No Products in the Cart

Aviation Life Support Equipment (ALSE) is the gear that keeps flight crews and passengers alive when the friendly skies turn hostile. It’s a bit like a car’s seatbelts, airbags, and emergency kit all rolled into one, but engineered for the unique and unforgiving environment found miles above the ground.

This equipment is your lifeline during routine flights, sudden in-flight emergencies, and even in post-crash scenarios. It’s what stands between a manageable incident and a catastrophe.

When you step onto an aircraft, you see seats and windows. But the systems that really matter are often working quietly in the background, hidden in plain sight. ALSE is this unseen shield—a collection of technologies designed to help the human body function in an environment it was never built for.

The core principle is simple: counteract the harsh conditions of high altitude, like thin air, extreme temperatures, and powerful G-forces.

For the people making the purchasing decisions at airlines, medevac services, or logistics firms, understanding ALSE is about more than just ticking a box on a form. It's a cornerstone of operational safety, regulatory compliance, and mission success. The right equipment isn't just a line item; it's a direct investment in the safety of every soul on board.

The scope of ALSE is incredibly broad, touching every phase of flight from takeoff to a potential emergency landing. Its purpose boils down to three main jobs:

Think of it as a seamless safety net. From the oxygen mask that drops from the ceiling to the life raft tucked under a seat, every piece is part of a bigger strategy to protect human life against the unforgiving physics of flight.

Before we dive deeper, it's helpful to see how these functions translate into tangible categories of equipment.

Here’s a high-level look at the primary types of ALSE and the critical roles they play in keeping aviation safe.

| Equipment Category | Primary Function | Example Scenarios |

|---|---|---|

| Oxygen & Breathing Systems | Provide breathable air during high-altitude operations or in depressurised cabins. | A sudden cabin depressurisation event at 35,000 feet; smoke in the cockpit requiring crew to use supplemental oxygen. |

| Environmental Control Systems | Maintain survivable temperature, pressure, and air quality inside the aircraft. | Regulating cabin temperature during a long-haul flight over a polar region; filtering contaminants from cabin air. |

| Survival & Emergency Gear | Aid survival after a crash or forced landing, especially in remote or hostile environments. | Deploying life rafts and vests after a water landing; using a personal locator beacon to signal for rescue in a remote area. |

| Personal Protective Equipment | Protect crew members from specific flight hazards like high G-forces or extreme temperatures. | A fighter pilot wearing a G-suit to prevent blacking out during high-speed manoeuvres; helicopter crew wearing immersion suits for over-water flights. |

This table gives you a roadmap for the different systems we'll be exploring, each designed to tackle a specific set of risks.

To really appreciate why ALSE is so vital, you have to get to grips with its main components. In this guide, we'll walk through the critical categories that form the backbone of aviation safety.

We'll look at everything from the complex oxygen delivery systems—the lifeblood of high-altitude flight—to the rugged survival kits needed for remote operations. For any organisation managing a fleet, a deep understanding of these systems isn't just good practice; it's absolutely non-negotiable for making smart procurement decisions that balance cost, compliance, and, above all, safety.

Up at cruising altitude, the air is dangerously thin. The best way to think of an aircraft cabin is as a pressurised bubble, simulating sea-level conditions while flying through an environment as hostile to human life as the deep ocean.

A scuba diver needs a tank of compressed air to explore underwater, and for the same reason, pilots and passengers depend on aviation life support equipment to breathe safely miles above the Earth. This isn't just a comfort feature; it's a fundamental requirement for survival.

If an aircraft suffers a sudden loss of cabin pressure at 35,000 feet, a person can become incapacitated in less than a minute. Oxygen systems are the first and most critical line of defence against hypoxia—the physiological state of oxygen deprivation. For any procurement manager, understanding the different types of systems is key to matching the right tech to the mission profile.

Aircraft oxygen systems fall into two main camps: fixed systems built right into the aircraft and portable units designed for mobility and emergencies. Each serves a distinct but complementary role.

Fixed systems are the primary source of emergency oxygen for everyone on board. They're permanently installed and designed to activate, either automatically or manually, during a depressurisation. This is the system that deploys the iconic yellow drop-down masks you see in commercial airliners.

Portable systems, on the other hand, are completely self-contained. These are vital for flight crews who might need to move around the cabin during an emergency or for administering first aid to passengers. They serve as a flexible backup, making sure breathable air is always within arm's reach.

Not all oxygen systems are built the same. The technology used to store and deliver that precious O2 has massive implications for an aircraft's weight, maintenance schedule, and overall operational cost.

Here are the main types you'll find in modern aircraft:

The choice between a heavy but refillable gaseous system and a lightweight, single-use chemical generator is a classic engineering trade-off. For a high-frequency, short-haul fleet, the maintenance cycle of gaseous systems might be a burden, making chemical generators a more practical choice for passenger oxygen.

While passengers typically get continuous-flow oxygen, flight crews need far more sophisticated gear to handle their duties, especially in worst-case scenarios like a cockpit fire. This is where specialised breathing apparatus comes in.

Pilots often use pressure-demand regulators connected to full-face masks. Unlike passenger masks that supply a constant stream, these regulators deliver oxygen only when the user inhales. During a smoke-in-the-cockpit emergency, they can provide 100% oxygen under positive pressure, actively pushing toxic fumes away from the mask's seal.

This level of protection is non-negotiable for maintaining control of the aircraft during a critical event. For those interested in the fundamental science, you can learn more about the properties of oxygen in our detailed overview.

While oxygen systems are designed to handle the challenge of thin air, a whole other category of aviation life support equipment exists to shield occupants from the physical extremes of flight. You can think of a modern aircraft as a protective bubble, but maintaining that bubble requires a sophisticated dance between the aircraft's own systems and the specialised gear worn by the crew.

This protective layer really starts with the aircraft itself. The Environmental Control System (ECS) is the unsung hero of every flight. It's responsible for keeping a safe, low-altitude pressure inside the cabin, even when you're flying seven miles above the earth. Essentially, it's the aircraft's own life support, creating an artificial environment where we can function comfortably.

A good ECS also manages temperature, stopping the cabin from becoming dangerously cold at altitude or a furnace on the ground. It creates a stable, liveable space, but personal protective equipment (PPE) is still absolutely critical for handling specific, high-stakes situations.

For pilots in high-performance aircraft, the raw physical forces of flight can be incapacitating. During tight turns or rapid acceleration, gravitational forces—known as G-forces—can literally pull blood away from the brain. This leads to vision loss or, in the worst cases, a complete loss of consciousness.

This is where the anti-G suit proves its worth. This specialised garment has inflatable bladders that wrap around the legs and abdomen. When the aircraft's systems detect high G-forces, these bladders instantly inflate, squeezing the lower body. This simple action keeps blood circulating to the pilot's brain, ensuring they stay alert and in control.

Of course, personal protection goes well beyond just G-forces. It includes a whole range of gear built for safety and communication.

The selection of this gear is never a one-size-fits-all decision. For an institutional buyer, the mission profile dictates the equipment. A commercial transport pilot's gear is vastly different from that of a high-altitude research pilot or a search-and-rescue crew member.

Nowhere is the importance of mission-specific gear more obvious than in emergency medical services. Helicopter Emergency Medical Service (HEMS) crews operate in incredibly demanding conditions, and they need specialised aviation life support equipment to care for patients while in the air.

This is a sector that has seen significant growth. Germany, for example, saw a 25% jump in air ambulance missions between 2010 and 2015, partly driven by its ageing population. The country's HEMS programme has flown around 1 million missions since it started, showing just how deeply integrated these aircraft are in its emergency response. Helicopters are perfect for their ability to land in tight spots, but their equipment loadout is what makes patient care possible. You can get a better sense of these trends by reading more about the European air ambulance services market.

For these kinds of operations, the equipment list gets a lot longer. It includes not just the crew's personal protective gear but also portable medical devices, climate-controlled transport incubators for newborns, and advanced patient monitoring systems. Every single piece must be certified for aviation use, ensuring it won’t interfere with the aircraft’s systems and can handle the rigours of flight. It’s a perfect example of how procuring the right protective gear is directly tied to the specific services an organisation provides, ensuring both crew safety and mission success.

While the systems we’ve discussed so far protect against the immediate threats of high-altitude flight, a whole other category of aviation life support equipment comes into play after a forced landing. This is the gear that deals with survival on the ground or at sea, designed to turn a worst-case scenario into a manageable situation until rescue arrives.

Picture an aircraft forced down in a remote, snow-covered mountain range. Suddenly, the dangers aren't hypoxia or G-forces anymore; they’re exposure, injury, and the desperate need to signal for help. In that moment, a well-prepped survival kit becomes the most valuable asset in the world.

These kits are far from a random assortment of gear. They are meticulously thought-out systems. Every single item has a critical job, whether it's providing shelter, administering medical care, or helping search parties pinpoint your location. For any organisation buying this equipment, the decision has to be driven by regulations, the operating environment, and the specific risks of their flight routes.

Although survival kits are categorised by their intended environment, a few core components are nearly universal. Each one addresses a fundamental post-crash need, creating a layered safety net for survivors.

The main goal is simple: keep people safe and get rescuers to you. This is achieved through several key systems working together.

A common mistake is seeing a survival kit as just a box of stuff. It’s an integrated system. The ELT calls for help, the raft provides shelter from the elements, and the first-aid kit patches people up—all working in concert to bridge that critical gap between the incident and rescue.

The contents of a survival kit absolutely must match the environment it might be used in. A kit designed for over-water flights will look completely different from one meant for polar or desert regions. This is a crucial point for procurement managers, as regulatory bodies like EASA and the FAA mandate specific equipment based on where an aircraft will be flying.

For example, an aircraft on an arctic route must carry serious cold-weather survival gear—thermal blankets, high-energy food rations, and tools to build a snow shelter. A flight crossing the open ocean, on the other hand, needs extra water purification tablets, desalination kits, and even fishing supplies. The choice of personal safety equipment is directly tied to these expected challenges. You can explore a range of certified personal safety equipment to get a better sense of the options available for different scenarios.

This kind of customisation ensures the equipment on board is genuinely useful for the specific challenges survivors will be up against. It’s a pragmatic approach that massively increases the chances of a good outcome.

Ultimately, survival and emergency kits are the final layer of protection in aviation. They’re a tangible admission that even with the best technology and training, things can still go wrong. By preparing for that possibility with the right equipment, organisations don't just meet regulations; they uphold their duty of care and provide a crucial lifeline when it's needed most.

Buying the right aviation life support equipment isn't like picking items off a shelf. For anyone managing a fleet or an organisation's assets, it's a strategic decision that ripples through every part of the operation—from safety and compliance to the long-term financial bottom line. To get it right, you need a framework that goes beyond the initial price tag to weigh the true lifecycle cost and utility of this mission-critical gear.

The first step is to shift your mindset. Don't just look for vendors; look for long-term safety partners. A supplier's reputation for reliability, after-sales support, and honesty is just as valuable as the hardware they sell. Can they guarantee a steady supply of spare parts? Will their technical team be there when you need them? Answering these questions is essential to avoiding unnecessary—and potentially dangerous—downtime.

Ultimately, you're building a partnership that strengthens your safety culture from the inside out.

The upfront cost of a piece of equipment is often just the tip of the iceberg. To get a real sense of the financial impact, you need to look at the Total Cost of Ownership (TCO), which accounts for every expense over the equipment's entire service life. It's not uncommon for a cheaper unit with heavy maintenance demands to end up costing far more than a premium alternative over a few years.

Here’s what really goes into the TCO calculation:

By thinking through these long-term costs, you can make a decision that protects both your people and your budget.

An effective procurement strategy isn't about finding the cheapest option. It's about balancing the upfront investment with predictable, manageable operational expenses. Choosing equipment with longer maintenance intervals and easily sourced parts means better fleet availability and lower lifetime costs. It's that simple.

Navigating the procurement process requires asking the right questions. This checklist provides a starting point for evaluating potential suppliers and equipment to ensure you're making a fully informed decision.

| Evaluation Category | Key Question to Ask Suppliers |

|---|---|

| Supplier Reliability | What is your track record for on-time delivery and order fulfilment? Can you provide references? |

| Technical Support | What are your support hours and typical response times for technical queries or issues? |

| Spare Parts Availability | Can you guarantee the availability of spare parts for the entire expected service life of the equipment? |

| Total Cost of Ownership | Can you provide a detailed breakdown of expected maintenance schedules, consumable costs, and service life limits? |

| System Interoperability | Is this equipment certified to integrate with our specific aircraft models and existing systems? |

| Regulatory Compliance | What certifications (e.g., EASA, FAA) does this equipment hold? Can you provide all necessary documentation? |

| Training & Documentation | What training materials and support do you offer for our maintenance and operational teams? |

Use this table as a foundation for your discussions. A transparent supplier will have clear, confident answers for every one of these points.

Another absolutely critical piece of the puzzle is integration. How will this new equipment play with your existing systems? Bringing in a new flight helmet might seem simple, but if it isn’t fully compatible with your aircraft's communications suite and oxygen supply, you’ve created a serious weak link. Mismatched components are a recipe for failure, compromising crew safety and effectiveness.

Before you sign any purchase order, get confirmation that the new aviation life support equipment is certified to work seamlessly with your fleet's current setup. This simple check can save you a fortune in costly retrofits and, more importantly, ensures all your systems work together as a single, reliable unit.

This need for smooth integration extends to the ground, too. Think about the explosive growth in air freight—in 2021, Germany alone handled a record 5.3 million tons, a jump of over 17% from the year before. This boom puts immense pressure on the entire support ecosystem. As the European ground support equipment market continues to expand, ensuring your logistical chain can handle ALSE supplies and maintenance is key to keeping your fleet ready to go.

Once the equipment is in your hands, the real work begins. A rock-solid inspection and maintenance programme is the absolute cornerstone of ALSE reliability. It’s what guarantees the gear will work flawlessly when a life depends on it. From a life raft to an oxygen mask, every single item must undergo the scheduled checks laid out by the manufacturer and aviation authorities like EASA.

Just as important is meticulous record-keeping. Every inspection, every repair, every component swap must be logged with precision. These aren't just internal notes; they are legal documents that will be put under a microscope during any regulatory audit. Sloppy or incomplete documentation can lead to severe penalties, including grounding your aircraft.

A well-oiled maintenance programme isn’t just about compliance—it’s about keeping your fleet safe, ready, and always able to complete its mission.

When your operations are based in Germany or the wider European Union, procuring aviation life support equipment is about much more than just picking the best tech. It's a deep dive into a stringent regulatory world built to enforce the highest possible safety standards. This legal framework is shaped by two major bodies, each with a crucial, and sometimes overlapping, role.

At a European level, the European Union Aviation Safety Agency (EASA) is the authority setting the baseline for airworthiness and safety across all member states. Think of EASA as the organisation that writes the rulebook for designing, manufacturing, maintaining, and operating aircraft and all their components—including every piece of life support equipment.

While EASA creates the overarching framework, it's the national authorities that are on the ground, handling implementation and day-to-day oversight. In Germany, that responsibility falls to the Luftfahrt-Bundesamt (LBA), the German Federal Aviation Office. The LBA’s job is to make sure every operator and all equipment in the country strictly follows EASA regulations. They're the ones conducting audits and issuing the necessary national approvals.

This two-tiered system means that compliance isn't a one-and-done deal. You have to satisfy both the broad European mandates and their specific German interpretations, which is especially important when certifying new equipment.

Think of EASA as the architect drawing up the master blueprint for aviation safety, while the LBA acts as the on-site inspector, ensuring every single brick laid in Germany meets that blueprint’s exact specifications. Getting it wrong at either level can lead to serious consequences, from hefty fines to having an entire fleet grounded.

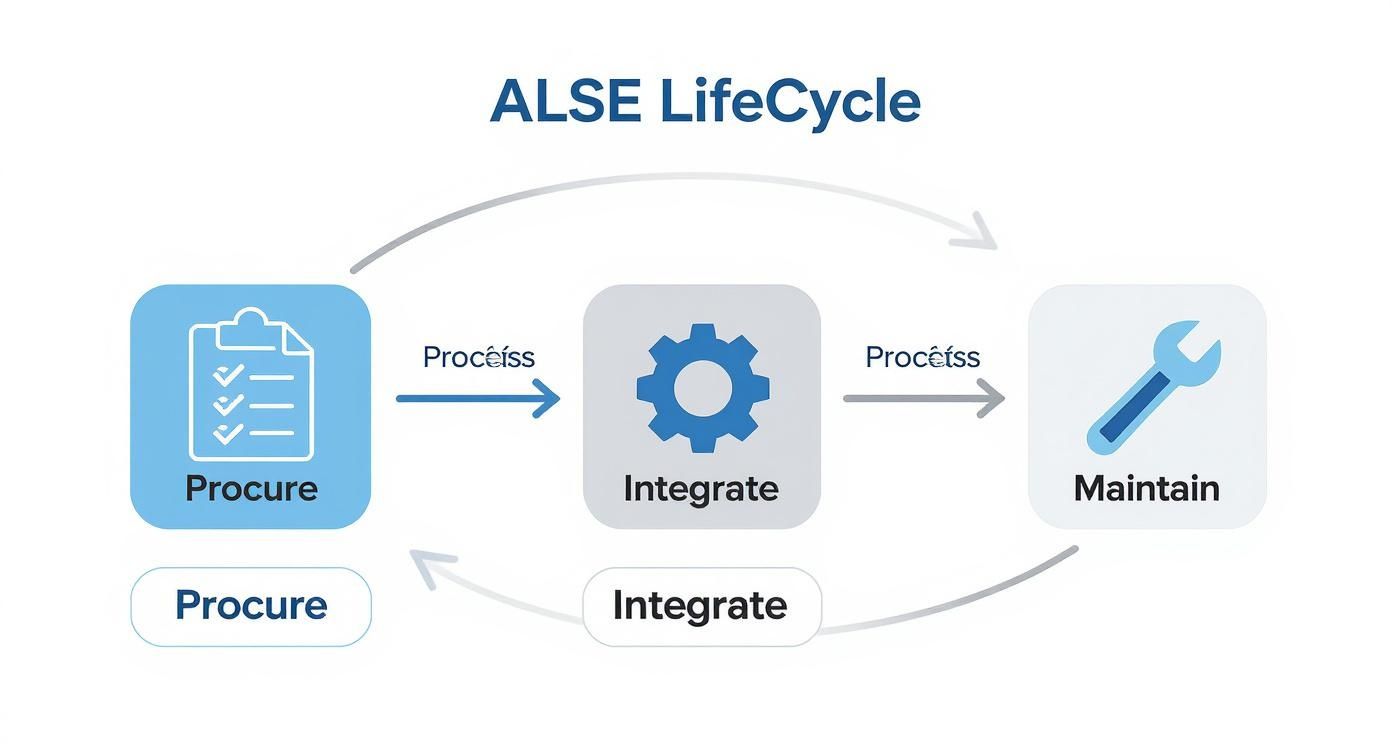

The lifecycle of ALSE, from the moment you procure it to its final day in service, is governed by these standards.

This flow underscores that regulatory compliance isn't just a hurdle to clear at the beginning; it's a continuous responsibility woven into every stage of the equipment's life.

For any piece of ALSE to be legally installed on an aircraft, it has to meet very specific technical benchmarks. One of the most critical certifications you'll encounter is the Technical Standard Order (TSO). A TSO isn't just a suggestion; it's a minimum performance standard for materials, parts, and appliances used on civil aircraft. When a product is TSO-authorised, it means the manufacturer has proven that it meets these tough safety and quality requirements.

These regulations go beyond just the type of gear you need. They dictate its precise placement on the aircraft, how accessible it is in an emergency, and the exact maintenance schedules you must follow. For compliance managers, keeping up with these constantly evolving rules is a full-time job.

This intense focus on safety and efficiency naturally extends to the ground operations that support these airborne systems. Germany's market for aircraft ground support equipment is projected to grow at a CAGR of about 6.2% from 2025 to 2035, a clear sign of this trend. This growth is fuelled by the modernisation of airport infrastructure and a major push toward sustainable technologies, all heavily influenced by EU directives and LBA oversight. You can read more about the trends in Western Europe's aircraft ground support equipment industry to see how closely linked these areas are. After all, state-of-the-art ground equipment is essential for keeping life support systems flight-ready.

When it's time to evaluate or procure aviation life support equipment (ALSE), key people in the organisation—from procurement managers to safety officers—tend to ask the same critical questions. Getting these answers right is fundamental to managing your fleet's safety, compliance, and budget.

The usable life of ALSE components is dictated by manufacturers and regulators, not just by how they look. This is a crucial difference between service life (how long a part can be actively used) and shelf life (how long it can sit in storage). Think of it like a "best before" date on food, but for safety-critical gear.

A chemical oxygen generator, for example, has a hard expiry date based on the stability of its internal compounds. It’s not something you can visually inspect. Similarly, the inflation cylinders on a life raft or the batteries in an Emergency Locator Transmitter (ELT) have mandatory replacement dates. These are set based on extensive reliability studies and material degradation data to guarantee they work flawlessly in an emergency.

There's no such thing as a "one-size-fits-all" ALSE package. The equipment you need is tied directly to your mission, as the risks and rules change dramatically from one type of flying to another.

A few real-world examples make this crystal clear:

Every type of operation faces its own unique physiological and environmental dangers. Because of this, the ALSE inventory has to be carefully chosen to counter those specific threats, ensuring you're not just compliant, but genuinely keeping your crew and passengers as safe as possible.

The best way to kick off any ALSE upgrade is with a thorough audit of what you already have. This isn’t just a simple stocktake; it's a deep dive comparing your current equipment against two main things: the latest regulatory requirements and the actual, day-to-day needs of your operations.

This process is invaluable. It quickly shows you where you might be falling short on compliance, flags any outdated tech, and pinpoints gear that just isn't right for your current missions anymore. The results of this review give you a solid, evidence-based foundation to build a detailed Request for Proposal (RFP), so you can go to suppliers with a clear, specific list of what you need for your next generation of aviation life support equipment.

For organisations seeking reliable, compliant equipment for the storage and transport of critical materials, Cryonos GmbH provides state-of-the-art cryogenic and industrial gas solutions backed by decades of technical expertise. Explore our turn-key systems at https://www.cryonos.shop.