No Products in the Cart

The pressure inside a typical CO2 Flasche (CO2 cylinder) is almost entirely dictated by temperature, not by how much gas you've used. As long as there's still liquid CO2 inside, you can expect the pressure to hover around 57 bar (approximately 830 PSI) at a standard room temperature of 20°C (68°F). This pressure climbs in warmer conditions and drops when it gets cooler.

It's one of the biggest misconceptions out there: that the high-pressure gauge on a CO2 cylinder acts like the fuel gauge in your car, slowly dropping as the contents are used up. The reality, however, is all about a fascinating bit of physics called saturated vapour pressure.

What this means is that as long as even a drop of liquid CO2 remains in the cylinder, it will continuously "boil" and turn into gas. This process keeps the pressure inside the tank remarkably stable.

Think of it like a sealed pot of water simmering on a stove. It doesn't matter if the pot is full or nearly empty; as long as water is boiling, the steam pressure inside remains constant. A CO2 cylinder behaves in much the same way, just at everyday room temperatures. The liquid CO2 turns to gas, filling the empty space (known as the headspace) and holding a steady pressure reading on your gauge.

This is exactly why the CO2 Flasche Druck seems to fall off a cliff right at the very end. The pressure only plummets once every last bit of liquid CO2 has finally evaporated. At that moment, you're running on fumes—just the remaining gas—and the pressure will drop very quickly, letting you know it's time for a refill.

The one big factor that does change the pressure is the ambient temperature. A cylinder left in a warm room will show a higher pressure reading than one stored in a cool cellar. This direct relationship is absolutely critical to understand for both safety and performance. Leaving a cylinder in a hot car, for instance, can cause the internal pressure to climb to dangerous levels.

To give you a clear picture of this effect, here’s a quick-reference table showing how the pressure inside a CO2 cylinder changes with temperature.

This table provides a practical look at the direct relationship between the ambient temperature and the resulting internal pressure (Druck) of a CO2 cylinder.

| Temperature (°C) | Pressure (bar) | Pressure (PSI) |

|---|---|---|

| 0°C (32°F) | 34.4 bar | 499 PSI |

| 10°C (50°F) | 45.0 bar | 653 PSI |

| 20°C (68°F) | 57.2 bar | 830 PSI |

| 30°C (86°F) | 72.1 bar | 1046 PSI |

As you can see, even a seemingly small change of 10°C can alter the internal pressure by more than 10 bar (over 150 PSI). This is why consistent storage temperature is key to both predictable performance and safe handling.

Ever stared at the pressure gauge on your CO2 cylinder, wondering why it stays stubbornly high, refusing to budge, right until the tank is practically empty? It's not a faulty gauge. It's a fascinating bit of physics happening inside that cylinder, and getting your head around it is the key to managing your gas supply like a pro.

Think about a sealed pot of water simmering on a stove. It doesn’t matter if the pot is full or nearly empty—as long as there's water boiling, it's constantly making steam and holding the same pressure inside. Your CO2 cylinder is doing the exact same thing, just at everyday room temperatures.

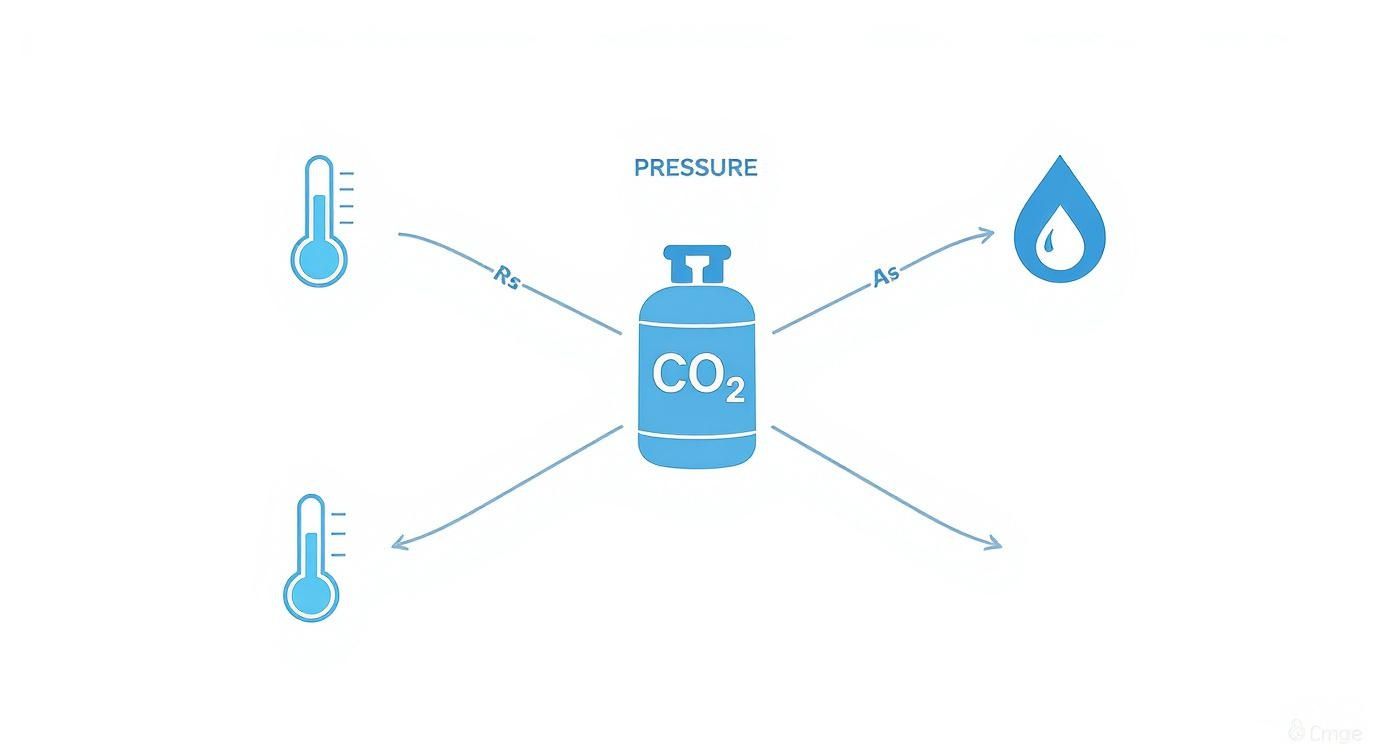

Inside that steel cylinder, you have a large volume of liquid CO2 at the bottom and a smaller amount of gaseous CO2 (the headspace) at the top. The two exist in a perfect balance. As you draw gas from the headspace, a little bit of the liquid instantly boils to replace it, keeping the pressure consistent. This means the cylinder pressure, or co2 flasche druck, is driven entirely by the surrounding temperature, not the amount of liquid left.

This diagram breaks down how temperature, pressure, and the liquid-gas balance all interact inside your cylinder.

The crucial takeaway here is simple: as long as there's any liquid CO2 in the tank, the temperature outside is the only thing that dictates the pressure reading inside.

This constant state of equilibrium is exactly why a high-pressure gauge is a terrible "fuel" indicator. It will read a steady pressure—say, around 57 bar at 20°C—whether the cylinder is 95% full or just 5% full. The pressure only takes a nosedive when the very last of the liquid CO2 has turned to gas. At that point, you’re just running on fumes, and the tank will empty in a flash.

The only reliable way to know how much CO2 you have left is to weigh the cylinder. Find the tare weight (T.W.) stamped on the cylinder's neck and subtract it from the total current weight. The difference is your remaining gas.

This behaviour is fundamental to how CO2 is handled across all industries. Standard practice is to store and transport CO2 in its liquid state at ambient temperatures, with cylinders typically held at pressures between 45-65 bar.

A key concept here is the "critical point" of CO2, which occurs at around 31°C and 74 bar. Above this point, there's no physical distinction between its liquid and gas phases—it becomes a supercritical fluid. This principle is a cornerstone of industrial safety protocols for handling CO2. You can learn more about these practices from leading CO2 safety standard organisations.

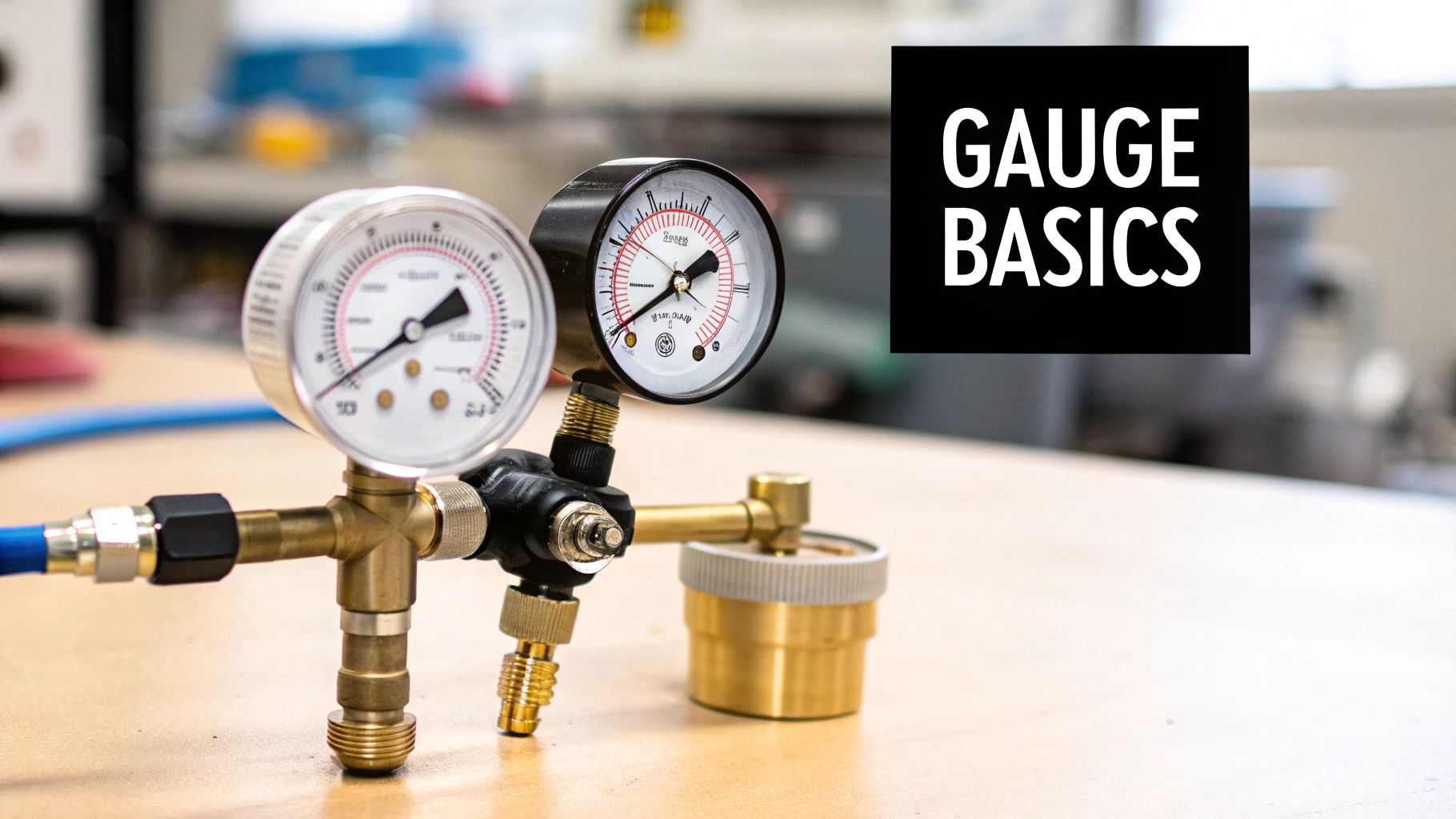

Staring at the two dials on your CO2 regulator can feel a bit like trying to decipher a secret code. But once you know what each one is telling you, managing your system becomes second nature. The trick is realising they measure two completely different things: the pressure inside the cylinder and the pressure going out to your equipment.

The first gauge, usually the larger of the two, shows the high pressure inside your CO2 cylinder. In German, this is known as the Zylinderdruck. As we’ve already covered, this gauge doesn't work like a typical fuel indicator. Instead, it mainly reflects the cylinder's temperature, holding steady at around 57 bar (830 PSI) at room temperature as long as there’s liquid CO2 inside.

This gauge is your real heads-up that the cylinder is about to run dry. The needle will only start to drop—and drop fast—when the very last of the liquid CO2 has turned to gas. When you see that needle finally begin its sharp descent, it’s time to get a refill on your shopping list.

The second gauge tells a completely different story. This is the low-pressure gauge, often called the working pressure or Arbeitsdruck. It measures the pressure of the CO2 gas after it leaves the regulator and heads towards your kegerator, aquarium, or welding torch.

This is the dial you actually control. By turning the regulator's adjustment knob, you can set the exact output pressure you need for whatever you're doing. This is the CO2 Flasche Druck you actively work with.

Different jobs need different settings. For instance:

Think of it this way: The high-pressure gauge tells you the state of the cylinder (is it pressurised and is it nearly empty?). The low-pressure gauge shows the output you've dialled in for your specific task.

Getting this distinction right is crucial for getting consistent results. If your beer pours are all foam or your aquarium plants aren't pearling, the working pressure gauge is the first place to check and adjust. For anyone needing to replace or upgrade their setup, a reliable pressure gauge is essential for keeping precise control over your system. Once you know how to read both dials, your regulator transforms from a confusing bit of hardware into a precision tool.

When it comes to CO2 cylinders, temperature isn't just a minor detail—it's the single most important factor determining the internal pressure and, by extension, the safety of your setup. The pressure inside that steel bottle is in a constant, dynamic dance with the ambient temperature.

Think of your cylinder like a pressure cooker. When you turn up the heat, the pressure inside skyrockets. This is why one of the most common—and dangerous—mistakes is leaving a CO2 cylinder in a hot car. On a sunny day, a car's interior can easily climb above 50°C (122°F). At that temperature, the pressure in a CO2 cylinder can surge to over 177 bar (2570 PSI), pushing it far beyond its safe operating limit and creating a serious risk of catastrophic failure.

Thankfully, CO2 cylinders are built with this risk in mind. Every cylinder is fitted with a crucial safety component called a burst disc (or Berstscheibe in German). This is a small, single-use disc engineered to rupture at a very specific, predetermined pressure, typically around 190 bar (2755 PSI).

If a cylinder gets dangerously over-pressurised from extreme heat, the burst disc is designed to be the weakest point. It will fail first, allowing the CO2 to vent in a controlled (though very loud and startling) manner. This prevents the entire cylinder from exploding, which would be a far more destructive event. It’s the safety system working exactly as intended.

This rapid depressurisation is a dramatic reminder of how CO2 pressure behaves under stress. The same physics applies in large-scale industrial applications, where precise temperature and pressure monitoring is absolutely essential for operational safety.

On the flip side, cold temperatures have the opposite effect, causing the pressure to drop significantly. If you’re running your CO2 system in a chilly workshop or cellar that dips below 10°C (50°F), don't be surprised if you run into performance issues. The lower pressure can lead to weak or inconsistent output, impacting everything from the carbonation level in your drinks to the quality of your welds.

You can see an extreme example of this principle in the production of dry ice, where liquid CO2 is rapidly depressurised. This causes its temperature to plummet instantly to -78.5°C (-109.3°F), solidifying it into snow.

To ensure both optimal performance and safety, stick to these simple storage rules:

Even with a perfectly calibrated setup, you can still run into puzzling issues with your CO2 Flasche Druck. The good news is that most problems are simple to solve. Knowing what to look for can turn a frustrating mystery into a quick fix, getting you back to your project in no time.

Most glitches you'll encounter fall into just a few common categories. By learning to recognise the symptoms, you can quickly get to the root of the problem and apply the right solution. Let's walk through some of the most frequent hiccups you might face.

This is easily the most common "problem," and it's usually not a problem at all. If your high-pressure gauge suddenly takes a nosedive to zero after holding steady for weeks or even months, it almost always means one thing: your cylinder is empty.

As we covered earlier, the pressure inside the cylinder remains stable as long as there's liquid CO2. The moment the last of that liquid turns to gas, you're running on fumes. The remaining gas gets used up very quickly, causing that dramatic, sudden drop on the gauge.

Ever noticed your regulator getting frosty, or even coated in a layer of ice? This often happens during periods of heavy use, like when you're force-carbonating a fresh keg of beer or running a high-flow application. It's a normal physical reaction, but one you need to keep an eye on.

This chilly effect is caused by adiabatic expansion. As the highly compressed CO2 gas leaves the cylinder and expands rapidly through the regulator, its temperature plummets. If the gas is flowing fast enough, this cooling effect can be intense enough to drop the regulator's metal body below freezing, causing moisture from the air to condense and freeze right on its surface.

A little bit of frost is often normal during high-flow tasks. However, if it's freezing up excessively or all the time, it could signal a bigger issue like a leak or a flow rate that’s too high for your regulator to handle, which could lead to inconsistent output pressure.

To manage this, first double-check that all your connections are tight and leak-free. If the icing continues, the easiest fix is to simply reduce your CO2 flow rate. Slowing things down gives the regulator more time to manage the temperature change, preventing ice build-up and ensuring your output pressure stays stable and accurate.

Recognising these common signs will help you confidently tackle most pressure-related issues that pop up. For a quick reference, the troubleshooting table below breaks down the most common symptoms and their fixes.

When something goes wrong with your CO2 setup, a quick diagnostic can save you a lot of guesswork. This table maps out the most frequent symptoms you'll see, their likely causes, and the straightforward steps to get things running smoothly again.

| Symptom | Potential Cause | Recommended Solution |

|---|---|---|

| Sudden pressure drop | Cylinder has run out of liquid CO2. | Replace or refill the CO2 cylinder. |

| Regulator is frosty | High flow rate causing adiabatic expansion. | Reduce the CO2 flow rate and check for minor leaks. |

| Inconsistent output | Regulator freezing or a leak in the system. | Lower flow rate; perform a leak test with soapy water. |

| Gauge won't move | System not in use; normal vapour pressure. | This is normal; the gauge only drops when the liquid is gone. |

Think of this table as your first line of defence. In most cases, the solution is simple and won't require much more than a quick adjustment or a cylinder swap.

Knowing the physics behind CO2 Flasche Druck is one thing, but responsible ownership is really about building safe, everyday habits. A high-pressure gas cylinder isn't something to be trifled with; it demands respect and a consistent routine to keep you and everyone around you safe.

One of the most fundamental rules of handling CO2 is to always secure your cylinder. It's easy to think it won't get knocked over, but accidents happen. If a cylinder falls and the valve assembly snaps off, it can instantly become a high-speed projectile with enough force to go through walls. Always chain or strap it securely in an upright position to a wall or another sturdy, unmoving object.

Where you store your cylinder is just as important as how you use it. It needs a cool, dry, and well-ventilated space, well away from direct sunlight, radiators, or any other heat sources. Proper ventilation is a serious point—a slow, unnoticed leak in a small, enclosed room can displace oxygen, creating a dangerous risk of asphyxiation.

Transporting cylinders requires the same level of care. If you're moving a cylinder in a vehicle, it absolutely must be secured so it can't roll or slide around. And just like with storage, ventilation is key. Crack a window open to ensure any potential leaks can disperse safely instead of building up inside the cabin. For a deeper dive, check out our guide on the rules for transporting gas cylinders.

Safety standards, like the TÜV inspections here in Germany, are in place for a reason. These checks aren't just bureaucracy; they're a critical safety net that verifies the structural integrity of your cylinder over time, protecting against material fatigue or hidden damage.

It's also worth remembering the environmental side of things. The heavy-duty construction needed to handle these pressures has a footprint. For instance, manufacturing advanced pressure vessels from materials like carbon fibre reinforced polymer (CFRP) can release up to 2.5 tonnes of CO2 per vessel. This really puts into perspective the amount of energy required to create containers strong enough to keep high-pressure gases safely contained. You can read more about the CO2 balance of hydrogen pressure vessels to get a better sense of the industrial scale.

Even after getting your head around the science of temperature and pressure, you're bound to have some questions once you start working with a CO2 system day-to-day. We get it. Here are some quick, no-nonsense answers to the most common queries that land in our inbox, designed to help you sort out practical issues and feel more confident with your setup.

If you've just received a brand-new, full CO2 cylinder, the gauge should read around 57 bar (830 PSI), assuming it's sitting at a normal room temperature of about 20°C (68°F). Don't sweat it if the needle is a little higher or lower. This is just a direct reflection of the temperature where it was last stored or filled. As long as the pressure reading makes sense with the temperature chart, your cylinder is good to go.

This is the number one question we hear from new users, and thankfully, it almost never means something is wrong. Your regulator's high-pressure gauge will stay remarkably steady for nearly the entire life of the cylinder. That’s because as long as there's liquid CO2 inside, the pressure is dictated by temperature, not volume.

Once the very last of that liquid CO2 turns to gas, the remaining vapour gets used up in a flash. That's when you'll see the needle take a nosedive.

A sudden drop in your co2 flasche druck (CO2 bottle pressure) is the best indicator you have that it's time for a refill. It simply means the party's over and the cylinder is empty.

Yes, that’s perfectly normal, especially when you're actively using the gas. When CO2 expands as it leaves the cylinder, it gets cold—fast. This phenomenon is known as adiabatic expansion. It’s quite common for the cylinder valve and the body of the regulator to feel chilly or even grow a thin layer of frost, particularly during high-flow tasks like carbonating a keg.

A word of caution, though: if you see an excessive amount of ice building up, it might be a sign that your flow rate is too high or you have a small leak. If the frost seems unusually heavy, it's always a good idea to double-check that all your connections are tight.

Absolutely not. You must never store or use a CO2 cylinder on its side. These cylinders are specifically designed to stand upright. When you lay one down, you allow liquid CO2 to flow directly into the valve and regulator, which are only built to handle gas.

Letting liquid into the regulator can cause a cascade of serious problems:

Always make sure your cylinder is secured in an upright position so it can't be tipped over. It’s a simple rule, but it's absolutely critical for the safety and proper function of your entire system.

At Cryonos GmbH, we build state-of-the-art cryogenic and gas solutions with safety and reliability at their core. Explore our range of high-quality cylinders, regulators, and accessories to ensure your setup performs flawlessly. Visit us at https://www.cryonos.shop to find the right equipment for your needs.