No Products in the Cart

When you're trying to figure out which shielding gas to use—or as they say in Germany, "schutzgasschweißen welches gas"—the right answer always comes down to your metal and what you're trying to achieve with your weld. For most hobbyists working on mild steel, an Argon/CO2 mixture (like an M21) hits the sweet spot between performance and cost. But if you're welding something like aluminium or stainless steel, pure Argon or more specialised blends are non-negotiable for a quality job.

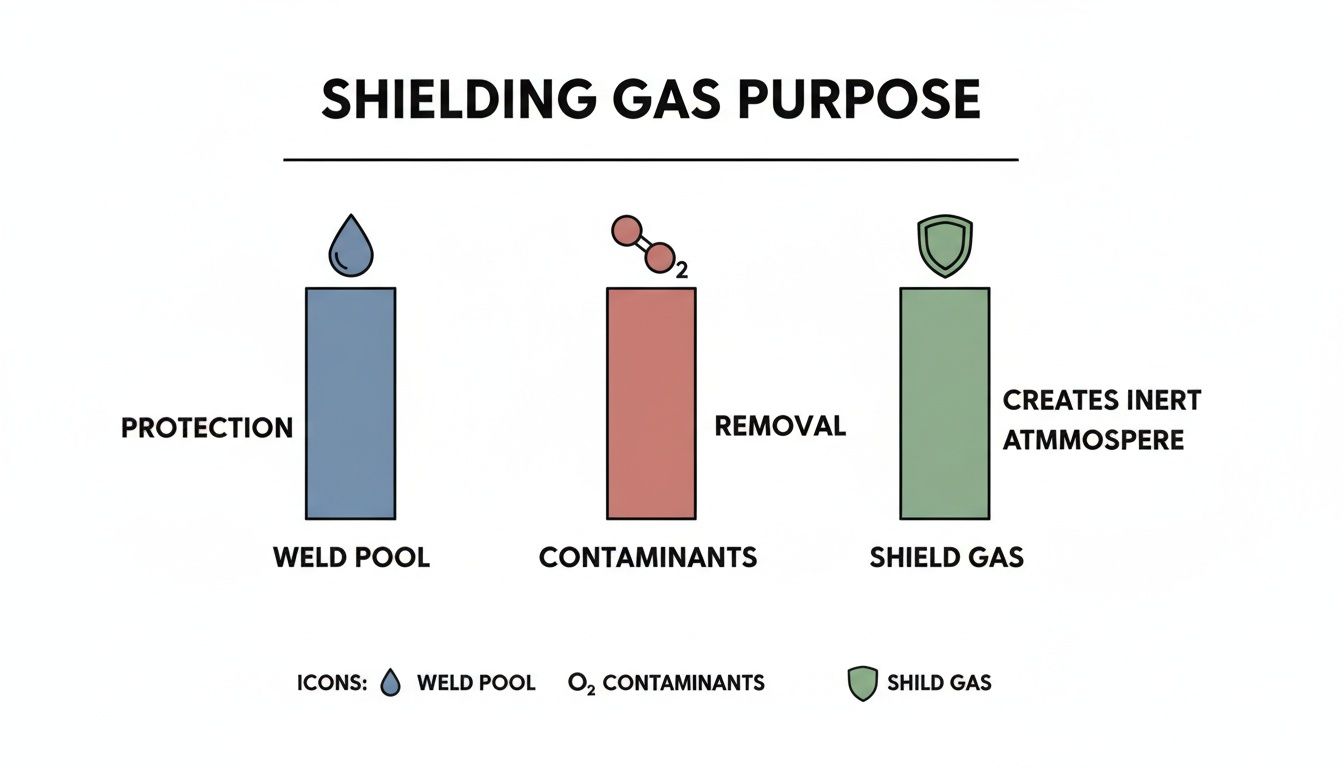

Think of shielding gas as the invisible guardian of your molten weld pool. Its main job is to push away atmospheric gases—especially oxygen and nitrogen—which love to react with hot metal. Without that protective shield, these contaminants wreak havoc, causing defects like porosity (tiny gas bubbles), brittleness, and a mess of spatter. The result is a weak, ugly weld that nobody wants.

But the gas you choose does more than just protect. It directly shapes the welding process itself, influencing everything from how stable the arc is to how deeply the weld penetrates the metal. The first big decision is always between an inert gas and an active one. Getting this right is fundamental.

The world of shielding gas is split into two camps based on how they behave at high temperatures. Understanding the difference is the key to picking the right gas for your project.

Here’s a quick breakdown of this fundamental difference:

| Gas Category | Primary Gases | Reactivity | Common Welding Process | Typical Materials |

|---|---|---|---|---|

| Inert | Argon (Ar), Helium (He) | Non-reactive | TIG, MIG | Aluminium, Stainless Steel, Copper |

| Active | Carbon Dioxide (CO2) | Reactive with metal | MAG | Mild Steel, Low-Alloy Steel |

The choice isn't just about protection; it's about control. An inert gas gives you a calm, stable environment for fussy metals, while an active gas gets in there and energises the arc to dig deep into tough materials like steel.

Picking the right shielding gas is a bit like choosing the right lens for a camera; each one gives you a completely different result. To really get to the bottom of the schutzgasschweißen welches gas (shielding gas welding which gas) question, we need to put the industry workhorses head-to-head. Forget simple pro/con lists—let's look at how Pure Argon, Pure CO₂, and common Argon/CO₂ mixes actually perform out in the workshop.

At its core, a shielding gas has one primary job: to throw a protective barrier around the molten weld pool, keeping nasty atmospheric contaminants like oxygen and nitrogen out.

As this diagram shows, the gas envelops the molten metal, preventing oxidation and porosity. This is fundamental to creating a clean, strong, and lasting weld.

When it comes to welding non-ferrous metals like aluminium, magnesium, or copper, Pure Argon is the undisputed champion. It’s a completely inert gas, meaning it doesn't react with the weld pool at all. It just sits there and does its job of protecting the metal from the air.

This stability is its biggest advantage. It creates an incredibly smooth and predictable arc, which is absolutely essential for the fine control needed in TIG welding. For MIG welding aluminium, pure Argon is what allows for that clean spray transfer, giving you minimal spatter and a beautiful, tidy weld bead. If you're serious about non-ferrous work, especially TIG, it's worth diving deeper into gas selection. We cover the finer points in our guide on TIG welding gas.

The only real downside? Argon is a bit of a "cool" gas in terms of thermal conductivity. This tends to produce a wider weld bead with shallower penetration, which can be a problem if you're trying to weld thicker sections of aluminium.

At the complete opposite end of the spectrum, we have pure Carbon Dioxide (C1). This is an active gas, meaning it gets right in there and participates in the MAG welding process on steel. The result is a characteristically hot, forceful, and aggressive arc.

That high thermal energy is exactly what you want for digging deep into thick mild steel. If structural integrity is your priority and looks don't matter as much, 100% CO₂ is a fantastic choice. Of course, its main draw is its cost—it’s almost always the most budget-friendly option you can get your hands on.

But that raw power has its trade-offs. The arc from pure CO₂ is turbulent and far less stable than what you get with Argon. This volatility kicks up a huge amount of spatter, which translates directly into more time spent cleaning up your welds with a grinder.

While pure CO₂ delivers deep penetration for thick steel at a low cost, its volatile arc produces significant spatter, demanding extensive post-weld cleanup. This makes it a trade-off between cost-efficiency and finishing work.

Here’s the sweet spot where most welders—from weekend hobbyists to full-scale industrial fabricators—find their perfect match. By blending inert Argon with active CO₂, you get the best of both worlds for MAG welding steel. In Germany, a very common mixture known as M21 typically contains 82% Argon and 18% CO₂.

This blend marries the smooth, stable arc of Argon with the heat and deep penetration of CO₂. The result is an arc that’s far more controllable than pure CO₂, leading to a dramatic reduction in spatter and a much cleaner, more aesthetically pleasing weld bead. This balance makes it incredibly versatile for welding a huge range of steel thicknesses.

Yes, it’s more expensive than pure CO₂, but that initial investment often pays for itself. The time you save on post-weld grinding and cleanup is significant, making it a far more efficient choice in production settings or for anyone who values a quality finish straight off the gun.

To make the choice a bit clearer, here's a quick-reference table that summarises the key performance differences between these common gases for MIG/MAG welding.

| Gas Type | Primary Application | Penetration Profile | Spatter Level | Cost Factor |

|---|---|---|---|---|

| 100% Argon (I1) | TIG (all metals), MIG (non-ferrous) | Wide & Shallow | Very Low | High |

| 100% CO₂ (C1) | MAG (mild steel) | Narrow & Deep | Very High | Very Low |

| Argon/CO₂ Mix (M21) | MAG (mild/stainless steel) | Good & Balanced | Low-Medium | Medium |

This table provides a snapshot, but remember the best choice always depends on your specific material, thickness, and desired finish. The mixed gas often represents the most practical and efficient solution for general steel fabrication.

Picking the right shielding gas isn’t just some minor technical detail—it’s one of the most important decisions you'll make, directly impacting the quality, strength, and final look of your weld. While it's good to know the theory, real success comes from matching the gas to whatever material you’ve got clamped to your bench. Let’s move from the abstract to the practical and look at the best choices for the metals you're most likely to work with.

The question of schutzgasschweißen welches gas is best answered by looking at what mild steel, stainless steel, and aluminium actually need. Each one reacts differently to heat and air, so they each demand a specific type of gas shield to create a solid, professional-looking joint. Get this choice right, and you'll sidestep common headaches like porosity, ugly spatter, and poor fusion.

Mild steel is the bread and butter for most general fabrication and hobby projects. When it comes to shielding gas, you have two main options, and it's a classic trade-off between cost and the quality of the finish.

For most MAG jobs on mild steel, a mixed gas just gives you a better balance of performance and ease of use. You can dive deeper into the specifics in our detailed guide on gas for MAG welding.

Working with stainless steel requires a bit more finesse. The whole point of using it is its corrosion resistance, and the wrong shielding gas can ruin that property in a heartbeat.

You can forget about using pure CO₂. It will actually increase the carbon content in the weld, which compromises the steel's ability to resist rust. To do the job properly, you need specialised mixes that protect the material's integrity and give you that clean, professional finish.

With stainless steel, the aim is to get a stable arc and a good-looking bead without contaminating the weld. That means using a gas mixture with a very small active component.

Welders typically reach for an Argon mixture that has just a tiny percentage of CO₂ or Oxygen—we're talking 1-2%. That small kick of active gas is just enough to improve the arc stability and help the molten pool flow smoothly. The result is a well-formed bead with that classic, colourful stainless steel appearance.

Aluminium is extremely reactive with oxygen, so for both MIG and TIG welding, using a completely inert shielding gas is non-negotiable. Any active gas in the mix would cause immediate, heavy oxidation, leaving you with a weak, porous, and frankly, useless weld.

For this reason, 100% pure Argon is the undisputed industry standard. It creates the perfectly clean and stable environment needed to weld aluminium properly, preventing defects and ensuring a strong joint. If you're tackling thicker sections (over 6 mm), sometimes a blend of Argon and Helium is used. The helium cranks up the heat in the arc, which allows for deeper penetration and lets you move a bit faster.

In the German aluminium industry, Schutzgasschweißen is absolutely critical, with Argon being the top choice to prevent oxidation. Production data shows that the DIN EN ISO 14175 standard mandates pure Argon (I1) for non-ferrous metals to ensure defect-free welds. It's estimated that 85% of aluminium welding jobs in key sectors rely on Argon-based gases, which can slash porosity by up to 40% compared to using an unsuitable mix.

While your standard Argon and CO₂ blends will get you through the bulk of your welding jobs, some materials and applications just demand a more specialised touch. For high-performance work, especially on thick or thermally conductive metals, these advanced mixtures are the secret to getting superior results. Going beyond the basics helps you nail the answer to schutzgasschweißen welches gas when facing a real challenge.

These blends are meticulously engineered to tweak the arc's thermal profile and control how the molten weld pool behaves. By introducing elements like Helium, Oxygen, or even Hydrogen, a skilled welder can get pinpoint control over penetration, travel speed, and the final look of the bead, pushing past the limits of a standard gas.

One of the most reliable ways to crank up the heat input is to add Helium to your Argon base. Helium has a much higher thermal conductivity than Argon, which creates a hotter, more energetic arc that really packs a punch.

This is a game-changer when you're welding thick sections of aluminium or copper. The hotter arc results in a more fluid weld puddle that flows better, wets out nicely, and gives you much deeper penetration. As a result, you can often pick up your travel speed, boosting productivity and minimising the heat-affected zone.

Mixtures can run anywhere from 25% to 75% Helium, with the higher percentages reserved for the heaviest materials. This isn't just a workshop trick; it's critical in demanding industries. For instance, research into German magnesium welding highlighted Schutzgasschweißen processes where Argon-Helium blends were key for controlling oxidation. By 2008, institutes in Northern Germany found that 65% of magnesium automotive components were welded with Ar-He mixes (classified as I3), which slashed defects by 50% when using a gas flow of 20-30 l/min. You can dive deeper into these findings on welding high-performance alloys.

Sometimes, even a tiny amount of an active gas added to Argon can make a massive difference. These aren't your all-purpose mixes; they're formulated for very specific jobs.

Oxygen Additions: Adding a tiny pinch of Oxygen (1-2%) to Argon is a common tactic for improving bead wetting on stainless and low-alloy steels. It makes the weld pool more fluid, helping it flatten out and create a smoother, cleaner transition at the weld toes.

Hydrogen Additions: Bringing small percentages of Hydrogen (up to 5%) into an Argon mix is usually reserved for automated TIG welding of austenitic stainless steels. Hydrogen boosts the arc's heat and voltage, allowing for faster welding speeds while providing a reducing atmosphere that helps clean the surface.

Think of these specialised blends as the tools of a master craftsperson. They aren't for everyday use, but you pull them out strategically to solve specific problems—like perfecting the bead appearance on stainless steel or getting maximum penetration on thick aluminium plate.

Choosing the right shielding gas is a massive first step, but a great weld depends just as much on proper setup and safe handling. This is the practical knowledge that turns a good gas choice into a high-quality, defect-free weld, all while keeping your workspace safe. Getting the settings wrong doesn't just waste expensive gas; it can actively ruin your work.

The single most critical setting is your gas flow rate, measured in litres per minute (l/min). If you set it too low, you won't get enough shielding, and atmospheric oxygen and nitrogen will contaminate the molten weld pool. This leads to porosity—tiny gas bubbles trapped in the weld—which will severely weaken the joint.

On the other hand, cranking the flow rate way too high is a classic beginner's mistake. Not only does it chew through your gas supply, but it also creates turbulence around the nozzle. This turbulence can actually suck in outside air, defeating the whole purpose of the shielding gas and causing the same porosity problems you get with a flow that's too low.

A solid starting point for most MIG/MAG welding jobs is somewhere between 15 and 25 litres per minute. Think of this as a baseline, not a hard rule. You’ll need to fine-tune it based on a few key factors:

The goal is a gentle, smooth flow that blankets the weld zone without causing any disruption. Use your ears: a quiet hiss is perfect, but a loud, rushing noise is a sure sign your flow rate is too high.

While inert gases like Argon and CO2 aren't toxic, they are asphyxiants. In a small, poorly ventilated space, a leak can displace oxygen and create a genuinely dangerous breathing environment. Always make sure you have adequate ventilation.

Proper cylinder handling is also non-negotiable. Gas cylinders must be stored upright and securely chained to a wall or a cart to stop them from falling over. A damaged valve can turn a heavy cylinder into a very dangerous, unguided projectile. For a complete breakdown of cylinder safety, have a look at our guide covering the regulations for transporting gas cylinders.

Finally, make it a habit to check for leaks every time you connect a new cylinder. A simple spray of soapy water on the connections will bubble up if gas is escaping. This simple trick lets you tighten up the fittings before you strike an arc.

When you get into welding, you'll find that theory only takes you so far. The practical questions always pop up, and getting clear, straightforward answers is what helps you lay down a solid bead. Let's tackle some of the most common queries about schutzgasschweißen welches gas to give you some actionable advice for your next project.

A question I hear all the time is whether you can use the same gas for both MIG and TIG welding. The answer is a hard no. TIG welding relies on a non-consumable tungsten electrode, and the reactive gases used in MAG welding would utterly destroy it in an instant. For TIG, you need a 100% inert atmosphere, which is why pure Argon is the go-to choice for pretty much any material you'll weld with that process.

Figuring out the right gas flow rate can feel like a bit of a dark art. So how do you know if you've got it right? A great place to start is just to listen. The gas coming out of your nozzle should sound like a quiet, gentle hiss. That sound tells you you've got a smooth, laminar flow that's properly blanketing the weld pool. If it's loud and rushing, you've got turbulence, and that's just pulling in air and contaminants from the workshop.

Of course, the weld itself is the ultimate judge. If you're seeing porosity—those tiny pits and bubbles in the finished bead—your shielding isn't doing its job. This could be a flow rate that's too low, a draught blowing through your workspace, or simply holding the torch too far from the workpiece.

Is a more expensive gas mix really worth it? For most steel work, the answer is a resounding yes. Pure CO2 might be cheap to buy, but the time you'll spend grinding away spatter will almost always cost you more in labour and consumables than you saved on the gas. An Argon/CO2 mix pays for itself with less cleanup and a much better-looking weld.

If you're a hobbyist working mostly on mild steel—think car repairs or general fabrication—you'll want a good all-rounder gas. An Argon/CO2 mixture, like an M21 blend (typically 82% Argon, 18% CO2), hits that sweet spot perfectly. It gives you a stable arc, keeps spatter to a minimum, and produces great-looking welds across a huge range of steel thicknesses.

This versatility makes it a much smarter investment than pure CO2 for anyone who cares about a clean finish. Even when you move to more specialised materials, Argon-rich mixes are often the answer. Take copper alloys, for example. Recent German studies found that using an Ar/CO2 mix could achieve deep penetration with defect rates under 2%, producing welds as strong as the base metal itself. You can read more about these findings in this detailed report on copper alloys.

At Cryonos GmbH, we understand that superior results start with high-quality industrial gases. We provide state-of-the-art cryogenic solutions for storage and transport, making sure you have the pure gases and reliable equipment you need for any job. Check out our complete range of products at https://www.cryonos.shop.