No Products in the Cart

Here's the rewritten section, crafted to sound like it was written by an experienced human expert, following all the provided instructions and examples.

The whole idea of hydrogen's energy density feels like a bit of a paradox, doesn't it? On one hand, hydrogen packs more punch per kilogram than any other fuel out there—a hefty 33.3 kWh per kilogram. But on the other hand, it's the lightest element in the universe, meaning in its natural gas form, it's incredibly bulky and takes up a huge amount of space for the energy it holds. This split personality is the core puzzle we need to solve to make hydrogen a truly practical energy source.

Think of it like this: would you rather carry around a fluffy down pillow or a small steel ball? The pillow is incredibly light but takes up a massive amount of room, making it a nightmare to store or transport. The steel ball is the opposite—compact, dense, and heavy for its size.

Right now, hydrogen gas is the pillow. It's brimming with potential energy, but it's just too spread out to be useful for most things, whether you're powering a vehicle or running equipment in a biobank. To make it work, we have to turn it into the steel ball: dense, compact, and easy to manage.

To really get a handle on the energy density of hydrogen, you need to look at it from two different perspectives. Each one tells a vital part of the story and shapes how we can actually use hydrogen in the real world.

Gravimetric Energy Density (kWh/kg): This is where hydrogen shines. It’s a measure of energy per unit of mass, and hydrogen is the undisputed champion. It stores about three times more energy per kilogram than petrol or diesel. This is its superstar quality.

Volumetric Energy Density (kWh/L): This is hydrogen's weak spot, at least in its natural state. It measures energy per unit of volume. As a gas, hydrogen’s low density means you'd need an impractically enormous tank to store any meaningful amount of energy.

This isn't just some academic detail. The relationship between weight and volume has massive implications for logistics, infrastructure design, and day-to-day operational costs. If your business is looking at hydrogen—whether you’re an industrial gas supplier or a cryogenic logistics firm—getting your head around both of these concepts is absolutely non-negotiable.

The real job isn't just about unlocking hydrogen's energy; it's about taming its volume. The solution lies in cranking up its density, transforming a wispy, bulky gas into a potent and manageable liquid fuel.

This brings us neatly to the most effective way to do just that: cryogenic liquefaction. By chilling hydrogen gas down to an incredibly cold -253°C, it transforms into liquid hydrogen (LH2). This process dramatically boosts its volumetric energy density, finally unlocking its true potential and turning it into a powerful tool for modern industry.

When you start digging into the numbers on hydrogen's energy density, you find two very different stories playing out. These two measures—gravimetric and volumetric density—neatly capture both hydrogen's incredible promise and its single biggest practical challenge. Getting your head around this duality is essential, whether you're in industrial gas supply, cryogenic logistics, or advanced research.

The first story is all about weight. Gravimetric energy density tells us how much energy is packed into a given mass, usually measured in kilowatt-hours per kilogram (kWh/kg). In this arena, hydrogen is the undisputed champion, boasting an impressive 33.3 kWh/kg.

This incredible energy-to-weight ratio is exactly why sectors like aerospace and long-haul transport are so keen on hydrogen. For any application where every single gram counts against your bottom line, no other fuel even comes close.

But then there's the second story, the one about volume. Volumetric energy density, measured in kilowatt-hours per litre (kWh/L), reveals how much energy you can fit into a specific space. And here, hydrogen in its natural gaseous state has a real problem. It's the lightest element in the universe, which means its molecules are incredibly spread out, giving you very little energy for the amount of space it takes up.

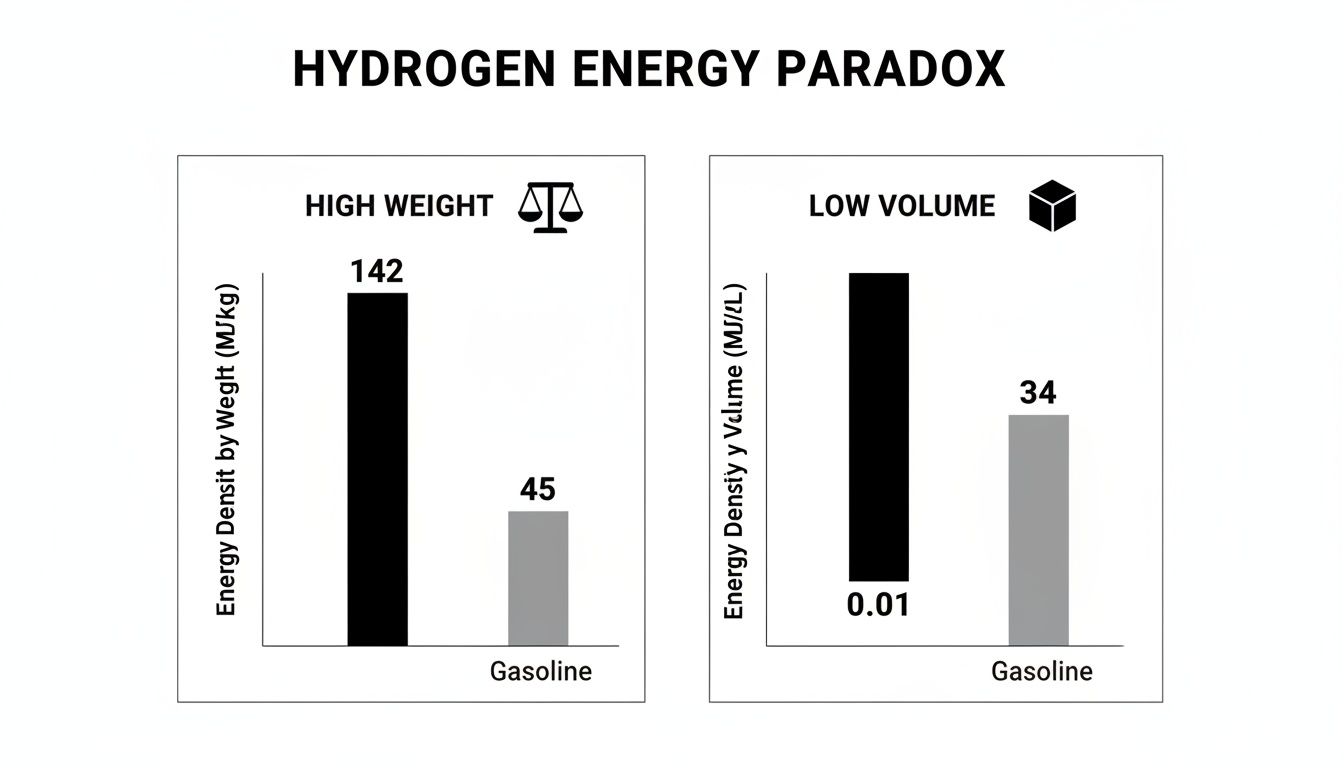

This clash between high energy per kilogram and low energy per volume is often called the "hydrogen paradox". This image shows it perfectly.

As you can see, while hydrogen wins hands-down on a weight basis, it really struggles to compete on space efficiency when it’s just a gas.

To make this tangible, think about a long-haul lorry. Based on weight alone, you could load it with enough hydrogen to cross continents without stopping. The problem? The tank needed to hold that much gaseous hydrogen would be so monstrously huge that there would be no room left for cargo, making the whole exercise pointless.

In any real-world application, from industrial backup power to vehicle fleets, space is the ultimate currency. An energy source is only useful if it can be stored in a manageable footprint.

This is where the physical state of hydrogen becomes absolutely critical. Compressing the gas helps, but it’s still not enough to truly solve the volume problem.

To get a clearer picture of how hydrogen stacks up against fuels we use every day, let's compare the numbers directly.

The table below provides a side-by-side look at the gravimetric and volumetric energy densities of hydrogen in its various forms compared to common energy carriers like petrol, diesel, and modern batteries.

| Energy Carrier | State | Gravimetric Density (kWh/kg) | Volumetric Density (kWh/L) |

|---|---|---|---|

| Hydrogen | Gaseous (700 bar) | 33.3 | 1.4 |

| Hydrogen | Liquid (LH2) | 33.3 | 2.36 |

| Petrol | Liquid | 12.2 | 8.76 |

| Diesel | Liquid | 12.7 | 9.7 |

| Li-ion Battery | Solid | ~0.15 | ~0.4 |

This comparison highlights the core challenge: even when compressed or liquefied, hydrogen struggles to match the volumetric density of traditional hydrocarbon fuels, which pack a lot of energy into a small, convenient liquid volume.

This characteristic is central to Germany's national energy strategy. Hydrogen's gravimetric energy density is a massive advantage, with one kilogram providing around 120 megajoules (MJ)—nearly three times that of natural gas. This makes it an ideal candidate for decarbonising sectors where weight is a primary concern.

But its low volumetric density of just 0.09 kg/m³ at normal pressure is a major roadblock for storage and transport. You can learn more about how these properties are shaping the German energy transition.

To make hydrogen a viable, mainstream fuel, we have to dramatically increase how much energy we can pack into a given volume. The most effective route isn't just more compression; it's changing its state entirely.

This leads us directly to the cryogenic solution: turning gaseous hydrogen into a dense liquid. By cooling it to an incredibly cold -252.87°C, we shrink its volume by a factor of more than 800. This is the key that finally unlocks its potential for widespread industrial and logistical use.

The biggest headache with hydrogen isn't a lack of energy, but its sheer, unwieldy volume. Sure, compressing it helps, but that only gets you so far. To really pack a punch and make hydrogen energy density viable for industrial use, we need to think smaller—by fundamentally changing its physical state. This is exactly where cryogenic technology comes in.

The most effective way to solve hydrogen's volume problem is to turn it into a liquid. This means chilling hydrogen gas down to an incredibly cold -252.87°C (-423.17°F). At this extreme temperature, the gas condenses into a clear, colourless liquid we call LH2, or liquid hydrogen.

This isn't just a simple change of state; it's a monumental leap in density. The process boosts hydrogen's density to roughly 70.8 kilograms per cubic metre (kg/m³). To give you an idea of what that means, liquefaction shrinks the volume of hydrogen gas by a factor of over 800.

Think of it like turning a room full of steam back into a small puddle of water. That's the kind of compression we're talking about. This incredible densification makes storing and moving huge amounts of energy far more practical and efficient.

Working with a substance as cold as liquid hydrogen is a serious engineering challenge, demanding specialised equipment and a lot of know-how. The good news is the principles aren't new. They're built on decades of experience handling other industrial cryogenic gases, like liquid nitrogen (LIN) and liquid oxygen (LOX).

The main goal for any LH2 storage system is simple: keep it cold and minimise evaporation, a phenomenon known as "boil-off." Even the tiniest bit of heat leaking in from the outside world can cause the liquid to turn back into gas. This leads to product loss and a potentially dangerous build-up of pressure.

Several key technologies make this possible:

The success of a liquid hydrogen system all comes down to its ability to minimise boil-off. High-performance cryogenic vessels are engineered to keep evaporation rates below 1% per day. This ensures the safe, stable, and cost-effective storage of this high-density fuel over long periods.

If you work in industrial gas supply, biobanking, or logistics, a lot of this will sound familiar. The core principles behind designing and running liquid nitrogen freezers are the same ones applied to liquid hydrogen systems, just with extra precautions for flammability. The engineering needed to maintain stable cryogenic temperatures is a proven science.

Critical components like vacuum-insulated transfer lines and efficient heat exchangers are essential in both worlds. For example, the design of a plate-fin heat exchanger is fundamental to the liquefaction process itself, enabling highly efficient thermal exchange. If you're curious about the mechanics, you can learn more about how a plate-fin heat exchanger works in these systems.

By adopting these tried-and-tested cryogenic solutions, we can finally crack the volumetric density problem that has long held hydrogen back. This shift turns hydrogen from a bulky, hard-to-handle gas into a transportable, high-density energy carrier, clearing the path for its widespread use in heavy transport, industry, and large-scale energy storage.

Understanding the physics of hydrogen's energy density is one thing, but applying that knowledge to make smart business decisions is something else entirely. The choice between compressed gaseous hydrogen (CGH₂) and cryogenic liquid hydrogen (LH₂) has massive consequences for your infrastructure, logistics, and, ultimately, your bottom line. It’s a decision that shapes everything from on-site safety protocols to long-term operational costs.

For industrial gas suppliers, this choice defines the scale and efficiency of the entire distribution network. Transporting hydrogen as a compressed gas means deploying fleets of heavy, high-pressure tube trailers. Each truck can only carry a limited amount of energy because of the sheer volume and weight of the steel cylinders, leading to more trips, higher fuel costs, and more complex logistics.

On the other hand, a single cryogenic tanker carrying liquid hydrogen can transport the same amount of energy as several compressed gas trucks. This is a direct result of LH₂'s superior volumetric density. For large-scale industrial users, this means fewer deliveries, reduced traffic on-site, and a much more streamlined, cost-effective supply chain.

For organisations like laboratories and biobanks, the principles are the same, just on a different scale. Many are already skilled at managing cryogenic liquids, particularly liquid nitrogen (LIN) for cryopreservation. This existing expertise offers a solid foundation for bringing in liquid hydrogen, perhaps to power on-site fuel cells for critical backup power.

The operational parallels are clear: both need specialised dewars, personal protective equipment (PPE) for handling extreme cold, and robust safety procedures. The main difference, of course, is hydrogen's flammability, which demands extra ventilation and certified equipment. Still, the fundamental skills in cryogenic management are directly transferable.

Choosing liquid hydrogen over compressed gas isn't just about operational preference; it's a strategic decision about space optimisation. In facilities where every square metre is valuable, the smaller footprint of an LH₂ system can be a huge competitive advantage.

Let's make this more concrete. Imagine your facility needs enough backup power to run essential equipment for one week without a break. You're looking at two hydrogen-based options: a compressed gas array and a liquid hydrogen dewar.

This dramatic space saving comes directly from the vastly superior volumetric energy density of liquid hydrogen. For any facility with limited space—from urban research centres to compact industrial sites—this difference isn't trivial; it's a critical factor in planning and investment.

This growing reliance on hydrogen is mirrored in Germany's ambitious economic plans. The country's hydrogen demand is projected to be between 95-130 TWh just to kick-start its economic transition, with forecasts soaring to 400-800 TWh by 2050. This surge is driven by heavy industry, energy, and mobility sectors that depend on hydrogen’s high gravimetric energy density of 33.3 kWh/kg. You can find more insights about Germany's hydrogen strategy on gtai.de.

Ultimately, whether you're managing a fleet of tankers or ensuring a biobank’s power stays on, the density of your chosen hydrogen form dictates your operational reality. High-performance cryogenic hardware with minimal evaporation isn't just a piece of equipment; it's what makes safe, efficient, and economically sound hydrogen operations possible.

Getting the technical details of hydrogen's energy density right is one thing, but placing that knowledge into the bigger picture is where the real business opportunities lie. For any company operating in Germany, that bigger picture is the country's ambitious National Hydrogen Strategy.

This isn't just another policy paper. It's a multi-billion-euro plan to build a hydrogen economy from the ground up, backed by over €20 billion in government investment. For businesses in cryogenic logistics and industrial gas supply, this represents a fundamental market shift—a clear roadmap for the future of energy in Germany.

Two key goals are driving this national effort, and they directly shape the future of hydrogen infrastructure and logistics. They dictate how hydrogen will move from production sites to end-users, affecting everything from storage depots to last-mile delivery.

10 GW of Electrolysis Capacity: By 2030, Germany is aiming for at least 10 gigawatts of domestic electrolysis capacity. This massive push will create a reliable supply of green hydrogen, which is vital for decarbonising heavy industry and transport. We dive deeper into the specifics of green hydrogen production in our detailed guide.

A 9,000+ km Pipeline Network: There’s a plan underway to build out a hydrogen core network spanning over 9,000 kilometres by 2032. This involves both converting existing natural gas pipelines and constructing new, dedicated infrastructure to move hydrogen efficiently through the country's industrial heartlands.

This planned infrastructure completely changes the supply chain. Instead of relying only on tanker trucks, large-scale users will eventually plug directly into a national grid. This creates a powerful new logistics model where cryogenic tankers handle regional distribution from major pipeline hubs.

For companies already skilled in cryogenic technologies, this strategy is a direct invitation to lead the transition. Your expertise in handling liquid nitrogen isn't just a technical skill; it's a strategic asset that perfectly aligns with the future of Germany’s energy landscape.

The German government's strategy implicitly acknowledges the challenges of energiedichte von wasserstoff (hydrogen's energy density). While pipelines will move huge volumes of gaseous hydrogen, the final delivery to many industrial sites, fuelling stations, and backup power systems will still depend on the superior volumetric density of liquid hydrogen.

This is where your capabilities become critical.

Businesses that already have cryogenic storage vessels, transport tankers, and the know-how to manage super-cooled liquids are perfectly positioned. As the hydrogen network expands, the demand for efficient, localised liquid hydrogen storage and distribution will only grow. Your existing infrastructure for liquid nitrogen can be adapted, and your operational experience gives you a significant head start.

In Germany's race for green hydrogen, energy density is the key factor driving these infrastructure decisions. Hydrogen's impressive weight-based (gravimetric) density of 120 MJ/kg easily beats methane's 50 MJ/kg, but it needs cryogenic liquefaction to reach a practical volume-based (volumetric) density of 70 kg/m³. This makes it a perfect match for companies that specialise in cryogenic vessels.

You can find more insights into Germany's hydrogen roadmap on cleanenergywire.org. By understanding and aligning with the national strategy, you can future-proof your operations and find your place in Germany's evolving energy ecosystem.

Handling any industrial fuel demands respect, but working with cryogenic liquid hydrogen brings a unique set of challenges. It calls for robust, non-negotiable safety protocols. While its incredible energy density makes it an exceptional fuel, we can't ignore its physical properties—namely, its extreme cold and high flammability. This isn't cause for alarm, but it does demand a clear-eyed and professional approach. Fortunately, these hazards are well-understood and entirely manageable with the right gear, procedures, and training.

The first hazard is the intense cold. At -252.87°C, liquid hydrogen is cold enough to cause severe burns or frostbite on contact with skin. It can also make common materials like carbon steel dangerously brittle, a phenomenon known as cryogenic embrittlement. This is precisely why all equipment—from storage vessels to transfer lines and valves—must be made from specific materials, like stainless steel or certain aluminium alloys, that are certified for cryogenic hydrogen service.

The second, and perhaps more well-known, hazard is its flammability. Hydrogen gas is flammable over a massive range of concentrations in air, from 4% to 75%. This is a far broader range than petrol or natural gas. What's more, it’s colourless, odourless, and burns with a nearly invisible flame. This makes specialised detection equipment not just a recommendation, but an absolute necessity wherever hydrogen is stored or handled.

Managing these risks boils down to a multi-layered safety strategy. It’s a combination of personal diligence, environmental controls, and certified hardware. When you adhere to these protocols, what might seem like a hazardous operation becomes a controlled, routine, and professional process.

Safety isn't about avoiding risk; it's about mastering it. With cryogenic hydrogen, this means respecting its properties through meticulous engineering, consistent training, and unwavering adherence to established safety standards. The goal is to make safe operation the default.

Beyond personal and environmental controls, the integrity of the equipment itself is paramount. Every single component in a liquid hydrogen system has to be designed, tested, and certified specifically for that job. Using equipment meant for other cryogenic liquids, like nitrogen, is completely unacceptable due to the different material requirements and the added flammability risk.

Regulations provide a clear framework for ensuring this level of safety, especially in transport. The ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) lays out strict requirements for building and operating vehicles and tanks used to move liquid hydrogen. Compliance with ADR standards ensures that every piece of the transport puzzle, from vessel design to driver training, meets the highest safety benchmarks. For those new to cryogenic handling, getting the fundamentals right is the best place to start. You can read more about the 7 important rules for safe work with cryogenic liquids to build a solid foundation.

Ultimately, while the hazards linked to liquid hydrogen are significant, they aren't new or unknown. Decades of experience in the industrial gas sector have cultivated a mature ecosystem of engineering controls, best practices, and regulatory standards that make its handling a safe and reliable process.

When it comes to hydrogen energy density, a few key questions always come up, especially for labs, logistics providers, and industrial teams planning their next steps. Let's get right to them.

The short answer is space. Liquid hydrogen (LH₂) simply packs far more energy into the same container than its gaseous form, even when you compress the gas to incredibly high pressures. For any serious transport application, this superior volumetric energiedichte von wasserstoff makes a world of difference.

Think of it this way: one cryogenic tanker carrying liquid hydrogen can do the job of several trailers loaded with compressed gas cylinders. That means fewer trips, longer vehicle ranges, and more room for actual payload instead of heavy, cumbersome tanks. For any logistics operation, those are massive economic wins.

There are really two main hurdles to clear: the energy needed to make it liquid in the first place, and managing what's known as "boil-off". Getting hydrogen down to a frigid -253°C takes a significant amount of energy. Once it's in that liquid state, a tiny fraction will naturally warm up and turn back into a gas over time—that's the boil-off.

But this is a solved problem. Modern cryogenic vessels are engineered specifically to combat this. Using advanced vacuum insulation, they are so effective at keeping the heat out that boil-off rates are often less than 1% per day. This makes long-term storage not just possible, but efficient and safe.

While both are cryogenic liquids and require similar protective gear to handle the extreme cold, there's one massive difference: flammability. Liquid nitrogen is inert; it won't burn. Hydrogen, on the other hand, is flammable over a very wide range of concentrations in the air.

This single fact changes the handling requirements significantly. It means you must take extra precautions, including:

With proper training and the right equipment, these risks are well-understood and completely manageable. It's what makes liquid hydrogen a practical and safe fuel for today's industrial applications.

For state-of-the-art cryogenic solutions designed for the safe storage and transport of industrial gases like hydrogen, trust the experts at Cryonos GmbH. Explore our ADR-licensed vessels and find the right equipment to future-proof your operations by visiting us at https://www.cryonos.shop.