No Products in the Cart

The choice between buying and renting your gas cylinders—or "gasflaschen kaufen oder mieten" as it's known locally—boils down to your specific usage. For anyone with consistent, long-term needs, purchasing is almost always the more cost-effective route. Renting can be a lifesaver for short-term projects or fluctuating demand, but that flexibility usually comes at a higher total cost over the long haul.

When your lab or facility depends on a steady supply of industrial or cryogenic gases, deciding between buying and renting your cylinders is a major strategic move. This isn't just about the initial outlay; it's a decision that echoes through your operational agility, safety protocols, and long-term financial health. The best path forward depends entirely on the unique rhythm of your organisation.

Before you start crunching the numbers, it’s worth taking a step back to look at the bigger picture of your gas consumption.

Answering these questions first gives you the right context to weigh the financial and operational trade-offs. While renting neatly offloads the burdens of maintenance and compliance, purchasing gives you complete control and, often, significant long-term savings.

Our economic analyses consistently show that for most regular users, purchasing is the smarter financial choice, even with the initial capital investment. For example, when you look at a standard 10-litre mixed gas cylinder needing three refills a year, the total cost of ownership for a purchased cylinder is far lower. Why? Because rental models bake the cost of the cylinder into every single refill, quietly inflating your per-unit price over time. You can find more detailed insights into gas cylinder economics on gase-kaufen.de.

To put everything into perspective, the table below gives a quick summary of the essential differences between the two approaches.

This table offers a high-level summary of the primary differences between purchasing and renting gas cylinders, helping you grasp the core trade-offs at a glance.

| Consideration | Buying Gas Cylinders | Renting Gas Cylinders |

|---|---|---|

| Initial Cost | High upfront capital investment | Low to no upfront cost |

| Long-Term Cost | Lower Total Cost of Ownership (TCO) | Higher TCO due to recurring fees |

| Maintenance | Owner's full responsibility (TÜV, valves) | Supplier's responsibility (included in fee) |

| Flexibility | Less flexible; committed to the asset | Highly flexible for short-term needs |

| Supplier Choice | Freedom to choose any gas supplier for refills | Locked into a single supplier for refills |

| Control | Full control over asset and logistics | Limited control; dependent on supplier |

Ultimately, this comparison highlights the fundamental balance: buying is an investment in long-term savings and control, whereas renting prioritises immediate flexibility and outsourced responsibility.

When you're deciding whether to gasflaschen kaufen oder mieten, the sticker price is just the beginning of the story. A smart financial decision goes much deeper, looking past the initial cost to the Total Cost of Ownership (TCO). This is where you get the full picture, pitting the one-time capital expense (CapEx) of a purchase against the ongoing operational expense (OpEx) of renting.

Looking at it through the TCO lens uncovers the long-term financial reality that a simple price tag hides. Sure, renting gets you started with little upfront cash, but you pay for that convenience with endless recurring fees. Buying demands a bigger investment at the start, but it steadily shrinks your operational costs over the cylinder's entire life.

At its heart, the decision boils down to one big payment now versus a stream of smaller payments forever. Let's pull apart the financial guts of each option to see exactly where the money goes.

Renting Gas Cylinders (OpEx Model):

Buying Gas Cylinders (CapEx Model):

This difference is critical. Renting feels affordable because the smaller payments are spread out, but they never stop. Buying has a clear finish line—once your initial investment is paid off, the asset is yours.

To see how this plays out, let's imagine a biobank that needs a steady flow of liquid nitrogen for its cryogenic storage. To guarantee an uninterrupted supply, they need two large cryogenic cylinders, swapping one out while the other is in use.

Scenario Breakdown:

Now, let's run the numbers over a three-year period to see the TCO in action.

| Cost Component | Renting (3-Year Total) | Buying (3-Year Total) |

|---|---|---|

| Upfront Cost | €0 | €5,000 (Initial Purchase) |

| Rental Fees | €7,200 (€200/month x 36) | €0 |

| Refill Costs | €10,800 (€300/fill x 36) | €7,200 (€200/fill x 36) |

| Transport Fees | €1,800 (€50/delivery x 36) | €1,800 (Assuming similar fees) |

| Total Cost (3 Years) | €19,800 | €14,000 |

Even with a hefty initial investment, this realistic scenario shows the biobank saving €5,800 over three years by buying their cylinders. They break even on their investment in about 2.5 years, and after that, the savings really start to pile up.

Key Financial Takeaway: The lower cost per fill is the single biggest driver of long-term savings when you own your cylinders. For any lab or business with consistent gas needs, this factor alone often makes buying the smarter economic move.

There's another piece to the financial puzzle when you buy: depreciation. A purchased gas cylinder is a fixed asset on your balance sheet. As it loses value over time, this depreciation can be claimed as a business expense, which can lower your taxable income.

A rental payment is just a line-item expense that disappears. An owned cylinder, however, is an asset you can manage strategically in your financial planning. High-quality cylinders, like those from Cryonos, are built to last. They often remain perfectly functional long after they've been fully depreciated on paper, continuing to provide value. This turns a simple cylinder from a consumable into a long-term operational investment.

Beyond the numbers on a balance sheet, the choice between buying or renting gas cylinders fundamentally changes your day-to-day workload and safety obligations. This isn't just a financial decision; it dictates who is responsible for navigating complex regulations, managing transport, and guaranteeing that every cylinder on-site is safe to use. Each path comes with a distinct set of duties your organisation needs to be ready for.

When you purchase your gas cylinders, you're taking on full ownership of every single responsibility that comes with them. Your team is now directly accountable for meeting Germany's stringent safety standards. That covers everything from setting up compliant storage areas to ensuring periodic safety checks are done on schedule.

Renting, on the other hand, effectively outsources the bulk of these complex tasks. The rental company owns the cylinders, and with that ownership comes the legal duty for maintenance and compliance. It’s a much simpler operational model for your team.

Owning your cylinders places the legal burden squarely on your shoulders to comply with all relevant technical rules, especially the TRGS 510 for storing hazardous materials in portable containers. This means you have to create and maintain designated storage areas that meet specific requirements for ventilation, signage, and separating different gas types.

Your team must be trained to understand and follow these rules to the letter. Failing to do so can lead to hefty fines, but more importantly, it puts workplace safety at risk. This often means appointing a dedicated safety officer or investing in specialised training for your staff.

With a rental model, the supplier provides cylinders that are already fully compliant. They can even offer guidance on best practices for on-site storage, which cuts down on your internal admin. You are, however, still responsible for handling them safely once they're on your premises. For a deeper dive on this, take a look at our guide covering the 7 important rules for safe work with cryogenic liquids.

Moving gas cylinders is another critical area where the responsibilities split. Transporting pressurised or cryogenic gases by road is tightly regulated by the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR).

Critical Safety Insight: Non-compliance with ADR is a serious matter. It can result in severe penalties, vehicle impoundment, and massive liability if an accident occurs. For organisations without a dedicated, ADR-trained logistics team, renting is almost always the smarter, safer path.

Finally, there’s the logistics of getting your cylinders refilled, which presents a clear trade-off between cost control and pure convenience.

Ownership gives you the freedom to choose your gas supplier, a move that can lead to major long-term savings. You can shop around for the best prices on refills, playing the market to your advantage. While many common gas cylinders operate on a deposit system, owning your own specialty or cryogenic vessels gives you real negotiating power.

Rental agreements, however, almost always lock you into a single provider for both the cylinder and the gas inside it. This certainly simplifies procurement, but it completely removes your ability to hunt for more competitive pricing on refills. You’re tied to their price list and their delivery schedule, sacrificing flexibility for the convenience of having one point of contact.

Beyond the initial price tag and day-to-day logistics, the choice between buying or renting gas cylinders opens up another critical conversation: maintenance and regulatory compliance. This is where the long-term operational headaches can really pile up.

When you buy a cylinder, you're not just getting a piece of equipment. You're adopting its entire lifecycle, along with all the legal and technical duties that come with it. Renting, on the other hand, is a service designed to take these complex tasks off your plate. The rental provider owns the cylinder, so they're legally on the hook for keeping it safe, certified, and ready for work. For any organisation without the in-house expertise to manage industrial kit, that's a massive distinction.

Purchasing a gas cylinder makes you solely responsible for its upkeep and legal compliance for its entire service life. This goes way beyond just scheduling refills; it means active management and meticulous record-keeping.

Here’s a taste of what ownership entails:

This kind of proactive management requires a solid tracking system and a budget for repairs you didn't see coming. Missing a TÜV deadline can instantly make a cylinder unusable and non-compliant, causing operational delays and creating a serious safety risk.

Renting pretty much eliminates these management burdens. That rental fee isn't just for using the cylinder; it covers a whole service package, including all the legally required maintenance. Your supplier tracks inspection dates, services the valves, and handles recertification as part of their routine.

The real value of renting is guaranteed compliance. You get a fully certified, ready-to-use cylinder every single time, without ever having to juggle inspection schedules or service vendors yourself. It dramatically simplifies your safety management.

This approach is a game-changer for organisations that don't have a dedicated facilities or safety team. It turns a complex asset management chore into a predictable, manageable expense, freeing up your team to focus on their actual jobs instead of equipment maintenance.

Another practical point to chew on is long-term support. When you buy, you're betting on the warranty and the future availability of spare parts like valves or safety caps. A reputable supplier like Cryonos will offer a strong warranty—often up to five years—and guarantee that spare parts will be available down the line, protecting your investment.

With renting, this is someone else's problem. If a valve acts up or a part breaks, the supplier just swaps out the cylinder. You’re never left scrambling to find a specific component or dealing with repair logistics, which means your work doesn't have to stop.

Finally, owning high-pressure or cryogenic vessels can have a direct impact on your company's liability insurance. Your policy will likely require you to declare these assets, and your insurer will want to see documented procedures for storage, handling, and maintenance. In short, owning cylinders increases your direct liability if something goes wrong. Understanding the rules for moving these assets is also crucial; you can learn more in our detailed guide on the regulations for transporting gas cylinders.

Renting can make this side of things simpler, too. Because the rental company owns the asset and is responsible for its certified condition, a good portion of the liability stays with them. You're always responsible for handling it safely on your own premises, of course, but the burden of proving the equipment's technical integrity rests with the supplier. It’s an often-overlooked factor that can make a big difference in your overall risk management strategy.

The theory is one thing, but how does this buy-versus-rent debate play out in the real world? All the talk about TCO and operational burdens comes into sharp focus when you look at your own specific situation. The best decision depends entirely on your day-to-day needs, your budget cycles, and how much risk you’re willing to take on.

To make this tangible, let's walk through a few common scenarios. You’ll see how different operational demands can quickly make one choice far more logical and cost-effective than the other.

University labs are dynamic environments. Funding is often project-based and can be unpredictable. One semester, you might need a steady stream of argon for welding experiments; the next, it could be all about high-purity nitrogen for preserving samples. This constant change is the most important factor.

Renting gives labs the flexibility they desperately need. They can adapt to changing research priorities without sinking capital into cylinders that might just gather dust for months. The rental model lets you get the specific gases you need, when you need them, and return the cylinders as soon as the project wraps up. It’s a perfect match for the fast-paced nature of academic research.

For a biobank, the mission is simple: long-term, stable preservation of biological samples. This means they need a constant, completely reliable supply of liquid nitrogen. Their demand is high, predictable, and mission-critical. Any interruption isn't just an inconvenience—it's a potential catastrophe.

Buying their own cryogenic vessels is a strategic move for a biobank. It's an investment in stability and long-term cost control. Owning the containers gets rid of endless rental fees and, crucially, lets them source liquid nitrogen from any supplier. This creates price competition and builds resilience in their supply chain. Over time, the lower TCO frees up the budget for other vital work. Getting that initial purchase right is critical; you can read our guide on how to avoid common mistakes when buying a cryogenic container.

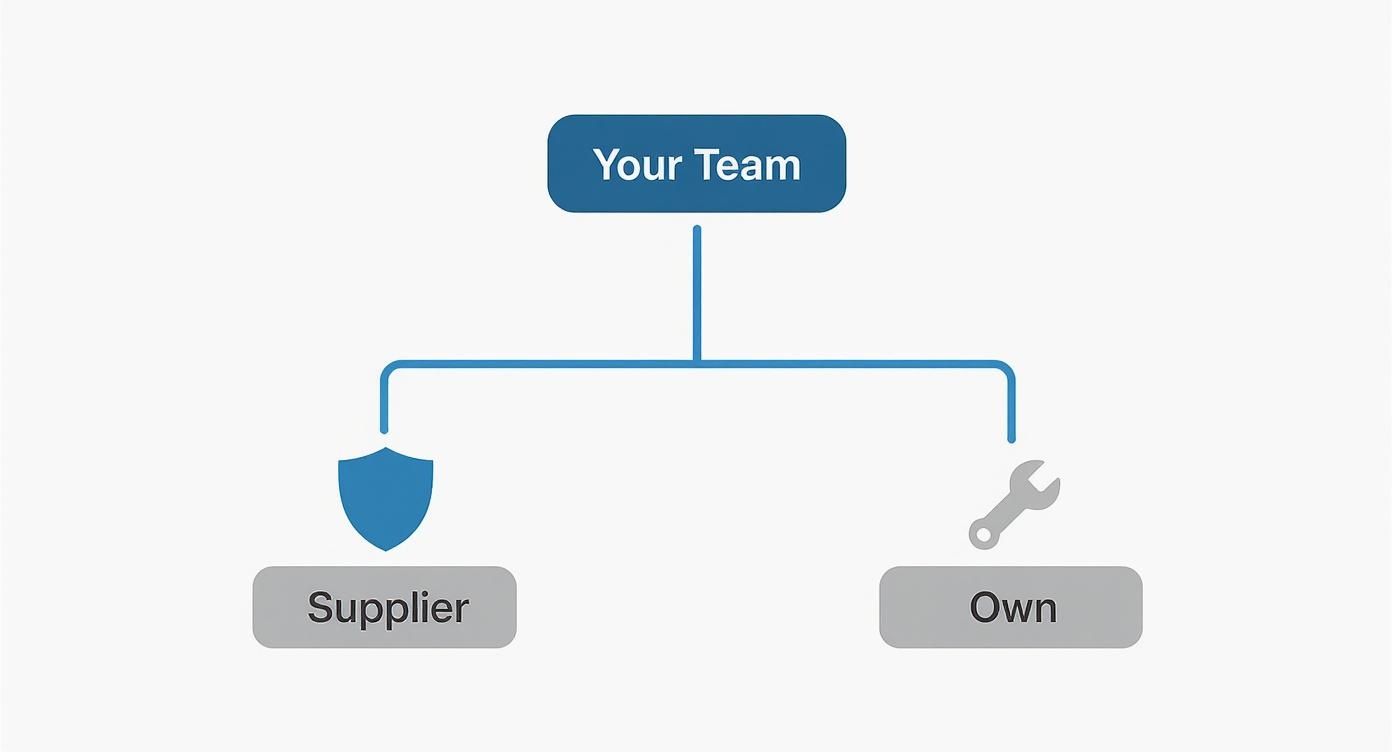

This diagram simplifies who handles the maintenance, depending on whether you own or rent.

As you can see, renting keeps the maintenance burden squarely with the supplier. When you own, that responsibility shifts to your team—a key detail to factor into your operational planning.

Imagine a small workshop that specialises in custom metalwork. They use a consistent amount of shielding gas for welding, month in and month out. Their consumption is easy to predict, and that gas is a fundamental part of their daily production.

Just like the biobank, the workshop stands to gain a lot from the lower long-term costs of ownership. The upfront investment in buying their own welding gas cylinders pays for itself within a few years, thanks to the significant savings on refills. For a small business managing a tight budget, that kind of financial predictability is a huge advantage.

Decision Insight: For any operation where a specific gas is a core, predictable consumable, ownership almost always delivers a better return on investment. The key is consistent usage, which allows the lower per-fill costs to quickly erase the initial purchase price.

A construction company lands a six-month contract for a major building project. They'll need various industrial gases on-site for cutting and welding. But once the project is done, they won't have an immediate need for those gases again until the next big job comes along, which could be months away.

Renting is the obvious solution here. It provides all the necessary equipment for the exact project timeline without leaving the company with assets they have to store, maintain, and haul between job sites. The slightly higher cost of renting is easily baked into the project's direct expenses, offering maximum operational and financial agility.

To pull all this together, this matrix offers a quick reference guide. It connects common operational factors directly to a recommended course of action, helping you see where your own needs fit in.

| Use Case Scenario | Usage Frequency | Demand Variability | Recommended Option | Key Rationale |

|---|---|---|---|---|

| University Research Lab | Sporadic | High | Rent | Flexibility is paramount; avoids capital outlay for assets that may sit idle. |

| Biobank (Cryogenic Storage) | Constant | Low | Purchase | Ensures supply chain control and delivers the lowest TCO for mission-critical needs. |

| Small Fabrication Workshop | Daily/Weekly | Low | Purchase | Predictable usage makes ownership the most cost-effective option in the long run. |

| Construction Site (Project) | Intense, Short-Term | High (Project-Based) | Rent | Avoids owning and managing assets during downtime between projects; scales with work. |

| Start-up/Low Initial Capital | Varies | Varies | Rent | Preserves cash flow by converting a large capital expenditure into a smaller operating expense. |

| High-Volume Industrial Plant | Constant | Low to Medium | Purchase | Economies of scale on refills and full control over supply logistics justify the investment. |

Ultimately, the goal is to align your procurement strategy with your operational reality. Whether you’re dealing with the fluctuating demands of research or the steady rhythm of industrial production, the right choice is the one that best supports your mission without creating unnecessary financial or logistical strain.

Choosing between buying and renting gas cylinders (gasflaschen kaufen oder mieten) always brings up a few key questions. It boils down to long-term value, who’s responsible for what, and the day-to-day logistics. Let's get straight to the common queries to help you make a final decision with your eyes wide open.

For a standard industrial gas cylinder in regular use, you can typically expect to recoup your initial investment within 18 to 36 months. It really all comes down to how often you use it.

The return on your investment comes from the much lower cost per refill when you own the cylinder. Gas suppliers don't have to build their own rental or 'flaschinvestment' fees into the price, so you just pay for the gas itself. For high-value cryogenic gases or operations that burn through gas quickly, this payback period can shrink even further.

A quick Total Cost of Ownership calculation will make this crystal clear for your situation. Just estimate your annual fills and stack up the total rental costs against the cost of buying plus refilling over a three-year window.

Yes, absolutely. While renting avoids that big upfront payment, it can sneak in several less obvious costs over the life of the contract. The biggest one is the higher price you pay for every single gas fill, which is how the supplier covers their own investment in the cylinder.

Beyond that, you might run into other charges, including:

Always read the fine print on any rental agreement. Ask for a complete breakdown of every potential charge—not just the monthly rental fee. It’s the only way to grasp the true long-term financial picture.

When you own the cylinder, you own its entire lifecycle, and that includes the legally required inspections. In Germany, cylinders typically need a check-up every 10 years, a date that’s stamped right on the cylinder's shoulder. When that date approaches, it's on you to take it to a certified TÜV inspection facility.

The process involves a pressure test and a full visual inspection. If it passes, it gets a new stamp with an updated expiry date. If it fails, it has to be professionally decommissioned—you can’t just toss it with the scrap metal because of the risk of residual pressure. Gas suppliers or specialised disposal firms can handle this for you for a fee. This is a core responsibility that comes with ownership.

Of course. This is arguably the biggest financial advantage of owning your cylinders. You aren't locked into a contract with one supplier, which gives you the freedom to shop around for the best price, service, and availability for every single refill.

This kind of market agility can lead to huge long-term savings, especially when gas prices are fluctuating. When you own the cylinder, you're only buying the gas inside it. A rental agreement, on the other hand, contractually ties you to one provider for both the cylinder and its contents, which completely removes your negotiating power and stops you from taking advantage of better deals elsewhere.

For state-of-the-art cryogenic solutions with robust warranties and guaranteed long-term spare part availability, trust Cryonos GmbH. Explore our portfolio of high-quality cryogenic vessels and equipment designed for reliability and a low total cost of ownership. Visit our shop to find the right solution for your needs.