No Products in the Cart

Moving gas cylinders, or transport von gasflaschen as it’s known here in Germany, is a job that demands serious attention to detail. It’s not just about getting from A to B; it’s about careful handling, secure loading, and having all your paperwork in order. The whole process is guided by a set of strict safety rules, primarily the ADR (Accord Dangereux Routier), which covers everything from checking the cylinders before they move to making sure the driver knows exactly what they’re doing.

Let's be clear: moving gas cylinders isn’t just another logistics task. It's a critical safety operation. The contents are held under immense pressure and could be flammable, oxidising, toxic, or pose a cryogenic hazard. A slip-up doesn't just mean a potential fine; it can lead to disaster—explosions, fires, or a dangerous chemical leak. Think about it: a single loose cylinder in a moving vehicle can become a high-speed projectile, powerful enough to tear through the side of a van.

This isn't a niche activity, either. The compressed gas market in Germany is huge, pulling in USD 291.4 million in revenue in 2024 alone, and it's only set to grow. With an estimated 2.5 million tons of compressed gases travelling on German roads every year, the need for watertight safety protocols is obvious.

The main rulebook for the transport von gasflaschen across Europe, Germany included, is the ADR. This isn't just red tape; it's a comprehensive agreement that classifies dangerous goods and spells out exactly how they should be carried by road. Understanding its basic principles is your first step towards being fully compliant and, more importantly, safe.

To give you a better overview, here’s a quick summary of the key regulations you’ll encounter.

| Regulation | Governing Body | Key Focus Areas |

|---|---|---|

| ADR (Accord Dangereux Routier) | United Nations Economic Commission for Europe (UNECE) | Classification of dangerous goods, packaging, labelling, vehicle requirements, documentation, driver training. |

| Gefahrgutverordnung Straße, Eisenbahn und Binnenschifffahrt (GGVSEB) | German Federal Ministry of Transport and Digital Infrastructure (BMDV) | National implementation of ADR, specific German rules and exceptions, penalties for non-compliance. |

| Betriebssicherheitsverordnung (BetrSichV) | German Federal Ministry of Labour and Social Affairs (BMAS) | Workplace safety, including the safe handling, storage, and inspection of pressure equipment like gas cylinders. |

This table provides a starting point, but the ADR itself is where the real detail lies. It's a harmonised safety system built on decades of experience, designed to prevent accidents before they happen.

At its heart, the ADR isn't designed to be a bureaucratic hurdle. It's a harmonised safety system built on decades of experience, designed to prevent incidents before they happen by ensuring everyone in the transport chain—from the filler to the driver—understands the risks involved.

For tradespeople, small businesses, and labs, the full weight of ADR regulations can seem overwhelming. Luckily, there's a crucial exemption known as Limited Quantities (LQ), or more commonly, the "1,000-point rule" (found in ADR 1.1.3.6). This rule is a lifesaver, allowing you to move smaller amounts of dangerous goods without needing a fully ADR-kitted vehicle or a specially certified driver.

Here’s how it works: every gas is given a "transport category" with points assigned per litre or kilogram. If the grand total of points for your entire load stays under 1,000, you fall under the exemption. This doesn't mean you can throw safety out the window, though. The cylinders still have to be properly secured, the vehicle needs ventilation, and you must do your pre-trip checks. Knowing your limits is key, which is why we've put together a specific guide on gas cylinder transport quantities.

Not all gas cylinders are created equal. Being able to identify the type you're handling and its specific dangers is the foundation of safe transport.

Understanding what you’re about to move is the first and most critical step. It dictates everything that follows—from handling procedures and segregation rules to your emergency plan. This knowledge is the bedrock of any safe transport von gasflaschen operation.

Before a single cylinder gets loaded onto your vehicle, a thorough inspection is your first, and frankly, most important line of defence against a serious incident. Taking just a few minutes to perform these checks can be the difference between a routine delivery and a catastrophic failure on the road. This isn't about ticking boxes; it’s a hands-on assessment to be certain a high-pressure vessel is fit for travel before it moves an inch.

Start with a simple walk-around. Look for obvious signs of damage or neglect. Are there any deep dents, nasty gouges, or patches of heavy, flaking rust? These are far more than just cosmetic blemishes; they can signal a compromise in the cylinder's structural integrity, turning it into a ticking time bomb.

If you spot a cylinder that looks questionable, the rule is simple: do not transport it. It needs to be moved to a designated quarantine area and clearly marked as faulty. Your next step is to get on the phone with your gas supplier for instructions.

Once you're satisfied with the physical condition, turn your attention to the labels. Think of these as the cylinder's passport—they tell you exactly what’s inside and confirm its identity. It is absolutely vital that the information on the cylinder's shoulder stamp and its hazard labels perfectly matches your transport documents.

Here's what you're looking for:

Any discrepancy is a red flag. An unreadable label, a torn hazard diamond, or conflicting information means the cylinder must be rejected. Moving a misidentified gas is not only illegal under ADR regulations but also incredibly dangerous, as it can lead to incorrect handling and storage down the line.

The valve assembly is, without a doubt, the most vulnerable part of a gas cylinder. It’s the primary point of containment, and a failure here means a rapid, uncontrolled release of gas.

Your inspection here needs to be meticulous. First, confirm the valve is completely closed. A gentle clockwise turn will tell you if it's seated firmly shut. Then, look closely at the valve itself. Do you see any damage, like a bent handwheel or cracked fittings? If you're in doubt, a leak detection spray is a great tool. Any bubbles forming around the valve stem are a clear sign of a leak, and that cylinder is going nowhere.

Finally, make sure the protective valve cap is screwed on tight. This isn't just a dust cover; it's a heavy-duty piece of safety equipment designed to take the brunt of an impact and prevent the fragile valve from being sheared off in a fall. A missing or loose cap is a major safety failure. To really grasp its importance, you can learn more about the protective cap for a gas cylinder in our detailed article.

It's a common mistake to see the valve cap as optional. In reality, it's a non-negotiable safety device. ADR regulations demand its use during transport for a very good reason—it’s the last line of defence for the cylinder’s most critical component.

A crucial part of your preparation is knowing what not to load together. Throwing incompatible gases into a confined space like a van is asking for trouble. The golden rule here is to always segregate flammable gases from oxidising gases.

Picture this: a propane cylinder (flammable) loaded right next to an oxygen cylinder (oxidiser). If that propane cylinder develops a leak, the oxygen-rich atmosphere will turn a tiny spark into a violent explosion. Always check the hazard labels to identify these incompatibilities.

This separation is a fundamental principle of the safe transport von gasflaschen.

Of course, cylinder checks are only half the battle. Your vehicle also needs to be in top condition. Modern systems can even help with proactive vehicle health monitoring to catch potential mechanical issues before they become a problem on the road. By carefully preparing each cylinder and planning your load, you’re preventing potential disasters before the journey even begins.

Getting your cargo secured properly is hands down the most critical physical task when it comes to the transport von gasflaschen. A cylinder that shifts, rolls, or even just tips over during transit can lead to catastrophic failure. The principles behind securing them are simple physics—stop them from moving—but getting it right takes care and the right gear.

For any professional job, cylinders must travel in an upright position. No exceptions. This orientation is all about protecting the valve, which is by far the most vulnerable part of the cylinder. If you're serious about safety, specialised cylinder pallets or fixed racks are the gold standard. They're engineered to hold cylinders snugly in place, eliminating any chance of them toppling over.

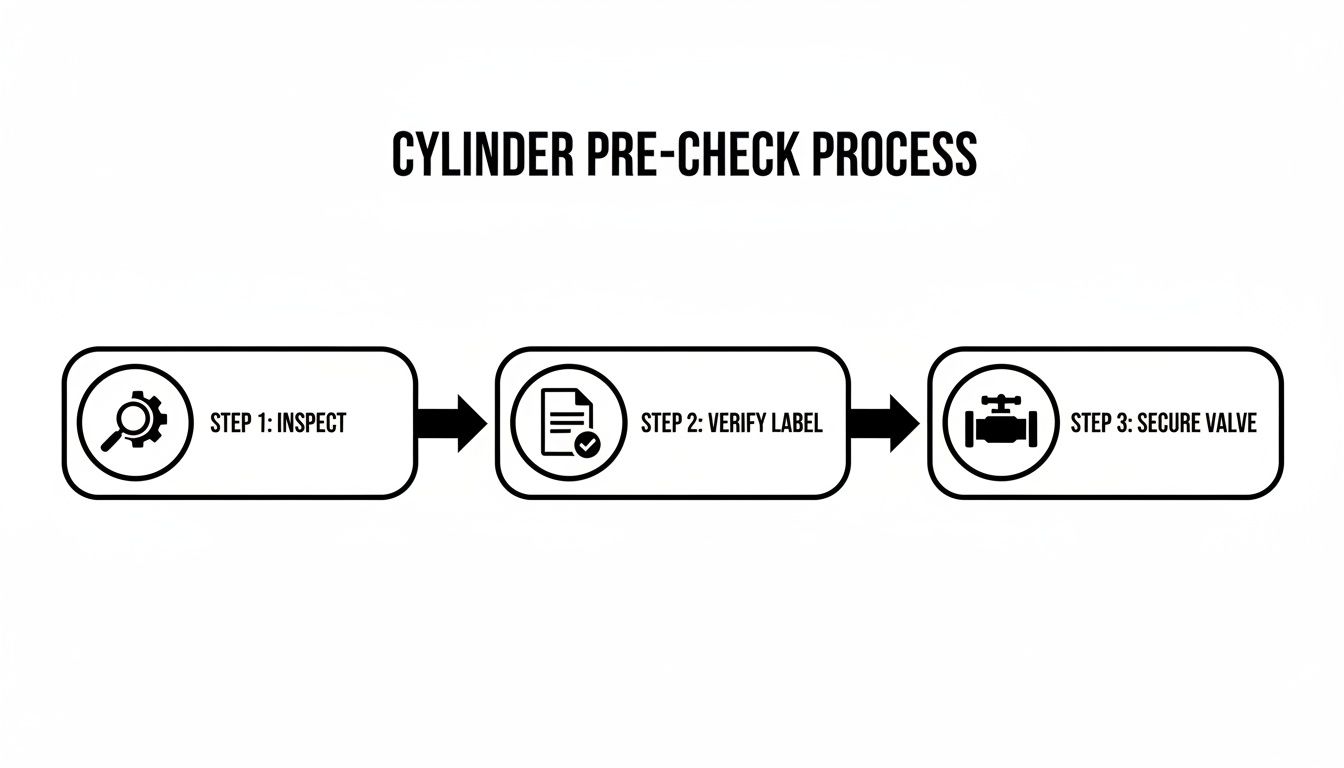

Before any cylinder even gets near your vehicle, a quick pre-check is essential. This sequence is your first line of defence against loading a compromised cylinder.

Running through these steps ensures that no unsafe cylinder makes it onto your vehicle, laying the groundwork for a safe journey.

How you secure your cylinders depends entirely on what you're driving. The approach for a large commercial truck is worlds away from what's needed for a tradesperson's van.

Never, ever underestimate the forces at play when you're on the road. A sudden brake check or a sharp turn can put immense strain on your restraints. This is a job for chains and high-quality, load-rated straps. Bungee cords or a bit of old rope? Absolutely not. They are never acceptable for securing high-pressure gas cylinders.

The goal is zero movement. If you can give a cylinder a good push and it wobbles, it’s not secure enough. It needs to feel like it’s part of the vehicle itself. That’s the standard you must hit before you turn the key.

There's one rule that is completely non-negotiable: gas cylinders must never be transported in the passenger cabin of a vehicle. The biggest risk here is a leak. Most industrial gases are asphyxiants, meaning they push oxygen out of the air. In a small, enclosed space like a car, even a tiny, slow leak can drop the oxygen level to a dangerous point, causing drowsiness, loss of consciousness, and potentially fatal consequences for the driver.

For vans, the cargo area needs to be completely sealed off from the driver's cabin and have proper ventilation. This typically means a solid, sealed bulkhead. Good ventilation is crucial; it ensures that if a leak does happen, the gas can escape outside instead of building up inside the vehicle.

When you're dealing with larger cryogenic vessels, using purpose-built equipment like an AC Trolley for Liquid Cylinders can make a world of difference. It simplifies the handling and positioning within the vehicle, making the final securing process much safer and easier.

Once your load is secure, you have to think about the signs on your vehicle—the placarding required by ADR. This is how you tell emergency services what they're dealing with if something goes wrong.

The 1,000-point rule is a key concept for anyone carrying mixed or smaller quantities of dangerous goods. Every gas is assigned a point value per kilogramme based on its risk. If the grand total of points for everything you're carrying stays below 1,000, you're exempt from some of the heavier requirements, like full placarding and special driver certification.

But remember, even if you're under the 1,000-point threshold, all the rules about securing your load and proper ventilation still apply. Getting the loading and securing right is the most important, tangible step you can take to ensure a safe and compliant transport von gasflaschen.

Getting your cylinders properly secured is a huge part of the job, but it’s only half the battle. Real compliance for the transport von gasflaschen boils down to having the right paperwork in order and a properly trained driver behind the wheel. These things are just as critical as any physical strap or chock because they ensure everyone involved knows exactly what they’re dealing with and how to respond if things go sideways.

Think of your documentation as the official story of your cargo. If you get pulled over for an inspection or, worse, you’re involved in an incident, these papers are what tell emergency responders the specific hazards they’re up against. This isn’t just bureaucratic red tape; it’s a vital communication tool when seconds count.

The cornerstone of all your paperwork is the ADR transport document, or Beförderungspapier as it’s known in German. This document must be with any load of dangerous goods unless you fall under some very specific, small-quantity exemptions. It's your neck on the line to make sure every single detail is spot-on before the wheels start rolling.

For every type of gas cylinder you’re hauling, the document needs to list several key pieces of information, and the order is non-negotiable under ADR rules.

So, a correct entry for a load of argon might look something like this: "UN 1006, ARGON, COMPRESSED, 2.2, (E)". Getting this sequence and the details exactly right isn't just a good idea—it's mandatory.

A sharp, well-informed driver is your single most important safety asset on the road. Depending on what you're hauling and how much of it, specific training and certifications become a legal requirement. Once your load exceeds the 1,000-point rule threshold, the driver absolutely must hold a valid ADR training certificate (the ADR-Schein).

This certificate proves the driver has been properly trained in hazard awareness, what to do in an emergency, and the nitty-gritty of the regulations. For anyone moving gas cylinders, understanding the specific training needed is key. You can get a better sense of what this specialised training involves by looking into the requirements for a hazardous material endorsement.

No matter what, every driver—ADR certificate or not—must be familiar with the 'Instructions in Writing' (Schriftliche Weisungen). This is a standardised, four-page document that gives clear, step-by-step guidance on handling an emergency, from using a fire extinguisher to calling the right authorities.

These instructions have to be in the cab, in a language the driver understands. When things get stressful—say, a leak or a fire—this document is the cool-headed guide to taking the right actions immediately. It’s not enough to just have it stuffed in the glove box; the driver needs to know exactly where it is and how to use it.

Finally, your vehicle itself has to be kitted out with specific safety gear mandated by ADR. This isn't optional stuff; it's the equipment that helps a driver manage an incident and protect themselves and the public. The exact list can change a bit depending on the load, but some items are non-negotiable for a compliant transport von gasflaschen.

Here’s a quick overview of the essential documents and safety equipment that should always be in the vehicle. Think of it as your pre-trip checklist to stay safe and avoid hefty fines.

| Item | Requirement Details | Applicability (LQ, Full ADR) |

|---|---|---|

| ADR Transport Document | Must contain UN number, proper shipping name, class, and quantity for each substance. | Full ADR (often required for LQ too, depending on total quantity) |

| Instructions in Writing | Standardised 4-page emergency guide. Must be in the driver's language. | Full ADR |

| Fire Extinguishers | Min. one 2 kg dry powder for the cab. Another for the cargo (size based on vehicle weight). | Full ADR |

| Wheel Chock | At least one, sized appropriately for the vehicle's wheels. | Full ADR |

| Warning Triangles | Two self-standing warning triangles. | Full ADR |

| Personal Protective Equipment (PPE) | High-vis vest, protective gloves, and eye protection for each crew member. | Full ADR |

| Portable Lighting | A non-sparking torch or lamp. | Full ADR |

Having this gear isn't just a suggestion. It must be present, in good condition, and easy to grab in a hurry. You can bet that any roadside police check will involve a look at these items. Missing equipment is an easy way to get hit with significant fines and have your journey brought to a dead stop.

Even with the best planning in the world, the road can be an unpredictable place. Knowing exactly how to react during an emergency when you’re managing a transport von gasflaschen isn’t just good practice—it’s a vital skill that protects you, the public, and the environment. A cool head and a methodical response can turn a potential disaster into a managed incident.

Your first line of defence is always the 'Instructions in Writing' (Schriftliche Weisungen) document in your cab. This is your immediate action plan, spelling out the hazards of your specific cargo and the first steps to take. The time to get familiar with it is before you even start your engine.

That distinct smell of gas or a hissing sound coming from the cargo area is an immediate red flag. How you react in the first few seconds is critical.

While every gas transport job demands care, some types of cargo require an even higher level of attention because of their unique properties. These special cases often involve materials where purity is non-negotiable or their physical state presents extra dangers.

Transporting medical-grade gases like oxygen or nitrous oxide, for example, is about more than just pressure safety; it's about protecting purity. Any contamination could have devastating consequences for a patient. This means ensuring cylinders are dedicated to medical use only, with valves properly sealed and shielded from environmental contaminants.

Cryogenic liquids, like liquid nitrogen (LIN) or liquid argon (LAR), pose a dual threat that you must respect.

For any cryogenic transport, proper ventilation isn't just a suggestion; it's a critical safety requirement. The vehicle's cargo area must be well-ventilated to stop gas from building up. Drivers also need to be equipped with and trained to use specialised PPE, including cryogenic gloves and face shields, anytime they handle these containers.

The demand for this kind of specialised transport is only growing. Looking ahead, Germany’s shift towards hydrogen-ready infrastructure, with plans for hydrogen-capable pipelines over 40% longer than previously recorded, is set to boost specialised cylinder transport needs by an estimated 15-20% by 2030. You can find more details about these infrastructure developments and their impact on future energy logistics.

Even with the best preparation, real-world questions always pop up when you're dealing with the day-to-day realities of transport von gasflaschen. Let's tackle some of the most common queries with clear, practical advice to keep you safe and on the right side of the regulations.

This is a big one, and the short answer is: you really shouldn't. While it might be technically permissible for a tiny personal-use cylinder (think small barbecue tank), it's strongly discouraged.

If you absolutely must, the cylinder has to be perfectly upright and secured in the boot. Never, ever transport it in the passenger cabin. The valve needs to be fully closed with the safety cap screwed on tight. Most importantly, the area must be ventilated—even cracking a window can make a difference. For any commercial purpose, or for cylinders over 5 kg, using a private car is a non-starter. It’s not just unsafe; it's a direct violation of ADR rules which demand a separate, properly ventilated cargo area.

The biggest risk inside a car is asphyxiation. Industrial gases are often odourless and heavier than air. In a confined space like a car's interior, even a tiny, slow leak can displace oxygen, leading to drowsiness or, terrifyingly, loss of consciousness behind the wheel.

The 1,000-point rule, found in ADR 1.1.3.6, is an essential exemption that every tradesperson should understand. It allows for the transport of smaller quantities of dangerous goods without triggering the full, more complex ADR requirements like needing an ADR-certified driver or displaying orange warning placards on the vehicle.

It’s based on a simple points system where each gas is assigned a value per kilogramme, depending on its hazard level. For example:

You just multiply the weight of each gas by its point value and sum them up. If your total is under 1,000 points, you can operate under this exemption. This is how a welder can legally carry up to 333 kg of propane before needing full ADR compliance. It’s a practical rule for smaller loads.

In Germany, the authorities do not mess around with transport safety, and the fines can be steep. The number one reason for getting penalised is, without a doubt, improper load securing. This covers everything from cylinders lying down unsecured to those that can roll around in the back of a van. Fines for this alone can quickly escalate into hundreds or even thousands of euros.

Coming in a close second is missing or incorrect paperwork, particularly an incomplete ADR transport document. Other common, and costly, mistakes include:

Regulators view these not as minor slip-ups but as serious breaches of safety protocol.

Think of a gas cylinder as a high-pressure vessel; it needs regular checks to ensure it’s safe. For most standard steel cylinders across the EU, the inspection interval is 10 years. You can easily find the date of the last inspection—and often the next due date—stamped right onto the cylinder's shoulder.

But this isn't a one-size-fits-all rule. Certain cylinders, especially those containing corrosive gases, might need re-testing every 2 to 5 years. Newer composite cylinders also follow different, often shorter, inspection schedules. It’s illegal to either fill or transport a cylinder that’s past its inspection date, so make checking that stamp a mandatory part of your pre-transport routine.

At Cryonos GmbH, we know that transporting sensitive materials safely and compliantly is non-negotiable. We provide cutting-edge, ADR-licensed cryogenic vessels and equipment engineered to the highest safety standards for laboratories, biobanks, and industrial clients. See how we can support your work at https://www.cryonos.shop.