No Products in the Cart

To successfully produce green hydrogen, or grüner wasserstoff herstellen, the journey starts with electrolysis. This process uses electricity from renewable sources to split purified water into its basic components: hydrogen and oxygen. This technique isn't just a lab experiment; it's the bedrock of Germany's energy transition, offering a solid path to decarbonise heavy industry and effectively store surplus renewable energy.

Getting into green hydrogen production is a serious commitment to a cleaner energy future. At its core, the whole setup is a clever way of taking renewable electricity—from wind turbines or solar panels—and converting it into a chemical energy carrier that you can store and move around. This isn't just theory; it's a practical solution being rolled out right now to tackle some of our biggest climate challenges.

Germany is all in on this, making it a central pillar of its national energy strategy. By tapping into its ever-growing renewable energy capacity, the country is carving out a position as a leader in green hydrogen technology. To put it in perspective, in the first quarter of 2024, renewables already covered 46.9% of Germany's total electricity consumption, highlighting the massive potential available to power electrolysers. This strategic focus helps create flexible energy storage and supplies clean fuel for tough-to-decarbonise sectors like steel manufacturing and long-haul transport.

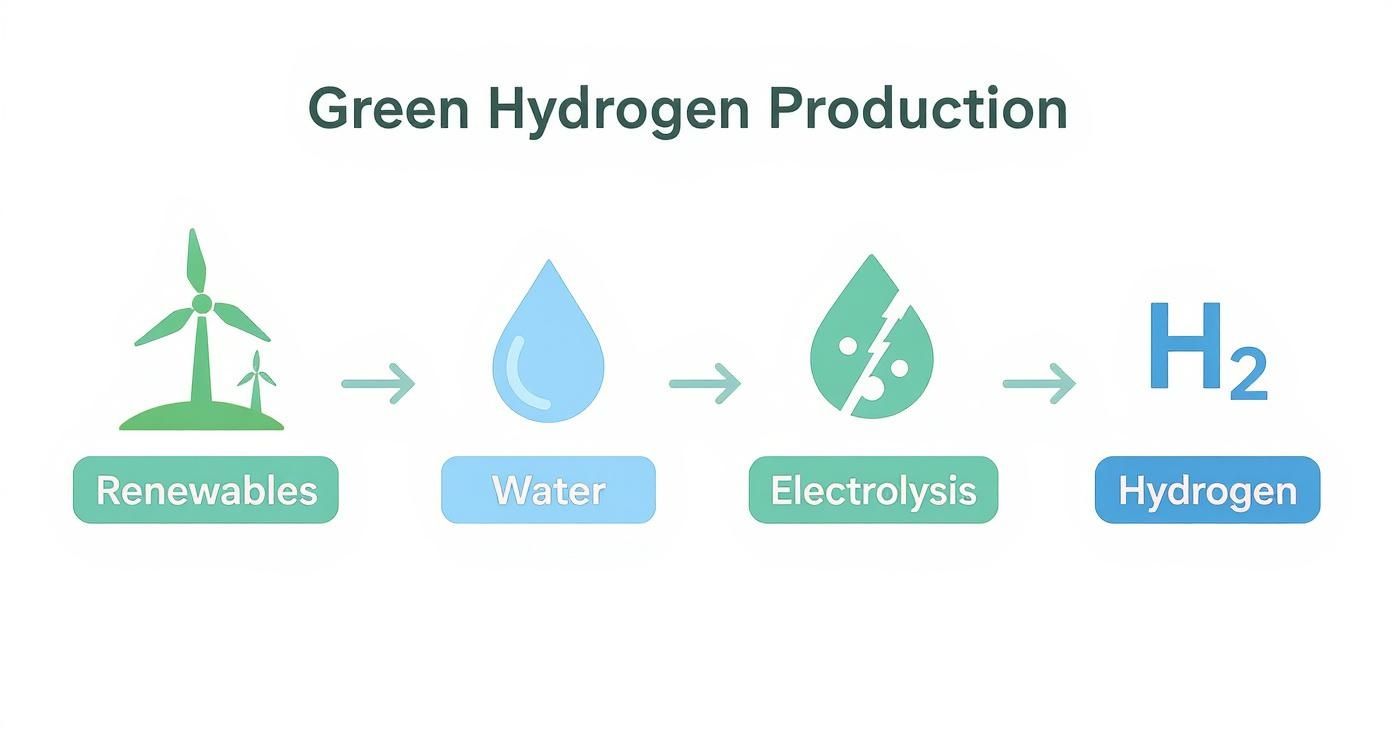

The path from a wind turbine spinning in a field to a tank of usable hydrogen involves several critical stages. It's essential to understand this flow before we get into the nitty-gritty of electrolyser types or system sizing.

This diagram lays out the simple, linear process of turning renewable power and water into pure hydrogen.

As you can see, the chain kicks off with a certified green power source and finishes with a highly versatile energy carrier. The whole operation hinges on that clean electricity, and the efficiency of the conversion is a make-or-break factor for the project's economics.

At its essence, producing green hydrogen is about creating a bridge between intermittent renewable energy generation and constant industrial demand. The process captures fleeting electrons from the sun and wind and locks them into stable hydrogen molecules for later use.

Once the hydrogen gas is produced, it needs to be prepped for storage and transport. This usually means either compressing it to incredibly high pressures or liquefying it, which involves chilling the gas to a mind-bogglingly low temperature of -253°C.

This step is a real energy hog, but it's often a necessary evil for moving large quantities of hydrogen efficiently. The science behind handling materials at these frigid temperatures is a field in itself. If you're curious, you can learn more in our guide that explains what is cryogenics.

This downstream processing is just as vital as the initial electrolysis. It requires specialised equipment and deep expertise to ensure safety and keep energy losses to a minimum. Next, we'll dive into the three main electrolysis technologies—Alkaline, PEM, and SOEC—to give you a solid grasp of the fundamentals.

When you decide to grüner wasserstoff herstellen, picking your electrolyser is the single most important decision you'll make. Think of it as choosing the engine for your entire operation—it dictates everything from performance and cost to operational flexibility. Let's cut through the technical jargon and match the right technology to your real-world needs.

Right now, three technologies dominate the market: Alkaline (AEC), Proton Exchange Membrane (PEM), and Solid Oxide Electrolysis Cells (SOEC). Each comes with its own distinct set of trade-offs. What makes one a perfect fit for a particular project could make it a terrible choice for another.

Getting this right isn't just about the upfront cost. It’s about how the electrolyser integrates with your power source, what its maintenance demands will be, and its overall efficiency over its entire lifespan. A mismatched technology can easily lead to higher running costs and lower hydrogen output, completely undermining your business case.

Alkaline electrolysis is the old guard, the most mature and widely deployed technology out there. It's been a staple in industrial applications for decades, which makes it a reliable and incredibly well-understood option. AEC systems use a liquid alkaline electrolyte, usually potassium hydroxide (KOH), to split water into hydrogen and oxygen.

Their biggest selling point? Cost. The materials they use, like nickel-based catalysts, are relatively cheap and abundant. This translates to a lower capital expenditure compared to the newer kids on the block, making AEC the go-to for large-scale, continuous hydrogen production where keeping that initial investment down is a top priority.

But AEC isn't without its limits. These systems are generally less responsive to swings in power input. They're happiest with a stable, continuous load, which makes them less than ideal for being directly hooked up to a single, intermittent wind turbine.

PEM electrolysis is a more modern approach. Instead of a liquid electrolyte, it uses a solid polymer membrane that only lets protons pass through. This design allows for a much more compact system and brings some major operational advantages to the table.

The absolute standout feature of PEM electrolysers is their speed. They can respond almost instantly to changes in power, ramping up and down in a flash. This makes them perfectly suited for direct connection to fluctuating renewables like solar and wind farms. That dynamic response means you can capture every last available kilowatt-hour of green electricity.

Of course, that flexibility comes at a price. PEM technology relies on precious metals like platinum and iridium for its catalysts, which drives up the initial cost. While prices are coming down, the capital investment is still higher than for a comparable AEC system.

When your business model depends on capturing surplus energy from a volatile grid or a dedicated wind farm, the rapid response of a PEM electrolyser is not just a feature—it's a necessity. It turns unpredictable power into a predictable asset.

SOEC is the newest of the three and operates on a completely different principle. These systems use a solid ceramic material as the electrolyte and run at blistering hot temperatures, typically between 700 and 900°C.

This high-temperature operation is both its greatest strength and its biggest challenge. All that heat drastically improves the efficiency of the electrolysis process. If you have a source of waste heat—say, from a steel mill or a chemical plant—you can feed it into the SOEC system, pushing conversion efficiencies to exceptional levels.

The flip side is the need for specialised materials that can withstand those temperatures, plus slower start-up times. This makes SOEC best suited for continuous, industrial-scale applications where top-tier efficiency is the number one goal and a steady supply of waste heat is readily available.

To help you weigh the options, here’s a quick breakdown of how the technologies stack up against each other.

| Technology | Efficiency Range (%) | Operating Temperature (°C) | Key Advantage | Ideal Application |

|---|---|---|---|---|

| Alkaline (AEC) | 60–70 | 60–90 | Lowest capital cost, mature technology | Large-scale, continuous production with stable power |

| PEM | 65–75 | 50–80 | Fast response time, compact design | Direct coupling with intermittent renewables (solar/wind) |

| SOEC | 80–95+ | 700–900 | Highest efficiency, can use waste heat | Industrial sites with available high-grade waste heat |

Ultimately, the best choice depends entirely on your specific circumstances—your power source, your budget, and your operational goals.

The ambitious goals set by Germany's updated national hydrogen strategy really underscore the growing need for efficient production methods. With projected hydrogen demand soaring to between 360 and 500 TWh by 2045, maximising every bit of efficiency will be critical. It's the only way to scale up production to meet the immense needs of sectors like steel and chemicals. You can find more insights on Germany's energy strategy on trade.gov.

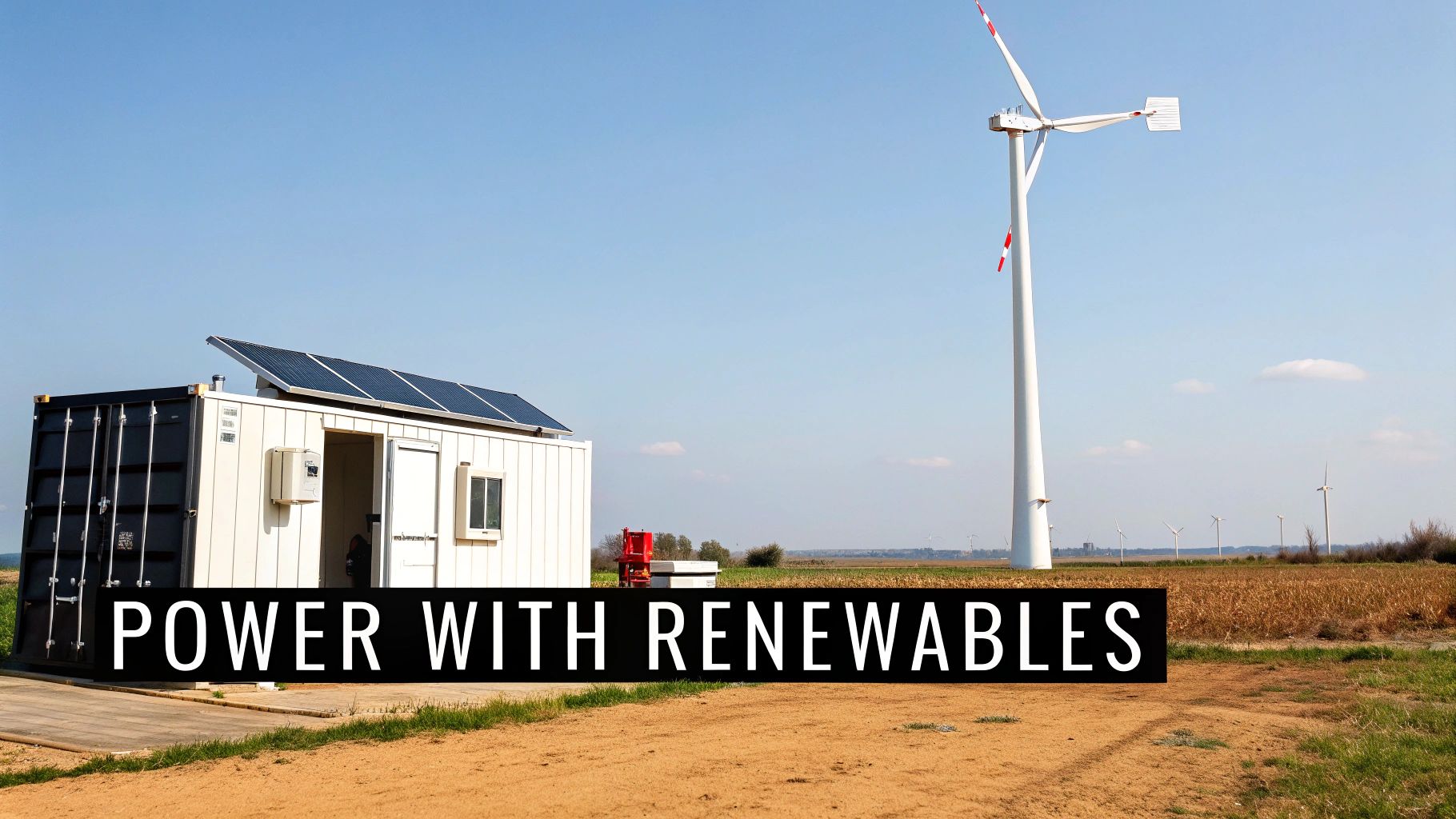

The "green" in green hydrogen is non-negotiable—it comes directly from the electricity source. To genuinely grüner wasserstoff herstellen (produce green hydrogen), your electrolyser absolutely must be powered by renewables. This isn't just a detail; it’s a critical choice that defines the environmental integrity of your entire project and heavily influences its economic viability.

You've got two main pathways to secure this green power: either by directly coupling your setup with dedicated renewables or by purchasing certified green electricity from the grid. Each approach comes with its own set of operational headaches and financial realities that you need to weigh up carefully.

Your decision here is far more than just ticking a sustainability box. It’s a fundamental architectural choice that will dictate your system design, operational schedules, and the overall cost structure of your hydrogen production from day one.

The purest approach to green hydrogen is through direct coupling, often called an "island" or off-grid setup. This means wiring your electrolyser straight into a dedicated renewable energy source, like a solar farm or wind turbine, without any grid connection in between.

This model gives you complete energy independence and shields you from the rollercoaster of grid electricity prices. The flip side? Your hydrogen production becomes entirely beholden to the weather. When the sun isn't shining or the wind isn't blowing, production grinds to a halt unless you've invested in a battery storage system.

Sizing a system like this involves some pretty straightforward but essential calculations. The core principle is simple: match the energy output of your renewable asset to the energy demand of your electrolyser.

As a rule of thumb, it takes roughly 50-55 kilowatt-hours (kWh) of electricity to produce 1 kilogram (kg) of hydrogen. This number depends on your electrolyser's efficiency, but it's the bedrock for all your capacity planning.

Let's walk through a practical scenario. Say you want to produce 20 kg of hydrogen per day using a dedicated solar array.

For wind power, the maths is similar but is based on the turbine's specific power curve and your site's average wind speed. A direct connection like this is perfect for projects where energy autonomy and a fully verified carbon-free production chain are the absolute top priorities.

Let's be realistic—not every project has the space or capital for its own renewable energy farm. The alternative is to connect your electrolyser to the public grid and procure certified green electricity. This route offers far greater operational flexibility, allowing you to run your system 24/7, completely independent of the weather.

The crucial part here is making sure the electricity you're using is verifiably renewable. In Europe, this is handled through Guarantees of Origin (GOs). A GO is essentially an electronic certificate that proves 1 MWh of electricity was generated from a renewable source. When you sign a green electricity contract, your supplier buys and retires these GOs on your behalf, legally certifying that your consumption is matched with an equivalent amount of renewable generation.

This model brings several big advantages to the table:

The catch, of course, is that you're subject to grid electricity prices, which can be notoriously volatile. To counter this, many operators using this model sign long-term Power Purchase Agreements (PPAs) directly with renewable energy generators. This lets them lock in a predictable electricity price for years, blending the financial stability of ownership with the operational flexibility of a grid connection. This hybrid approach is quickly becoming a popular and effective strategy for scaling green hydrogen production in Germany.

Successfully producing green hydrogen is a huge milestone, but the gas coming directly out of your electrolyser is rarely ready for its final application. Think of this next stage as the crucial refining and packaging step that prepares your hydrogen for the market.

These post-production steps—purification, compression, and storage—are just as vital as the electrolysis itself. Getting them wrong can lead to damaged equipment, inefficient operations, and a final product that doesn't meet the demanding specs for applications like fuel cells.

How you handle the hydrogen depends entirely on its intended use. Are you fuelling a fleet of vehicles, injecting it into the gas grid, or using it as a chemical feedstock? Each path demands different levels of purity, pressure, and storage.

The hydrogen gas produced by electrolysis is already quite pure, but it isn't perfect. It usually has trace amounts of water vapour and, depending on the electrolyser, tiny amounts of oxygen or electrolyte aerosols. While minor, these impurities can wreak havoc on certain applications.

For instance, hydrogen fuel cells in vehicles are extremely sensitive. Even minute quantities of moisture or other contaminants can degrade their performance and drastically shorten their lifespan. This is where purification becomes non-negotiable.

The industry standard for achieving ultra-high-purity hydrogen (99.999% purity or higher) is a process called Pressure Swing Adsorption (PSA).

For less sensitive uses, simpler and cheaper methods like membrane separation might be enough. The key takeaway is to match your purification method to the purity level your end-user actually needs.

Hydrogen is the lightest element in the universe, which means it has a very low energy density by volume. To store a useful amount of it, you have to either compress it to extremely high pressures or cool it down until it becomes a liquid. For most applications, compression is the more practical route.

Compressing hydrogen is an energy-intensive process, often consuming a good chunk of the energy contained within the hydrogen itself. Your choice of compressor technology is therefore a critical one, directly impacting your operational costs.

Compressing hydrogen is a fundamental trade-off. You spend energy to increase the gas's energy density, making it practical to store and transport. The goal is to find the most efficient compression method to minimise these energy losses.

Different compressor types are suited for different scales and pressure targets:

For vehicle fuelling, pressures of 350 bar (5,000 psi) and 700 bar (10,000 psi) have become the global standards. Reaching these pressures demands multi-stage compression and careful thermal management to handle the heat generated along the way.

Once purified and compressed, the hydrogen needs to be stored safely and moved efficiently. The right storage solution will be dictated by the quantity of hydrogen and how it will be used.

For smaller, mobile applications, high-pressure gas cylinders are the most common solution. These cylinders are typically made from steel or lighter composite materials, built to handle the immense pressures. Transporting them, especially in Germany, involves strict regulations to ensure safety on the road. For anyone moving pressurised gas, it's essential to understand the rules; you can read more about the regulations for transporting gas cylinders in our related article.

For larger, stationary storage, several options exist:

Each method comes with its own set of challenges, from material compatibility issues like hydrogen embrittlement in metals to the "boil-off" losses associated with cryogenic liquid storage. Careful planning is essential to select the most cost-effective and safe solution for your project's scale.

Moving from a technical blueprint to a functioning green hydrogen facility is where the theory ends and the real work begins. If you’re looking to grüner wasserstoff herstellen in Germany, you're stepping into a landscape of rigorous safety regulations and intricate project economics. This is the phase that truly tests your planning and ultimately decides if your project is not just safe, but financially viable.

Getting the regulatory side right means treating hydrogen with the immense respect it commands as a highly flammable gas. On the financial side, it’s all about mastering the numbers—from the initial cost of your electrolyser to the long-term price of your electricity—and knowing where to find the government support that can make or break your business case.

Handling hydrogen safely isn’t just a box-ticking exercise; it's the absolute foundation of your operation. German regulations are famously thorough, and for good reason. Your facility’s design needs to be built around robust safety measures, with a sharp focus on preventing leaks and managing them instantly if they ever occur. This is about protecting your people, your investment, and the community around you.

There are a few critical areas you absolutely have to get right:

In Germany, the DVGW (German Technical and Scientific Association for Gas and Water) is the authority that sets many of the key technical standards for hydrogen systems. Getting to know their codes of practice early on will save you a world of headaches during the approval process.

When it comes to the financial health of your project, there's one number that matters more than any other: the Levelized Cost of Hydrogen (LCOH).

This metric boils down all your lifetime costs into a single, simple figure in €/kg. It’s the number that tells you if you can actually compete in the market.

Your LCOH is shaped primarily by two major cost buckets:

Think of LCOH as the absolute break-even price for your hydrogen. It takes all the complicated investments and running costs and turns them into one straightforward number. It's the ultimate benchmark for comparing your project against others and against traditional fossil fuels.

Electricity is the real giant here, typically making up 60-80% of the final LCOH. Securing a long-term, low-cost renewable power supply through something like a Power Purchase Agreement (PPA) is often the single most critical factor for a project's profitability. Another key cost to factor in is hydrogen storage. As you weigh your options, our guide on the pros and cons of buying or renting gas cylinders can give you a clearer picture of the associated costs.

Let’s be honest: the high upfront costs of green hydrogen projects can be a massive barrier. The good news is that both Germany and the European Union know this. They've rolled out a whole range of funding programmes designed to speed up the energy transition and take some of the risk off the table for early investors. These subsidies can slash your LCOH and make an otherwise borderline project completely viable.

Germany has put itself at the forefront of this movement, with an ambitious goal to build out 10 GW of domestic electrolyser capacity by 2030. This isn't just talk; it's backed by a serious project pipeline and substantial financial incentives. You can get a sense of the broader European landscape by checking out the full report on Europe's hydrogen project pipeline.

Here are a few key programmes to look into:

Navigating the application process for these funds can feel like a full-time job, but the financial boost they offer can be the very thing that gets your green hydrogen operation off the ground and running successfully.

After diving into the technical details of producing green hydrogen (grüner Wasserstoff herstellen), a few common, practical questions always seem to pop up. Let's tackle them head-on to clear up any lingering uncertainties about the resources, costs, and realities of the process.

On paper, the chemistry is simple. You need about 9 litres of perfectly pure water to get 1 kilogram of hydrogen from electrolysis. But that's a lab number, not a real-world figure.

In any practical setup, you'll lose some water during the purification process (like reverse osmosis) and through other small system inefficiencies. A much more realistic number to work with is 10 to 13 litres of initial tap water for every kilogram of H₂ produced. The critical takeaway is that the water must be deionised to avoid wrecking the sensitive components inside the electrolyser.

Please don't. That's probably the fastest way to turn a very expensive electrolyser stack into a boat anchor. Tap water is loaded with minerals, chlorine, and all sorts of dissolved solids that will instantly start contaminating catalysts and clogging up the system's delicate membranes.

This process, known as fouling, doesn't just tank the system's efficiency; it causes permanent damage. You're looking at costly repairs and a dramatically shorter operational life. Every single commercial electrolysis system has a dedicated water purification unit for a reason—it’s a non-negotiable step to protect your investment and ensure safe operation.

Hands down, it's the electricity. The cost of renewable power is the dominant factor, making up anywhere from 60% to 80% of the final Levelized Cost of Hydrogen (LCOH). More than anything else, this determines if a green hydrogen project makes financial sense.

The entire business case for green hydrogen lives or dies on access to cheap, abundant renewable electricity. The most successful projects are built in places with low-cost solar or wind, or are cleverly designed to absorb surplus grid energy that would otherwise be wasted.

The upfront cost of the electrolyser is significant, no doubt. But it's the monthly electricity bill over the long run that will make or break your project's profitability. This is why careful site selection and smart energy procurement strategies are absolutely vital.

Yes, absolutely. Germany has a whole host of funding programmes at both the federal and state levels designed to kickstart its hydrogen economy. While many of the big-ticket funds are aimed at massive industrial deployments, there are definitely pathways for smaller projects to get support.

Here are a few key programmes worth looking into:

If you're running a pilot or research-focused project, don't overlook partnerships. Teaming up with universities or applying for regional economic development funds can be a very effective way to secure the financial backing you need.

For robust and reliable equipment to handle industrial gases and cryogenic liquids, trust the experts at Cryonos GmbH. Our state-of-the-art solutions ensure the safe storage and transport of your valuable materials. Explore our complete product portfolio.