No Products in the Cart

The most crucial ingredient for any TIG weld is an inert gas, usually pure argon. Think of it as an invisible force field that shields the molten weld pool and the glowing hot tungsten electrode from the air around it. This protective bubble isn't just a nice-to-have; it's absolutely essential for creating a clean, strong, and top-quality weld.

Ever tried to build a perfect sandcastle right at the water's edge, only to have the tide rush in and wash it all away? That’s what TIG welding is like without a good shielding gas. The everyday air we breathe is packed with oxygen and nitrogen, and for a molten weld pool, those elements are the enemy. Let them mix with the hot metal, and you're guaranteed a weld full of impurities, porosity, and brittleness—in other words, a failed weld.

A steady flow of TIG welding gas from your torch pushes all that contaminated air aside, creating a pure, non-reactive atmosphere right where you need it most. This invisible bubble is the secret behind the clean, precise, and beautiful welds that TIG is famous for. It ensures the molten metal and the tungsten electrode are completely protected from anything that could compromise the joint.

The gas you hook up to your welder is far from a minor detail. It has a massive impact on how the welding arc behaves and what the final bead looks like. Your choice directly influences a few key things:

Getting this right is especially important in high-stakes industries. Here in the DE region, TIG welding—or WIG (Wolfram-Inertgas), as it's known locally—is the go-to process for critical applications in aerospace and automotive manufacturing. The German welding equipment market, which leans heavily on TIG technology, was worth around USD 1.08 billion in 2023 and is only expected to grow. This boom is driven by the demand for flawless welds in new sectors like automotive battery production and hydrogen infrastructure. You can dig deeper into these market trends over at Fortune Business Insights.

A TIG weld's real strength and quality come from something you can't even see—that invisible shield of gas. Getting your gas selection right isn't just a step in the process; it's the foundation of mastering TIG welding itself.

Ultimately, picking the right TIG welding gas isn't just about avoiding ugly welds. It's about taking control of the physics of the weld itself. Whether you're running pure argon, helium, or a custom blend, each one is a different tool in your toolbox, giving you what you need to get the job done right.

When you're picking a TIG shielding gas, you're really choosing between two main players: Argon and Helium. But don't think of it like picking a brand of coffee. This is more like choosing between a fine-tipped pen and a broad marker—each is the right tool for a very specific job. The gas you choose directly impacts how the arc behaves, how your weld puddle flows, and ultimately, the quality of the finished weld.

For the vast majority of TIG welding jobs you'll ever come across, 100% pure Argon is the undisputed king. It’s the reliable, cost-effective workhorse you’ll find in almost every workshop, from a hobbyist's garage to a massive industrial fabrication plant.

Argon's biggest advantage comes from its atomic weight; it's about 38% heavier than air. This density is key. It allows the gas to form a tight, effective blanket over the weld pool without you needing to crank up the flow rate. The result is a beautifully stable, focused, and quiet arc that's easy to control—perfect for precise work on steel, stainless steel, and most common thicknesses of aluminium.

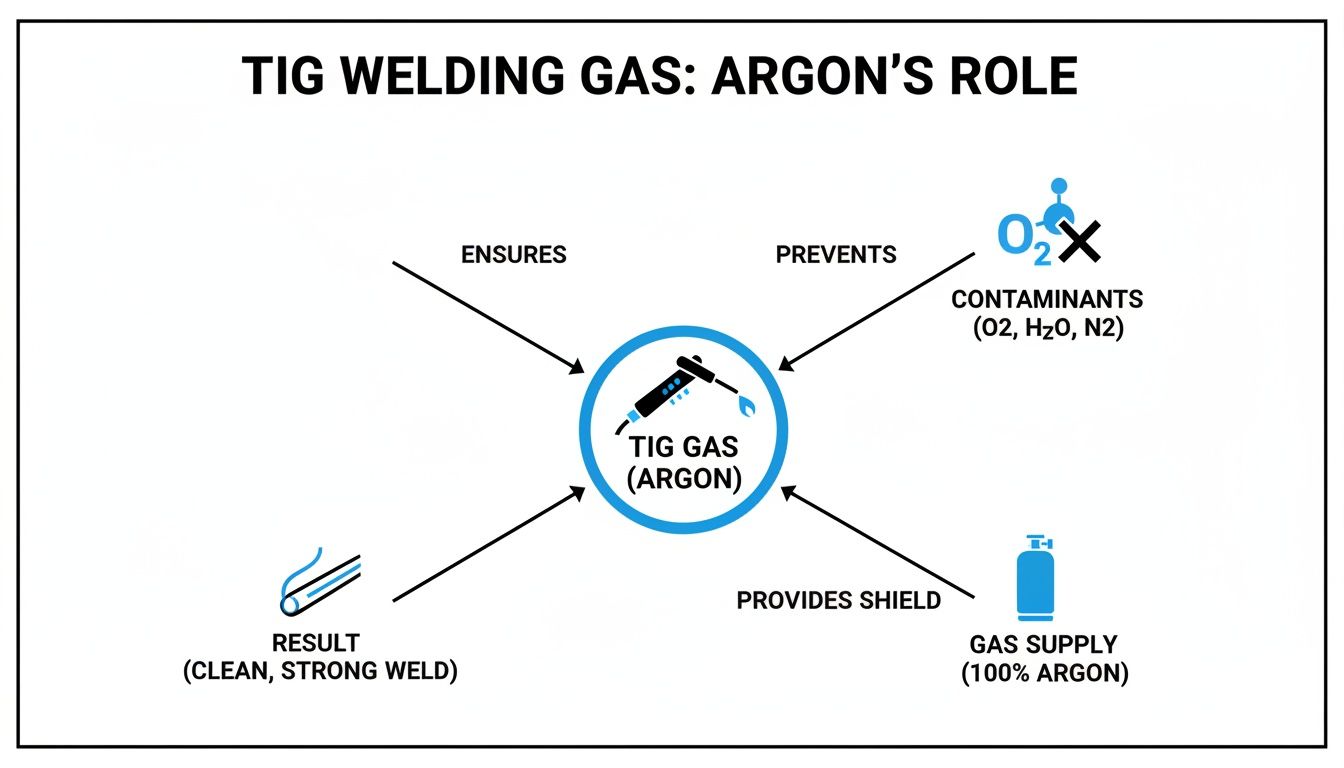

This diagram really nails down the fundamental role of shielding gas—protecting the weld from all the nasty stuff in the atmosphere to get a quality result.

As you can see, a proper gas shield is the only thing standing between a clean, strong bead and a contaminated, failed weld.

If Argon is your dependable daily driver, then Helium is the high-performance racing engine. It's much lighter and has a far higher thermal conductivity. In practical terms, this means a welding arc running on Helium is significantly hotter and wider than an Argon arc at the very same amperage.

Now, you don't need that extra heat for every job. It’s a specialist tool you pull out when you need a serious power boost.

Pure Helium creates an arc that can be 30-40% hotter than a pure Argon arc. This extra energy is exactly what you need to get deep penetration on thick sections of non-ferrous metals like aluminium, copper, and magnesium alloys.

Using Helium lets you weld with much faster travel speeds while still getting deep penetration, which is a massive win in production settings where every second counts. The trade-off? Because it's so light, you need a much higher flow rate—often two to three times that of Argon—to get the same shielding coverage. That, plus its higher price tag, makes it a premium choice for specific, demanding jobs.

Your choice between Argon and Helium really boils down to the material you're welding, how thick it is, and what you're trying to achieve. Neither gas is universally "better"; they are simply built for different tasks. One offers precision and fine control, while the other brings raw power and speed to the table.

To make it simple, here’s a straightforward table comparing their key characteristics to help you decide which gas is right for your project.

| Characteristic | Argon | Helium |

|---|---|---|

| Arc Temperature | Lower | Significantly Higher |

| Penetration Profile | Deeper and narrower | Shallower and wider |

| Arc Stability | Excellent, very smooth | Less stable, needs more skill |

| Flow Rate Needed | Low | High (2-3x Argon) |

| Cost | Lower, more economical | Higher, more expensive |

| Best For | Steel, stainless steel, thin-to-medium aluminium | Thick aluminium, copper, magnesium, high-speed automated welding |

For welders here in Germany working on a mix of projects, starting with pure Argon is almost always the right call. It covers the widest range of common materials and gives you the control needed to produce top-quality welds. But when you run into a tough job with thick aluminium or copper, knowing what Helium can do gives you a powerful tool to get results that Argon alone just can't deliver.

While pure argon and helium are the workhorses of TIG welding, the real high-performance work often demands something more. This is where gas blends come in. Think of it like a chef in the kitchen: salt and pepper are great on their own, but the right combination creates a much better flavour. Mixing shielding gases is no different—it allows you to cherry-pick the best properties of each to solve specific welding challenges.

Gas blends are all about fine-tuning the welding arc. They give you a new level of control over heat input, puddle fluidity, and how fast you can move. Instead of being stuck with either argon’s stability or helium’s raw heat, you can dial in a precise mix that gives you a bit of both. This is absolutely essential when you're pushing the limits on thick materials, high-speed jobs, or projects where quality is everything.

By far, the most common and versatile blend for TIG welding gas is a mix of argon and helium. When you add helium into an argon base, you truly get the best of both worlds. You get the smooth, predictable arc starts that argon is famous for, combined with the hotter, more focused arc and deeper penetration that helium brings to the table.

These argon-helium mixes really shine when welding thick sections of non-ferrous metals like aluminium and copper. A very popular blend, 75% Argon / 25% Helium, creates an arc that's noticeably hotter than pure argon. That extra punch of energy lets you crank up your travel speed and get much better fusion on materials over 6mm thick, making it a go-to for high-speed automated welding.

For even tougher jobs, a 50/50 Argon/Helium mix provides a serious heat boost, perfect for heavy-duty aluminium fabrication where deep, consistent penetration is non-negotiable.

The real beauty of an Argon/Helium blend is efficiency. You get a hotter arc without having to jack up the amperage, which helps reduce tungsten erosion and improves the overall weld quality on thick, conductive metals.

Looking beyond argon and helium, a few highly specialised blends introduce small amounts of other gases to solve very specific metallurgical problems, especially with stainless steels. Just be aware, these aren't your everyday, all-purpose gases and should only be used when recommended for certain alloys.

These advanced gas blends are a cornerstone of modern manufacturing. In Germany, for example, industrial hubs in Baden-Württemberg and Bavaria are pioneering advanced gas delivery systems to guarantee weld integrity on complex alloys. This push for efficiency is also echoed in wider European goals. The EU's Green Deal encourages the adoption of energy-efficient TIG systems that depend on precise gas mixtures for top-tier quality with minimal waste. You can learn more about how Germany's advanced manufacturing sector is setting the pace in the European welding market at Fortune Business Insights.

Ultimately, picking the right blend is all about matching the gas to the material and the result you need. While a hobbyist can get fantastic results with pure argon, a production welder tackling thick aluminium or specialised stainless will find that a carefully chosen gas blend is the key to unlocking peak performance, speed, and quality.

Getting the right TIG welding gas is only half the story. The other, equally important half is delivering it correctly. This is where real precision and weld quality are made or broken.

A classic rookie mistake is cranking up the gas, thinking more is always better. In reality, too much flow is just as bad as too little. It creates turbulence around the torch, which actually sucks in atmospheric contaminants and poisons your weld. The goal isn't a powerful blast of gas, but a gentle, laminar column that completely cocoons the molten weld pool and the glowing tungsten tip.

This is all about setting the right flow rate, measured in litres per minute (L/min) or cubic feet per hour (CFH). Nailing this number means you get perfect protection without needlessly emptying your expensive gas cylinder.

There’s no single magic number for flow rate; it's a moving target that depends entirely on your setup and environment. Learning to read the situation and adjust accordingly is a core skill for any serious TIG welder.

Here’s what you need to be thinking about when you reach for that regulator knob:

Thinking through these factors moves you from guesswork to making deliberate choices that directly lead to better, cleaner welds.

Your ability to precisely control your shielding gas hinges on the quality of your gear. Your regulator and flowmeter are the heart and lungs of the system, and skimping here is a false economy. Good equipment pays for itself through better results and less wasted gas.

The regulator is the first piece of the puzzle. It takes the immense pressure from inside the gas cylinder—which can be over 200 bar—and steps it down to a safe, usable level. You'll generally run into two types.

A single-stage regulator does this pressure reduction in one go. They're simpler and cheaper, but they have a critical flaw: as the cylinder pressure drops, their outlet pressure tends to creep up, which can mess with your flow rate mid-bead.

For TIG welding, a dual-stage regulator is the far better option. It reduces the pressure in two steps, delivering rock-solid, consistent outlet pressure from a full tank right down to the last gasp.

That consistency is everything in TIG. A dual-stage regulator stops those little gas flow fluctuations that cause arc instability and porosity. It's a smart investment for anyone who cares about quality.

After the pressure is regulated, the flowmeter takes over to control the volume of gas heading to your torch. The old-school floating ball flowmeters are common, but for dead-on accuracy, modern digital flowmeters are much easier to set and monitor.

Thinking about gas efficiency is also smart. Industrial data shows that poor practices can lead to an incredible 63% of gas being wasted. That's a huge hit to your operating costs and environmental footprint. In response, innovative gas saver systems are gaining traction in Europe. By better regulating flow and purging stagnant gas from hoses, they can cut argon consumption by over 50% without compromising the weld.

Finally, proper cylinder handling is non-negotiable. Make sure you're up to speed on the safety standards by checking our guide on the regulations for transporting gas cylinders. Mastering your equipment is how you turn knowledge into clean, strong, and repeatable welds.

Sooner or later, every welder runs into a frustrating weld defect. It happens. The real skill isn't just about laying a perfect bead; it's about knowing how to read a bad one and figure out what went wrong. When problems pop up, your TIG welding gas delivery system is one of the very first places you should look.

Learning to play detective with your welds turns every mistake into a lesson. It takes you from just following a chart to genuinely understanding the physics of the arc. Once you can trace a defect back to its source, you can make targeted adjustments and be confident your next weld will be spot on.

Porosity is, without a doubt, the most common gas-related headache. You'll see it as tiny pinholes peppering the weld bead, or sometimes as larger, worm-like tunnels inside the metal. At its heart, porosity is just gas bubbles that got trapped in the weld pool as it cooled and solidified.

Those bubbles are almost always caused by atmospheric contamination. Plain and simple, it means your invisible shield of inert gas failed, allowing oxygen and nitrogen from the air to sneak in and mess up your weld. When you see porosity, it’s a massive red flag telling you to inspect your entire gas setup, from the tank right up to the torch.

Here's a quick checklist to run through the moment you spot those tell-tale pinholes:

Another all-too-common problem is a weld that comes out looking burnt, sooty, or covered in a dull grey, crusty-looking scale. This isn't just a minor issue; severe discolouration points to a massive failure in gas coverage, often a much bigger problem than what causes minor porosity.

While a bit of a straw or light blue tint on stainless steel can be perfectly fine, a grey and oxidised weld is a sign that the metal was essentially cooked without any real protection. This doesn't just look bad—it severely compromises the weld's strength and corrosion resistance.

A clean, shiny weld bead isn't just for looks; it's a direct visual indicator of proper gas shielding and metallurgical soundness. If your weld is grey and dull, its structural integrity is compromised.

The culprits behind this level of oxidation are usually more fundamental than just having your flow rate set a little off.

By carefully observing the story your weld bead is telling you, you can get straight to the root of the problem. Think of that finished weld as a report card for your setup and technique—read it carefully, and you'll know exactly how to improve.

Working with high-pressure gas cylinders is just part of the job in TIG welding, but it’s something that demands your full respect and a consistent safety routine. Think of a compressed gas cylinder as a source of concentrated energy; getting complacent with it can lead to catastrophic failure. The goal isn't to be scared, but to be methodical and build solid habits so you can focus on laying beads without worrying about what’s behind you.

The most fundamental rule is also the simplest: always secure your cylinders upright. It doesn’t matter if they’re in storage or hooked up to your welder—they need to be chained or strapped to a wall, a solid post, or a proper welding cart. A falling cylinder can easily snap its valve clean off, instantly turning it into a high-speed, unguided projectile. The damage it can cause is no joke.

Your first line of defence is proper storage. Your TIG gas cylinders belong in a designated area that meets a few non-negotiable criteria. Above all, this spot must be well-ventilated to make sure any gas from a slow leak can dissipate safely instead of building up.

You also need to keep the cylinders clear of any potential hazards. This is common sense, but it’s easy to forget in a busy workshop. Keep them away from:

Any time you move a cylinder—even if it’s just a few feet across the floor—the safety cap needs to be screwed on tight. This heavy chunk of metal is there for a reason: it protects the delicate valve from getting knocked around. For a closer look at why this is so critical, check out our detailed article on the importance of a protective cap for your gas cylinder.

Before you hook up a new bottle, take a second to inspect the valve for any dirt or oil. Then, standing off to the side, "crack" the valve—just a quick, split-second burst—to blow out any debris that might be lodged inside. Once the regulator is on, you absolutely have to check for leaks.

The most reliable method is also the simplest: a bit of soapy water. Brush or spray it on all your connections and watch closely for bubbles. If you see bubbles forming, you've got a leak that has to be fixed before you even think about striking an arc.

Finally, always gear up with the right Personal Protective Equipment (PPE) when handling cylinders. This means safety glasses and a good pair of sturdy gloves at a minimum. Taking these simple, deliberate steps turns a potentially hazardous task into a safe, routine part of your workflow.

Even when you've got a good handle on shielding gases, some practical, real-world questions always pop up in the workshop. Let's tackle some of the most common ones with direct, clear answers to help you make the right calls.

Absolutely not. You must never use a typical MIG welding gas, like an Argon/CO₂ mix, for TIG welding. MIG gas is designed with active gases like Carbon Dioxide (CO₂) or Oxygen, which are thrown in to help stabilise the arc for a wire-feed process.

If you tried to use that gas for TIG, those active gases would immediately attack your non-consumable tungsten electrode. The result? It would burn up in an instant and leave you with a heavily contaminated weld. TIG welding is a delicate process that absolutely requires a 100% inert gas—think pure Argon or an Argon/Helium blend—to shield the tungsten and the weld pool without sparking any chemical reactions.

That’s the classic "how long is a piece of string" question. It really boils down to three things: the size of your cylinder, your gas flow rate, and how much time you're actually spending with the arc on.

As a rough rule of thumb, you can multiply the cylinder's volume in litres by 0.58. This gives you a ballpark estimate of the total welding minutes you'll get at a common flow rate of 10 L/min (litres per minute).

But that's just an estimate. The only truly reliable way to know where you stand is to keep an eye on the high-pressure gauge on your regulator. Once that needle dips into the red zone, it's time to start planning for a refill or a cylinder swap.

Don't forget to account for post-flow! That's the gas that keeps flowing to shield the weld after the arc stops. It's not wasted gas; it's essential for preventing oxidation on sensitive metals like stainless steel and titanium, but it does eat into your total supply.

If you're a hobbyist or running a small workshop and tackling a mix of materials like mild steel, stainless steel, and aluminium up to about 6mm thick, 100% pure Argon is your best bet. It's easily the most versatile, cost-effective, and widely available gas for TIG welding.

Pure argon delivers excellent arc stability and control, helping you produce clean, high-quality welds across most common jobs. While you might hear about helium blends for thicker materials, pure Argon will capably handle the vast majority of projects a hobbyist is likely to come across.

Of course, getting the gas is only half the battle; you also have to decide whether buying or renting a cylinder makes more sense for you. For a deeper dive into that topic, check out our guide on the pros and cons of buying versus renting gas cylinders.

At Cryonos GmbH, we provide state-of-the-art solutions for industrial gas storage and transport. Ensure you have a reliable supply of high-purity TIG welding gas by exploring our range of cryogenic vessels and equipment at https://www.cryonos.shop.