking for a more sustainable option, they're becoming an attractive alternative.

While the engineering inside a ULT freezer is a marvel, its real importance lies in the critical work it makes possible. These machines aren't just lab equipment; they are guardians of future discoveries, preserving biological materials that might one day cure diseases, create life, or drive incredible innovation.

From sprawling biobanks to specialised fertility clinics, the ultralow temperature freezer is an indispensable part of the background. Every sample stored within—whether it's a delicate cell line or a complex vaccine compound—depends on the extreme cold to press pause on biological decay. This stability is the bedrock of reliable, repeatable, and groundbreaking work.

Think of biobanks as vast libraries of biological information. They house millions of tissue, blood, and DNA samples, all for future study. A ULT freezer is the vault where these priceless collections are protected. At -86°C, the genetic integrity of a sample is essentially locked in, stopping the degradation of DNA and RNA that would otherwise make them useless for genomic research.

For instance, researchers studying hereditary diseases can pull samples stored for decades to look for genetic markers that weren't even known when the samples were first collected. This long-term preservation allows scientists to look back in time, connecting genetic data with health outcomes across generations. Without the unwavering environment of a ULT freezer, this kind of long-view research simply couldn't happen.

The rising rate of cancer in Europe puts these facilities in high demand. With Europe accounting for about a quarter of global cancer cases, and Germany seeing particularly high incidence, there's a constant push for clinical trials and biomaterial preservation. This boosts the need for dependable ULT freezers to store oncology samples for research into new treatments. You can dive deeper into the market trends in the European ultralow temperature freezer market analysis.

In the pharmaceutical world, a ULT freezer is non-negotiable for creating next-generation medicines, especially biologics and vaccines. Many modern vaccines, like the mRNA-based ones we've all become familiar with, are notoriously fragile. Their active components can break down quickly at warmer temperatures, making ultralow cold storage a mandatory link in the supply chain.

Let's look at the development of a new cell therapy:

Every single step demands absolute temperature stability. A single fluctuation could ruin an entire batch, costing millions and delaying patient access to potentially life-saving treatments.

For pharmaceutical companies, a ULT freezer is more than just cold storage; it's a critical piece of quality control infrastructure. It guarantees that the product reaching the patient is the same one that proved effective in clinical trials, ensuring both safety and efficacy.

Beyond the high-stakes worlds of biobanking and pharma, the impact of ULT freezers extends into both deeply personal and surprisingly industrial fields. Fertility clinics depend on them for the long-term cryopreservation of oocytes, sperm, and embryos, offering invaluable options for family planning. The entire success of these procedures hinges on keeping these delicate biological materials viable over many years.

Meanwhile, in the industrial sector, ULT freezers are workhorses for materials science. Engineers will subject components like plastics, composites, and electronics to extreme cold to test their durability and performance limits. This simulates harsh environments found in aerospace or arctic applications, ensuring that materials used in critical infrastructure won't fail under severe temperature stress.

Choosing an ultralow temperature freezer isn't just another equipment purchase. It’s a major investment that has a direct impact on the security of your research and the day-to-day efficiency of your lab. With so many models and features out there, making the right choice means taking a hard look at your specific needs. It’s all about balancing capacity, performance, and long-term running costs to find a unit that will be a reliable guardian for your invaluable samples.

This decision goes way beyond just comparing datasheets. You have to think about your daily workflow, try to anticipate future storage demands, and understand the subtle differences in performance that can have massive consequences down the line. A structured approach is the best way to ensure you pick a freezer that not only meets your current scientific needs but also fits your lab's budget and sustainability goals for years to come.

First things first, let's talk about space. How much do you actually need? Sizing your ultralow temperature freezer correctly is absolutely critical. A unit that's too big just wastes energy and precious floor space. On the other hand, one that's too small quickly leads to a disorganised mess and the headache of another costly purchase sooner than you'd planned.

Start by doing a proper audit of your current sample inventory. Get a real count of the number of boxes or racks you're storing now, and then project your growth over the next five years. You need to consider things like upcoming projects, new research grants, or an expanding team, as these will all ramp up your storage requirements.

Thinking ahead like this prevents the classic problem of outgrowing your freezer in no time. And remember to leave some breathing room! You need enough space to maintain a proper inventory system, not just cram every last centimetre full of boxes.

You'll also need to decide on the physical form factor that best suits your lab. The two main options are upright and chest freezers, each with its own set of pros and cons depending on how you work.

Deciding between an upright and a chest freezer often comes down to your lab's layout and how you need to access your samples. Here’s a quick breakdown to help you weigh the options.

| Attribute | Upright Freezers | Chest Freezers |

|---|---|---|

| Footprint | Smaller footprint, taller profile. | Larger footprint, lower profile. |

| Accessibility | Easy access to all shelves with minimal bending. | Requires reaching down into the unit. |

| Organisation | Shelves and racks make for easy organisation. | Can be harder to organise; items can get buried. |

| Cold Air Loss | More cold air escapes when the door is opened. | Less cold air escapes as it's heavier and stays in. |

| Energy Efficiency | Generally less energy-efficient due to cold air loss. | Typically more energy-efficient and stable. |

Ultimately, upright models are fantastic for labs where floor space is tight and frequent, quick access is a priority. Chest freezers are the go-to for long-term storage where energy efficiency and temperature stability are paramount, and you don't mind the larger footprint.

Once you have a clear idea of the size and type you need, it's time to dig into the performance metrics. These are the specs that separate a basic freezer from a high-performance scientific instrument. Don't get fixated on the lowest possible temperature; focus on the numbers that define stability and reliability.

Three of the most critical performance indicators are:

The real test of an ultralow temperature freezer isn't just reaching -80°C; it's staying there consistently. Prioritising uniformity, stability, and fast recovery is the best way to safeguard your irreplaceable work against temperature-related degradation.

In a modern lab, you simply can't afford to lose samples because of equipment failure. This is where backup systems and robust monitoring become essential. Look for a freezer with a comprehensive alarm system that gives you audible and visual alerts for temperature deviations, power failures, and a door that’s been left ajar. Remote monitoring capabilities, which can send notifications straight to your phone or email, offer an invaluable extra layer of security.

Energy consumption is the other big piece of the puzzle. ULT freezers are power-hungry, often using as much electricity as a small house. Newer models with variable-speed compressors, advanced insulation, and natural hydrocarbon refrigerants can slash energy use by up to 50% compared to older units.

While these high-efficiency models might have a higher price tag upfront, the savings on your electricity bill can lead to a surprisingly quick return on investment.

If you want to dive deeper into the purchasing process for this type of equipment, consider reading our guide on the key things to consider before buying cryogenic equipment. This will provide an even broader framework for making an informed decision.

If you’re looking to source ultra-low temperature freezers in Europe, you have to understand the regional landscape. And that landscape is dominated by one country in particular: Germany. With its powerhouse combination of advanced healthcare and a world-class pharmaceutical research sector, Germany isn't just a major player—it's the continent's central hub for ULT storage. This leadership role shapes everything from supply chains to technology trends, setting the standard for quality across the EU.

For any institution planning a major freezer purchase, getting a handle on this is essential. The German market is not just big; it's mature. There's a clear preference here for durable, high-performance equipment that can stand up to incredibly strict regulations. For buyers, this means you get access to the best technology, but it also underscores the need to work with suppliers who have deep roots and a proven history in this demanding environment.

Germany's commanding position is no accident; it’s built on massive and sustained investment in the biomedical sciences. The country holds an impressive 23% of the entire European ultra-low temperature freezer market. This strength comes from its bustling R&D sector and the widespread use of highly sophisticated storage solutions.

In 2025, the German market was valued at roughly USD 44.93 million. Projections show it growing at a healthy 6.1% compound annual rate in the years ahead, largely driven by new innovations and a big push for sustainability. For a deeper dive, you can explore this detailed German ULT freezer market analysis.

This growth fuels a very competitive environment, where manufacturers are constantly pushing the limits of what an ultralow temperature freezer can achieve. A few key drivers in Germany and across Europe really stand out:

When you look at the wider European Union, the market priorities are much the same. There's a definite trend towards upright freezer models, especially in biobanks and large research labs where staff need organised, frequent access to samples as part of their daily work. Their smaller footprint and user-friendly design make them a practical pick for labs where every square metre counts.

One of the most important takeaways for European buyers is the shift towards thinking about the total cost of ownership. It’s no longer just about the sticker price. Institutions are now zeroing in on long-term value, which includes energy bills, maintenance needs, and whether they can get responsive, local technical support when they need it.

In the end, it doesn't matter if you're based in Germany or elsewhere in Europe. Choosing the right ultralow temperature freezer means finding a supplier who really gets these regional quirks. Making efficiency, compliance, and long-term service your top priorities is the smartest move you can make to secure an asset that will protect your invaluable work for years to come.

Getting the most out of your ULT freezer starts the moment it arrives at your facility. Proper installation isn't just a box-ticking exercise; it's the very first step in protecting your invaluable samples and ensuring the unit has a long, reliable life. A sloppy setup can lead to poor performance, sky-high energy bills, and even premature component failure.

Think of it like laying the foundation for a new building. If the groundwork is solid, the whole structure will be stable and perform as it should. The same principle applies here—giving your freezer the right environment from day one is crucial for its demanding job.

An ultralow temperature freezer is a beast of a machine, and like any hard-working equipment, it generates a lot of heat. The number one rule is to give it room to breathe. Squeezing it into a tight, unventilated corner forces the compressors to work overtime, which means more wear and tear and higher electricity costs.

Follow these simple site prep steps for the best results:

Once your freezer is up and running, a little proactive maintenance goes a long way in preventing unexpected breakdowns. A simple, consistent routine can dramatically extend the life of the unit and safeguard what's inside. Skipping this is a gamble that can lead to expensive repairs and the catastrophic loss of irreplaceable samples.

A well-maintained ultralow temperature freezer is a dependable asset. A neglected one is a liability waiting to happen. Regular checks are not a chore; they are an essential part of responsible sample management.

This doesn't have to be complicated. By breaking down the essential tasks into a simple schedule, you can keep your unit in peak condition without disrupting the workflow of your lab.

While some jobs are best left to a certified technician, your own team can handle several crucial checks. The easiest way to make sure these get done is to build them right into your lab's standard operating procedures.

Monthly Checks:

Quarterly Checks:

Working with an ultralow temperature freezer day in and day out naturally brings up a few questions, especially around proper care and emergency planning. Getting these details right is the key to making sure your unit runs smoothly and your priceless samples stay safe. Here are some straightforward answers to the questions we hear most often.

There's no single magic number here—it really depends on the humidity in your lab and how frequently the door is opened. A good rule of thumb is to plan for a full defrost once a year, or whenever you see ice building up more than 1 cm thick on the inner doors and walls.

Think of that ice buildup as an unwanted insulator. It makes the compressor work overtime just to hold its temperature, which not only wastes energy but can also start to affect the freezer's stability.

Pro Tip: You can push back the need for a full defrost by regularly wiping away light frost from door gaskets and interior surfaces with a soft cloth or plastic scraper. Just make sure you always have a backup freezer ready to go before you start a full defrosting procedure.

When a freezer fails, whether from a power cut or a mechanical issue, everything comes down to "warm-up time." The clock starts ticking, and how long your samples stay safely frozen depends on a few things: the quality of the freezer's insulation, its thermal mass (a full freezer stays colder much longer), and the ambient temperature of the room.

A modern, well-maintained ULT freezer can usually keep its contents below -60°C for several hours after it loses power. But hope is not a strategy. This is exactly why a rock-solid emergency plan is non-negotiable for any facility storing critical samples.

Your plan absolutely must include:

The biggest differences are the temperature range they can hit and the technology they use to get there. Your standard lab freezer usually runs somewhere around -20°C to -40°C. It uses a single-compressor system, which works on the same basic principle as the freezer in your kitchen at home.

A ULT freezer, often just called a "-80°C freezer," gets down to its chilly -60°C to -86°C range by using a much more sophisticated cascade refrigeration system. This setup is a real powerhouse, using two coordinated cooling circuits that work as a team to aggressively pull heat out of the chamber. This two-stage approach is what makes it possible to preserve highly sensitive biologicals like DNA, RNA, and cell lines, which would degrade in a heartbeat at warmer temperatures.

At Cryonos GmbH, we provide state-of-the-art cryogenic solutions backed by decades of technical expertise. Explore our reliable, compliant equipment for the secure storage and transport of your most critical biological materials. Find your ideal cryogenic solution at https://www.cryonos.shop.