No Products in the Cart

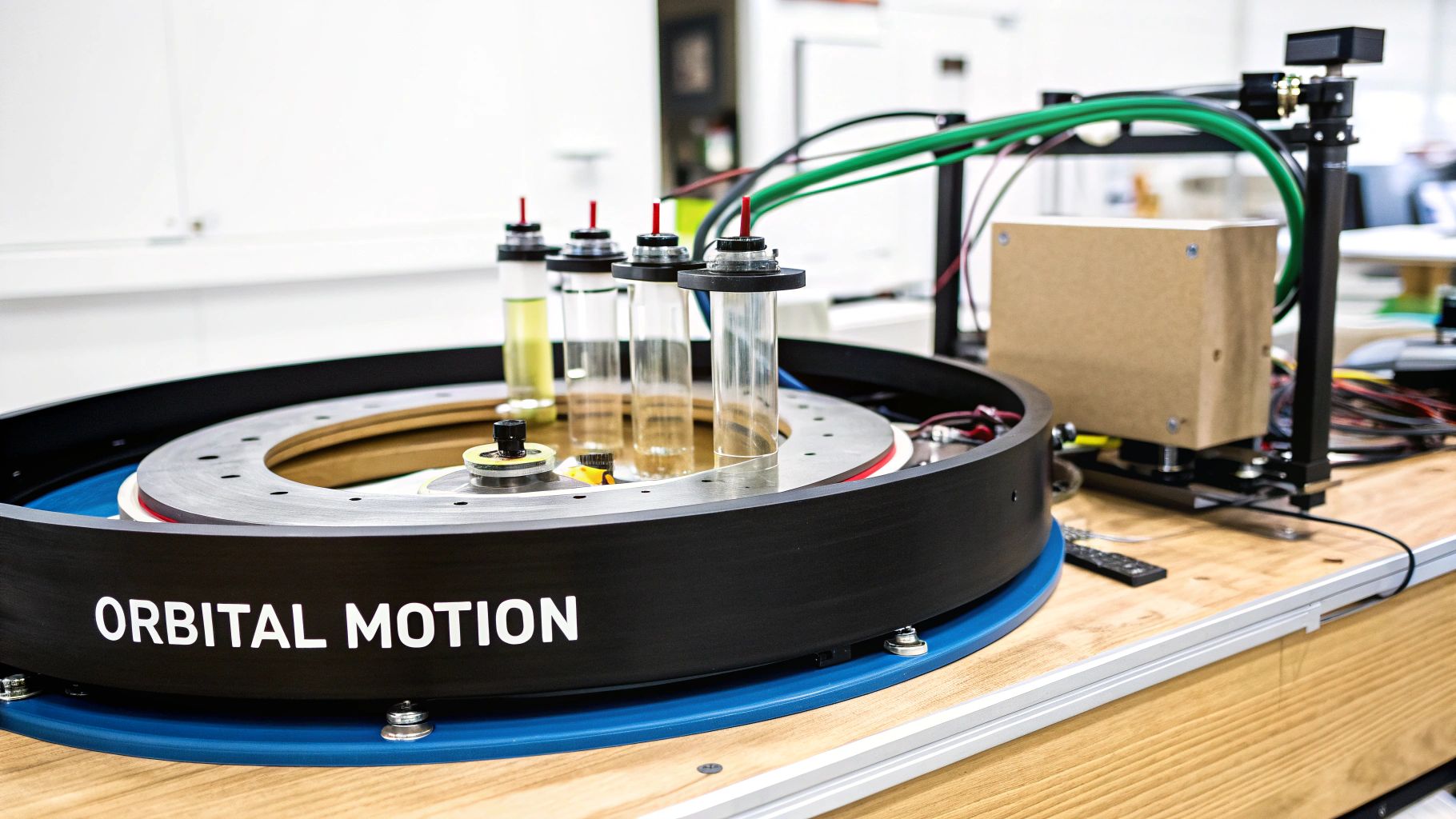

Step into any modern research lab, and you’re almost guaranteed to spot an orbital shaker humming away. It's the unsung hero of countless experiments, the lab's most reliable assistant, tirelessly swirling samples in a perfect circular motion. This simple action is crucial for everything from growing cells to dissolving delicate powders.

The orbital shaker is a cornerstone of modern science, an essential tool for getting reliable, reproducible results. Its whole job is to agitate samples in flasks, beakers, or tubes by moving them in a smooth, horizontal, circular pattern. This gentle yet thorough motion is the key—it prevents damage to fragile biological samples while making sure everything is perfectly uniform.

Think about trying to mix sugar into iced tea without creating a messy vortex that splashes everywhere. The orbital shaker does exactly that, but on a microscopic scale. It creates the ideal conditions for aeration and nutrient distribution without the high shear forces that would tear cells apart, making it the go-to for many sensitive applications.

You'll find orbital shakers used all over the lab because their controlled movement is so versatile. It’s critical for:

The purpose of shaking is to increase the availability of nutrients and improve oxygen transfer to gain a higher biomass compared to static incubation. This simple principle underpins countless breakthroughs in biotechnology and pharmacology.

In this guide, we'll break down exactly why this one piece of equipment is so foundational to research. We’ll look at how it works, its most important applications, what to look for when choosing one, and the best practices for keeping it running perfectly. Once you understand its fundamental role, you'll see how it turns complex protocols into routine procedures with outcomes you can trust.

That smooth, hypnotic swirl you see in an orbital shaker laboratory unit isn't just for show. It’s the product of clever engineering aimed at one thing: creating the perfect, uniform agitation for your samples. At the heart of it all is a simple but brilliant bit of kit called the eccentric drive mechanism. This is the engine that converts a motor's basic spinning into a consistent, horizontal circular motion.

Think of a bicycle pedal. As you push, it rotates around a central point but is offset from the main gear. An orbital shaker’s drive operates on a similar principle. A counterbalanced weight spins off-centre, forcing the whole platform to move in a precise circle without actually rotating itself. It's an incredibly effective design that produces gentle, low-vibration mixing.

This smooth motion is precisely why the orbital shaker is so critical for sensitive biological work. It avoids the harsh, shearing forces from other mixing methods that can easily tear delicate cell membranes apart.

The real magic of an orbital shaker comes down to two key settings: speed and orbit diameter. Getting a handle on how these two interact is the secret to tailoring the agitation to your specific samples, whether you're growing tough bacteria or much more fragile mammalian cells.

Speed (RPM): This is measured in revolutions per minute (RPM) and tells you how quickly the platform completes one full circle. Cranking up the speed increases the agitation, which is great for aeration because it creates a bigger surface area for gas exchange between your liquid media and the air. Most shakers give you a broad range to play with, typically from 20 to 500 RPM.

Orbit Diameter: Sometimes called the orbital throw, this is simply the diameter of the circular path the platform follows. You'll see common diameters ranging from a tiny 3 mm for microplates to a hefty 50 mm for big flasks. A larger orbit generates a much more vigorous swirl even at the same RPM, which massively boosts oxygen transfer—perfect for dense microbial cultures.

These two parameters work in tandem to control the level of shear stress, which is the force your cells feel as layers of fluid slide past one another. Finding the right balance between speed and orbit diameter is the key to getting optimal growth without shredding your cells.

For many labs, the goal is to maximise aeration and mixing while keeping shear stress below a critical threshold. This is particularly important for mammalian cell cultures, which are far more sensitive than microbial cultures.

You might see other types of shakers in a lab, but for cell cultivation, the orbital motion has become the gold standard for a few very good reasons. Linear shakers, which just move back and forth, can create messy, turbulent flows and geyser-like splashes, especially when you turn up the speed. That’s a contamination risk for your flask closure and it provides inconsistent mixing.

Then you have rocking shakers, which use a seesaw motion. They're great for gentle washing steps like staining gels, but they just can't provide the vigorous aeration needed for high-density cell cultures.

The orbital shaker neatly solves these issues by creating a consistent, gentle swirl with predictable, laminar flow. This motion ensures every cell in the flask is experiencing the same conditions, from nutrient levels to oxygen availability. That uniformity is absolutely critical for getting reproducible results, experiment after experiment. For any orbital shaker laboratory application where cell viability is the top priority, this controlled, gentle agitation is non-negotiable for ensuring robust and healthy growth.

The real magic of an orbital shaker isn’t just what it does, but how widely it’s used. Walk through any research centre, from a university lab to a major pharmaceutical company, and you'll find these workhorses quietly driving countless experiments. This single piece of kit is a cornerstone of modern science precisely because it does one thing exceptionally well: it mixes things gently and consistently, ensuring reliable, repeatable results every time.

At first glance, the applications might seem worlds apart, but they all hinge on the need for uniform mixing without wrecking the sample. The orbital shaker's smooth, circular agitation is the perfect answer, making it an indispensable tool for biologists, chemists, and clinical researchers alike. Let's dig into a few of its most critical roles to see why it’s become such a lab staple.

Perhaps the most common job for an orbital shaker is in suspension cell culture. This is all about growing huge numbers of cells—like bacteria, yeast, or even fragile mammalian cells—that float freely in a liquid nutrient broth. If you just let them sit, the cells clump at the bottom, but constant shaking keeps them evenly distributed and, crucially, breathing.

This continuous motion is non-negotiable for two main reasons:

For instance, when you're producing recombinant proteins in E. coli, running an orbital shaker at a brisk 200-250 RPM gives the bacteria all the oxygen they need to multiply like crazy and pump out your target protein. Without that constant agitation, your yields would plummet.

The gentle, low-shear motion of an orbital shaker is especially critical for mammalian cell cultures. These cells don't have a tough cell wall and are easily ripped apart by harsh mixing. The smooth swirl of an orbital shaker is the gold standard for keeping them happy and growing.

Beyond just growing cells, the orbital shaker is a powerhouse in molecular biology labs, where precision is everything. A ton of different multi-step procedures depend on its ability to gently wash and incubate samples, making sure reactions happen uniformly across the board.

A classic example is washing membranes for techniques like Southern and Northern blots. After you’ve transferred DNA or RNA onto a membrane, you have to wash it repeatedly to get rid of any unbound probes and cut down on background noise. Just placing the membrane in a container on a shaker ensures the wash buffer sloshes evenly over the entire surface. This gentle, consistent motion is far more effective and reproducible than trying to rock it by hand.

Other bread-and-butter molecular biology tasks include:

The utility of an orbital shaker also extends deep into general chemistry and analytical labs. Its ability to mix solutions for hours on end without anyone watching over it is a massive efficiency booster for dissolving solids, performing extractions, and prepping uniform samples. This simple automation frees up a technician's valuable time for more complex work.

If you're trying to dissolve something that doesn't want to cooperate, just using a magnetic stirrer can create a vortex that only mixes the centre of the liquid. An orbital shaker, on the other hand, creates a gentle swirl that agitates the entire volume, speeding up dissolution much more effectively. This is also a game-changer for liquid-liquid extractions, where it maximises the surface area between two unmixable liquids for efficient transfer of your compound. After these intensive procedures, proper long-term cell storage and management strategies are often the next critical step to preserve valuable biological samples for future analysis.

Picking the right orbital shaker laboratory equipment can feel daunting, but it doesn't have to be. When you break it down into a few key decisions, the process becomes much clearer. Getting this choice right is a big deal—it directly affects how reliable and repeatable your experiments are. The best shaker isn't just about the motion; it’s about perfectly matching its capabilities to your specific scientific work, from the volume of your samples to the exact environmental conditions they need to thrive.

The first step is to get crystal clear on what you'll be using it for most of the time. Are you growing huge batches of bacteria? Gently swirling sensitive mammalian cells? Or maybe just dissolving chemical compounds on the benchtop? Each of those jobs needs a different set of features, and lining up the shaker with the task is your first move towards getting great results. This guide will walk you through everything you need to consider, making sure you end up with a machine that becomes a dependable workhorse in your lab for years.

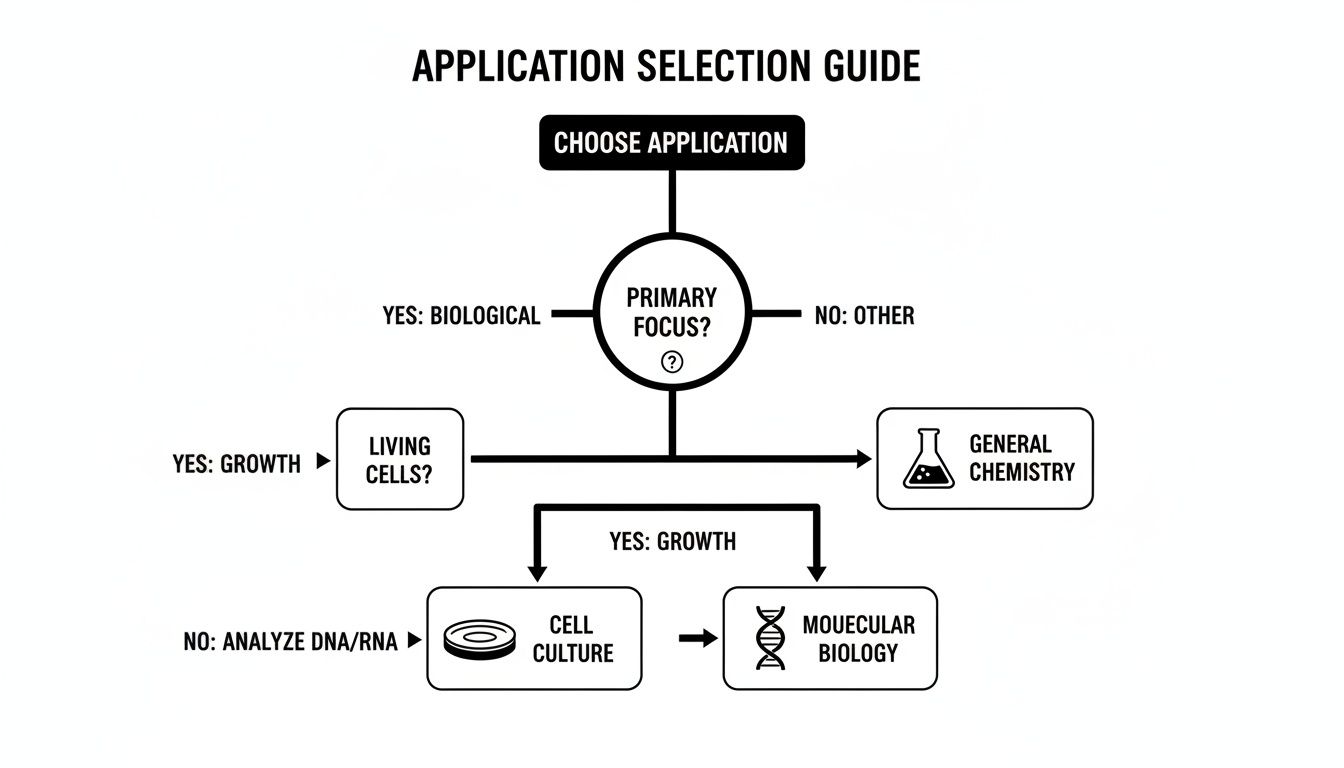

This decision tree is a great starting point for figuring out which path to take based on your lab's main focus.

As the chart shows, different fields like cell culture, molecular biology, and general chemistry have very different demands. This can help you quickly narrow down the features that matter most to you.

Let's get practical. The first questions to answer are all about size and volume. Think about both the size of your flasks or plates and how many you need to run at once. An orbital shaker laboratory platform should handle your current workload comfortably, with a little extra room for when your projects get bigger.

For smaller projects or labs tight on space, a compact benchtop model is often the perfect fit. But if you’re doing high-throughput screening or growing cells in large volumes, you’ll probably want to look at a bigger floor model or even a stackable system to make the most of your lab’s square footage.

The motion of a shaker really comes down to two things: speed (RPM) and orbit diameter. These two parameters work together to create the perfect mixing environment for your samples. Nailing this combination is key to getting great aeration without creating destructive shear forces that could ruin your cells.

A small orbit diameter, something like 3–19 mm, is perfect for gentle mixing in microplates or for keeping sensitive cell lines happy. On the other hand, a larger orbit of 25–50 mm creates a much more vigorous, splashing motion. This is great for pumping more oxygen into dense microbial cultures like E. coli. The same logic applies to speed—slow speeds for gentle agitation, higher RPMs for when you really need to mix things up.

For mammalian cell culture, a larger orbit diameter (19–50 mm) at a moderate speed is the sweet spot to minimise shear stress. For microbial cultures, you'll often see a smaller orbit (around 25 mm) at a higher speed to maximise oxygenation.

Your next big decision is whether you need environmental control. The choice between a simple open-air shaker and a more complex incubator model comes down entirely to what your application needs in terms of temperature, humidity, and atmospheric gases.

To help you decide, here’s a quick comparison of the features you’ll find on different types of orbital shakers, tailored to specific lab needs.

| Feature | Benchtop Shaker | Incubator Shaker | High-Capacity Stacking Shaker | Key Consideration |

|---|---|---|---|---|

| Footprint | Small, fits on a bench | Medium, often a floor model | Large, vertically oriented | Maximising throughput per square metre of lab space. |

| Capacity | Low (e.g., 4 x 1L flasks) | Medium (e.g., 9 x 2L flasks) | High (e.g., 3-4 units stacked) | How many samples do you need to run at once? |

| Environment | Ambient room conditions | Precise temp, CO₂, humidity | Precise temp, CO₂, humidity | Is environmental control critical for your cells/process? |

| Best For | Staining gels, dissolutions | Cell culture, protein expression | High-throughput screening, scale-up | Matching the tool to the specific biological or chemical task. |

| Cost | Low | Medium to High | High (per stack) | Balancing budget against throughput and control needs. |

As you can see, an incubator shaker is basically a high-performance incubator with a shaker built right in. These are absolutely essential for any kind of cell culture, letting you lock in a stable 37°C and 5% CO₂ atmosphere, which is non-negotiable for keeping mammalian cells alive. They're also vital if you need to keep samples at a steady temperature below or above the room's ambient temperature.

Of course, for simpler jobs like staining gels or mixing solutions, a standard open-air shaker is a reliable and much more affordable choice. It's also worth remembering that many processes require stable cold temperatures. To get a better sense of how critical precise temperature control can be, check out our guide on the ultralow temperature freezer.

If your lab operates under strict regulatory guidelines like Good Manufacturing Practice (GMP), choosing a shaker involves another level of detail. In these environments, things like data integrity, process validation, and full traceability are absolutely essential. An orbital shaker laboratory unit in a regulated lab has to do more than just shake reliably.

Here are a few key features to look for:

In this high-stakes world, Europe is the second-largest global market for laboratory orbital shakers, and Germany is leading the charge. This is largely thanks to its powerhouse life sciences sector and incredibly high standards in pharmaceutical manufacturing. The country's biotech hubs are driving the need for this equipment, especially for advanced therapies that require exquisitely controlled cell culture conditions. Germany’s market is set to grow at a 5.2% CAGR, pushed by institutions and companies that simply must have precise, GMP-compliant gear.

Think of your orbital shaker as a long-term investment in your lab's productivity and the integrity of your data. To make sure it delivers reliable performance for years to come, setting up a solid routine for its initial setup, ongoing maintenance, and regular calibration is non-negotiable.

Proper care does more than just extend the equipment's lifespan; it's what guarantees the consistency and reproducibility of your experiments. A well-maintained shaker runs smoothly, protecting sensitive cell cultures from damaging vibrations and ensuring every single sample experiences the exact same conditions, batch after batch.

The journey to reliable operation begins the moment your orbital shaker arrives. A rushed or sloppy setup can lead to a host of persistent problems, from excessive noise and premature wear on the drive mechanism to inconsistent mixing that could throw your results way off. It's worth taking the time to get it right from the very start.

Follow these key steps for a flawless setup:

Being proactive with maintenance is always better than reacting to a breakdown. A simple weekly or monthly checklist can keep your orbital shaker laboratory equipment in peak condition and help you catch potential issues before they cause any serious downtime.

Your regular maintenance schedule should include:

A well-documented maintenance log is invaluable, especially in regulated environments. It provides a clear history of the shaker's upkeep and performance, which is essential for audits and troubleshooting.

In any scientific experiment, accuracy is everything. Calibration is simply the process of verifying that your shaker is performing exactly as its display says it is. This is absolutely critical in GMP-compliant labs where process validation is mandatory, but it’s a best practice for any research setting.

There are two main parameters you'll want to calibrate:

Regular calibration protects the integrity of your data by ensuring your results are based on precise, validated conditions. And whenever you're performing these procedures, safety should be your top priority. For a complete overview of lab safety protocols and gear, explore our resources on personal safety equipment.

Even the most reliable piece of orbital shaker laboratory equipment will have an off day. Knowing how to quickly spot and fix common problems can be the difference between a minor pause and a major experimental delay. Let's walk through the most frequent issues you're likely to face.

The good news is that most orbital shaker hiccups are surprisingly simple fixes that don't require a service call. With a bit of logical troubleshooting, you can often have your shaker back up and running in minutes, keeping your research on track.

This is the number one complaint we hear: a shaker that suddenly starts rattling, groaning, or vibrating across the bench. More often than not, this is a dead giveaway that the load on the platform is unbalanced, putting a huge amount of strain on the motor and drive system.

Here's how to tackle it:

A correctly balanced load is the single most important factor for quiet operation and long-term mechanical health. Making this a standard practice will dramatically extend the life of your shaker.

For any orbital shaker laboratory unit, precision is everything—especially with incubator models. If you notice the speed is fluctuating or the temperature is drifting away from your setpoint, a few culprits could be to blame.

Start by checking for an overloaded platform, as this can strain the motor and throw off its speed stability. If it's a temperature issue in an incubator shaker, inspect the door seal. A cracked or poorly fitted seal lets in ambient air, forcing the unit to work overtime to maintain a stable climate. And, as we've mentioned, regular calibration is key to confirming whether the display is accurate or if a sensor is starting to give out.

The demand for this kind of high-precision equipment is only growing, especially in advanced biotech. Germany's laboratory shakers market, for example, is projected to see a 5.2% CAGR. This growth is fuelled by strict pharmaceutical quality standards and a 30% rise in cell-based therapeutic research. Labs in this region heavily favour models with CO₂ incubation and easy-to-clean chambers to minimise contamination risks. You can explore more about these market trends and their drivers.

To wrap things up, let's get into some of the practical questions that pop up all the time when you're working with an orbital shaker in the lab. Think of this as the quick-start guide to using your gear safely and getting the best results.

What's the real difference between orbital and linear shaking? Imagine you're swirling a cup of coffee versus sloshing it back and forth. That's the core of it.

An orbital shaker moves in a smooth, continuous circle, perfect for gently aerating cell cultures and making sure everything is mixed evenly. A linear shaker, on the other hand, moves in a straight line, creating a much more turbulent, sloshing motion. This is great for things like chemical extractions or washing blots where you need more vigorous action.

Getting the load balanced on the platform is absolutely critical if you want your shaker to last. An unbalanced load creates a ton of vibration and puts serious strain on the motor, which is a recipe for an early breakdown.

The fix is simple: always spread your flasks and vessels out symmetrically across the platform. If you’ve only got one flask to shake, don't just stick it in the middle. Grab another flask, fill it with a similar amount of water, and place it directly opposite to act as a counterweight. This little habit takes seconds but ensures the machine runs smoothly and quietly.

A well-balanced load is the single most important factor for preventing premature wear and tear on your orbital shaker. Taking a few seconds to arrange samples evenly can add years to the equipment's lifespan and protect the integrity of your experiments.

Yes, but you need to be careful. Your standard, off-the-shelf shaker is built for life at ambient room temperatures. Throw it into the cold, humid environment of a cold room, and you're asking for trouble. Condensation can easily form on the internal electronics, which is a major safety risk.

For any work at low temperatures, you absolutely must use a shaker that is specifically designed and rated for cold room operation. These models are built to handle the conditions, keeping both you and your experiments safe and sound.

At Cryonos GmbH, we provide state-of-the-art cryogenic and laboratory solutions designed for reliability and compliance. Explore our comprehensive portfolio of equipment to support your research. https://www.cryonos.shop