No Products in the Cart

At its core, a flüssig sauerstoff tank (liquid oxygen tank) is essentially a highly sophisticated thermos flask, purpose-built for storing oxygen in its incredibly dense liquid form. By chilling gaseous oxygen down to a cryogenic temperature of -183°C, its volume shrinks dramatically. This makes it far more efficient to store and transport compared to bulky, traditional gas cylinders.

To really get your head around the importance of a flüssig sauerstoff tank, just think about the difference between a cloud of steam and a glass of water. They're both H₂O, but the water is obviously much more compact. Liquid oxygen (LOX) technology works on the exact same principle, transforming huge volumes of oxygen gas into a manageable, dense liquid. This simple concept allows a facility to keep a massive oxygen supply on-site within a surprisingly small footprint.

The magic behind this is cryogenic insulation. A liquid oxygen tank isn't just a container; it's a precision-engineered vessel designed to win the battle against heat. Without top-notch insulation, the frigid liquid oxygen would quickly boil back into a gas and disappear, making long-term storage impossible.

The secret to the tank's incredible performance is its construction, which is very similar to a high-end thermos. It features two separate vessels—one nested inside the other—with a near-perfect vacuum in between.

This vacuum layer is the heart of the thermal insulation. Since there are almost no air molecules in that space, heat from the outside world struggles to transfer to the inner vessel holding the liquid oxygen. This clever design dramatically slows the rate at which the LOX absorbs heat, keeping the natural evaporation process, or "boil-off," to an absolute minimum. A well-made flüssig sauerstoff tank can hold LOX for weeks with very little loss, guaranteeing a steady and reliable oxygen supply.

Before we go further, it’s useful to see just how much more efficient this method is.

This table offers a quick comparison, showing why storing oxygen as a liquid is often the better choice for high-volume users.

| Feature | Liquid Oxygen (LOX) | Compressed Gaseous Oxygen |

|---|---|---|

| Storage Density | Extremely high; stores vast quantities in a small space. | Low; requires many large, heavy cylinders for the same amount. |

| Footprint | Compact, single tank installation. | Large area needed for cylinder racks and storage. |

| Pressure | Low pressure (typically 5-15 bar). | Very high pressure (up to 200 bar or more). |

| Handling | Minimal; supply is continuous from a stationary tank. | Labour-intensive; constant swapping of heavy cylinders. |

| Supply Continuity | Uninterrupted flow, ideal for continuous use. | Risk of supply gaps during cylinder changeovers. |

| Cost-Effectiveness | More economical for large-scale, consistent demand. | Can be cheaper for very low or intermittent usage. |

As you can see, for any operation that can't afford interruptions or doesn't have endless space, the liquid option is a clear winner.

Of course, while storing oxygen as a liquid is efficient, most applications need it as a gas. A flüssig sauerstoff tank comes equipped with an internal system to handle this conversion whenever it's needed. This system usually includes:

This all-in-one system makes a flüssig sauerstoff tank a complete, self-sufficient supply solution. You get the high-density storage benefits of a liquid with the ready-to-use convenience of a gas.

Key Takeaway: A liquid oxygen tank uses vacuum insulation to store oxygen at cryogenic temperatures. This drastically cuts down its volume, making it the best choice for places needing large, continuous oxygen supplies, like hospitals, industrial fabrication shops, and research labs. The ability to efficiently store LOX and convert it to gas on demand is what makes this technology so indispensable.

Choosing the right flüssig sauerstoff tank isn’t about finding the “best” one available, but the best one for your specific job. A mobile healthcare provider and a huge industrial fabrication plant are worlds apart in their needs, so understanding the distinct categories of tanks is the first real step toward making a smart investment.

Each type is engineered to solve a different operational puzzle, striking a careful balance between capacity, portability, and pressure. Let's break down the main players to see which solution truly fits your work.

Portable liquid oxygen tanks, often called "dewars," are built for one thing above all else: mobility. These compact, relatively lightweight vessels are the go-to standard for home oxygen therapy, giving patients the freedom to live their lives without being tethered to a single spot.

They hold just enough liquid oxygen for a continuous flow over several hours. The design intentionally sacrifices long-term storage for portability, making them easy to carry or wheel around. Refills are typically handled from a larger, stationary reservoir unit installed right in the patient's home.

Beyond personal use, you’ll find these smaller tanks in emergency medical services and clinics—anywhere a quick, mobile oxygen source is a must-have. Their simple operation and small footprint are perfect for situations where every second and every square centimetre counts.

This category is the versatile middle ground, hitting the sweet spot for research labs, small manufacturing workshops, and specialised clinical settings. These cylinders are a big step up from portable units, with capacities often falling between 160 to 240 litres.

While you wouldn't want to carry them around daily, they are still "man-portable" and can be easily moved around a facility on a trolley. They offer a massive advantage in volume over standard compressed gas cylinders, which means fewer deliveries and less time spent swapping out heavy bottles.

A key feature here is the integrated pressure-building coil and vaporiser. This clever internal system lets the tank deliver a steady supply of gaseous oxygen at a stable, adjustable pressure, making it a complete, self-contained solution.

Think of a university research lab using a 200-litre liquid cylinder to supply several workstations. They get the high-purity, uninterrupted flow they need for sensitive experiments. In the same way, a welding shop can count on one of these cylinders to power its cutting torches without the constant downtime of changing out gas bottles.

Cryonos liquid cylinders are engineered for exactly these kinds of jobs. With superior insulation to keep evaporation to a minimum and rugged construction, they deliver a reliable, on-demand gas supply that makes mid-scale operations run much more smoothly.

When your oxygen demand is high and constant, bulk storage systems are the only way to go. These large, stationary tanks are the lifeblood of hospitals, industrial gas suppliers, and major manufacturing plants. Capacities can start around 1,000 litres for a "micro-bulk" system and go all the way up to over 50,000 litres for full-scale bulk tanks.

These are permanent installations, typically set on a concrete pad outside the main facility and plumbed directly into the building's internal gas piping network. Their job is to act as an enormous reservoir, guaranteeing an unwavering supply that can last for days or even weeks at a time.

Ultimately, picking a flüssig sauerstoff tank comes down to your operational scale and how critical an uninterrupted supply is. Whether you need mobility for individual care, a flexible on-site supply for a workshop, or a massive reservoir for an entire hospital, there’s a cryogenic solution designed to meet the challenge.

When you're evaluating a flüssig sauerstoff tank, you’re looking at more than just its size. You’re assessing a piece of precision engineering where specific metrics directly impact performance, safety, and what it’s going to cost you to run long-term. Getting a handle on these specs is the only way to make an informed choice that actually fits what your facility needs.

Think of it like buying a car. You wouldn't just look at the colour; you'd be checking the engine power, fuel efficiency, and how much it can carry. In the same way, the data sheet for a liquid oxygen tank tells a story about its efficiency and whether it’s the right tool for the job, whether that’s a high-tech lab or a busy industrial workshop.

One of the first numbers you'll come across is the Maximum Allowable Working Pressure (MAWP). This isn't just a friendly suggestion; it's the absolute highest pressure the tank is certified to operate at safely. It’s a critical benchmark for both performance and safety, set in stone by the manufacturer.

Different jobs have different pressure needs. For example:

Picking a tank with the right MAWP is vital. If the pressure rating is too low, it simply won't be able to supply your equipment. Go too high, and you might just be paying for capability you'll never use. The goal is to match the tank’s power precisely to the tools and processes it will support.

A tank's MAWP is its absolute pressure limit, determined by its design, materials, and construction. Pushing past this point is dangerous. It can trigger safety relief valves, leading to product loss and creating potential hazards.

This is probably the single most important factor affecting your long-term costs: the Static Evaporation Rate. You'll also see it called Static Holding Time or the boil-off rate. Because liquid oxygen is cryogenically cold, it’s always soaking up a tiny bit of heat from its surroundings. This causes a small, constant amount of liquid to turn back into gas and vent away.

This rate is a direct measure of how good the tank's insulation is. A lower evaporation rate means better vacuum insulation, which means you lose less product over time. It's usually measured as a percentage of volume lost per day (like 1.5% per day). A tank with a low boil-off rate is like a premium thermos that keeps your coffee piping hot for hours, while a poorly insulated one is like a paper cup.

Over the life of a tank, even a tiny difference in this rate adds up to significant savings. You'll buy less liquid oxygen just to make up for these natural losses, which directly cuts your operating budget. This push for efficiency is a big deal in the industry. The global industrial oxygen market is projected to hit USD 119.90 billion by 2033, and liquid oxygen is expected to grab a dominant 57% share, highlighting just how much everyone relies on high-performance cryogenic tanks. You can find more details on the industrial oxygen market's growth over at SNS Insider.

Finally, let’s talk about what these tanks are made of. The materials used to build a flüssig sauerstoff tank are chosen specifically for their ability to handle extreme conditions. The inner vessel, which is in direct contact with liquid oxygen at -183°C, has to stay strong and flexible without becoming brittle. If you want to dive deeper into the science, check out our guide on the temperature of liquid oxygen in our article.

This is why special grades of stainless steel are the gold standard for cryogenic work. These alloys are engineered to keep their structural integrity at ridiculously low temperatures, preventing fractures and ensuring the tank remains safe and reliable for the long haul. The outer vessel, while not getting quite as cold, still needs to be tough enough to protect the vital vacuum space from any physical damage. When you choose a tank built with high-quality, certified materials, you're investing in a safer, more durable asset for your entire operation.

Working with a flüssig sauerstoff tank demands a healthy respect for the material and an unwavering commitment to safety protocols. One of the most common—and dangerous—misconceptions about liquid oxygen (LOX) is that it's flammable. It’s not. Instead, it’s a powerful oxidiser, which means it can make other materials ignite far more easily and burn with frightening speed and intensity.

Think of it like this: trying to light a damp log is a struggle. But what if that same log were suddenly bone-dry and doused in something that made fire burn hotter and faster? That's the effect LOX has on its surroundings. This single distinction is the bedrock of every LOX safety procedure. The goal isn't to stop the oxygen itself from burning, but to prevent it from turning a tiny spark into a major inferno.

When you're dealing with something at -183°C, your first and most important line of defence is your Personal Protective Equipment (PPE). Handling LOX without the right gear is a fast track to a serious injury. This equipment is absolutely non-negotiable:

This gear isn't just a recommendation; it's the bare minimum for anyone working near a flüssig sauerstoff tank during filling, transport, or maintenance.

One of the most subtle but serious dangers is oxygen enrichment. As liquid oxygen evaporates, it creates a pocket of air with a much higher oxygen concentration than the 21% we normally breathe. In this oxygen-rich bubble, flammable materials become incredibly volatile.

A simple spark from a dropped tool or a bit of static electricity—something you wouldn't think twice about in normal air—can trigger a violent fire. This is exactly why proper ventilation is not just important, it's absolutely critical.

Safety Mandate: Any area where liquid oxygen is stored, handled, or used must have excellent ventilation. Never, ever work with LOX in a confined space. Leaking gas can displace normal air, creating an invisible and extremely dangerous hazard.

To further reduce the risks, you must establish and enforce a strict exclusion zone around any flüssig sauerstoff tank.

By understanding and internalising these principles, you create a robust culture of safety. For a deeper dive, check out our guide on the 7 important rules for safe work with cryogenic liquids, which offers more crucial insights. These protocols are more than just rules in a manual; they are the actions that ensure every single operation with liquid oxygen ends safely.

If your organisation is based in Germany, handling a flüssig sauerstoff tank means following strict regulations isn't just a good idea—it's the law. These rules are non-negotiable and form the bedrock of operating safely and legally. The guidelines for transporting and using liquid oxygen are incredibly precise, all designed to ensure safety on public roads and absolute purity in medical settings.

It's helpful to see these regulations not as bureaucratic hurdles, but as critical safety nets. They exist to protect your team, patients, and the general public. Let's break down the two main pillars of compliance you'll need to master: the ADR rules for transport and the BfArM standards for medical applications.

Whenever liquid oxygen (classified as UN 1073) hits the road, it falls under the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR). These aren't local suggestions; they're internationally recognised and legally binding rules that spell out exactly how cryogenic liquids must be moved.

ADR compliance is a system of interlocking parts, all working together to guarantee safety from the filling station to the final destination.

Here are the key ADR requirements you can't ignore:

Crucial Insight: The most straightforward path to compliance? Using a pre-certified, ADR-compliant vessel, like the ones offered by Cryonos. It takes all the guesswork out of the equation and ensures your equipment meets every legal standard for road transport from day one.

While they are chemically identical, the law treats medical-grade and industrial-grade oxygen very differently. The difference isn't the O₂ molecule itself, but the intense quality control and documentation demanded for anything that will be administered to a patient. This is where the German Federal Institute for Drugs and Medical Devices (Bundesinstitut für Arzneimittel und Medizinprodukte, BfArM) steps in.

BfArM classifies medical oxygen as a medicinal product. That means it's subject to the same strict oversight as any prescription drug.

This involves three critical areas:

Germany's thorough regulatory framework has made it a cornerstone of Europe's medical gas supply. This expertise is clear in its export numbers; back in 2019, Germany exported medical oxygen worth USD 8.28 million. This leading position highlights the nation's deep commitment to quality and compliance. For a more detailed breakdown of gas cylinder transport rules, check out our guide on transporting gas cylinders.

Picking the right flüssig sauerstoff tank is about more than just your immediate needs; it’s about making a smart decision for the long run. You're essentially matching the tank's capabilities to your specific world, whether that's a bustling university lab, a critical care hospital, or an industrial fabrication shop. Get it right, and you have a reliable, compliant, and cost-effective cryogenic solution.

This means looking past the initial price tag and thinking about the total cost of ownership. Things like maintenance schedules, warranty coverage, and how easy it is to get spare parts are just as vital as capacity or pressure ratings. A well-chosen tank becomes a dependable workhorse, not a source of constant headaches.

First things first: you need a solid grasp of your oxygen consumption. If you overestimate, you’re just tying up capital in a tank that's too big and losing more product to natural evaporation. But underestimate, and you're stuck with frequent, expensive refills and the constant risk of running dry at a crucial moment.

To nail it down, you need to look at both your peak and average daily usage.

A quality cryogenic vessel is a long-term investment. What you really pay over the tank's lifespan goes far beyond the initial sticker price. A solid warranty, like the five-year warranty offered on Cryonos vessels, is invaluable—it gives you peace of mind and protection from unexpected defects.

Just as important is the availability of spare parts. A tank is only as good as its valves, gauges, and safety devices. Knowing you can easily get replacements for years to come is what separates a good supplier from a great one and prevents costly downtime.

Expert Insight: The total cost of ownership is a mix of the initial purchase, ongoing operational costs (including losses from evaporation), and maintenance. A tank with a superior evaporation rate and strong warranty support will almost always prove more economical over its entire service life.

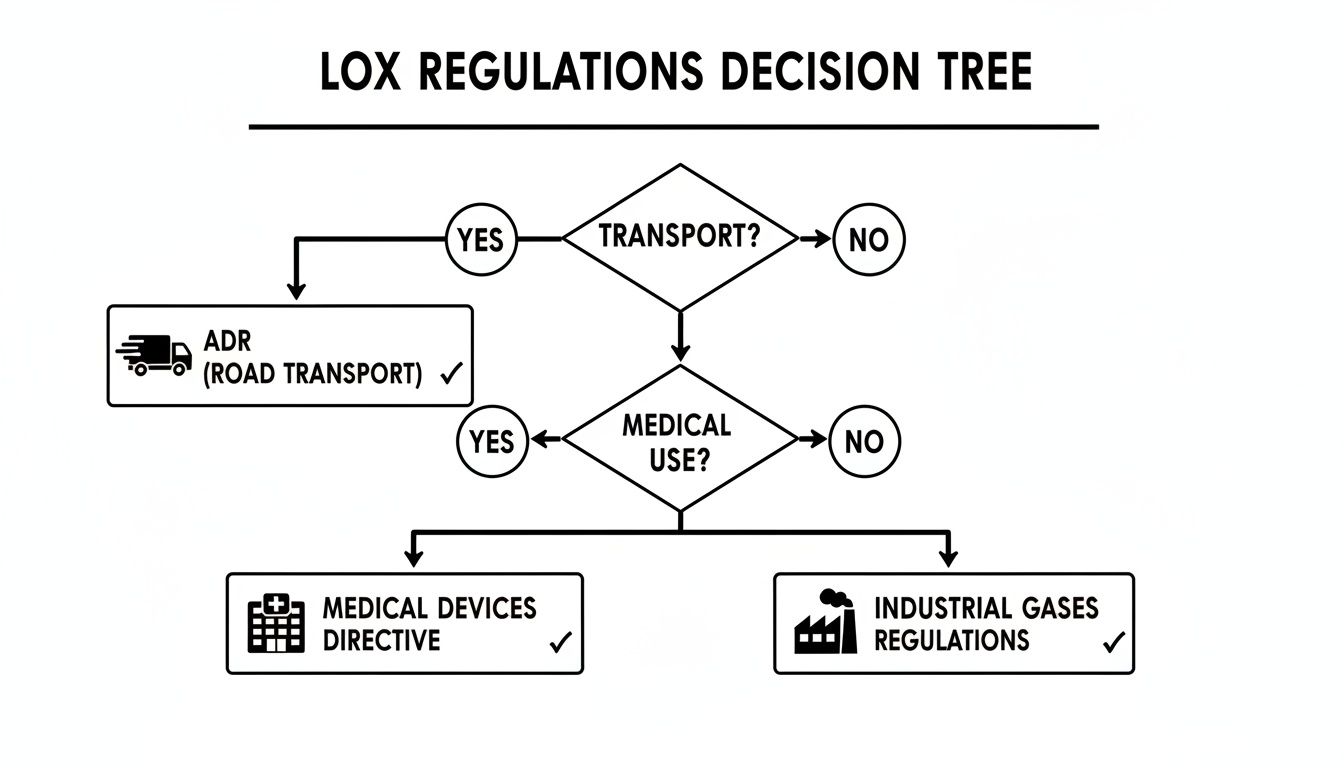

Navigating the web of regulations for transport and medical use is another crucial piece of the puzzle. This infographic breaks down the main compliance pathways to make it a bit simpler.

As the decision tree illustrates, if you're moving the tank, ADR compliance is mandatory. For any medical applications, you must follow specific healthcare standards.

The strong demand for these systems is clear from the market's size alone. The German liquid oxygen and respiratory devices market was valued at around USD 794.87 million, largely fuelled by oxygen-heavy industries like steel and chemical manufacturing. You can discover more insights about the liquid oxygen market drivers and see how they affect your own industry. By carefully weighing your demand, long-term costs, and regulatory duties, you can choose the perfect flüssig sauerstoff tank with confidence.

When you start looking into cryogenic solutions, it's natural for questions to pop up about the day-to-day realities of using a flüssig sauerstoff tank. Here are some straightforward answers to the questions we hear most often, designed to help you feel confident in your decisions.

How long your liquid oxygen supply holds up really comes down to three things: the size of your tank, how good its insulation is, and how quickly you're using the oxygen.

A top-quality stationary tank can keep LOX for several weeks with very little loss from natural evaporation. A portable medical unit, on the other hand, might only last a few hours or a couple of days—it all depends on the patient's prescribed flow rate.

The number to watch here is the Static Evaporation Rate. This tells you the percentage of product that boils off each day. A tank with superior vacuum insulation will have a lower rate, which means it holds its contents longer and saves you money over time.

It’s a common question, and the answer isn't about the oxygen molecule itself. The real difference lies in the incredibly strict purity standards and regulatory hoops required for medical use.

Medical oxygen is officially classified as a drug by authorities like Germany's BfArM. This means it must meet extremely high purity levels, typically ≥99.0%.

For medical oxygen, the entire supply chain is scrutinised—from the tanks and valves right down to the handling procedures. Everything is meticulously controlled and documented to rule out any chance of contamination. Industrial oxygen, while still very pure, doesn't go through that same level of validation, which is why it can't be used in healthcare.

For a stationary tank at your facility, you generally don't need a specific operational licence. What you do need is to follow all local and national safety regulations to the letter. This covers everything from where the tank is placed to ensuring proper ventilation and safe handling protocols.

Moving a flüssig sauerstoff tank on public roads is a different story entirely. That falls under ADR regulations, which means you need certified vehicles and specially trained drivers. The easiest path here is to work with a supplier whose vessels are already pre-certified and ADR-compliant, taking the guesswork out of meeting your legal transport duties.

At Cryonos GmbH, we provide state-of-the-art cryogenic vessels that meet the highest standards for both medical and industrial use, including full ADR compliance. Explore our reliable solutions at https://www.cryonos.shop.