No Products in the Cart

At its core, liquid air technology is surprisingly simple. We take the ordinary air we breathe and cool it down—way down, to below -190°C—until it turns from a gas into a dense, cryogenic liquid. It's the same principle as steam condensing into water, just at unbelievably frigid temperatures. This transformation turns everyday air into a powerful medium for storing energy and a crucial source for industrial gases.

To really get a grip on this technology, you have to start with the air itself. The atmosphere is a blend of gases, mostly nitrogen (about 78%) and oxygen (about 21%), plus a dash of argon and other elements. When we plunge its temperature, we're not changing its chemistry, just its physical state. We're forcing it into a liquid form that concentrates its potential.

In this liquid state, air becomes roughly 700 times denser than it is in its gaseous form. This incredible density is the magic behind its usefulness. It means you can store and transport a massive amount of atmospheric gas in a surprisingly small and manageable volume. This is the jumping-off point for everything from producing high-purity industrial gases to a whole host of other cryogenic applications.

Creating liquid air isn't just a matter of putting it in a fancy freezer. It’s a sophisticated engineering process built on cycles of compression and expansion. By manipulating pressure and temperature in a controlled way, we force the air to shed its thermal energy until it finally hits its liquefaction point.

Liquid air plays a dual role. It's both a direct source of cryogenic temperatures and the raw material we use to separate out high-purity industrial gases like nitrogen and oxygen through fractional distillation.

For anyone working in biobanking, cell therapy, or industrial logistics, this isn't just abstract science—it connects directly to the daily realities of the job. For example:

Getting your head around this foundational technology is the first step. It helps you appreciate the elegant solutions that make modern cryogenic operations possible. It’s the invisible engine powering the preservation of life-saving cells and driving countless industrial processes forward.

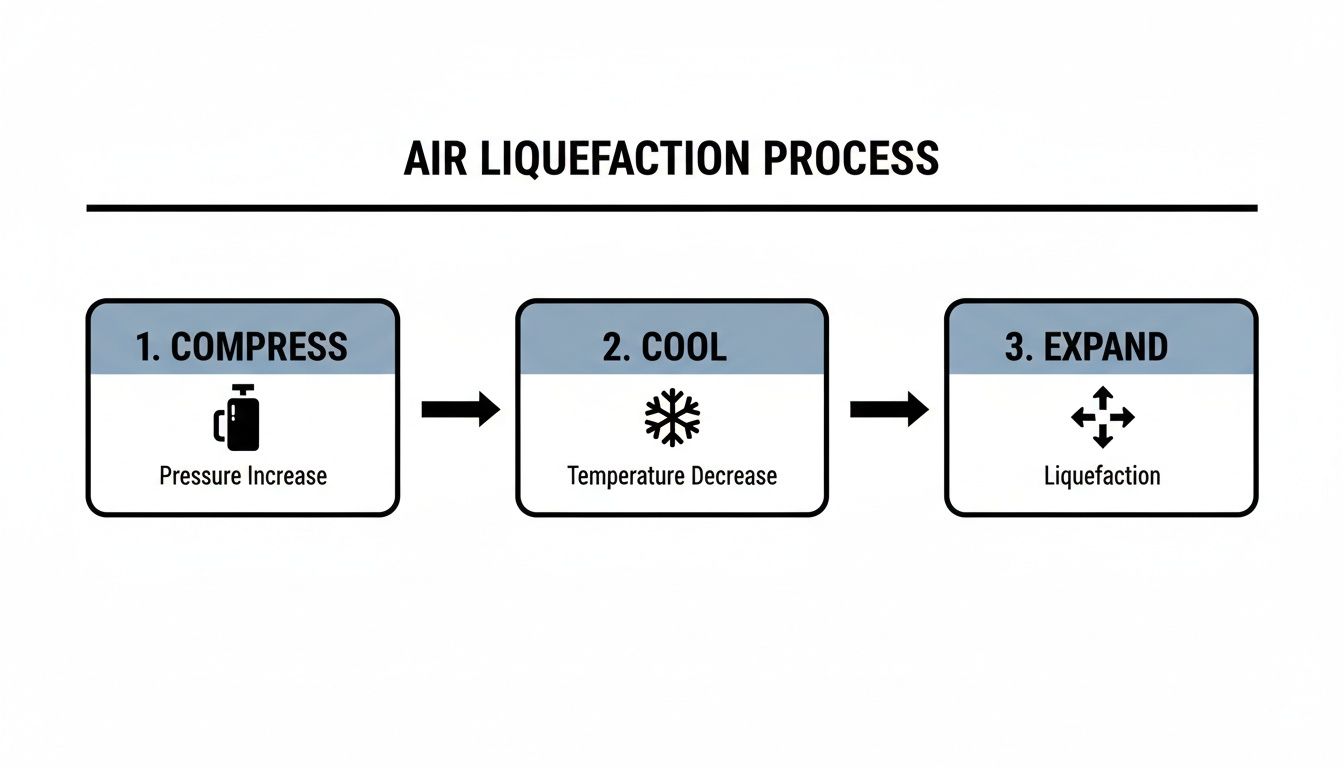

Turning the air all around us into a powerful cryogenic liquid isn't magic. It's actually a beautiful display of smart engineering built on the fundamental laws of thermodynamics. The whole process boils down to cleverly manipulating the relationship between the pressure, volume, and temperature of a gas. By forcing air through a carefully controlled cycle of compression, cooling, and expansion, we can get it to shed its heat and finally transition into its liquid state.

At the very heart of this transformation is a key physical principle known as the Joule-Thomson effect. This law of science states that when a compressed gas is allowed to expand rapidly through a valve into a lower-pressure area, its temperature drops—often quite dramatically. Think about letting the air out of a pressurised can; it feels noticeably colder. That's because the escaping gas is doing work to expand, and it uses its own internal energy (heat) to do so. This effect is the real engine driving the liquefaction of air.

To put the Joule-Thomson effect to work efficiently, engineers have come up with several methods, or "cycles," each with its own clever refinements. Two of the most foundational and influential are the Linde-Hampson and Claude cycles. While they share the same goal, their approaches differ slightly in the quest for maximum cooling efficiency.

The Linde-Hampson cycle is a pure application of the Joule-Thomson effect within a regenerative cooling system. Here’s a simple look at how it works:

This regenerative process is the secret sauce for reaching cryogenic temperatures. Each cycle makes the incoming gas colder than the last, progressively chilling the system until liquefaction becomes constant and efficient.

The Claude cycle introduces a major improvement. It adds an expansion engine or turbine to the mix. A portion of the compressed gas is diverted to do work in this engine, a process which cools it far more effectively than the Joule-Thomson effect can alone. This intensely cold gas then rejoins the main flow, giving a powerful pre-cooling boost before the final expansion stage. This innovation makes the entire process more energy-efficient, especially for large-scale production.

The development of these cycles was a defining moment in industrial history. This history is vital for understanding how Germany became a leader in modern cryogenic solutions. Back in 1902, French scientist Georges Claude pioneered a process for liquefying air that also allowed for separating its core components. This breakthrough led to the founding of Air Liquide. Its influence grew significantly in 2007 when it acquired the German engineering firm Lurgi, establishing its global engineering headquarters in Frankfurt and cementing Germany's role as a hub for advanced cryogenic technologies. You can explore more about this pivotal acquisition and its impact on the industry's growth here.

This foundational science is what makes all modern applications possible. The equipment that facilitates these cycles—especially the heat exchangers—has to be incredibly efficient to manage the extreme temperature differences. Specialised designs, like those in a plate-fin heat exchanger, are essential for getting the most thermal transfer in a compact space, making the whole liquefaction process practical. Grasping these core scientific principles is the first step to appreciating the precision engineering needed for the safe handling and application of liquid air.

Liquid air technology is far more than just a fascinating bit of physics; its practical uses are incredibly widespread, underpinning everything from preserving life-saving biological materials to enabling massive industrial processes. By harnessing the intense cold and purified gases from liquefied air, we can achieve things that would otherwise be impossible. This isn't just an academic exercise—it's a foundational technology for modern science and industry.

At its heart, the process of creating these cryogenic liquids is surprisingly straightforward. The infographic below breaks down the core steps.

This cycle of compressing, cooling, and then expanding the air is what effectively pulls the thermal energy out until it finally condenses into a cryogenic liquid. It’s from this basic process that we get essential components like liquid nitrogen, which is the workhorse behind countless applications.

When it comes to biobanking and cell therapy, there is zero room for error. You have to maintain sample viability over decades, and even the smallest temperature fluctuation can ruin irreplaceable materials like stem cells or reproductive tissues. This is exactly where liquid nitrogen, a key product of liquid air technology, becomes absolutely essential.

Stored in highly specialised cryogenic vessels, liquid nitrogen creates an ultra-low and rock-solid temperature of -196°C. This environment effectively puts all biological activity on pause—a state called cryopreservation—making sure cells and tissues can be stored for years on end without degrading.

This is a level of stability that mechanical freezers simply can't promise. Machines depend on compressors and a constant supply of electricity, but a well-insulated cryogenic dewar provides passive temperature control. That completely removes the risk of mechanical failure, giving you unmatched security for truly priceless assets.

Moving beyond biology, liquid air is also the source of industrial gases that are the lifeblood for a huge number of manufacturing and healthcare operations. Using a process called fractional distillation, liquefied air is gently heated. As the temperature rises, its different components boil off one by one and are collected at their specific boiling points.

This separation process gives us high-purity gases crucial for a variety of industries:

The industrial powerhouses that handle this task are called Air Separation Units (ASUs). They operate on a massive scale to guarantee a steady supply of these gases to markets all over the world.

The ability to separate air into its constituent parts is a cornerstone of the modern industrial economy. This process provides the raw materials needed for everything from producing high-quality steel to ensuring patient care in medical facilities.

Getting cryogenic materials from where they're made to where they're needed is a unique logistical puzzle. Whether you're moving bulk liquid nitrogen to a research lab or shipping cryopreserved cell therapies to a clinic, keeping the cold chain intact is absolutely critical.

This is where cryogenic logistics steps in. It all hinges on specially designed and certified transport vessels built to handle extreme temperatures and the bumps and rattles of transit. These containers use advanced vacuum insulation to keep evaporation to a minimum, ensuring the contents stay at cryogenic temperatures for long stretches.

For the most sensitive shipments, particularly in the medical field, these vessels have to meet tough regulatory standards like the Accord Dangereux Routier (ADR) for transport on European roads. This ensures that everything arrives safely and in perfect condition.

This logistics network is the crucial link. Without a dependable way to transport liquid nitrogen and other cryogenic gases, the benefits of liquid air technology would be stuck at the production site. Effective cryogenic logistics gives them a global reach, allowing advanced science and industry to thrive. The rising interest in cryogenic energy storage market prospects only underscores the growing importance of these logistical networks.

When you’re tasked with safeguarding priceless biological samples or keeping industrial processes stable, your choice of cooling technology is everything. Mechanical freezers are a common sight in many labs, but solutions born from liquid air technology—mainly liquid nitrogen storage—offer a completely different, and arguably more robust, way to hit and hold cryogenic temperatures.

The biggest difference comes down to their core operating principles. One is active and complex; the other is passive and beautifully simple.

Mechanical systems are always working. They need a constant supply of electricity to run compressors and circulate refrigerants, actively pumping heat out of an insulated box. It’s an effective way to get to temperatures like -80°C or even -150°C, but it’s a system loaded with potential points of failure. A power cut, a faulty compressor, or a refrigerant leak can send temperatures soaring, putting your valuable samples in immediate danger.

Liquid nitrogen storage, on the other hand, runs on a passive principle. A high-quality cryogenic vessel, often called a dewar, is really just a highly engineered thermos flask. Its vacuum-insulated walls are designed to stop heat from getting in. The liquid nitrogen sitting inside at a steady -196°C simply boils off at a glacial pace, absorbing any ambient heat and keeping the interior frigid. No electricity, no moving parts—just physics.

To really understand the difference, it helps to put these two technologies side-by-side. For high-stakes work like biobanking and cell therapy, the contrasts in reliability, running costs, and temperature stability are what truly matter.

Here's a look at how liquid nitrogen storage, the direct result of liquid air technology, stacks up against traditional mechanical freezers.

| Feature | Liquid Nitrogen Storage (e.g., Cryonos AC FREEZER) | Mechanical Freezers (-80°C or -150°C) |

|---|---|---|

| Ultimate Reliability | Extremely high. With no moving parts or need for electricity to maintain temperature, it’s immune to power cuts. | Moderate to low. Totally dependent on a steady power supply and reliable parts like compressors and fans. |

| Temperature Stability | Exceptional. Holds a rock-solid -196°C in the liquid phase or below -180°C in the vapour phase. | Variable. Prone to temperature swings during door openings and defrost cycles. Can struggle with uniform cooling. |

| Operational Costs | Moderate. The main ongoing cost is replenishing the liquid nitrogen. The storage unit itself uses no electricity. | High. Racks up significant, continuous electricity bills to power the compressor and cooling system 24/7. |

| Maintenance Needs | Minimal. It’s mostly about checking the vacuum integrity and safety devices from time to time. | Regular and complex. Needs routine servicing for compressors, filter cleaning, and possible refrigerant top-ups. |

| Long-Term Security | Superior. The passive system gives you a level of peace of mind that is simply unmatched for irreplaceable samples. | Vulnerable. Mechanical failure is a constant, significant risk without robust and expensive backup systems in place. |

Ultimately, this table highlights a fundamental trade-off: the perceived simplicity of plugging in a mechanical freezer versus the inherent, failsafe security of a passive liquid nitrogen system.

The core advantage of liquid nitrogen storage can be summed up in a single word: security. In fields where the integrity of a sample is everything, taking mechanical failure completely out of the equation is a massive win. There are no compressors to break down in the middle of the night, no electrical circuits to short, and no reliance on a backup generator that might not even start when you need it most.

The passive nature of a liquid nitrogen dewar provides a level of operational security that active mechanical systems cannot replicate. This inherent reliability is the bedrock of long-term cryopreservation and risk management in critical laboratory environments.

This security goes beyond just surviving power outages. Mechanical freezers are noisy and pump out a lot of heat, which drives up HVAC costs and makes the lab a less pleasant place to work. They also need frequent, specialised maintenance. A liquid nitrogen system, by contrast, is silent and generates no ambient heat. Your main logistical task is simply sourcing liquid nitrogen from a reliable supplier—a far more predictable process than dealing with emergency freezer repairs.

For any facility that puts the long-term, fail-safe preservation of its valuable assets first, the benefits of using liquid air technology are impossible to ignore.

When you're dealing with the power of liquid air, there’s no room for compromise on safety. Working with materials at cryogenic temperatures—anything below -150°C—comes with a unique set of risks. These aren't just boxes to tick on a checklist; managing them with precision and expertise is what separates a reliable operation from a dangerous one. A strong safety culture is everything.

The main hazards tied to cryogenic liquids are surprisingly straightforward, yet their consequences can be severe. Getting to grips with them is the first, most critical step toward creating a safe working environment.

When handling cryogenic liquids, you’re primarily looking out for three major dangers: direct contact, asphyxiation, and over-pressurisation. Each one demands its own specific set of protocols and gear to keep things under control.

A proactive safety culture begins the moment you stop seeing cryogenic liquids as just "cold stuff" and start treating them as the potent, powerful materials they are. Proper training and the right equipment aren't optional—they are absolutely essential for any team in this field.

Understanding these risks is paramount. For a deeper dive, our guide on the hazards of cryogenic liquids lays out exactly what you need to know and how to manage it.

To tackle these risks, you need a safety plan with multiple layers, covering personal protection, environmental controls, and the right equipment. It’s about making sure every angle is covered.

Your first line of defence is always Personal Protective Equipment (PPE). This isn't a recommendation; it's a must for anyone handling cryogenics. The essential kit includes:

Beyond what you wear, your surroundings are just as important, especially for preventing asphyxiation. Proper ventilation is non-negotiable wherever cryogenic liquids are used or stored. The best practice? Install oxygen monitoring systems with alarms. These sensors keep a constant watch on the oxygen levels and will sound an alert long before they drop to a dangerous point.

A solid safety programme is built on a foundation of regulatory compliance. Germany’s strong history of improving industrial and environmental standards has created a dependable framework for handling advanced materials. The country’s emissions have dropped by over 35% since 1990, thanks to systematic changes that now support the safe use of cryogenic technologies. You can learn more about Germany's air quality journey and its regulatory evolution at Breeze Technologies.

When it comes to moving cryogenic materials, following regulations like the Accord Dangereux Routier (ADR) for road transport in Europe is mandatory. Using ADR-certified equipment ensures that every container is designed, tested, and approved for moving dangerous goods safely. It’s all about preventing spills and accidents on public roads, making compliance the true cornerstone of any responsible operation.

Knowing how liquid air technology works is one thing, but putting it into practice means picking the right tools for the job. The cryogenic equipment you choose has a direct impact on your operational efficiency, the security of your samples, and your long-term costs. This isn't just about buying a container; it's about investing in a reliable system that guards your most valuable assets.

For applications where temperature stability is absolutely critical—think long-term biobanking or cell therapy storage—the freezer you select can make or break your entire operation. The system has to protect irreplaceable biological samples from every possible threat, from power cuts to equipment failure. This is where passive storage solutions really prove their worth.

Likewise, moving cryogenic materials safely demands specialised transport vessels. Whether you’re bringing a bulk supply of liquid nitrogen to your facility or shipping sensitive cell lines across the country, maintaining the cold chain is completely non-negotiable.

The right choice begins by matching a piece of equipment's features to your specific operational needs. In the demanding world of cryogenics, a "one-size-fits-all" approach simply doesn't cut it.

Investing in premium cryogenic hardware is not an expense; it is a critical measure for risk mitigation. High-performance equipment provides the foundation for operational excellence, protecting both your assets and your reputation.

Opting for a high-performance partner like Cryonos brings concrete advantages that go far beyond just holding cold liquids. These benefits translate directly into lower running costs and much greater peace of mind.

Premium equipment really comes down to a few key features:

Ultimately, selecting the right cryogenic solution is about guaranteeing reliability and security. By prioritising quality engineering, you give your operation the tools it needs to tap into the full potential of liquid air technology safely and efficiently.

As you start working with cryogenics, a few key questions always come up. Here are some straightforward answers to help you get a better handle on liquid air technology and what it means for your day-to-day work.

Think of liquid air as the raw material. It’s simply the air around us, cooled down until it becomes a liquid, which means it’s mostly 78% nitrogen and 21% oxygen, with a few other gases mixed in.

Liquid nitrogen, however, is what you get after you purify that raw liquid air. Through a process called fractional distillation, we isolate just the nitrogen. For nearly all scientific work, especially in sensitive fields like biobanking and cell therapy, this pure liquid nitrogen is the gold standard. Its inert nature is crucial—it won’t react with precious biological samples. Plus, it provides that stable, ultra-low temperature of -196°C without the risks that come with reactive liquid oxygen.

There's no getting around it: liquefying air takes a lot of energy. You need powerful compressors and advanced cooling systems to hit those extreme temperatures. That said, modern Air Separation Units (ASUs) have come a long way and are now designed for impressive efficiency, getting the most out of every kilowatt used in large-scale production.

Interestingly, this technology is also becoming a big player in grid-scale energy solutions.

Liquid Air Energy Storage (LAES) systems act like giant, rechargeable batteries for a power grid. They use excess energy from renewable sources (like wind or solar) during off-peak hours to liquefy air, effectively storing that energy. When demand spikes, the liquid air is allowed to expand back into a gas, which drives a turbine and generates electricity.

This clever approach flips the script, turning an energy-heavy process into a vital component of our renewable energy future.

High-quality cryogenic vessels are brilliantly engineered for a long, low-maintenance life. Their secret is the design: a double-walled chamber with a high-grade vacuum sealed in between, which acts as a super-insulator.

The main thing to keep an eye on over the years is the integrity of that vacuum. If it starts to degrade, heat can slowly leak into the vessel, causing your liquid nitrogen to evaporate faster than it should. The best practices for upkeep are simple but essential:

Top-tier vessels are built to go for long stretches without needing service, giving you peak performance and peace of mind while protecting your valuable samples with minimal fuss.

For state-of-the-art cryogenic solutions designed for maximum reliability and minimal maintenance, trust the experts. Cryonos GmbH provides a comprehensive portfolio of storage and transport vessels backed by decades of experience. Explore our medically certified and ADR-compliant products today at https://www.cryonos.shop.