No Products in the Cart

Container ISO Tank function much like oversized, industrial-grade vacuum flasks—designed to haul bulk liquids and gases securely by sea, rail and road. Robust and reliable, these cylinders safeguard product integrity, regulate temperature and slot seamlessly into any intermodal chain.

ISO tanks trace their roots back to the 1960s, when innovators fused a stainless-steel vessel into a standardised, steel frame. Overnight, shipping bulk liquids became a true intermodal breeze: load it on a vessel, roll it onto rail, and drive it off on a truck without unpacking a single drop.

Key Advantages:

Iso tank containers stitch together ships, trains and trucks into one continuous liquid highway.

Today’s ISO tanks come in three main flavours—standard, insulated and cryogenic—each tailored to specific cargo demands. You’ll often find extras like shock absorbers, stack locks and enhanced insulation bolted on to meet rigorous transit conditions.

The cutaway below from Wikipedia reveals the tank’s layered defence and its external frame, built to global intermodal specs:

By 2023, Europe boasted over 210,000 ISO tank containers—with Germany, France and the Netherlands at the helm. This concentration highlights the region’s bulk-liquid prowess and deep logistical expertise. For wider market data, check out the latest from MarketGrowthReports.

You might also be interested in our guide on ISO tank containers for deeper operational tips.

From petrochemicals to gourmet oils and biotech samples, ISO tanks streamline workflows and shrink losses. Take one sunflower oil shipper: switching to insulated tanks trimmed transit losses by 2 %.

These perks translate directly into cost savings, lower emissions and simplified compliance—especially when you’re dealing with high-value liquids across borders.

Rigorous rules like ISO 668 and ADR keep every tank in check, from its size to its safety features. Nailing compliance not only speeds border crossings but also trims insurance costs.

Grasping these standards sets the stage for diving into tank variants, technical specs and handling protocols in the next chapters of your liquid-logistics journey.

Think of ISO tanks as you would your wardrobe: you layer up for the weather, and tanks adapt their features for cargo and temperature. A standard stainless-steel tank is like a trusty lightweight jacket—sturdy, corrosion-resistant and a solid all-rounder for many chemicals.

Slip on an insulated model, and it’s akin to adding a fleece layer. That thermal blanket smooths out temperature swings. Go a step further with a cryogenic tank, your heavy-duty parka equipped with an internal cooling system, capable of holding substances at –160 °C.

While these three styles handle most logistical challenges, each brings unique construction details and ideal use cases to the table.

To get a clear picture, let’s lay out the main traits side by side.

Comparison Of Iso Tank Variants

| Variant | Temperature Range | Common Uses | Typical Capacity |

|---|---|---|---|

| Standard | –40 °C to 100 °C | Chemicals, edible oils, solvents | 20,000–26,000 L |

| Insulated | –20 °C to 80 °C | Food-grade oils, mild refrigerants | 21,000–25,000 L |

| Cryogenic | –160 °C to –40 °C | Industrial gases, biotech samples | 18,000–22,000 L |

Each row hints at where a variant shines: broad chemical compatibility with standard tanks, stable chill for insulated units, and ultra-cold performance in cryogenic vessels.

Standard ISO tanks rely on stainless steel grades such as 1.4401 or 316L to resist corrosion without extra insulation. The wall thickness and corrosion allowance do the heavy lifting. For instance, a sunflower oil exporter keeps their product above 25 °C throughout a 10-day sea voyage simply by choosing the right stainless-steel alloy and tank dimension.

An insulated tank wraps the core vessel in polyurethane or mineral wool, taming internal swings by up to 15 % on extended routes. Food processors value this consistency: edible oils and mild acids arrive with uniform viscosity, reducing spoilage and downtime.

Cryogenic ISO tanks marry a vacuum jacket with multiple insulation layers to trap extreme cold. The inner vessel often uses high-nickel alloys that stay ductile at frigid temperatures. University laboratories depend on these tanks to ship liquid nitrogen and oxygen for days without topping up, safeguarding research samples.

Here’s a screenshot illustrating shell thickness, insulation layers and frame design differences.

The image highlights insulation jackets and vessel grades, showing why some tanks excel under extreme cold.

Germany contributes 21.2 % of total EU empty container TEUs and a major slice of loaded TEU-km on inland waterways for 2023, trailing only the Netherlands among the top four nations covering 99 % of EU performance.

Germany’s inland waterways heavily feature container ISO tanks for reliable, intermodal liquid transport.

Read more about EU inland waterways performance on the Eurostat site.

Selecting the right variant hinges on cargo sensitivity, transit duration and budget. Standard tanks suit general chemicals, insulated models serve foods and mild-temperature goods, and cryogenic vessels meet deep-cold demands. Matching these parameters avoids costly mismatches and drives safe, efficient delivery.

Start by mapping out:

Labs shipping cryogens will zero in on low boil-off, while edible-oil traders chase insulation ROI. This checklist steers you toward an informed selection that protects both cargo and bottom line.

A German chemical producer shipping acid from Hamburg to Stockholm opted for insulated tanks to maintain a 40 °C to 5 °C window across sea and rail legs. This move cut energy topping-up by 12 % and eliminated product losses, proving variant match drives efficiency. Significant gains.

First off, you need a detailed pre-flight checklist before filling an ISO tank. That means double-checking external dimensions, wall thickness and all sealing components down to the millimetre.

In most cases, a standard 20 ft frame ISO tank measures:

Engineers typically choose stainless-steel grade 1.4401 for its corrosion resistance and purity. Then comes pressure rating: a standard tank usually handles 4 bar, while a cryogenic variant can exceed 7 bar.

Finally, read the serial plate to confirm ADR compliance, UN codes and test dates. Getting every spec right can cut downtime by 20% and even lower insurance premiums.

Below is a snapshot of the must-inspect specifications for any ISO tank container.

Key Iso Tank Standards Overview

| Parameter | Description | Applicable Standard |

|---|---|---|

| Dimensions | External frame size for intermodal compatibility | ISO 668 |

| Material Grade | Stainless-steel type for chemical resistance | EN 10028-7 |

| Pressure Rating | Maximum working pressure capacity | ADR Chapter 6.8 |

| Hydrostatic Test | Interval and method for leak-proof validation | ADR Annex B |

| Serial Plate Data | Markings with UN number, approval and test date | ADR 2.2 |

Before each load, cross off every row in this table against your tank’s paperwork. It’s the quickest route to smooth border crossings.

Here’s a simple four-step process to turn that cryptic serial plate into a clear compliance plan:

Valves and seals are the safety gates of your ISO tank. You must ensure each gasket and valve matches your cargo class and shows no signs of wear.

These routine checks stop minor issues from becoming expensive incidents.

In practice, ISO standards let your tank glide between ship, rail and road without a hitch. ADR rules then step in to govern design, testing and marking of dangerous goods, protecting both people and the environment.

Key standards at a glance:

“Accurate specification checks cut border clearance times by up to 30%,” shares a logistics safety specialist.

The diagram pinpoints shell thickness, valve locations and test points, showing exactly where to focus your measurements.

Before every journey, ISO tanks must pass a hydrostatic test at 1.5× their working pressure. This confirms the vessel can handle sudden surges or temperature swings.

Next, vacuum-jacket integrity tests reveal any insulation breaches. Document every result in your log and update the serial plate record immediately.

These procedures lock in both safety compliance and operational efficiency.

When it comes to bulk chemical shipping, ISO tank containers behave much like the mains in a city’s water network. They convey corrosive liquids under pressure, cutting out extra handling steps and slashing spill risks.

From the port terminal right through to the processing plant, this approach keeps operations tight and predictable.

Take Germany’s chemical industry. In 2023 it saw a 6.6% drop in production as energy costs spiked, yet by 2024 output had bounced back 1.9%. Much of this turnaround hinges on ISO tank containers meeting ADR safety standards. Learn more about these trends from MarketGrowthReports

These features help exporters comply with strict EU rules and avoid costly hold-ups.

Here’s a visual snapshot of how ISO tanks adapt across industries:

The image highlights chemical, food and cryogenic applications side by side—complete with temperature ranges and flow paths.

Switching gears to the food sector, ISO tank units act like refrigerated pipelines for edible oils. They lock in viscosity and freshness, even over long hauls.

Producers of sunflower oil rely on these tanks to meet hygiene standards and preserve flavour when crossing borders.

This simple sequence drives down spoilage and guarantees consistent quality.

In the lab environment, cryogenic ISO tanks are mobile freezers, holding samples at –196 °C. When a research team shipped stem cell batches from Munich to Stockholm, vacuum-jacketed tanks prevented any warming.

“Cryogenic ISO tanks ensure sample integrity over extended transit, reducing lab downtime and repeat testing,” says a lab manager.

Stories like this show how life-science operations adapt ISO tanks to safeguard sensitive cargo.

Consider a sunflower oil exporter crossing three borders. By switching to insulated ISO tanks, they cut product loss by 2%—translating into higher yields and more satisfied buyers at the fryer.

Temperature logs tied into quality control revealed tiny drifts before spoilage could occur. The result? Repeat orders and a stronger reputation.

Industrial gas suppliers treat cryogenic ISO tanks like oversized, refillable Dewars. These vessels move bulk liquid nitrogen and oxygen safely over long distances.

One provider shipped 5 tonnes of liquid nitrogen from Berlin to a steel mill in Poland in a single run. Thanks to precise pressure control, boil-off stayed below 0.5%.

90% of industrial gas suppliers report fewer handling incidents after switching to ISO tanks.

Custom trolleys and integrated lifting points sped up unloading and cut site setup by 25%.

Finally, ISO tank containers roll straight from truck to rail to ship—no repacking needed. Visualise your supply chain as a continuous pipeline and you eliminate manual transfers and contamination points.

Across chemicals, food oils and cryogenic samples, ISO tanks prove their worth in cost savings, time efficiency and regulatory compliance.

Next, you’ll learn how to choose the right variant for your specific lab or logistics needs.

Picking an ISO tank is a lot like choosing the perfect drill bit for a home project: match the tool to the task, and everything runs smoothly. Get it wrong, and you’ll pay in delays, extra costs and, worst of all, safety headaches.

Begin by listing your liquid or gas properties alongside purity requirements. This will guide you toward the right tank lining, material grade and corrosion allowance.

Key Factors To Consider:

This mini-audit clarifies which ISO-tank variants can handle your payload.

Temperature swings can make or break a shipment, especially when cryogenics are involved. Start by charting the extremes at loading and delivery points.

Follow These Steps:

“A precise temperature match cuts topping-up needs by up to 15%,” notes a logistics engineer.

Balancing insulation efficiency with pump-down schedules keeps your cargo within its safe zone.

Don’t let ADR, RID or IMDG paperwork trip you up at the loading dock. Check every approval your cargo needs, then cross-reference with import rules at your destination. Missing a certificate can halt your shipment before it even leaves.

Price tags only tell half the story. You also need to budget for:

An older ISO tank with a flawless service record often beats a brand-new one that’s never seen proper upkeep.

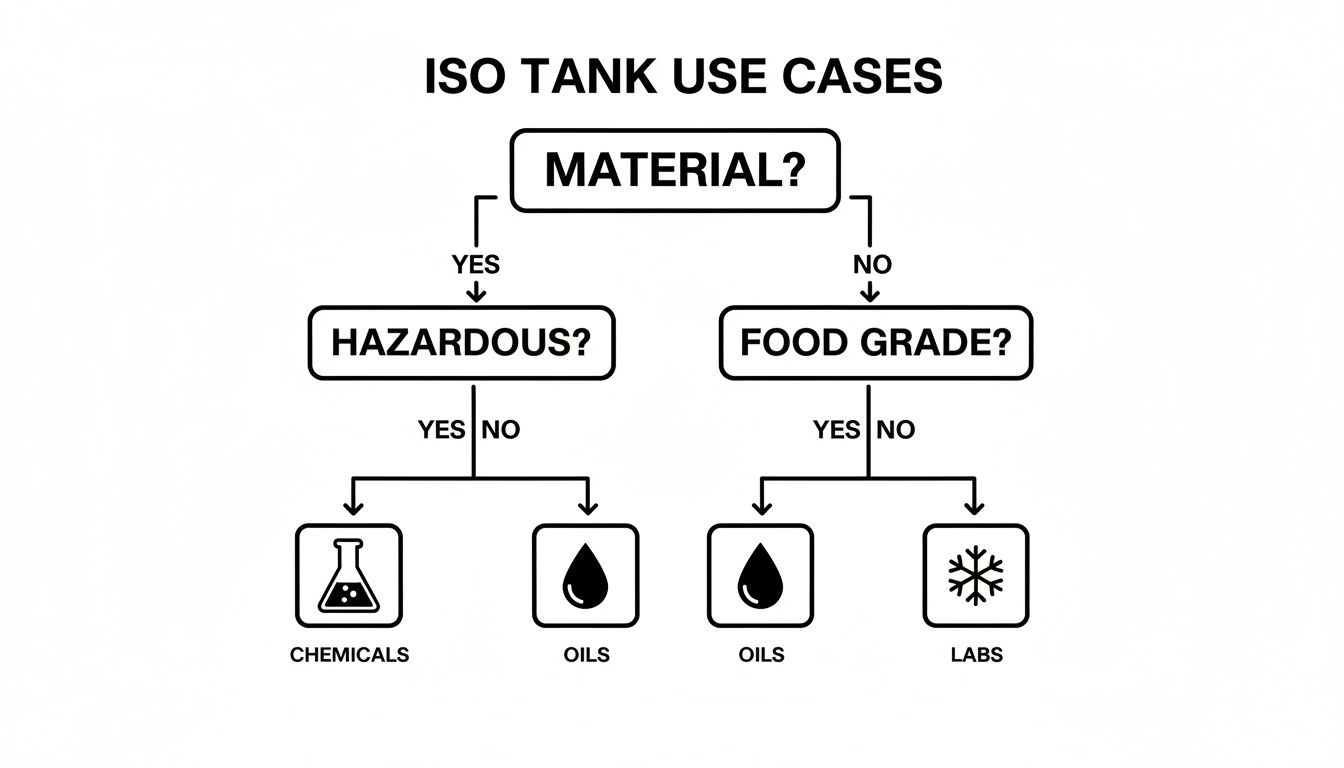

Below is an infographic illustrating a decision tree for choosing the right iso tank for chemicals, oils and lab samples.

This chart shows when to opt for standard, insulated or cryogenic tanks based on cargo type and temperature sensitivity.

For a deeper dive into route planning, packaging tips and customs support, see our guide on Transport Services at Cryonos.

Remember, data-driven selections reduce delays by up to 20% according to industry surveys.

Start using this checklist on your next shipment to guarantee you choose the most reliable ISO tank and eliminate uncertainty.

Happy shipping!

Safe travels!

Think of routine maintenance on a container iso tank as tuning a high-performance sports car before hitting the open road.

Inspect external fittings and placards just like you’d check tyre pressure—small issues pop up before they become big headaches.

Keep a detailed log of every inspection to trace wear and tear over time.

Before each run, verify every valve aligns with the cargo’s hazard class and shows the correct UN number.

Even a tiny crack in a gasket can lead to leaks when pressure builds. Track torque readings on opening and closing valves to catch stiffness early.

“Consistent valve torque records can prevent up to 25% of operational leaks,” notes a safety engineer.

These steps spot faults before they turn into costly spills or regulatory fines.

Pressure tests are like examining your car’s tyres for bulges—both catch hidden defects.

Schedule a hydrostatic test every two years to reveal tiny leaks in the shell. Vacuum-jacket integrity checks keep cryogenic tanks insulated and ice-free.

Regular cleaning is as vital as an oil change—it keeps everything running smoothly.

For cryogenic units, make sure no moisture remains to prevent ice blockages.

Digital logs act like a flight recorder, capturing every maintenance detail you’ll need in an audit.

If a spill occurs, activate your containment plan and alert local emergency services immediately. Keep spill kits and absorbent booms ready at loading points.

A clear record reduces investigation time by up to 30% and strengthens your safety culture.

Learn more about safe cryogenic liquid work in our detailed guide on 7 important rules for safe work with cryogenic liquids.

Sometimes a container iso tank overshoots your volume or usage needs.

Volume thresholds under ADR regulations will determine which option fits best. Labs often pick dewars for runs under 500 L to avoid complex permits.

Choosing the right vessel prevents overcapacity risk and simplifies compliance.

After any spill cleanup, inspect placards and fittings to confirm full tank integrity.

Train your team quarterly on emergency shutdown procedures and leak response. Maintain date-stamped photos and records to back up audits and insurance claims.

Following these routines helps you avoid delays, fines and environmental incidents.

Use this guide as your starting point for safe, efficient container iso tank operations across all transport modes.

Stay vigilant and compliant.

Choosing the right container ISO tank often feels like solving a puzzle—every detail counts. These FAQs draw on real-world experience to guide your decision, whether you’re hauling edible oils or corrosive acids.

Think of an ISO tank as a heavy-duty thermos on wheels. It handles everything from edible oils and food-grade syrups to industrial acids and solvents. Thanks to inner linings and high-grade stainless steel, you get a corrosion-resistant vessel that keeps your product pure.

Whenever your cargo crosses a national border, ADR regulations kick in. That means you must:

Skipping these checks is like driving without insurance: you might make it a few miles, but the risk isn’t worth it.

What Liquids Can a Container Iso Tank Carry

From edible oils and food-grade ingredients to industrial solvents and acids.

When Is ADR Approval Required

Always check the UN codes and confirm the ADR plate before each cross-border journey.

How to Maintain Temperature Control

Use insulated or cryogenic tanks, keep sensors online and stick to tight transfer schedules.

Why Choose Cylinders Over Iso Tanks

For volumes under 50 L, cylinders simplify documentation and cut costs on short hauls.

Insulated tanks act like a giant flask, keeping liquids between –196 °C and 100 °C. Pair them with real-time sensors and plan your transfers to minimise exposure. That way, you won’t lose your setpoint to ambient heat or unexpected delays.

When your shipment is under 50 L, cylinders make more sense. They’re lighter on paperwork and cheaper to move on short-haul routes. Plus, booking is faster—no need for extensive ADR checks on every trip.

“Properly matching tank type to cargo volume and temperature needs prevents costly delays,” notes a logistics safety specialist.

If your load drops below 200 L or ADR hoops become a headache, look at dewars or micro-bulk options. A micro-bulk tank (500–1 000 L) often hits the sweet spot between volume and simpler compliance.

Keep these pointers in your back pocket to speed up decisions and cut operational risk.

For tailored cryogenic solutions, visit Cryonos GmbH to explore our certified tanks for labs and industrial gases.