No Products in the Cart

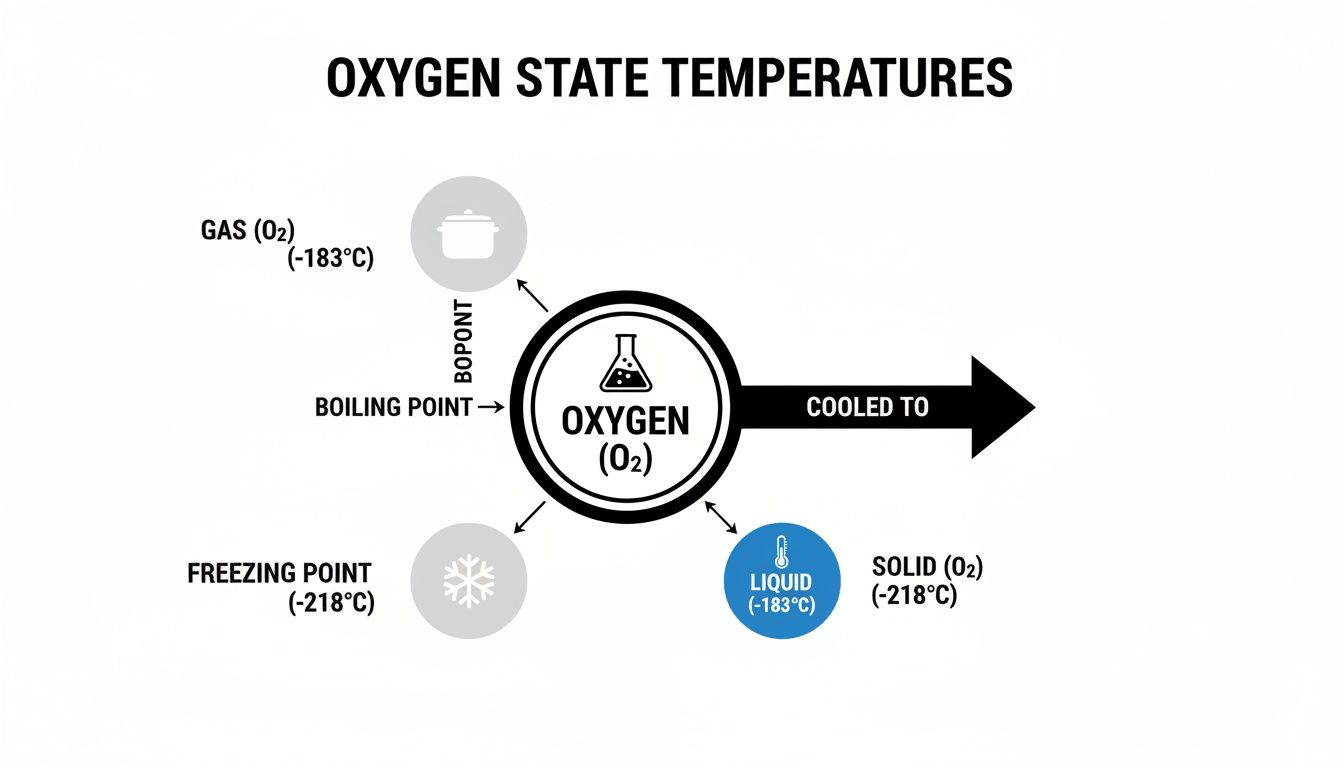

When you're working with liquid oxygen, the one number you absolutely have to know is its boiling point: -183°C (-297°F or 90 K) at standard atmospheric pressure. This isn't just a fact for a trivia night; it's the defining flüssiger sauerstoff temperatur that dictates everything about how we handle it.

That incredibly low temperature puts liquid oxygen squarely in the cryogenic category—substances so cold they demand specialised equipment and serious respect. Getting a handle on this critical temperature is the very first step to using it safely and effectively.

Think about a pot of water boiling on your stove. That transformation from liquid to steam happens at 100°C. Liquid oxygen does the same thing, just at the extreme opposite end of the thermometer. It "boils" back into a gas at a bone-chilling -183°C.

This intense cold is precisely what makes liquid oxygen, often called LOX, so incredibly useful. It allows a massive volume of oxygen gas to be compressed into a much smaller, more manageable liquid. But that same property also throws some major challenges our way.

To really get a feel for just how cold we're talking about, it helps to see the boiling point across the different temperature scales. This table summarises the key figures you'll encounter.

| Property | Celsius (°C) | Fahrenheit (°F) | Kelvin (K) |

|---|---|---|---|

| Boiling Point | -183.0°C | -297.3°F | 90.1 K |

This boiling point is the most important number for anyone working with LOX, whether in medical supply systems or aerospace engineering. It represents the normal storage temperature because any heat that gets into the container will simply cause the liquid to boil off, rather than raising its temperature.

While liquid oxygen is a powerful tool, its utility is completely tied to its extreme cold. This temperature is quite different from other common cryogens. For instance, you can learn more about the properties of liquid nitrogen and its much lower boiling point here. Every engineering decision and safety rule for handling LOX revolves around managing this incredibly low temperature to keep things both efficient and safe.

The incredibly low temperature of liquid oxygen isn't just a random number; it's rooted in fundamental physics. At its heart, the state of any substance—whether it's a solid, liquid, or gas—comes down to a tug-of-war between the energy of its molecules and the forces pulling them together. Oxygen, the gas we breathe every day, only becomes a liquid when you drastically reduce its molecular energy.

Think of oxygen molecules as dancers on a dance floor. At room temperature, the music is blasting, and the dancers are full of energy, bouncing around wildly and filling the entire room. That energetic state is oxygen gas.

Lowering the temperature is like turning the music way down. As the energy drains away, the dancers slow down and start to huddle together. Once you hit the critical boiling point of -183°C, they’re moving slowly enough to cluster into a tight group, forming a liquid.

Getting a handle on how pressure and temperature affect oxygen is key to understanding cryogenics. The interplay between these two factors dictates whether oxygen will be a gas, a liquid, or even a solid.

This diagram perfectly illustrates the critical temperature where gaseous oxygen condenses into its liquid form under normal atmospheric pressure.

As you can see, crossing that -183°C threshold is the make-or-break step for creating liquid oxygen. It's the physical process that underpins every single cryogenic application that relies on this substance.

For a long time, scientists genuinely believed some gases, including oxygen, were "permanent gases"—substances that could never be turned into a liquid. This idea was a major roadblock for anyone trying to push the boundaries of low-temperature physics and engineering.

The big breakthrough finally came in the late 19th century. While some early progress was made in 1877, it was Polish scientists Zygmunt Wróblewski and Karol Olszewski who, in 1883, managed to produce stable, visible amounts of liquid oxygen for the very first time.

This achievement was monumental. It completely demolished the long-held concept of 'permanent gases.' It proved that any gas could be turned into a liquid if you just got it cold enough, flinging the doors wide open for modern cryogenics.

This discovery wasn't just some academic curiosity. It laid the scientific groundwork for everything from modern medical oxygen systems to the incredibly powerful rocket engines that launch spacecraft into orbit. You can explore more about the history of this scientific achievement and its importance. This foundational grasp of how temperature changes a gas's physical state is exactly what allows us to harness the power of materials like liquid oxygen today.

While the bone-chillingly low flüssiger sauerstoff temperatur is what makes it a cryogenic liquid, there are several other properties that are just as vital for anyone planning to use it. These characteristics dictate how liquid oxygen behaves in the real world—in storage tanks, transfer lines, and at the point of application.

Getting a grip on these properties isn't just an academic exercise; it's fundamental to designing safe equipment and effective procedures.

One of the most mind-boggling facts about liquid oxygen is its density. It’s over 860 times denser than oxygen gas at room temperature. This is the magic behind liquefaction. It allows an enormous amount of oxygen to be compressed into a manageable volume, which is why it's the go-to solution for everything from supplying hospitals to fuelling rockets.

Another key trait to understand is the heat of vaporisation. Think of this as the energy toll liquid oxygen has to pay to turn back into a gas. For anyone trying to store it, a high heat of vaporisation is a good thing—it means the liquid can absorb more heat from the surroundings before it starts boiling away.

This leads us directly to the constant headache known as "boil-off." No matter how good your insulation is, some heat will always find its way into a cryogenic container. This causes a slow but relentless evaporation, and managing the resulting pressure build-up is one of the biggest challenges in cryogenic storage.

Scientists have been refining our understanding of liquid oxygen for decades. A major leap forward occurred in 1977 when new experimental data pushed the measurable pressure range for oxygen's properties up by 143%, from 33 MPa to 80 MPa. This allowed for a far more detailed picture of how it behaves under intense pressure. You can explore the original rigorous P-ρ-T measurements on oxygen to see the science firsthand.

Beyond density and its resistance to boiling, other characteristics have very tangible impacts on how you handle liquid oxygen safely and effectively.

Low Viscosity: Liquid oxygen flows more freely than water. This might not sound like a big deal, but it means that even a tiny pinhole leak can lead to a significant spill very quickly.

Surface Tension: This property affects how the liquid "wets" surfaces and moves through pipes, which is a crucial detail when engineering pumps and transfer systems.

Thermal Expansion: When liquid oxygen warms up and becomes a gas, it expands with incredible force. This is precisely why a sealed container without a pressure relief valve is a recipe for disaster.

Each of these traits directly shapes the engineering and safety rules for working with LOX. To dig deeper, you can check out this detailed guide on the properties of oxygen. A solid understanding is the first step towards ensuring your equipment is up to the task and your handling protocols are sound.

Managing the extreme flüssiger sauerstoff temperatur of -183°C isn’t just a challenge; it’s a constant battle against the laws of physics. At these temperatures, you need highly specialised equipment designed for one primary purpose: to keep the relentless heat of the outside world at bay. This is the job of cryogenic storage vessels, often called dewars.

You can think of a dewar as a high-tech thermos flask. Its most critical feature is a vacuum jacket—the empty space between an inner and outer wall where nearly all the air has been pumped out. This vacuum is an incredible insulator, massively cutting down on heat transfer through conduction and convection. It’s what keeps the liquid oxygen cold and stable.

But even the best insulation isn't perfect. A tiny amount of ambient heat always manages to sneak in, causing the liquid to slowly but constantly evaporate. This "boil-off" process turns the liquid oxygen back into a gas, which starts to build up pressure inside the container.

If that pressure isn't managed correctly, the situation can get dangerous fast. A completely sealed container of liquid oxygen is essentially a ticking time bomb. As the gas expands, it can lead to a catastrophic rupture.

That’s why every single cryogenic storage tank is fitted with safety relief valves and bursting discs. These aren’t optional extras; they are non-negotiable safety features engineered to automatically vent excess pressure long before it reaches a dangerous level, protecting the vessel's structural integrity.

For anyone working in logistics, knowing the specific rules for moving cryogenic materials is absolutely critical. Our detailed guide breaks down the complex regulations for transporting gas cylinders, giving you the essential information needed to stay safe and compliant.

Selecting the right materials is just as crucial as the design of the tank itself. At the frigid flüssiger sauerstoff temperatur, many common materials become completely unreliable and even dangerous.

Take standard carbon steel, for example. It experiences something called a "ductile-to-brittle transition." At room temperature, it’s tough and can bend under stress. But at -183°C, it becomes as fragile as glass and can shatter from a simple impact.

This is exactly why materials used in cryogenic service are meticulously chosen for their ability to stay tough in the cold:

Ultimately, ensuring the safe containment of liquid oxygen is paramount. Getting familiar with general principles for safe chemical storage solutions can offer valuable insights into industry best practices. Every single component, from the tank walls down to the smallest valve and fitting, must be made from materials certified for cryogenic use. It's this combination of intelligent vessel design, dependable pressure relief systems, and correct material selection that forms the bedrock of safe liquid oxygen handling.

Knowing the theory behind flüssiger sauerstoff temperatur is one thing. Safely managing it in a bustling lab or industrial plant is another challenge entirely. Working with liquid oxygen isn't a casual affair; it demands absolute commitment to safety protocols, starting with the correct personal protective equipment (PPE). Think of it not as a suggestion, but as your first and most critical line of defence against severe injury.

Anyone handling liquid oxygen must be kitted out in gear specifically designed for cryogenic temperatures. This means thermal insulating gloves—often called cryogenic gloves—to protect hands from the instant frostbite that contact would cause. A full-face shield and safety goggles are also non-negotiable, guarding your eyes against splashes that could cause irreversible damage.

Beyond the immediate threat of extreme cold lies a more subtle, yet equally dangerous risk: oxygen enrichment. As liquid oxygen evaporates, it releases a high concentration of oxygen gas into the air. The air we breathe is about 21% oxygen, but even a small spill can rapidly push that number up, especially in a poorly ventilated space.

An oxygen-rich atmosphere dramatically increases the flammability of almost everything. Materials that wouldn't normally burn in regular air can ignite with ease and burn with explosive force.

This is precisely why proper ventilation is mandatory. Always handle liquid oxygen in a well-ventilated area, ideally outdoors or under a local exhaust system. This prevents a dangerous build-up of oxygen gas, where a single stray spark could trigger a catastrophic fire.

Your handling technique matters, too. When transferring liquid oxygen, pour it slowly and deliberately. This minimises splashing and helps prevent thermal shock, which can cause non-cryogenic materials to crack or shatter under the sudden temperature drop.

It's a common misconception that all liquid oxygen is the same. In reality, different applications demand different purity levels, or "grades." Using the wrong type, particularly in a medical setting, can have devastating consequences.

The distinction is critical for patient safety. The fragility of the medical liquid oxygen supply chain was thrown into sharp relief during the 2021 COVID-19 surge. As hospital demand skyrocketed, suppliers were forced to redirect industrial oxygen, exposing just how vulnerable our critical infrastructure can be during a healthcare crisis. You can get a deeper look into the oxygen supply chain's profile and its dependencies.

Whether you're in a hospital or a factory, mastering these practical steps is key to ensuring this powerful substance remains a valuable tool, not a hazard.

Even after getting a good handle on the technical details, the extreme nature of liquid oxygen tends to kick up a few more questions. It's only natural. Answering these common curiosities is a great way to lock in the core safety principles and paint a complete picture of how this cryogenic liquid behaves in the real world.

Let's demystify some of the most striking characteristics of liquid oxygen, tying them back to the fundamental physics and safety protocols we've already covered.

One of the first things people notice about liquid oxygen is its beautiful, pale blue colour. This isn't from some dye or impurity; it's an intrinsic property of oxygen molecules when they're packed so tightly together in a liquid state.

The blue tint comes down to how the molecules absorb light. When O₂ molecules get that close to each other, they interact in a way that lets them absorb light from the red end of the visible spectrum. When you subtract red light from white light, what’s left to reflect to your eyes is blue. It’s a subtle effect, best seen in larger, purer quantities of the liquid.

Let’s be direct: direct contact with liquid oxygen is incredibly dangerous and something you must avoid at all costs. Touching it, even for a split second, would cause an instantaneous and severe cryogenic burn. This is a form of frostbite so extreme that it causes deep and permanent tissue damage.

At its boiling point of -183°C (-297°F), the liquid would immediately freeze any skin it touches. The water inside your cells would crystallise into ice, destroying cell structures and leading to an injury on par with a severe thermal burn.

This extreme hazard is exactly why specialised Personal Protective Equipment (PPE) is non-negotiable when handling liquid oxygen. Cryogenic gloves, full-face shields, and proper lab coats are essential to create a protective barrier and prevent the devastating consequences of accidental contact.

This is a critical question, and the answer requires a bit of nuance. Liquid oxygen itself is not flammable or explosive. However, it is an extremely powerful oxidiser. This means it aggressively supports and accelerates the combustion of other materials, and that’s what makes it so dangerous around anything that can burn.

If liquid oxygen spills onto materials like asphalt, wood, grease, or even certain plastics, it can create a mixture that is highly sensitive to ignition. A simple spark, a bit of static discharge, or even a mechanical impact could be enough to trigger a violent, explosive reaction.

There are actually two different ways an "explosion" can happen.

Understanding this distinction is crucial for safety. While liquid oxygen won't detonate on its own, its ability to make other materials burn with incredible force means it must be treated with the same respect as an explosive. Every single handling procedure is designed to keep it away from fuels and ensure it's always stored in properly vented containers.

For state-of-the-art cryogenic solutions designed for the safe storage and transport of industrial gases and biological samples, trust the experts at Cryonos GmbH. Our comprehensive portfolio, backed by decades of experience, ensures your materials are handled with the reliability and compliance you require. Explore our advanced cryogenic vessels and safety equipment at https://www.cryonos.shop.