No Products in the Cart

When you hear the term Inertisieren mit stickstoff, it's simply the process of replacing the oxygen in the atmosphere with nitrogen. Why do this? To stop unwanted reactions in their tracks, which is a critical step for ensuring both safety and the integrity of your products. This is especially true in biobanking and industrial settings, where valuable, sensitive materials must be shielded from combustion or degradation.

Before we jump into the "how," it's vital to grasp the "why." At its core, nitrogen inerting is all about creating a controlled, non-reactive environment. It’s a protective bubble where sensitive materials or processes are shielded from the damaging effects of oxygen and moisture.

For industries from pharmaceutical manufacturing to cryopreservation, this isn't just another box to tick on a checklist; it's the very foundation of operational safety and quality control. Oxygen might be essential for life, but it's also a highly reactive element that can fuel combustion, accelerate oxidation, and encourage microbial growth—all things that can destroy product stability or create seriously hazardous conditions.

The main objective is straightforward: get the oxygen concentration below a critical level, what we call the Limiting Oxygen Concentration (LOC). By pushing out the ambient air with high-purity nitrogen, you're essentially putting up a protective barrier. This simple action prevents dangerous situations, like the ignition of flammable solvents in a chemical reactor, while also preserving the quality of delicate products.

Think about the stakes in a biobank, where irreplaceable biological samples need to be kept viable for decades. Even the slightest exposure to oxygen during handling or storage can cause oxidative damage, threatening cell viability and the integrity of entire research projects. Likewise, in advanced manufacturing, inerting is the only way to guarantee that sensitive electronic components aren't corroded during production.

There are three main ways to create an inert atmosphere, and the one you choose really depends on the job at hand:

At its heart, nitrogen inerting is a proactive measure. It's about anticipating and neutralising risks before they can materialise, whether that risk is a fire hazard or the slow degradation of a life-saving pharmaceutical.

This strategic control over the atmospheric composition is a cornerstone of modern industrial processes, where precision and safety are non-negotiable. You can learn more about how cryogenic gases like nitrogen are applied to boost efficiency and precision in our guide to cryogenics in industrial processes. The choice of method depends entirely on your operational needs—from safeguarding cryogenic freezers to ensuring material purity in large-scale reactors—and it will directly impact the safety and success of your work.

Once you’ve got the theory down, the first real hurdle is picking the right approach for inertisieren mit stickstoff (inerting with nitrogen). This isn't just an academic exercise; your choice directly hits your efficiency, costs, and most importantly, safety. It all comes down to what you’re trying to achieve—is this a one-off prep job, or do you need constant protection?

There are three main ways to get this done: purging, blanketing, and displacement. Each one has its own playbook and is cut out for different scenarios. Getting a handle on these differences is the key to building an inerting strategy that actually works in the real world.

Purging is the most active method of the three. Think of it as a forceful flush. You're blasting a high flow of nitrogen into a vessel to rapidly kick out the existing atmosphere. The goal is to hammer the oxygen concentration down to your target level, often below 1%, in a very short amount of time. This is your go-to for prepping a reactor before adding a volatile chemical or quickly setting up a sensitive experiment in a glovebox.

Blanketing, on the other hand, is a much more passive, long-term game. Here, you're maintaining a continuous, low-pressure layer of nitrogen over a liquid or solid inside a storage tank. This "blanket" acts as a shield, stopping air from creeping in as the product level drops or temperatures change. It's the standard procedure for the long-haul storage of sensitive chemicals or pharmaceuticals, where you need to guarantee purity over weeks or months.

Finally, there’s displacement. This technique cleverly uses the physical properties of nitrogen—specifically, the fact that it’s slightly less dense than air—to gently push the existing atmosphere out. You typically introduce nitrogen at a low point in a large vessel, letting it slowly displace the lighter air upwards and out through a vent. It's a slower, more methodical approach that works beautifully for large, simply shaped containers.

Choosing the right method isn't about which is "best," but which is best for the task. A lab might purge a small reaction vessel every day, while a chemical plant will blanket a massive storage tank for an entire year. The context is everything.

To lay it all out, let's look at how these methods stack up against each other.

Here’s a quick comparative overview of the primary nitrogen inerting techniques. This table breaks down their objectives, where they're typically used, and what makes each one stand out, helping you match the method to your specific operational needs.

| Inerting Method | Primary Objective | Typical Application | Key Advantage |

|---|---|---|---|

| Purging | Rapid oxygen removal | Preparing reactors, gloveboxes, or short-term process vessels | Speed and achieving very low oxygen levels quickly |

| Blanketing | Maintaining a long-term inert atmosphere | Storage tanks for chemicals, pharmaceuticals, or sensitive liquids | Continuous protection with minimal nitrogen consumption over time |

| Displacement | Efficiently inerting large, simple volumes | Large storage silos, pipelines, or initial inerting of bulk tanks | Cost-effective for very large volumes; uses less gas than purging |

Understanding these distinctions is the first step. Next, you need to pick the hardware to make it happen.

With your method selected, it’s time to assemble the right gear. The equipment you choose will depend on things like how much nitrogen you'll be using, the purity you need, and the space you have to work with.

The first big decision is your nitrogen source. For a small-scale university research lab, portable liquid nitrogen dewars or high-pressure gas cylinders are usually perfectly fine. They’re flexible and don't require much permanent infrastructure.

But if you’re running an industrial-scale operation or a facility with a constant, high-volume demand like a biobank, you’ll quickly find that a bulk storage tank or an on-site nitrogen generator is the only practical way to go. A bulk tank guarantees a massive supply is always ready, while a generator frees you from supply chain headaches and can slash your long-term costs. If you’re looking into on-demand nitrogen, it's worth exploring the capabilities of a modern liquid nitrogen generator to see if it fits your scale.

Beyond the nitrogen source, a few key pieces of equipment are non-negotiable for a safe and controllable system.

Regulators: These are absolutely vital for taming the high pressure from your source down to a safe, usable level for your application. For sensitive work, I always recommend a dual-stage regulator. It gives you a much more consistent delivery pressure, even as the source cylinder starts to run low.

Flow Meters: You simply can't manage what you don't measure. A flow meter—whether it's a simple rotameter or a high-precision mass flow controller—lets you control exactly how much nitrogen is going into your system. This is crucial for optimising your gas consumption and hitting the calculated flow rates you need for an effective purge or blanket.

Oxygen Analysers: This is your proof. An oxygen analyser is the only way to confirm you’ve actually reached and are maintaining your target oxygen level. For any critical process, a permanent, in-line analyser with alarms is essential. For routine spot-checks, a reliable portable analyser is a must-have piece of kit for both safety and quality control.

The needs of a university lab and a production facility are worlds apart. The lab might get by with a single cylinder, a basic regulator, and a handheld oxygen meter. The industrial plant, however, will likely have a fully automated system with a bulk tank, precision mass flow controllers, and multiple in-line analysers all feeding back to a central control room. The golden rule is to match your gear to the scale and criticality of your application.

Guesswork has no place in a safe and effective inerting process. Getting the numbers right for your inertisieren mit stickstoff procedure is the difference between guaranteed safety and wasted resources—or worse, a false sense of security. Let’s get practical and walk through the calculations you’ll need to confidently size your nitrogen supply.

Whether you're purging a small laboratory reactor or blanketing a massive industrial storage tank, the core principles are the same. Overestimate, and you’re throwing money away on nitrogen you don’t need. Underestimate, and you could leave your product or process dangerously exposed to oxygen.

The most common calculation you'll run into is figuring out how much nitrogen you need to purge a vessel down to a specific oxygen level. The idea is simple: flush the existing atmosphere until the leftover oxygen is below your safety or quality threshold. A reliable formula for this is based on volume changes.

Here’s the formula you’ll want to use:

V_N2 = V_vessel × ln(C_initial / C_final)

Let’s break down what that actually means:

This formula assumes perfect, instantaneous mixing, which is great in theory but rare in the real world. From my experience, it’s always wise to add a safety factor of 10-20% to your final number. This accounts for imperfect mixing, tiny leaks, or slight variations in temperature and pressure.

Real-World Example: A Biobank Freezer Prep

Let's say you need to inert a 2 cubic metre (m³) cryogenic freezer before loading it with sensitive cell lines. To prevent any oxidative stress, your target oxygen level is 1%.

Plugging the numbers into the formula:

V_N2 = 2 m³ × ln(20.9 / 1.0)

V_N2 = 2 m³ × ln(20.9)

V_N2 = 2 m³ × 3.04

V_N2 = 6.08 m³Now, let’s apply a 15% safety factor (6.08 × 1.15). You should plan on using approximately 7 m³ of nitrogen to do the job right.

Blanketing is a different beast altogether. Instead of a one-time purge, you’re trying to maintain a constant, low-pressure inert atmosphere over time. The real challenge here is dealing with "vessel breathing"—the expansion and contraction of gas inside a tank as temperatures change or as the product is pumped out.

Calculating the necessary flow rate is less about a simple volume swap and more about managing these dynamic variables. You need a continuous, low flow of nitrogen to replace any gas that gets pushed out. This is closely tied to the smart management of your resources; you can dive deeper into this topic in our guide on what vessel inventory is and why it matters.

Your calculation needs to cover two main scenarios:

Whichever of these two values is higher will determine the minimum nitrogen flow rate you need. This ensures your vessel stays protected no matter what. Getting this number often means consulting engineering tables or software specific to your vessel’s design and local climate.

This need for precision is being felt across the German industrial gas sector. Between 2020 and 2025, the turnover for German industrial gas manufacturers—driven by applications like inertisieren mit stickstoff—grew at a compound annual rate of 5.6%, projected to hit €2.7 billion in 2025. This growth supports companies like Cryonos GmbH, which provides the critical cryogenic storage solutions needed by biobanks and pharmaceutical firms across Europe. You can explore more data on the German industrial gas market on ibisworld.com.

By moving past guesswork and applying these straightforward calculations, you can design an inerting system that isn't just safe and compliant, but also cost-effective.

You've done the maths and picked your method. Now it's time to move from paper to practice and get your system inerted. This is where careful planning pays off, but it's also where safety has to be front and centre of every single action you take.

Think of it as a pre-flight check. Before a single puff of nitrogen enters the system, you need a solid pre-procedure checklist. Get your eyes on the vessel and all the pipework. You're looking for any tell-tale signs of wear, corrosion, or damage that could spell trouble under pressure. Then, double-check every connection, from the nitrogen source right through to the final delivery point. A loose fitting is all it takes to ruin your purge and create a serious hazard.

And don't forget the most basic check of all: ventilation. If you're working in a confined area, this is non-negotiable. Displaced oxygen and leaking nitrogen can build up fast, creating a very real and dangerous asphyxiation risk.

With your checks done, you're ready to start the flow. The key here is to go slow. Gently open the valve from your nitrogen source, letting the gas enter at the controlled rate you calculated earlier. If you rush it, you'll create turbulence inside the vessel, which actually mixes the gases instead of pushing the oxygen out efficiently. It's a classic rookie mistake.

Once the nitrogen is flowing, your job shifts to monitoring. This is where your oxygen analyser becomes your best friend. Whether it's a portable unit for quick spot checks or a fixed in-line sensor giving you a constant data stream, it’s the only way to know for sure what's happening inside that vessel.

Keep a close watch on the readings. You should see them drop steadily as the nitrogen does its job. Your target is that pre-set oxygen level you defined in the planning stage—maybe it’s 5% to prevent combustion, or you might be aiming for less than 1% to protect delicate biological samples. Whatever the number, don't stop the process until your analyser shows stable readings at or below that critical point.

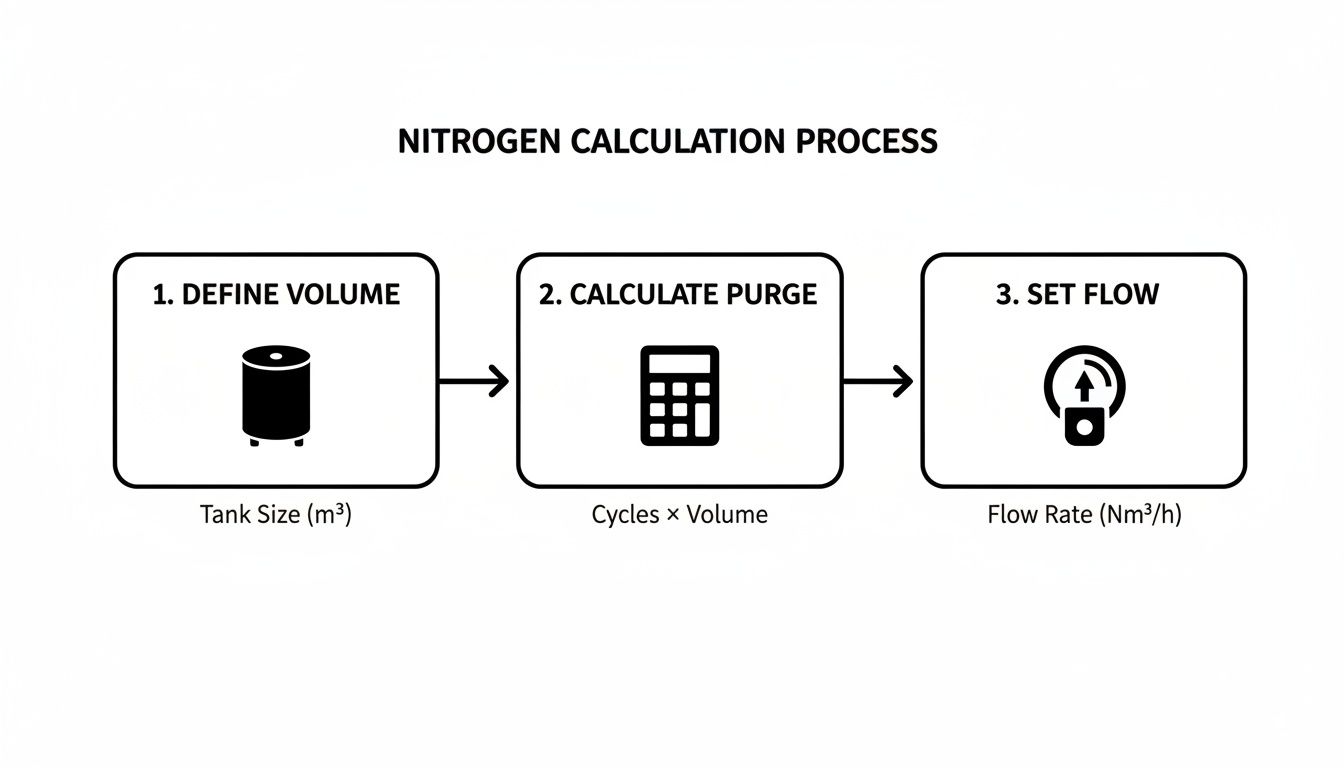

The flowchart below breaks down the core calculations you should have already completed. It's a good reminder of the groundwork this practical phase is built on.

As the graphic shows, getting the vessel volume right, calculating the necessary purge volume, and setting a controlled flow rate are the three pillars of a successful inerting procedure.

Nitrogen is fantastic for inerting because it doesn't react with anything. But that exact quality is what makes it so dangerous to people. It's colourless and odourless, so it can silently push all the breathable air out of a room without anyone noticing until it’s too late. This is why your safety protocols can't just be suggestions; they have to be strictly enforced.

The single most important rule when working with nitrogen: Never, ever assume the air is safe to breathe. Always verify the oxygen level before entering an area where nitrogen is in use.

Every single person involved in the process needs their own personal oxygen monitor. These little devices are lifesavers, sounding a loud alarm if oxygen levels dip to a dangerous point, which is typically set at 19.5%. This is your non-negotiable first line of defence.

Beyond monitors, the right Personal Protective Equipment (PPE) is a must. This isn't optional gear:

Finally, you need a clear, well-practised emergency plan. What happens if an alarm goes off? What's the procedure for an accidental release? Everyone needs to know the evacuation routes, who to call, and where the safety equipment is located. Using certified, well-maintained equipment from a reputable supplier not only makes the job safer but also helps you stay compliant with regulations.

This dedication to safety and precision is one reason Germany has become a powerhouse in the biotech and pharma sectors, fuelling major growth in the European industrial gases market. Projections show this market, where nitrogen is a key player, growing from USD 330.15 million in 2025 to USD 518.32 million by 2033. This highlights just how vital processes like nitrogen inerting have become. You can dig into the numbers in the full report on the European industrial gases market from Market Data Forecast.

Ultimately, running a safe and effective inerting procedure comes down to diligence. Follow your checklist, trust your monitoring tools, and build a culture where safety is always the top priority. That's how you protect your people and your work.

Even the most buttoned-up inertisieren mit stickstoff (nitrogen inerting) procedure can hit a snag. When things don't go according to plan, the real test is how quickly and methodically you can pinpoint the cause to get back online. In places like hospitals or biobanks, downtime isn't an option—it's a critical failure.

Let's walk through some of the most common headaches I've seen in the field and talk through practical solutions to get your system running smoothly again.

This is the big one. It's easily the most frequent and frustrating problem you'll encounter. You've run the purge for the calculated time, but your oxygen analyser is stuck, refusing to dip below your target—say, the crucial 1% mark for sensitive biological samples.

Now, before you crank up the nitrogen flow—a move that wastes gas and probably won't fix the underlying issue—it's time for a proper diagnosis. More often than not, the culprit is a hidden leak. A tiny breach in a gasket, a valve fitting that isn't quite tight, or a hairline crack in a hose can let just enough ambient air creep in, completely undermining your purge.

Start by methodically checking every connection and seal in the system. A simple but incredibly effective trick is to use a soapy water solution on joints and fittings while the system has a bit of pressure. Bubbles don't lie; they'll show you exactly where your leak is. Another possibility is an insufficient flow rate. Maybe the initial calculation was a bit optimistic, or there’s an obstruction somewhere throttling the nitrogen supply.

Here's a tip straight from experience: always double-check your flow meter's accuracy. A faulty meter might read 20 litres per minute, but if it's only delivering half of that, you'll be troubleshooting for hours. That one small check can save you a massive headache.

So you've successfully inerted a storage tank and have the blanketing system running, but the internal pressure is all over the place. That kind of instability is a major red flag. It compromises the inert atmosphere and, if it gets bad enough, can even become a safety hazard.

The very first thing to inspect is your pressure regulator. A faulty or poorly set regulator is the usual suspect, leading to an inconsistent supply of nitrogen. Make sure it's calibrated correctly for the very low pressures needed for blanketing.

Don't overlook the environment, either. Unexpected temperature swings can play havoc with your pressure. A sudden cold snap can cause the gas inside the vessel to contract, creating a vacuum effect. On the flip side, a tank sitting in direct sunlight will see its internal pressure climb. Your blanketing system is designed to handle this "vessel breathing," but extreme shifts can push it beyond its limits.

Are you burning through nitrogen cylinders way faster than you planned? That's a sure sign that gas is escaping somewhere. The most obvious cause is, you guessed it, a leak. But in this scenario, the leak is likely larger or located somewhere after the flow meter, so it’s not just contaminating your atmosphere—it's actively draining your supply.

An inefficient purging technique can also be a gas-guzzler. Blasting nitrogen into a complex vessel at a high flow rate creates turbulence. Instead of neatly displacing the air, it just mixes with it. This forces you to use way more gas to get the job done. Often, a slower, more controlled purge is far more efficient.

The cost of wasted nitrogen isn't trivial. It's a key commodity, which you can see reflected in the German industrial market. Despite challenges like volatile natural gas costs, prices held firm at 165 USD per metric tonne in March 2025, a testament to its importance. You can get more insights on nitrogen price movements and trends on openpr.com. By finding and fixing the source of high consumption, you're not just improving safety—you're directly managing your operational costs.

Even the best-laid plans for inertisieren mit stickstoff can run into questions. This section cuts straight to the chase, tackling the most common queries we hear from labs, biobanks, and industrial facilities. Think of it as a quick reference guide to get you the answers you need without having to sift through pages of documentation.

This is a great question, and the most truthful answer is: it really depends on what you're doing. There isn't a universal number that works for every single application. The right oxygen level is all about what you’re trying to protect and, just as importantly, what you’re trying to prevent.

Take flammable materials, for instance. Here, the number one priority is preventing a fire or explosion. To do that, you have to drive the oxygen concentration below the material's Limiting Oxygen Concentration (LOC). This is the absolute minimum percentage of oxygen needed to even allow combustion. For most common solvents, getting the oxygen level under 5% builds in a solid safety margin.

But for highly sensitive biological samples or delicate pharmaceuticals, the game changes completely. The enemy isn't fire; it's oxidation. Even minuscule amounts of oxygen can trigger oxidative damage, which can ruin product quality or destroy the viability of a cell line. In these cases, the target is much, much lower—often well below 1%, and sometimes you're chasing parts-per-million (ppm) levels for the most fragile materials.

Your best bet is always to start with the material's safety data sheet (SDS) and check any relevant industry standards. These documents will give you the specific LOC or recommended oxygen levels you need to maintain both safety and product integrity.

Technically, yes, you could use other inert gases like argon or carbon dioxide. But there are very good reasons why nitrogen is the go-to choice for the vast majority of jobs. It simply hits the sweet spot between several key factors, making it the perfect workhorse for most inerting tasks.

First off, nitrogen is chemically inert and non-reactive. Critically, it's also abundant and widely available, which makes it far more cost-effective than an alternative like argon. While argon has its place in specialised high-temperature applications or certain types of welding, its higher production cost makes it impractical for the large-volume inerting that's common in industrial settings.

So, what about carbon dioxide (CO2)? It sees a lot of use in the food and beverage industry for packaging. The catch is that CO2 isn't truly inert under all conditions. It can react with certain chemicals and, since it's denser than air, it behaves differently during a purge. For the overwhelming majority of industrial, pharmaceutical, and cryogenic applications where you absolutely need reliability and non-reactivity, nitrogen is the undisputed industry standard.

How often you monitor a blanketed vessel really boils down to two things: how critical the contents are, and how much you trust the integrity of your system. A "set it and forget it" mindset is a recipe for trouble.

For continuous blanketing of truly critical materials, the gold standard is a permanent, in-line oxygen analyser. This setup gives you real-time data and can be hooked up to an alarm system to alert you the second oxygen levels creep above your setpoint. It's the highest level of security and offers genuine peace of mind.

If you’re working with a portable analyser for manual spot-checks, you'll need to build a solid routine.

At the end of the day, your monitoring schedule should match the risk. The more valuable or sensitive the contents, the more often you need to be verifying the integrity of that inert atmosphere.

At Cryonos GmbH, we provide the state-of-the-art cryogenic storage and transport solutions that form the backbone of a reliable inerting strategy. From high-efficiency nitrogen storage vessels to complete inventory management systems, our equipment is designed for the safety and security your critical applications demand. Explore our comprehensive range of cryogenic solutions at https://www.cryonos.shop.