No Products in the Cart

A plate-fin heat exchanger is a marvel of engineering, a highly compact and efficient device built to transfer heat between several different fluid streams all at once. It works a bit like a high-performance radiator, but instead of just one job, it juggles multiple. It uses a clever stack of layered plates and corrugated fins to create a massive surface area in a tiny volume, making it indispensable for really demanding applications.

In high-stakes fields like industrial gas liquefaction and biobanking, you can't just be "good" at thermal management—you have to be perfect. These operations absolutely depend on hitting and holding cryogenic temperatures, often below -150°C. Even a small slip in efficiency can lead to huge energy waste or, even worse, compromise priceless biological samples.

This is where the plate-fin heat exchanger steps in. It's the unsung hero of the cryogenic world.

Think of it like the advanced radiator in a Formula 1 car. But instead of just cooling an engine, it masterfully manages multiple hot and cold fluid streams at extreme temperatures. Its design packs incredible thermal performance into a fraction of the space required by older, clunkier technologies.

For any business that leans on cryogenic infrastructure, like those served by Cryonos GmbH, getting to grips with this technology is crucial. The performance of a plate-fin heat exchanger has a direct line to your operational costs, system reliability, and your ability to scale up.

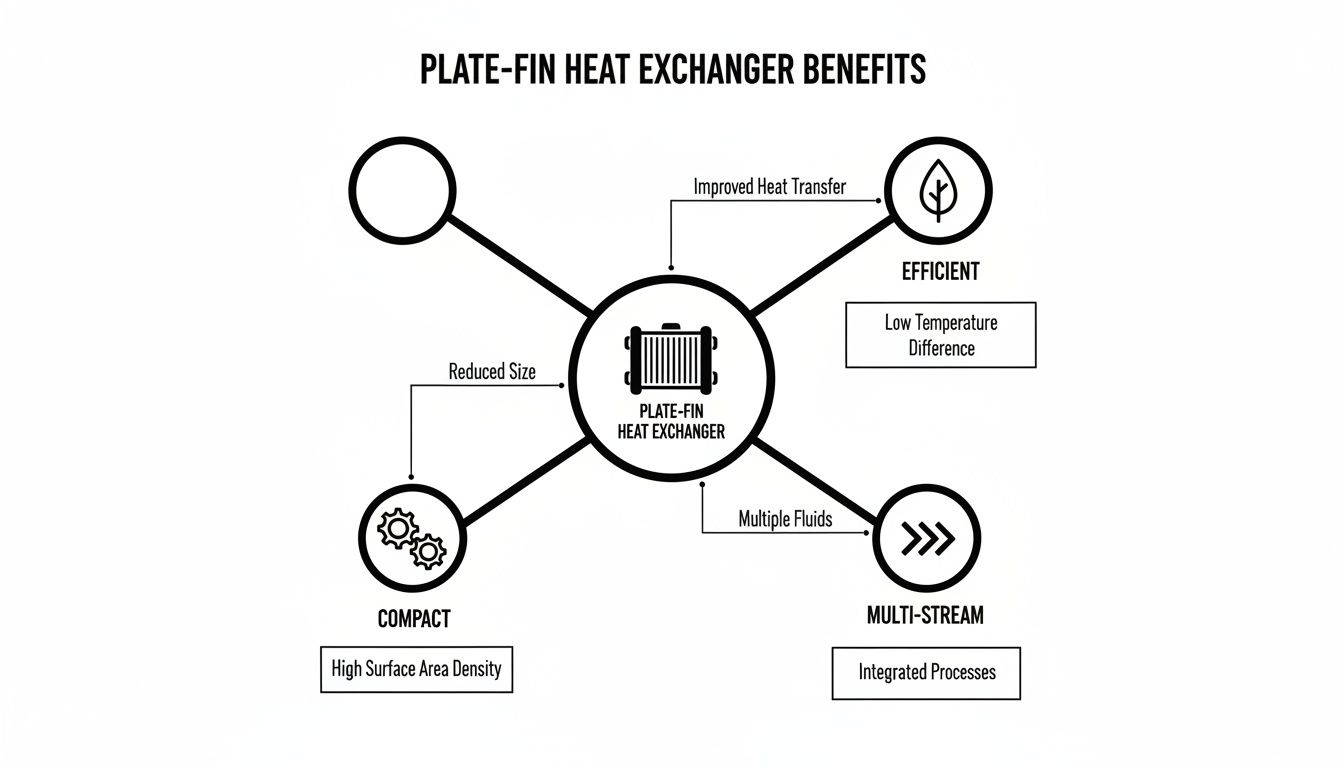

Its main advantages really stand out:

At its heart, the plate-fin heat exchanger solves a fundamental cryogenic puzzle: how to get massive amounts of heat transfer done quickly, efficiently, and in the smallest possible space. It’s the core technology that makes liquefying gases like nitrogen and preserving life-saving cellular materials possible.

In this guide, we’ll dive into how this remarkable device works, the special materials that let it thrive in extreme cold, and its vital role everywhere—from producing the liquid nitrogen for cryogenic freezers to supporting the entire biobanking supply chain.

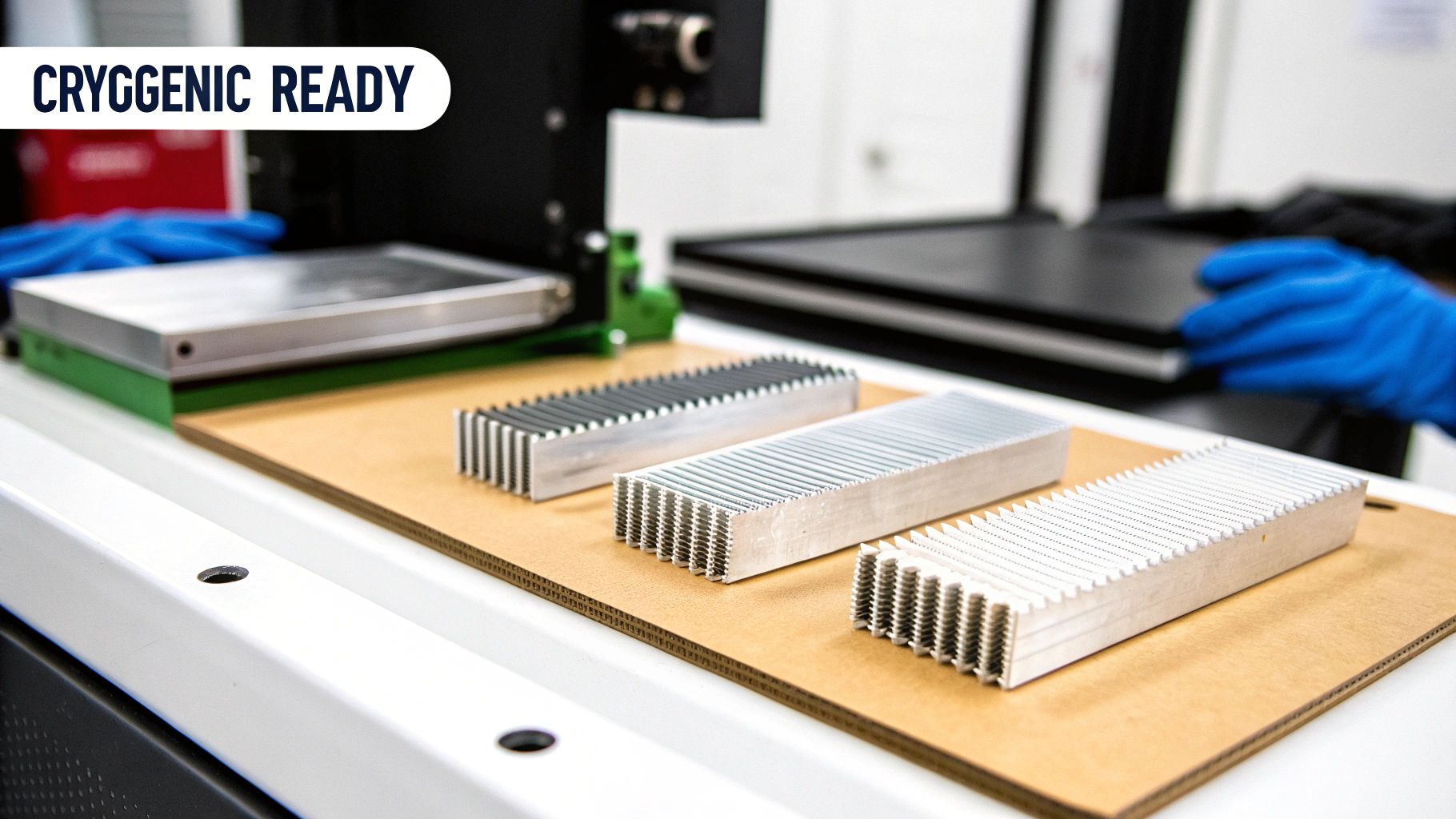

To get your head around a plate-fin heat exchanger, picture a perfectly layered cake. But instead of sponge and cream, this cake is built from alternating layers of thin metal sheets and intricately folded fins, all fused together into one solid, high-performance block. This clever construction is the secret behind its incredible ability to manage heat in the most demanding environments.

The entire unit is built from just three core components that work together in perfect harmony. Each one has a distinct and vital job in the heat transfer process, creating a symphony of thermal management inside a surprisingly small footprint.

The real genius of the design is in its simplicity and repetition. Thousands of these simple parts are stacked and bonded to create the exchanger's core.

Parting Sheets: These are flat, thin plates, usually made from an aluminium alloy. They act as barriers, separating the different fluid streams and making sure they don't mix. Think of them as the "floors" and "ceilings" for each fluid channel.

Corrugated Fins: These are the wavy, folded sheets of metal sandwiched between the parting sheets. They're the true workhorses of the unit, creating a massive internal surface area for heat to move across. Their design also gives the entire block its structural strength.

Side Bars: These solid bars seal the edges of each layer, keeping every fluid stream confined to its designated path as it flows through the exchanger.

This whole stack—parting sheets, fins, and side bars—is then placed into a vacuum furnace. Through a process called vacuum brazing, the components are heated until a special cladding on their surfaces melts, permanently fusing everything into a single, monolithic core. This creates a tough, leak-proof block that can handle serious pressures and thermal stresses.

Once it's all put together, this "layered cake" becomes a network of alternating passages. One layer might be for a cold fluid, like liquid nitrogen, while the layers directly above and below are for a warmer fluid—say, a process gas that needs cooling.

As the fluids enter the exchanger, they’re funnelled into their respective layers. The warm fluid flows through its channels, and its thermal energy transfers through the fins and the parting sheet into the neighbouring cold fluid channels. At the same time, the cold fluid absorbs this heat, warming up as it goes.

It's a continuous, highly efficient process. The immense surface area the fins provide—often more than 1,000 square metres per cubic metre of volume—means the heat exchange happens incredibly quickly and effectively. To dig deeper into the science behind this, you can explore the fascinating world of cryogenics and how it works.

This infographic gives a great visual breakdown of the key benefits that come from this unique design.

As the diagram shows, the intricate internal structure is what leads directly to a compact size, high efficiency, and the ability to handle several different fluid streams in a single unit.

The core principle is all about maximising surface area within a minimal volume. By forcing fluids through a dense matrix of fins, a plate-fin heat exchanger creates the perfect conditions for rapid thermal exchange, making it the go-to technology for applications where space and efficiency are everything.

This design doesn't just allow for counter-current flow—the most efficient way to transfer heat—but it also makes it possible to manage multiple streams in one unit. For instance, one exchanger can simultaneously cool down two different process gases while warming up another, simplifying complex industrial systems and cutting down on the amount of equipment needed.

Operating in the brutal cold of cryogenics, where temperatures can plummet below -150°C, isn’t just about making things colder. It’s a hostile world where ordinary materials become as brittle as glass, and the smallest design flaw can lead to catastrophic failure. A plate-fin heat exchanger built for this environment demands immense precision, starting with the very metal it’s made from.

The choice of material is the first, and most critical, decision. While steel is a workhorse in many industries, it suffers from severe embrittlement at cryogenic temperatures. This is precisely why aluminium alloys, especially from the 3000 and 5000 series, have become the undisputed standard for these applications.

Aluminium’s advantages are threefold. First, it has excellent thermal conductivity, letting heat move quickly and efficiently. Second, it’s lightweight, which makes installation easier and reduces the structural load. Most importantly, it holds onto its ductility and strength in the extreme cold, resisting the brittle fractures that would shatter other metals.

Beyond the base material, the exchanger's internal architecture—specifically the fin geometry—plays a massive role. The fins are the heart of the heat transfer process, creating the vast surface area needed for peak efficiency. But not all fins are created equal, and engineers have to pick the right tool for the job.

The selection comes down to a careful trade-off: you want to maximise heat transfer, but you also need to minimise the energy lost as fluid pushes its way through the unit. We call this energy loss pressure drop.

The real art of cryogenic heat exchanger design is selecting a fin geometry that creates just enough turbulence to hit your thermal targets without imposing an unacceptable energy penalty from pressure drop. It’s a delicate balancing act, tailored to each specific application.

Once the materials and fins are chosen, they need to be joined into a solid, leak-proof core. This is where a highly specialised process called vacuum brazing comes in. The entire assembly of plates, fins, and bars is placed inside a high-temperature vacuum furnace.

The vacuum is absolutely essential. It prevents oxidation, ensuring the brazing alloy flows cleanly and creates perfect, durable joints. What comes out is a monolithic block that can handle the immense thermal stresses of cycling between room temperature and deep cryogenic cold. For any system dealing with high-pressure liquefied gases, this robust construction is simply non-negotiable.

This level of engineering has made the plate-fin heat exchanger a cornerstone technology in Germany's advanced industrial and cryogenic sectors. For cryogenic duties like liquid nitrogen storage, these designs are dominant because they deliver very high surface-area-to-volume ratios, which can cut installation space by 30–50% compared with older shell-and-tube units. This compact footprint and high efficiency are why German operators in LNG, hydrogen, and air-separation are increasingly adopting them to meet stringent national and EU energy targets. You can find more insights on the European heat exchanger market on Research and Markets.

This technology is fundamental not only for large-scale gas liquefaction but also for on-site production systems, such as a modern liquid nitrogen generator, which relies on efficient heat exchange to function.

Looking at a plate-fin heat exchanger is one thing, but to really know what it can do, you need to get familiar with the numbers that define its performance. These metrics aren't just technical jargon; they tell you exactly how efficiently the unit will run, how much energy it's going to cost you, and if it's genuinely the right tool for your cryogenic setup. Getting a handle on these concepts is the key to making a smart decision that pays off in lower operational costs and better system reliability.

At the end of the day, three core metrics paint the full picture. Each one gives you a different piece of the puzzle, and when you look at them together, you get a clear and balanced view of what you're working with.

First up, and arguably the most important, is thermal effectiveness (ε). In simple terms, this tells you how close the exchanger gets to transferring the maximum possible amount of heat. It's a percentage that answers the real-world question: "How much of the available heat did we actually manage to move?"

A 100% effective heat exchanger is a theoretical unicorn—it would mean the cold fluid leaves at the exact same temperature the hot fluid came in. While that's not possible in the real world, a well-designed plate-fin unit can get incredibly close, often hitting effectiveness ratings well above 95%. This is all down to its clever counter-flow design and the sheer amount of internal surface area, which work together to squeeze every last bit of energy out of the process.

Next on the list is pressure drop (ΔP). You can think of this as the "energy tax" for pushing your fluid through the heat exchanger. As a gas or liquid winds its way through that intricate maze of fins and channels, it naturally loses some pressure due to friction. That loss means your pumps or compressors have to work harder, and that costs money.

This is where engineers face a classic trade-off. Fins that create more turbulence, like the serrated kind, are fantastic for boosting thermal effectiveness. But they also crank up the pressure drop. The real art is in finding a design that hits your heat transfer targets with the lowest possible pressure drop, striking that perfect balance between performance and running costs.

The interplay between effectiveness and pressure drop is the central challenge in heat exchanger selection. An overly aggressive design might achieve high effectiveness but impose an unsustainable energy penalty, while a conservative one might save energy but fail to meet critical cooling or heating duties.

The Number of Transfer Units (NTU) is a dimensionless value that, in essence, tells you the "thermal size" of a heat exchanger. It's a bit more of an academic measure, combining the unit’s heat transfer coefficient (U) and surface area (A) with the fluid's specific heat. Simply put, a higher NTU means a "bigger" heat exchanger from a thermal standpoint, one capable of achieving more heat transfer.

While thermal effectiveness is the practical result you ultimately care about, NTU is the tool engineers use to design for that result. It helps them figure out just how big a unit needs to be to hit a certain effectiveness target, given a specific set of flow rates and temperatures.

The demand for these high-efficiency plate-type heat exchangers is growing fast, especially across Europe. Germany, with its strong industrial backbone and relentless focus on energy efficiency, is a major driver of this trend. For German biobanks and gas logistics firms, this translates into better technology that directly reduces the power draw of their refrigeration systems. You can find out more about the plate-fin heat exchanger market growth on Market Data Forecast.

To really see how these metrics play out, let's compare a modern plate-fin unit to an old-school shell-and-tube design.

This table offers a quick look at how the two technologies stack up, especially in the demanding world of cryogenics.

| Performance Metric | Plate-Fin Heat Exchanger | Shell-and-Tube Heat Exchanger |

|---|---|---|

| Thermal Effectiveness | Typically >95% | Often 60-80% |

| Size & Footprint | Extremely compact and lightweight | Large, heavy, and space-intensive |

| Pressure Drop | Can be tailored, but often higher | Generally lower due to less complex flow paths |

| Multi-Stream Capability | Handles up to 12 streams simultaneously | Limited to two streams per unit |

As you can see, the plate-fin exchanger is in a different league when it comes to efficiency and compactness. That's precisely why it has become the go-to choice for cryogenic services where every degree of temperature and every watt of energy really counts.

The theory behind a plate-fin heat exchanger is one thing, but seeing where it gets put to work is where its true value becomes obvious. These compact units are the unsung heroes behind some of the most critical processes in cryogenics, forming the backbone of the cold chain from huge industrial plants right down to specialised laboratories. They aren't just components; they're what makes modern science and industry possible.

Their most common home is inside Air Separation Units (ASUs). Think of these as industrial giants that produce the ultra-pure liquid nitrogen, oxygen, and argon we rely on every day. In an ASU, the plate-fin heat exchanger is the absolute heart of the liquefaction cycle, taking atmospheric air and efficiently chilling it to temperatures below -190°C.

This is where their multi-stream capability really shines. A single unit can cool the incoming air while simultaneously using that cold to warm the outgoing product streams. This maximises energy recovery and is a key reason the entire process is economically viable.

The very same liquid nitrogen produced in those ASUs is the lifeblood of the biobanking world. Every single cryogenic freezer out there, preserving vital cells, tissues, and biological samples, needs a steady supply of liquid nitrogen to hold its rock-bottom temperatures. The plate-fin heat exchanger is the foundational technology that makes this entire supply chain work.

By making large-scale nitrogen liquefaction so efficient, these exchangers directly enable the critical work happening in research labs and hospitals. For a closer look at this crucial field, our guide on cryogenic storage for biobanking and stem cell research offers a deeper dive. Of course, in this environment, maintaining sterile conditions is non-negotiable, making a solid understanding of medical device sterilization validation essential for all related equipment.

The connection is direct and unbreakable: without the high-efficiency performance of a plate-fin heat exchanger in an air separation plant, the cost-effective production of liquid nitrogen at scale would be impossible, severely limiting the capabilities of modern biobanking.

Beyond separating air, this technology is a major player in the energy sector, especially in producing Liquefied Natural Gas (LNG). The process of cooling natural gas down to -162°C to turn it into a liquid is incredibly energy-intensive. Plate-fin heat exchangers are what make these massive facilities efficient enough to operate profitably.

Their small footprint and high effectiveness are a perfect match for the huge cooling demands of LNG trains. As the world shifts towards cleaner energy sources, the same principles are being applied to even tougher challenges.

From making the industrial gases that power manufacturing to preserving the biological materials that will drive future medical breakthroughs, the plate-fin heat exchanger is always there, working quietly in the background. It’s a fundamental piece of engineering that connects large-scale industrial processes to the precise, temperature-controlled worlds of cutting-edge science and medicine.

A plate-fin heat exchanger is a seriously tough piece of kit, but its high-performance nature means it needs consistent care to keep it running efficiently for the long haul. Think of proactive maintenance not as just fixing problems, but as preventing them. It’s all about safeguarding your investment and dodging the expensive downtime that can bring critical cryogenic operations to a halt.

Regular visual inspections are the bedrock of any solid maintenance plan. You or your operators should be giving the exchanger's exterior a frequent once-over. Look for any signs of damage, corrosion, or distortion, paying close attention to the inlet and outlet nozzles where stress tends to build up. Keeping an eye on system data for any sudden shifts in operating pressures and temperatures can also give you a crucial early warning that something is amiss.

For specialised equipment like this, many facilities are now leveraging predictive maintenance solutions to get ahead of potential issues and ensure a long service life.

Without a doubt, the most common headache you'll face with a plate-fin heat exchanger in cryogenic service is fouling. This happens when stray moisture, carbon dioxide, or other impurities in a gas stream freeze solid right onto the fin surfaces. This icy buildup acts like an insulator, killing thermal performance and ratcheting up the pressure drop.

If you let it go, fouling can lead to a complete blockage, forcing a full system shutdown. Your first and best line of defence is simply making sure the incoming process streams are exceptionally pure and dry.

The efficiency of a cryogenic plate-fin heat exchanger is directly tied to the cleanliness of its internal passages. Even a microscopic layer of ice can degrade performance, highlighting the importance of upstream gas purification and filtration.

When fouling does happen, the go-to remedy is a carefully controlled defrosting procedure. This involves warming the unit up to melt and flush out the solidified gunk. A common technique is thermal cycling, where you take the exchanger offline and push a warm, dry gas (like nitrogen) through it to clear out the blockages.

The vacuum brazing process creates an incredibly strong, single-piece core, but leaks can still happen over time. They're usually caused by thermal stress, vibration, or corrosion. Catching a leak early is absolutely vital to prevent fluids from cross-contaminating and to keep the whole system safe.

There are a few solid methods for pinpointing where a leak is coming from:

Regular, scheduled maintenance checks, paired with a watchful eye on day-to-day operations, are the keys to keeping your plate-fin heat exchanger running at its best. This disciplined approach doesn't just extend the equipment's lifespan; it guarantees the reliability and efficiency of your entire cryogenic system.

Even with a good grasp of the technology, you'll always have practical questions when you start looking at a plate-fin heat exchanger for a specific cryogenic system. Here are a few of the most common things engineers and operators ask, with some straightforward answers to help you out.

It really comes down to two design features working together perfectly. The first is its massive surface-area-to-volume ratio. All those corrugated fins packed into a small space create a huge internal surface, which is exactly what you need for fast, efficient heat transfer.

The second is its ability to achieve a true counter-flow. This setup keeps the temperature difference between your hot and cold fluids as large as possible along the entire length of the exchanger. Put those two things together, and you get incredible thermal performance in a surprisingly small package—perfect for the tough job of liquefying gases.

They can, but there are limits. A standard aluminium plate-fin heat exchanger is usually good for pressures up to about 120 bar (1,740 psi). While some specialised designs can go higher, this range covers the vast majority of industrial gas jobs like air separation, LNG production, and nitrogen liquefaction.

They aren't built for the really extreme pressures you might see in petrochemical plants, where a shell-and-tube design is often the only option. For most cryogenic work, though, the pressure rating is more than enough, and the benefits of their compact size and efficiency are a huge advantage.

Choosing the right plate-fin heat exchanger isn't a "one-size-fits-all" deal. It’s a proper engineering task that involves carefully balancing a few key operational needs to get it just right for your process.

A successful selection hinges on a detailed analysis of your system's thermal and hydraulic requirements. Getting this right from the start prevents operational inefficiencies and ensures the longevity of your equipment.

You absolutely have to consider these factors:

Because it’s a balancing act with so many variables, getting the sizing spot-on really calls for an expert.

For a tailored assessment of your cryogenic system needs, the experienced technicians at Cryonos GmbH can provide expert guidance to ensure you select the perfectly sized and configured equipment for optimal performance. Learn more at https://www.cryonos.shop.