No Products in the Cart

Think of a Schutzkappe für Gasflasche as a helmet for your gas cylinder. It’s a simple but absolutely critical piece of safety gear, designed to protect the most vulnerable part of the cylinder: the valve. This isn't just some optional accessory; its main job is to shield that valve from any knocks or falls that could lead to a catastrophic failure. An uncapped cylinder that takes a tumble can quickly turn into an extremely dangerous, uncontrolled projectile.

Picture a gas cylinder standing there without its protective cap. The valve assembly, a complex and surprisingly delicate mechanism, is just sitting there, completely exposed. Whether it's being moved, stored, or just handled on-site, a bump or a fall is always a real possibility. A direct hit to that valve can have devastating consequences, from expensive equipment damage to life-threatening accidents.

That valve is the gatekeeper, holding back the immense pressure locked inside the cylinder. If it gets sheared off or seriously damaged, the high-pressure gas will escape with incredible force. This sudden, violent release of energy can turn a heavy steel cylinder into an unguided rocket, powerful enough to smash through walls and cause unbelievable destruction. This is exactly the nightmare scenario a Schutzkappe für Gasflasche is built to prevent.

A good protective cap does more than just absorb a hit. It performs several vital jobs that create a complete safety system for the cylinder's valve.

A damaged valve is the culprit behind the vast majority of serious gas cylinder incidents. The simple act of making sure a protective cap is screwed on tight is one of the single most effective safety measures you can take when handling pressurised gas.

Because the risks are so high, using a protective cap isn't a suggestion—it's strictly required by safety regulations across Germany and Europe. These rules apply whether the cylinder is full, partially used, or even "empty," because residual pressure can still pose a serious threat.

Understanding the importance of workplace safety equipment is a must for any business handling these materials. For anyone involved with pressurised gas—from industrial sites to weekend camping trips—the Schutzkappe für Gasflasche is a non-negotiable part of doing things safely and responsibly. It’s the simple, effective barrier that stands between routine handling and a potential disaster.

Using a Schutzkappe für Gasflasche isn't just a friendly suggestion from a safety manual. It's a strict legal requirement, deeply woven into the fabric of German and European safety culture. These rules weren't dreamed up in a boardroom; they were forged from the hard lessons of real-world accidents, where the simple act of leaving a valve unprotected led to catastrophic results.

This robust legal framework creates a single, high standard of safety, whether you're handling industrial gases in Berlin or propane for a barbecue in Bavaria. The goal is simple: eliminate the most common point of failure on a gas cylinder to protect lives and property. Getting to grips with these regulations is essential, as they spell out your legal responsibilities for transport, storage, and handling.

The cornerstone of these rules is the ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road). Think of the ADR as the master rulebook for safely moving hazardous materials—including pressurised gas cylinders—across most of Europe. It ensures that a cylinder travelling from Spain to Germany is held to the same high safety standards.

A key command within the ADR is the absolute necessity of protecting cylinder valves during transport. The rules clearly state that valves must either be tough enough to withstand damage on their own or be shielded by a device like a protective cap. This makes the Schutzkappe für Gasflasche an indispensable tool for staying on the right side of the law. Forgetting to use one can lead to hefty fines and serious liability if an accident happens. You can dive deeper in our comprehensive guide on the regulations for transporting gas cylinders.

While the ADR sets the international stage, Germany applies these standards with its signature precision through national regulations, most notably DIN EN 1089. This standard focuses on the identification of portable gas cylinders, covering everything from colour-coding to safety features. It directly reinforces the ADR's principles, making valve protection a non-negotiable part of the safety chain.

The adoption of protective caps became rigorously standardised in Germany after DIN EN 1089 was introduced. The valve is, without a doubt, the weakest point of a gas bottle, responsible for a staggering 70-80% of all documented gas bottle accidents in Germany. When a valve snaps, the cylinder can turn into an unguided missile, powerful enough to punch through concrete walls.

Since the 1990s, the mandatory use of protective caps has driven an estimated 40-50% reduction in serious incidents tied to valve damage. With around 15 million gas bottles in circulation across Germany, the rules now demand that even empty bottles must be transported with their caps firmly in place.

The law is crystal clear: A gas cylinder in transport without a properly secured protective cap is a violation. This applies to full, partially full, and even 'empty' cylinders, because residual pressure is still a significant risk.

It’s a common question: why does an "empty" cylinder need the same protection as a full one? The answer comes down to simple physics. A cylinder is never truly empty; it always holds some residual gas and, therefore, residual pressure. That leftover pressure is more than enough to create a dangerous projectile if the valve is sheared off.

These stringent German and European regulations have dramatically cut down on valve-related incidents. They transformed safety from a collection of best practices into a legally binding system, making the humble Schutzkappe für Gasflasche an essential piece of equipment for compliance, safety, and peace of mind.

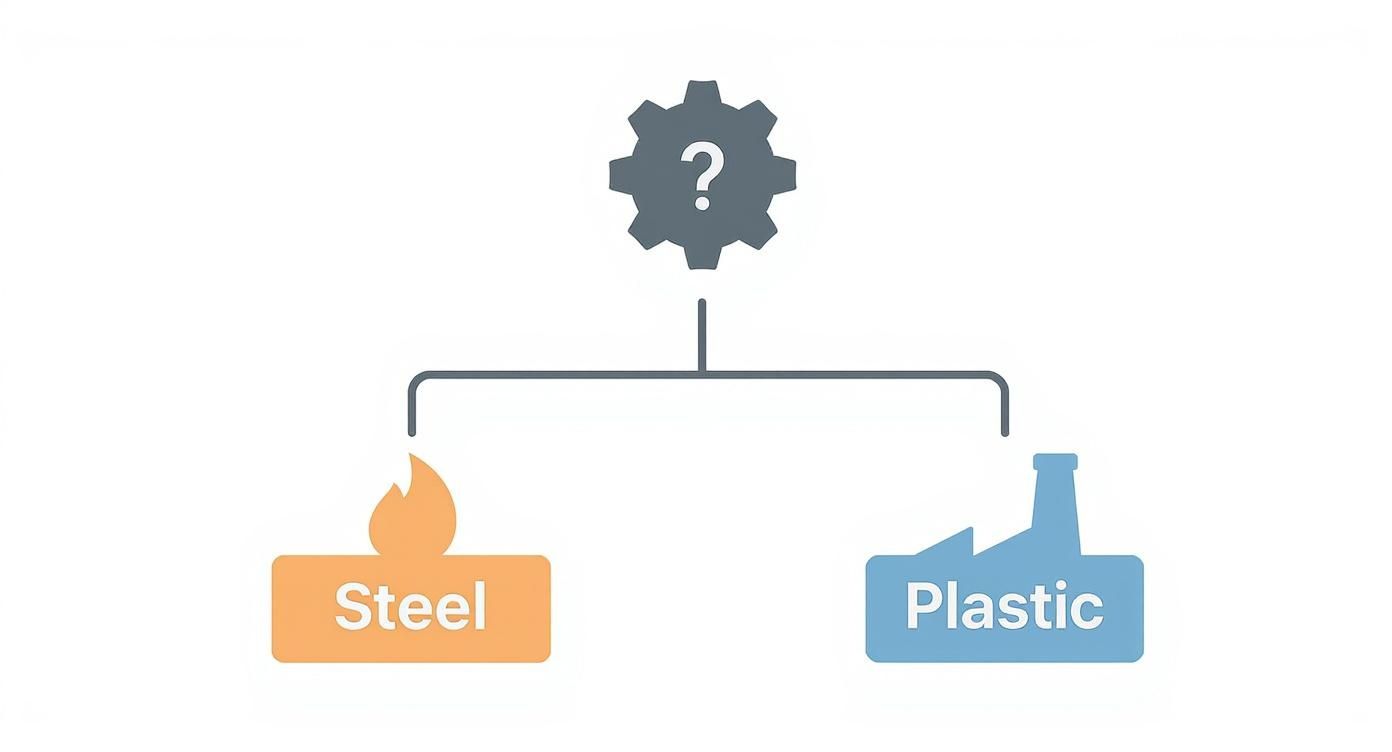

Not all protective caps are built the same. When you're choosing a Schutzkappe für Gasflasche, you’re not just picking a piece of hardware; you're selecting a specific set of safety features defined by its material and design. The choice between a classic steel cap and a modern high-impact plastic one is more than a matter of preference—it’s a critical decision based on your specific job, the gas you're handling, and the environment you work in.

The cap's material directly impacts its toughness, weight, and, most importantly, how it behaves around different hazards. A cap that's perfect for a rough-and-tumble construction site might be completely wrong—and dangerous—for a workshop where flammable gases are present. Getting to grips with these fundamental differences is the first step to making sure your gas cylinders are properly and safely kitted out.

For decades, pressed or forged steel has been the go-to for gas cylinder caps, and for good reason. Its sheer strength and resilience make it the ideal guardian for cylinders in tough, demanding places like industrial plants, building sites, and busy workshops.

Think of a steel cap as a suit of armour. It’s built to take a beating, protecting the delicate valve assembly from falling tools, bumps from heavy machinery, or just the general chaos of transport. This incredible robustness is its defining feature, offering a level of physical protection that’s hard to beat. For cylinders holding inert gases like nitrogen or argon in an industrial setting, a steel Schutzkappe für Gasflasche is often the default, and most reliable, choice.

But all that muscle comes with a few trade-offs.

Lately, high-impact plastic caps have really taken off, and they bring a whole different set of advantages to the table that make them the smarter choice in many situations. We're not talking about ordinary plastic here; this is engineered polymer, designed to be tough, durable, and shatter-resistant.

The single biggest win for a plastic Schutzkappe für Gasflasche is that it's non-sparking. This one feature alone makes it essential safety gear for any cylinder containing flammable or combustible gases. Dropping a plastic-capped cylinder or knocking it against something won't generate sparks, which drastically cuts down the risk of ignition in sensitive areas. For gases like propane, it's not just a good idea—it's mandatory.

In environments where flammable gases are present, the risk of ignition from a metallic spark is unacceptable. A non-sparking plastic cap is not just a preference; it is a fundamental safety requirement dictated by risk assessment and industry best practices.

Beyond that crucial safety point, high-impact plastic has other practical perks. It’s much lighter than steel, making cylinders easier to handle and reducing their overall weight. On top of that, it’s completely immune to rust and corrosion, which means it will have a long service life, even if left outside in the damp.

To make the choice clearer, let’s break down the key differences.

This table shows a side-by-side look at the two main materials for a Schutzkappe für Gasflasche, steel and high-impact plastic, helping you see where each one shines.

| Feature | Steel Protective Caps | High-Impact Plastic Protective Caps |

|---|---|---|

| Primary Advantage | Maximum impact resistance and durability | Non-sparking, lightweight, and corrosion-proof |

| Best Suited For | Industrial and construction sites with inert gases | Environments with flammable or combustible gases |

| Weight | Heavy | Lightweight and easy to handle |

| Spark Risk | High; unsuitable for flammable gases | None; ideal for flammable gases |

| Corrosion Resistance | Prone to rust if coating is damaged | Excellent; completely rust-proof |

| Common Application | Oxygen, Nitrogen, Argon, CO2 cylinders | Propane, Butane, Acetylene, Hydrogen cylinders |

Ultimately, steel is your fortress for heavy-duty industrial work with non-flammable gases, while plastic is the undisputed safety champion for any situation involving a fire risk.

Looking past the material, the design of the cap itself matters a lot. Two key things to pay attention to are ventilation and the thread design.

Vented vs. Non-Vented Caps: You might notice some caps have small openings or vents. These are critical for cylinders containing gases that might vent a tiny bit, like cryogenic liquids that naturally produce some boil-off gas. The vents let this gas escape safely, stopping pressure from building up inside the cap. For your standard compressed gases, a non-vented cap is perfectly fine.

Thread Mechanism: The threads are how the cap connects to the cylinder, and the fit has to be perfect. They need to be clean, well-made, and an exact match for the cylinder's collar (like the very common W 80 x 1/11" thread). A cap with damaged or mismatched threads won’t screw on securely, giving you a false—and very dangerous—sense of security. Always check that the threads engage smoothly and can be tightened by hand without a struggle.

Choosing and fitting the right Schutzkappe für Gasflasche isn't just a final touch—it's a critical safety step. A poorly fitting or incorrectly installed cap gives you a false sense of security, which can be far more dangerous than having no cap at all. Getting this right is the only way to ensure the valve is genuinely protected during transport and handling.

This guide will walk you through the essential measurements, compatibility checks, and proper installation techniques. Following these steps will help you protect your equipment, stay compliant with safety standards, and handle your gas cylinders with confidence.

Before you can pick a cap, you need the exact dimensions of your cylinder. Think of it like buying a helmet; a one-size-fits-all approach just doesn't cut it. You need two key measurements to get a perfect, secure fit.

Cylinder Collar Diameter: This is the outer diameter of the ring or collar on the cylinder's neck where the cap's threads will connect. For an accurate measurement, use a calliper. A common size, particularly in Germany, is designed for collars around 80 mm.

Thread Type and Size: This is the most crucial detail. The vast majority of standard industrial and consumer gas cylinders in Germany and across Europe use a W 80 x 1/11" whitworth thread. This spec tells you the thread has an 80 mm diameter with 11 threads per inch. Mismatched threads are the number one reason for caps that don't fit right.

Always double-check these details against the cylinder’s documentation or by measuring directly. Never guess. Even a tiny mismatch can stop the cap from securing properly, making it useless in an impact.

With your measurements in hand, the next step is matching them to the right protective cap. But compatibility is about more than just thread size; it also means picking the right material for your specific gas and work environment.

For instance, if you're handling flammable gases like propane or acetylene, a non-sparking, high-impact plastic cap is the only safe choice. For inert industrial gases on a rough construction site, a heavy-duty steel cap offers superior physical protection.

This visual decision tree helps simplify the material choice for your schutzkappe für gasflasche.

The key takeaway is straightforward: the type of gas dictates the material. Steel is for robust industrial jobs with non-flammable contents, while plastic is essential for preventing sparks around flammable gases.

Fitting the protective cap is a simple process, but it requires care and attention. Rushing this can easily damage the threads on both the cap and the cylinder collar.

Here’s a simple, step-by-step process for a proper installation:

Inspect the Threads: Before you start, give the threads on the cylinder collar and inside the cap a quick look. Check for any dirt, debris, or damage. A quick wipe with a dry cloth can ensure a smooth connection.

Position the Cap: Place the Schutzkappe für Gasflasche squarely over the valve and onto the cylinder collar. Make sure it’s level and not tilted, as that’s a common cause of cross-threading.

Engage the Threads Carefully: Start turning the cap clockwise slowly, by hand. The threads should catch smoothly with very little resistance. If you feel it binding or sticking, stop immediately. Unscrew it and try again.

Hand-Tighten Only: This is the golden rule. You must only hand-tighten the protective cap. Using a wrench or any other tool will overtighten it, which can strip plastic threads or damage the steel threads on the cylinder. A firm, hand-tight fit is all that’s needed.

A correctly installed protective cap should feel snug and secure, with no wobbling or looseness. The goal isn't an airtight seal, but a robust physical barrier that won't come loose during transport.

Even with a task this simple, mistakes can happen. Knowing the common pitfalls will help you avoid them and keep your cylinders protected.

Proper selection and installation are fundamental to gas cylinder safety. For those working with specialised systems, like in cryogenic applications, ensuring all components are correctly fitted is even more critical. You can learn more about other useful cryogenic accessories that will come in handy in our detailed guide.

A protective cap is only as good as its structural integrity. It's not enough to simply have a Schutzkappe für Gasflasche screwed on; it needs to be in excellent shape to offer any real protection. Just like any other critical piece of safety gear, it demands regular attention.

Setting up a simple but consistent inspection routine is the key to making sure your cap can do its life-saving job when it matters most. It doesn’t have to be complicated. A quick visual check every time you handle the cylinder is often all it takes to catch a problem before it turns into a serious risk. Think of it as a reliable guardian for the cylinder’s most vulnerable part—the valve.

Steel and plastic show wear and tear in different ways. Knowing what to look for is half the battle. Use this checklist as your guide to spot weaknesses quickly and effectively.

For Steel Protective Caps:

For Plastic Protective Caps:

A compromised cap is worse than no cap at all. It gives you a false sense of security while offering little to no actual protection in an accident. If you find any significant damage, replacement is not optional—it is mandatory.

The condition of the cap is only one part of the equation. The cleanliness of the threads is just as important for a secure fit. Dirt, grime, or rust on either the cap or the cylinder collar can stop the cap from seating correctly. This can lead to cross-threading, which permanently ruins the components, or a loose fit where the cap could just get knocked off.

Before you screw the cap on, always take a moment to clean both sets of threads.

This simple cleaning routine takes only a few seconds but makes a world of difference in the cap's reliability. It guarantees the threads engage fully, creating the strong, stable connection needed to protect the valve. A little attention to your Schutzkappe für Gasflasche is a small investment of time that pays off big in safety and peace of mind.

Even when you know what a Schutzkappe für Gasflasche is for, questions pop up all the time in day-to-day work. This section cuts straight to the chase with clear answers to the most common queries we hear. It’s all about helping you navigate the rules, fix potential problems, and handle your gas cylinders safely and with confidence.

Getting these details right isn’t just about protecting your gear; it's about staying on the right side of some very strict safety laws. From transport rules to knowing when a cap is past its prime, clarity is everything.

Yes, it absolutely is. This is a point of frequent confusion, but the reasoning is solid and vital for safety. Under German and European ADR regulations, a gas cylinder must have its protective cap on during transport, whether it’s full or supposedly "empty."

A cylinder that seems empty nearly always has some leftover gas and pressure. That means the valve is just as vulnerable to damage as it would be on a full cylinder. For the law, the risk is the same. That’s why the Schutzkappe für Gasflasche is always mandatory for transport and handling.

Putting a cap with the wrong threads on a cylinder is incredibly dangerous. It might feel secure, but it offers almost no real protection. A cap that doesn't fit properly simply can’t do its job.

Here are the main dangers:

Always double-check that your cap's thread specification, like the common W 80 x 1/11", is a perfect match for your cylinder.

Not quite. High-impact plastic caps have some great advantages, but whether one is right for the job depends on the gas inside and where you're working. Choosing between plastic and steel is a critical safety decision.

For flammable gases like propane or butane, plastic is the required choice. Its non-sparking property is a huge safety benefit. But in tough industrial settings where a cylinder might get hit by heavy machinery, a heavy-duty steel cap is often the safer bet for inert gases, simply because it offers better durability. You should always check the specific rules for your gas type and application.

A good rule of thumb is: if the gas can catch fire, the cap must not make a spark. For everything else, you need to balance the need for maximum impact resistance against the benefits of a lighter, rust-proof material.

The moment you spot any significant damage, the cap needs to be replaced. A compromised cap is no longer a safety device you can rely on.

Give your Schutzkappe für Gasflasche a regular once-over and look for these warning signs:

A damaged cap has failed its one job, making a quick replacement a non-negotiable part of your safety routine.

At Cryonos GmbH, we provide state-of-the-art cryogenic solutions and safety equipment designed for the secure handling of industrial gases and biological samples. Explore our full range of compliant, high-quality accessories at https://www.cryonos.shop.