No Products in the Cart

Liquid nitrogen isn't just cold; it's consistently, reliably, and profoundly cold. It boils at a constant -196°C (-320°F or 77 Kelvin), a physical benchmark that underpins its incredible power in science and industry. At this extreme temperature, the frantic dance of molecules slows to a near standstill, effectively putting biological processes on an indefinite pause.

When we talk about the liquid nitrogen temperature, we're referring to a fundamental physical constant. This isn't like the fluctuating temperatures inside a household freezer. As long as nitrogen stays in its liquid state, it holds this intensely cold temperature. It's a precise thermal threshold where the very rules of biology and material science begin to change.

Think of it as nature’s ultimate pause button. The extreme cold halts the metabolic processes that lead to cellular decay. This unique property is the very cornerstone of cryopreservation, allowing scientists and clinicians to store the building blocks of life—cells, tissues, and genetic material—for decades without any meaningful degradation.

The sheer reliability of -196°C has made it a universal standard in scientific research, medicine, and specialised industries. Because it's a constant, it allows for repeatable experiments and dependable long-term storage, whether you're in a lab in Berlin or a biobank in Boston. This stability is absolutely crucial for global collaboration in fields like cell therapy and biobanking.

Germany’s advanced biobanking sector, for instance, is built upon this precise temperature. With over 150 biobanks storing more than 50 million biological samples, maintaining viability isn't just important—it's everything. Facilities supported by specialists like Cryonos GmbH use this ultra-low temperature to prevent cellular breakdown. The results speak for themselves: research shows that samples preserved at -196°C retain 99.5% viability even after 10 years. That’s a world away from the 70% viability you might see in standard -80°C freezers. You can learn more about the findings on cryogenic preservation from this guide.

At its core, the liquid nitrogen temperature of -196°C is more than a number—it represents a state of suspended animation. It is the temperature at which time, for biological matter, effectively stops.

This section is just the starting point. Next, we'll explore exactly why this specific cryogenic temperature is so critical. We’ll look at how this unwavering cold enables groundbreaking work, from preserving the DNA of endangered species to advancing cutting-edge medical treatments, all built upon the simple, predictable physics of nitrogen at its boiling point.

So, what is it about the specific temperature of -196°C that makes liquid nitrogen the undisputed champion for preserving biological samples? It's not just about being incredibly cold; it's about crossing a critical scientific line that fundamentally changes how matter behaves on a molecular level. That line is called the glass transition temperature.

Think about what happens to the water inside a living cell when you cool it. As it gets colder, the water molecules slow down and eventually lock into place, forming ice crystals. These crystals are sharp, jagged, and absolutely catastrophic for the delicate structures inside a cell. They act like microscopic daggers, piercing membranes and shattering the very architecture of life. This is exactly what happens in a standard freezer, even a high-tech one that reaches -80°C.

But something incredible happens once you drop below roughly -135°C. At this point, the water molecules simply don't have enough energy left to arrange themselves into those destructive crystalline structures. Instead of freezing, the water undergoes vitrification.

Vitrification is the magic of turning a liquid into a glass-like, non-crystalline solid. Picture the difference between a snowflake (a highly structured crystal) and a windowpane (a disordered, amorphous glass). One is ordered and sharp, the other is solid but chaotic. By flash-cooling biological samples to -196°C, we blow right past the dangerous ice-formation zone and lock all the water into this safe, glassy state.

This process is like hitting a universal pause button on biology. At the -196°C temperature of liquid nitrogen, every single metabolic and enzymatic process that causes cellular decay grinds to a complete halt. There is no ageing. No degradation. No change whatsoever.

"Cryopreservation at -196°C isn't just about slowing down decay; it's about stopping it in its tracks. By preventing the formation of damaging ice crystals and shutting down all metabolic activity, we achieve a true state of suspended animation."

This is precisely why a standard -80°C freezer, while certainly very cold, just isn't up to the task for genuine long-term preservation. Over months and years at -80°C, microscopic ice crystals can still form and grow—a process known as recrystallisation—inflicting slow but certain damage. For irreplaceable materials like stem cells, reproductive tissues, or vital biological samples, this gradual decay is simply not an option.

The gap between -80°C and -196°C might look like just another number on a thermometer, but in the world of cryobiology, it’s the difference between temporary storage and truly indefinite preservation.

Choosing -196°C isn't an arbitrary preference; it's a decision grounded in the fundamental physics of water and biology. It's the only way to ensure that when a sample is finally 'unpaused'—whether for medical research, fertility treatment, or scientific discovery—it’s in the exact same condition as the day it was preserved.

The unwavering temperature of liquid nitrogen provides the only reliable environment to achieve this state of true suspended animation. This gold standard guarantees that the building blocks of life are kept perfectly intact, ready for the future without the silent threat of degradation that haunts higher-temperature storage. For any serious laboratory or biobank, that level of reliability is everything.

When you're setting up cryogenic storage, one of the first big decisions is whether to keep samples submerged directly in liquid nitrogen or suspended just above it in the ultra-cold vapour. This isn't just a technicality; it's a crucial choice that forces you to weigh up absolute temperature consistency against the risk of cross-contamination. Each method has its own clear advantages, making them suitable for different labs and different priorities.

The right call really hinges on what you’re storing, your lab’s protocols, and your overall tolerance for risk. At its core, the difference is between direct contact and indirect cooling, which brings entirely different considerations for temperature stability and sample integrity to the table.

Liquid phase storage is exactly what it sounds like: sample racks are completely immersed in liquid nitrogen. The main draw here is impossible to argue with: absolute temperature uniformity. Every single sample in the tank is held at a rock-solid -196°C, which is the boiling point of LN2. You simply don't have to worry about temperature gradients or warmer spots.

This approach guarantees that all your samples stay far below the critical glass transition temperature of around -135°C, ensuring they are fully vitrified and all biological activity has ground to a halt. For this reason, it has long been the go-to method for robust or less critical samples where locking in the coldest possible temperature is the number one goal.

But, this direct contact does come with a small but very real risk. If a vial is sealed improperly or happens to crack, its contents could leak out into the shared liquid nitrogen. This opens up a potential pathway for cross-contamination, where pathogens could theoretically travel from one compromised sample to others in the same dewar.

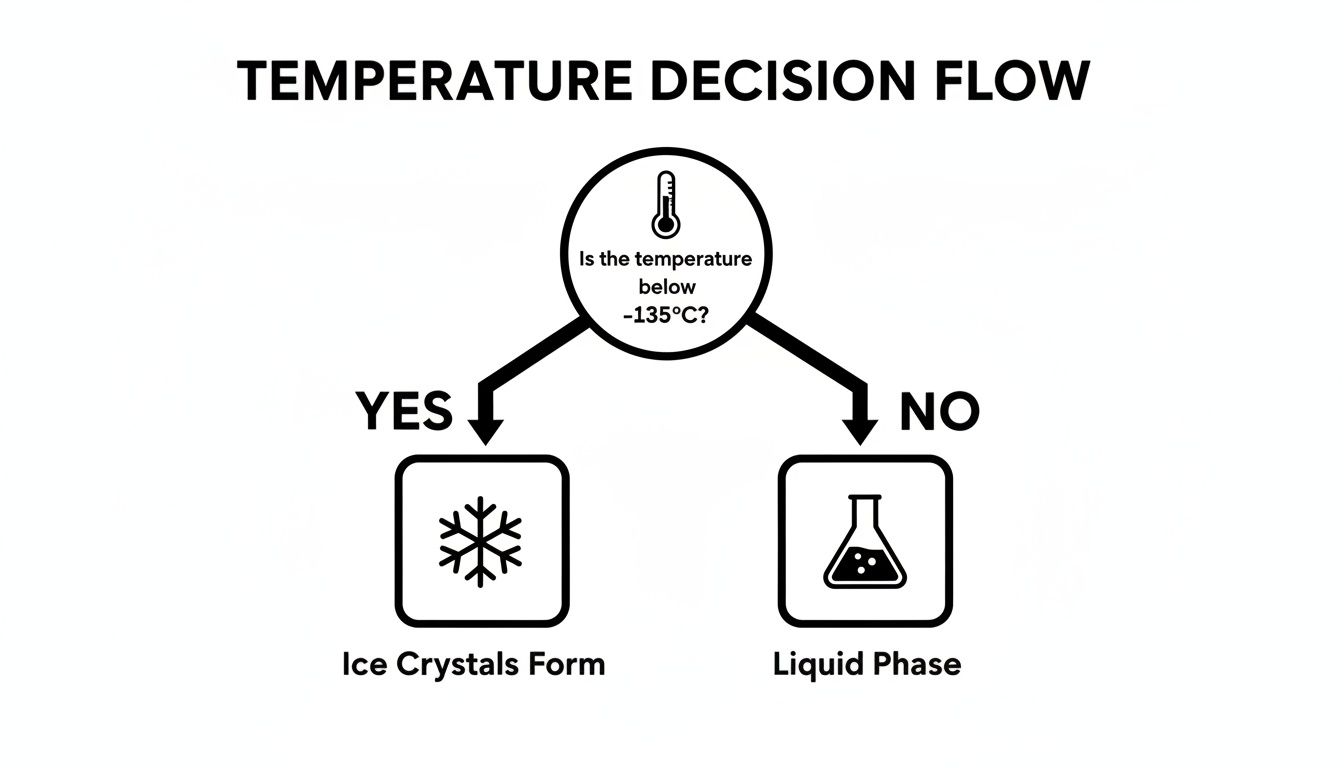

This flow chart helps to visualise why staying below that critical -135°C threshold is so important—a guarantee you get with liquid phase storage.

As you can see, keeping temperatures below -135°C is the only way to prevent damaging ice crystals from forming and ensure your samples are truly preserved for the long haul.

Vapour phase storage was developed for one primary reason: to eliminate that risk of cross-contamination. In this setup, a reservoir of liquid nitrogen sits at the bottom of the freezer, but the samples themselves are stored above it, suspended in the intensely cold nitrogen gas (or vapour) that boils off. This creates a physical separation from the liquid, completely removing any chance of contaminants spreading between samples.

The temperature in the vapour phase isn't a uniform -196°C. Instead, you get a temperature gradient, typically ranging from -190°C at the bottom (just over the liquid) to about -150°C at the very top of the storage space. While it's slightly warmer than the liquid phase, these temperatures are still safely below the glass transition point, making it an excellent and widely adopted method for high-value or irreplaceable samples, like those used in cell therapy and IVF clinics.

The main challenge with vapour phase systems is managing that temperature gradient. It demands careful monitoring and relies on high-quality, modern freezer designs engineered to keep temperature fluctuations to a minimum, especially when the lid is opened.

For irreplaceable or clinically sensitive materials, vapour phase storage has become the industry standard. It offers the best of both worlds: temperatures cold enough for indefinite preservation and complete isolation from cross-contamination risks.

To bring it all together, let’s compare the two methods side-by-side.

| Feature | Liquid Phase Storage | Vapour Phase Storage |

|---|---|---|

| Temperature | Uniform and constant at -196°C. | A gradient, from approx. -190°C to -150°C. |

| Contamination Risk | Low, but a non-zero risk of cross-contamination if a vial leaks. | Virtually zero risk of cross-contamination between samples. |

| Best For | Robust, lower-value samples, or when absolute lowest temp is critical. | High-value, irreplaceable, or clinical-grade samples. |

| Key Advantage | Unbeatable temperature stability and consistency. | Maximum sample safety and integrity. |

| Consideration | Requires carefully sealed, high-quality vials to mitigate risk. | Needs a well-designed freezer and monitoring to manage the temperature gradient. |

Ultimately, the choice comes down to a risk-benefit analysis based on your lab's specific needs. Consider these points:

Germany's cryogenic market, a major player in Europe, reflects these very considerations. Driven by liquid nitrogen's stability, the market saw a 4.2% CAGR from 2020-2025, hitting €450 million in 2024. Biobanks and cell therapy labs, which prioritise sample integrity above all else, account for 35% of this usage. A 2023 DFG-funded study drove this point home, highlighting that at -196°C, samples show zero metabolic activity, preserving DNA integrity at 99.8% over 20 years. This is a stark contrast to the 85% integrity seen at -135°C. This data underscores why choosing the right storage phase is so critical for the 15,000+ gene therapy projects currently active.

By understanding both methods inside and out, you can align your storage strategy perfectly with your scientific goals and operational needs. For a deeper dive, you can find further guidance on choosing the right cryogenic cell storage solution in our detailed guide.

While we often associate the -196°C chill of liquid nitrogen with pausing life in a biobank, its power in the industrial world is just as remarkable. Away from the quiet of the lab, this extreme cold becomes a powerful tool for shaping materials, streamlining manufacturing, and even making our food better. It’s less a preservative and more of an industrial workhorse, solving tough engineering problems that heat or force just can't handle.

This incredible cold gives engineers a unique advantage: the ability to temporarily change a material's physical properties. Metals shrink, plastics become brittle enough to shatter, and soft materials turn hard as rock. These changes, even though temporary, unlock a whole new set of possibilities for precision and efficiency across a surprising number of industries.

One of the most clever uses for liquid nitrogen is shrink-fitting. It's a technique for creating incredibly tight mechanical joints without a single weld or fastener. The process itself is wonderfully straightforward: an inner part, like a bearing or a shaft, gets a bath in liquid nitrogen. The intense cold makes the metal contract just enough.

While it's chilled and slightly smaller, the part slips easily into its housing. As it warms back up to room temperature, it expands with immense force, creating a powerful, perfectly uniform pressure fit. This bond is often stronger and far more reliable than a weld. You'll find this method used everywhere from aerospace to automotive manufacturing—places where a component failure simply isn't an option.

Think of it like a perfectly tailored suit. Instead of forcing a fit, you temporarily resize the material so it assembles effortlessly. Once it returns to its normal state, you're left with a flawless, permanent bond.

Ever tried to grind something soft, oily, or sticky, like a gummy candy or a spice? At room temperature, it just turns into a smeared, clumpy mess, making it impossible to get a fine powder. That's where cryogrinding steps in. By dousing these materials in liquid nitrogen, they become incredibly brittle.

This newfound brittleness means they can be pulverised into ultra-fine, consistent powders. It’s a technique that has become essential for several industries:

The food industry also leans heavily on the rapid cooling power of liquid nitrogen. When you freeze food slowly in a home freezer, large, jagged ice crystals form. These crystals puncture cell walls and ruin the texture—it’s why a thawed strawberry often turns into a mushy disappointment.

Flash-freezing with liquid nitrogen is a different world entirely. By dipping food into LN2 or spraying it, the product freezes almost instantly. This incredibly fast process creates minuscule ice crystals that don't damage the cellular structure. The result? The food's original texture, flavour, and nutrients are perfectly preserved. From high-end restaurants making instant ice cream to large-scale processors freezing delicate berries and seafood, the frigid liquid nitrogen temperature locks in premium quality all the way from the freezer to your plate.

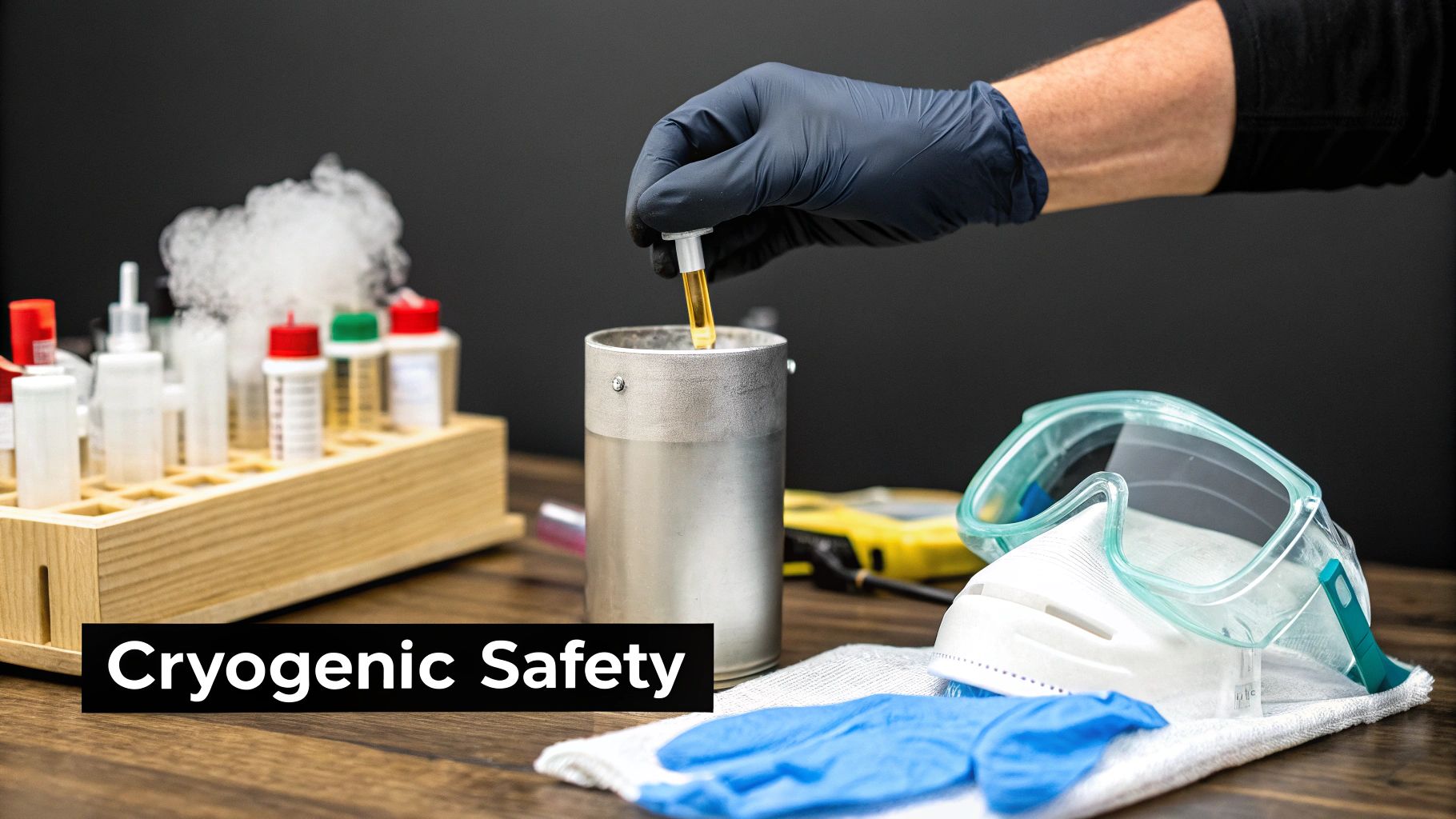

When you're working with something colder than the most brutal Antarctic winter, you need more than just a bit of caution. You need a deep, healthy respect for its power and an unwavering commitment to safety protocols. The extreme liquid nitrogen temperature of -196°C is an incredible tool, but it introduces serious hazards if you get complacent.

For any lab or industrial setting, understanding and managing these risks isn't just a good idea—it's completely non-negotiable.

The dangers of liquid nitrogen really boil down to three main categories. Each one is a distinct and serious threat, which is why a comprehensive safety strategy is so essential for protecting your team and your valuable materials.

The first and most immediate danger is severe cryogenic burns, which is essentially instant frostbite. Even a single splash of liquid nitrogen on exposed skin causes immediate tissue damage, far worse than a typical burn from heat. The intense cold freezes tissue on contact, killing cells and potentially causing permanent injury.

Next up is the risk of asphyxiation, a silent but deadly threat. As liquid nitrogen boils off, it expands at an incredible rate—one litre of liquid turns into nearly 700 litres of nitrogen gas. In a room without good ventilation, this colourless, odourless gas can quickly push out all the oxygen, leading to unconsciousness within minutes.

Finally, over-pressurisation creates an explosive hazard. Never, ever store liquid nitrogen in a sealed, non-vented container. As the liquid inevitably warms and turns back into a gas, the pressure inside the container builds to catastrophic levels, effectively turning the vessel into a projectile.

Your first line of defence against the intense liquid nitrogen temperature is the right Personal Protective Equipment (PPE). This is absolutely not the place to cut corners; your standard lab gear won't do the job.

Essential Cryogenic PPE includes:

Proper PPE isn't just a recommendation; it's the barrier that stands between you and a life-altering injury. Never handle liquid nitrogen without wearing the complete, appropriate set of gear.

Beyond what you wear, the work environment itself needs to be engineered for safety. This starts with robust ventilation anywhere liquid nitrogen is used or stored. Often, mechanical ventilation systems are required to stop nitrogen gas from building up.

An indispensable tool for any cryogenic storage room is an oxygen monitor. These devices constantly measure the oxygen level in the air and will sound an alarm if it drops to an unsafe concentration, typically below 19.5%. They provide a crucial early warning against the invisible threat of asphyxiation.

Proper container management is just as vital. By combining the right PPE with smart facility design and disciplined procedures, the formidable power of -196°C can be managed safely and effectively. For a detailed checklist, you can review our guide on the 7 important rules for safe work with cryogenic liquids.

Getting your samples down to a stable -196°C liquid nitrogen temperature is really just the beginning. The real challenge? Keeping them there. Protecting invaluable biological samples isn't a "set it and forget it" task—it's an active process that relies on a solid combination of robust monitoring and proactive equipment maintenance to head off disaster.

This constant oversight is non-negotiable. Why? Because even the most advanced cryogenic vessels can fail, or simply run out of liquid nitrogen. A slow, silent rise in temperature can quietly destroy years of research or irreplaceable clinical materials before anyone even notices.

The days of walking up to a freezer with a simple probe for manual temperature checks are long gone. Today's monitoring solutions are all about providing continuous, real-time data, ensuring your samples stay safely below that critical glass transition temperature. The whole point is to catch small deviations long before they snowball into a catastrophe.

Modern systems give you multiple layers of protection, from basic alarms right next to the unit to sophisticated notifications sent straight to your phone.

Constant monitoring is the ultimate insurance policy for your cryogenic assets. It transforms cryopreservation from a process of hope into one of certainty, providing peace of mind that your samples are always secure.

All the monitoring in the world won't help if the equipment itself isn't up to snuff. Your first line of defence against temperature swings is a high-quality storage vessel. Choosing a dewar or freezer with a low static evaporation rate is a smart move; it not only boosts stability but also reduces how much nitrogen you burn through, saving money in the long run.

A proactive maintenance schedule is just as vital. Regularly checking the vacuum integrity, inspecting the seals, and making sure pressure-relief devices are working as they should can prevent the vast majority of common equipment failures. Combining top-tier gear with a rigorous maintenance plan is the bedrock of good practice. For a deeper dive into all the best practices, check out our complete guide on how to manage your cryogenic storage.

Ultimately, holding that perfect liquid nitrogen temperature comes down to a dynamic partnership between good technology and solid procedures. By investing in reliable monitoring tools and committing to regular upkeep, you build a fortress of cold around your invaluable biological materials, ensuring they can remain perfectly preserved for decades. This disciplined approach guarantees that the unwavering cold of -196°C continues to protect your work without missing a beat.

To wrap things up, let's tackle some of the most common questions people have about liquid nitrogen temperatures. Getting these details right is crucial for proper storage, safety, and managing your equipment.

Theoretically, forever. At the frigid temperature of -196°C, all the metabolic activity that causes biological samples to break down grinds to a complete halt. This is far below the critical "glass transition" point of around -135°C, effectively pausing cellular ageing.

Scientific studies back this up, showing that cells and even complex tissues are perfectly viable after decades in deep-freeze storage. The real-world limits aren't about the temperature itself, but rather the quality of your initial freezing process and how well your storage tank holds up over the long haul.

If the liquid nitrogen runs out, the internal temperature will start to climb—there's no way around it. How fast this happens depends entirely on the quality of your freezer's insulation, which is measured by its static evaporation rate.

A top-tier, well-insulated vessel is engineered to keep temperatures safely in the cryogenic range for several days, sometimes even weeks, without a refill. Think of it as a built-in safety buffer against a catastrophic loss of your samples. This is precisely why having reliable temperature monitors and alarm systems is non-negotiable.

Once the temperature creeps above -135°C, you’re in the danger zone. Your samples are now at high risk of irreversible damage from destructive ice crystals forming inside the cells.

Yes, and the difference is massive. Medical-grade liquid nitrogen is held to incredibly strict purity standards, typically >99.9% pure. It's produced and handled following protocols that prevent any contamination, making it safe for anything involving sensitive biological samples.

Industrial-grade nitrogen, on the other hand, doesn't have the same quality control. It can contain impurities that, while harmless in a factory setting, could be disastrous for cryopreservation. Using it for clinical, research, or biobanking applications is a non-starter if you want to maintain the integrity and safety of your samples.

For state-of-the-art cryogenic solutions designed for maximum safety and reliability, Cryonos GmbH offers a full portfolio of equipment to protect your valuable samples. Ensure your storage meets the highest standards by exploring our systems at https://www.cryonos.shop.