No Products in the Cart

When you're dealing with priceless biological samples, "good enough" simply doesn't cut it. You need absolute stability. That’s where Flowserve flow control comes in—it's a complete system of engineered components, like valves and actuators, designed to precisely manage the flow of liquids and gases in the most demanding industrial settings. It’s the critical system that masters the immense challenges of ultra-low temperatures, from preventing costly evaporation to maintaining exact pressure.

Think of it as the central nervous system for your entire cryogenic setup. A Flowserve flow control system works silently in the background, safeguarding the integrity of your most sensitive assets. This isn't just a collection of parts; it's a fully integrated solution engineered to handle the extreme conditions of cryogenic applications. For anyone managing a biobank or laboratory, this level of precision brings real peace of mind.

The system’s advanced valves and actuators are the backbone of this reliability, working hand-in-glove with Cryonos storage and transport solutions. This synergy creates a perfectly controlled cryogenic environment where every single variable is meticulously managed. Whether you're dealing with large-scale industrial gas logistics or protecting individual cell lines, the goal is always the same: absolute control and safety. Nailing the management of these components is vital for maintaining that frigid environment. You can dive deeper into the specifics of liquid nitrogen temperature in our guide.

This commitment to precision is what’s driving a rapidly growing sector. You can see this trend clearly in the German control valve market, where Flowserve is a major player.

The expansion of this market shows just how much demand there is for high-performance industrial automation, especially in specialised fields like cryogenics. The sector is projected to surge from 390 USD Million to an impressive 1700 USD Million by 2035, growing at a robust 14.32% compound annual growth rate.

This isn't just an abstract number; it reflects the critical need for reliable flow control in the biobanks and pharmaceutical labs that depend on partners like Cryonos GmbH. This upward trend highlights a broader shift towards more sophisticated, reliable, and efficient industrial processes—places where precise control isn't just a nice-to-have, but an absolute necessity.

To really get a feel for the reliability of your cryogenic operations, it helps to peek behind the curtain at the technology doing the heavy lifting. You don't need a degree in engineering to grasp it. Let's break down the core of a Flowserve flow control system. The simplest way to think about it is like a highly coordinated team where every member has a critical job to do.

The first key players are the valves. These aren't just simple taps; they're intelligent gateways that open and close with microscopic precision to manage the delicate flow of liquid nitrogen. They act as the primary gatekeepers, making sure exactly the right amount of cryogen is delivered at precisely the right time. This prevents both waste and dangerous temperature swings.

Of course, operating these gateways requires both muscle and intelligence. This is where actuators come into play. Picture actuators as the powerful ‘muscles’ of the system. They receive commands and physically move the valves, responding instantly to ensure the system’s instructions are carried out without a hitch. Whether it's opening a valve completely for a rapid fill or tweaking it slightly for fine-tuned temperature control, the actuator delivers the necessary force.

Finally, you have the instrumentation, which acts as the system's ‘brain and senses’. This network of sensors and monitors provides a constant stream of real-time feedback on pressure, temperature, and flow rates. It continuously checks that every action is perfect and sends that data back to the central control unit, which can then tell the actuators to make adjustments on the fly.

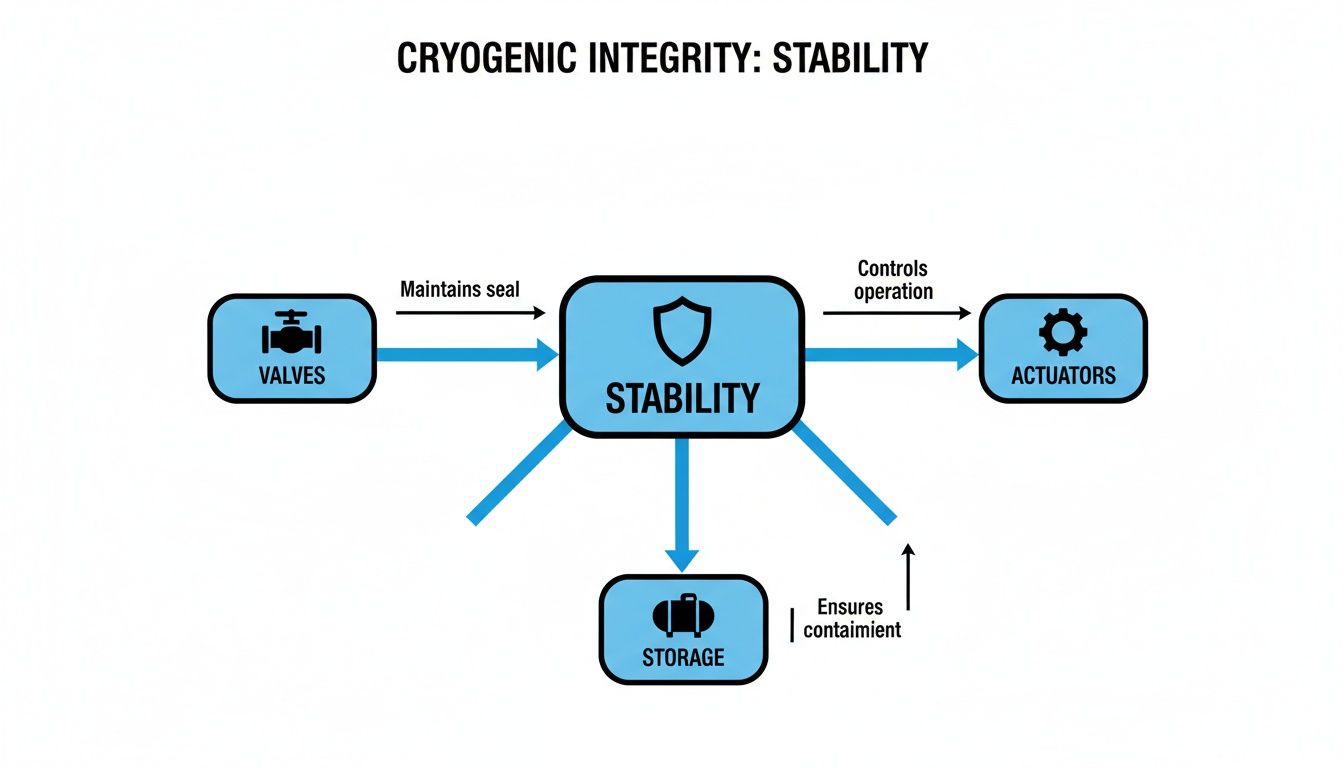

This simple flowchart shows how these core components—valves, actuators, and storage—work together to create unshakable system stability.

As you can see, true cryogenic integrity isn't about one single part. It’s about the seamless way they all interact. Each component is a pillar supporting the central goal: unwavering stability for your critical assets.

To make this even clearer, let's break down how each part of the Flowserve flow control system contributes to the whole. This synergy is what safeguards your valuable materials, whether you’re managing a hospital’s critical liquid nitrogen supply or protecting irreplaceable samples in a research laboratory freezer.

The following table simplifies this relationship, showing exactly what each piece does and why it matters for your Cryonos setup.

| Component | Analogy | Primary Function | Benefit for Cryonos Systems |

|---|---|---|---|

| Valves | Intelligent Gateways | To precisely open, close, or throttle the flow of liquid nitrogen. | Prevents temperature fluctuations and ensures exact dosing, protecting sample integrity. |

| Actuators | Powerful Muscles | To physically operate the valves based on electrical or pneumatic commands. | Provides the instant, reliable force needed for rapid response to system commands. |

| Instrumentation | Brain & Senses | To monitor system variables like temperature, pressure, and flow rate in real-time. | Delivers constant feedback, allowing for automatic adjustments to maintain perfect conditions. |

Ultimately, a complete system where valves, actuators, and instrumentation work in perfect harmony is far greater than the sum of its parts.

This integration transforms individual high-quality components into a single, reliable cryogenic ecosystem designed for maximum safety and efficiency.

The result is a system that doesn’t just perform a function—it does so with a level of precision that guards against even the smallest deviation. This is how the integrity of your cryogenic environment is maintained day in and day out, giving you the complete confidence you need to carry on with your work.

Theory is one thing, but seeing how Flowserve flow control solutions perform in the real world is where the rubber really meets the road. This technology isn’t just about tweaking gas and liquid flows; it's about delivering solid results in environments where precision is everything and the stakes are sky-high. Think of these systems as the unsung heroes working behind the scenes, making sure daily operations run smoothly, safely, and without a hitch.

Let's step into a modern biobank for a moment. Picture a Flowserve pressure control valve, perfectly integrated into a Cryonos AC FREEZER. This component is the quiet guardian of thousands, sometimes millions, of dollars worth of irreplaceable biological samples. Its entire job is to hold a rock-solid nitrogen vapour temperature, protecting these precious assets from even the smallest temperature swing that could spell disaster for their viability.

This isn't just a technical task—it's the very foundation of trust in the facility's ability to store these samples. For a lab manager, that level of reliability means guaranteed sample integrity, which is the bedrock of any successful research or clinical outcome. Every tiny adjustment the valve makes is a deliberate, calculated move to preserve years of hard work.

Now, let’s shift gears and look at the world of industrial gas transport. Imagine a Cryonos Micro Bulk tank being filled or emptied. Here, a different set of Flowserve control valves are putting in the work, ensuring liquid gases are transferred safely, quickly, and efficiently. These parts are built not just for raw performance but for navigating a maze of strict regulations.

In this context, the flow control system has to wrestle with high volumes and pressures while staying compliant with ADR (Agreement concerning the International Carriage of Dangerous Goods by Road) regulations. This ensures every litre of product gets from A to B safely, protecting personnel, the public, and the environment. Efficient flow control also means faster turnaround times, which cuts down on vehicle downtime and boosts logistical productivity. The precision of these valves is what optimises the entire supply chain.

The point of these real-world scenarios is simple: Flowserve technology is the bridge between sophisticated hardware and the results that actually matter to you—unwavering safety, streamlined efficiency, and total confidence in your processes.

At the end of the day, these examples show how engineered components directly impact the outcomes that define a successful day at work.

Whether it’s protecting cellular therapies or moving industrial gases, the core benefit is the same. The right flow control solution delivers the stability and reliability you need to focus on what you do best. In a way, the technology’s ability to maintain a perfect equilibrium is a lot like how a plate fin heat exchanger manages thermal transfer with incredible efficiency.

Picking the right flow control hardware isn't just a technical footnote; it's a decision that fundamentally shapes the safety, performance, and integrity of your entire cryogenic operation. But selecting the perfect Flowserve flow control solution for your specific needs doesn't have to be overwhelming. It really just boils down to understanding a few key factors about your application's unique demands.

This guide will walk you through the essential criteria. By matching the component's capabilities with your operational goals, you can build a system that is not only effective but also inherently safe and reliable for years to come.

First things first, we have to respect the extreme environment. Materials act completely differently at cryogenic temperatures. Something that's perfectly strong at room temperature can become as brittle as glass at -196°C. For handling liquid nitrogen, stainless steel and certain bronze alloys are the go-to choices because they hold their structural integrity without becoming dangerously fragile.

Flowserve cryogenic valves are engineered from the ground up with materials proven to handle these brutal conditions. Another critical design feature you'll notice is the extended bonnet. This clever design physically separates the valve packing and actuator from the ultra-cold fluid flowing through. It’s a simple but incredibly effective way to prevent the seals from freezing up—a common failure point in standard valves—ensuring your system operates consistently without leaks.

Once you've got the materials sorted, the next question is how much fluid you need to move. In technical terms, this is measured by the flow coefficient (Cv), which is just a fancy way of saying how much liquid can pass through the valve at a given pressure. It’s here that the needs of a biobank and an industrial gas transporter diverge completely.

Choosing the right Cv value is all about balancing speed with precision. It ensures your system is perfectly tuned for its main job, whether that's protecting delicate cells or moving bulk product as fast as possible.

Finally, think about the actuation type—how the valve actually opens and closes. For equipment you only adjust occasionally, a manual valve works just fine. But for automated systems like a Cryonos AC FREEZER, you'll need pneumatic or electric actuators. These integrate seamlessly with your control instruments, allowing for the kind of precise, automatic adjustments needed to maintain a perfect cryogenic environment around the clock. This final step aligns your component choice with your broader operational goals and safety protocols.

On their own, Flowserve components and Cryonos systems are at the top of their game in cryogenic engineering. But when you bring them together, something special happens. They create a unified, high-performance ecosystem where every piece works in perfect harmony, delivering reliability and operational intelligence that’s simply unmatched.

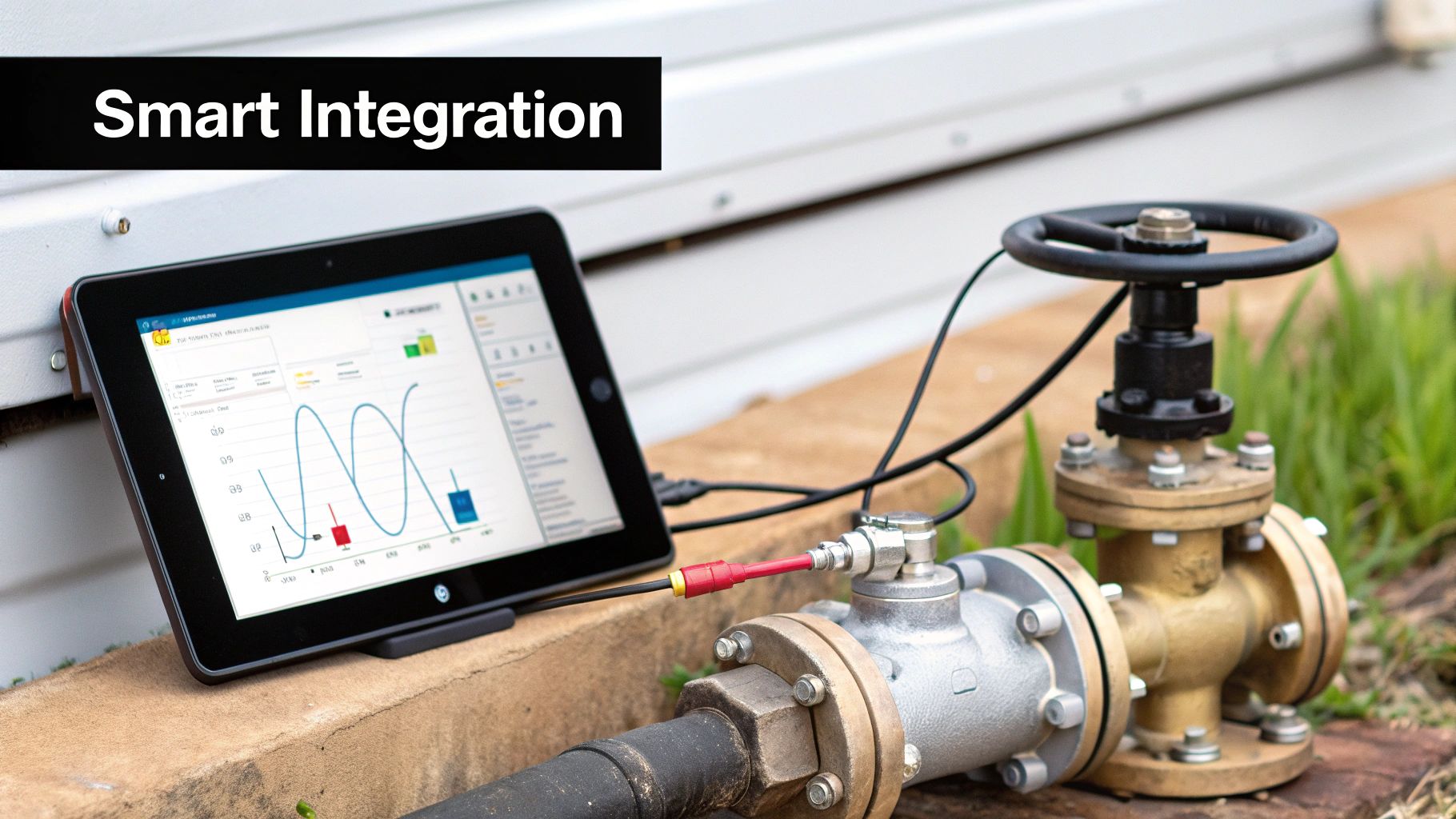

This is where your cryogenic system gets "smart". A Flowserve flow control valve fitted with modern IoT technology doesn't just open and close; it communicates. It can talk directly to a Cryonos vessel's inventory system, creating a seamless feedback loop between the hardware controlling the liquid nitrogen and the software that's watching over it.

This deep integration unlocks some seriously powerful capabilities. You get remote monitoring of your entire setup, giving you real-time visibility from practically anywhere. It also sets the stage for predictive maintenance, a strategy that pushes the already long service intervals of Cryonos systems even further by flagging potential issues before they can cause any downtime.

The real-world benefits of this partnership are immediate and significant. By creating a fully integrated network, you gain a level of control and automation that standalone components just can't offer. This connection transforms your cryogenic equipment into a responsive, self-regulating system that actively works to protect your assets and optimise your resources.

This synergy is particularly clear in Germany’s advanced IoT valves market, a key segment for cryogenic applications. The market was valued at 118.35 USD Million in 2022 and is expected to hit 265.56 USD Million by 2030. Flowserve is a leader here, especially with its pressure-independent control valves (PICVs), which are a perfect match for the stable pressure needs of Cryonos nitrogen vessels and cell transport units. You can find more details in this IoT valve market report from ResearchAndMarkets.com.

The result? An intelligent system built for unmatched reliability, efficiency, and total peace of mind, streamlining everything from laboratory work to industrial transport.

This smart integration gives you direct, practical advantages:

Of course, the connection between these systems isn't just about software. It also depends on rock-solid physical links, like a high-quality vacuum-insulated transfer hose, to make sure the physical transfer of cryogens is every bit as efficient as the data transfer.

Putting a cryogenic system in place is more than just the initial installation; it's a long-term commitment to reliable performance. When you look at the total cost of ownership, the tough engineering behind Flowserve flow control components really starts to pay off. Integrated into a Cryonos system, this quality means outstanding durability and much longer periods between maintenance checks.

This isn't just a happy accident. It's the direct result of careful design and using top-tier materials that are built to handle the intense cold of cryogenic environments, day in and day out. Because the components are so robust, they don't need constant attention, which cuts down on downtime and saves on operational costs over the system's entire life.

Even though Flowserve parts are built to last, a few simple, routine checks are the secret to getting the absolute most out of your Cryonos system. Staying ahead of any potential issues is the best way to keep everything running at peak efficiency.

Here are a few things to keep an eye on:

A well-maintained system isn't just more dependable—it's the backbone of your operational compliance. It helps you stay on the right side of regulations and keeps your people and your valuable assets safe.

In fields like biotechnology, pharmaceuticals, and industrial gas transport, there's no room for error when it comes to compliance. A certified and properly maintained Flowserve and Cryonos setup gives you the peace of mind that you're meeting these strict demands. This combination ensures your operations follow key industry standards, so you can be confident your processes are not just effective, but also completely safe and compliant.

Key certifications include:

When you're dealing with high-performance cryogenic systems, a few questions are bound to pop up. To give you some clarity, we've put together straightforward answers to the common queries we hear about using Flowserve flow control in these demanding environments. This should help clear things up and ensure you get the best from your setup.

Flowserve cryogenic valves aren't your run-of-the-mill, off-the-shelf parts. They are engineered specifically for the job, built from specialised materials like stainless steel that keep their strength and don't become brittle, even at a staggering -196°C (-320°F).

One of the smartest design features is the extended bonnet. Think of it as a long neck on the valve. This clever detail puts physical distance between the intensely cold liquid nitrogen and the valve's delicate seals and actuator. This separation is crucial—it stops everything from freezing solid, ensuring the valve works reliably and without leaks for years to come.

Precision is everything when it comes to efficiency, particularly with an expensive consumable like liquid nitrogen. By delivering only the exact amount of cryogen needed to hold a stable temperature, Flowserve control valves get rid of the costly problem of wasteful boil-off.

This optimised delivery prevents overcooling and drastically reduces your overall liquid nitrogen consumption. Over time, these savings in resources add up, significantly lowering your operational expenses.

Put simply, it means your investment works smarter, not harder.

While you can sometimes retrofit an existing system, getting that flawless performance and guaranteed reliability really comes from a fully integrated solution. When you start mixing and matching components, you can run into unexpected compatibility problems that might compromise the system's integrity and even its safety.

That's why we always recommend having a Cryonos technician take a look first. They can properly assess your current setup and design a complete, turn-key system where every part works in perfect harmony for optimal efficiency. This approach is also backed by our comprehensive five-year warranty and dedicated long-term support, giving you total peace of mind.

Ready to build a cryogenic system with unmatched reliability and efficiency? Explore custom-engineered solutions with Cryonos GmbH and discover how our integrated approach can safeguard your most valuable assets. Visit us at https://www.cryonos.shop to learn more.