No Products in the Cart

A gas in cylinder isn't just a simple container; it's a very specific piece of kit, engineered to hold immense potential energy, either under high pressure or at incredibly low temperatures. Knowing how to manage that energy is absolutely non-negotiable for keeping things safe, whether you're working in a high-tech lab, a hospital, or an industrial plant.

It helps to think of a gas cylinder less like a canister and more like a dormant force. When you know what you're doing, it's an essential tool that powers critical processes—everything from preserving biological samples in cryobanks to enabling precision welding on a factory floor.

But get it wrong, and that dormant force can become a serious hazard. We're talking risks of explosions, dangerous chemical exposure, and even asphyxiation. The potential for things to go sideways is very real.

This guide is designed to build your expertise from the ground up, giving you a clear path to mastering the hands-on skills you need for safe, efficient gas management.

Our aim here is to give you practical, no-nonsense knowledge that you can put to use right away. We'll walk through the key areas step-by-step, making sure you feel confident with each new concept.

Here's what we'll cover:

Getting a handle on gas cylinder management is a huge piece of the wider safety puzzle. In fact, it's a core part of meeting broader regulations, as you can see in this comprehensive UK workplace safety compliance guide.

Nailing these standards is the first, most important step toward creating a truly secure working environment. For anyone who deals with gas cylinders—from the person ordering them to the one connecting them up—this foundation is essential.

When we talk about a gas in cylinder, it’s easy to picture a standard steel tank. But what's inside, and how it's stored, can be worlds apart. You're generally dealing with one of two categories: compressed gases or cryogenic liquids. Understanding the difference isn't just academic—it's fundamental to working with them safely and effectively.

Each type operates on a completely different physical principle, which dictates everything from the cylinder design to the safety precautions you need to take.

Think of a compressed gas as an enormous volume of gas squeezed into a heavy-duty steel container. The defining characteristic here is pure, brute-force pressure. A standard cylinder of compressed nitrogen, for example, is under pressures exceeding 200 bar (that's about 3,000 psi).

This immense stored energy is what makes these gases so useful, but it’s also what makes them dangerous. It's all about keeping that energy safely contained within the cylinder and its valve.

Compressed gases are simply substances that stay in their gaseous state inside the cylinder, even when crammed in at high pressures and normal room temperatures. Common examples you’ll run into are nitrogen, oxygen, argon, and helium.

These gases are the workhorses of countless industries, and demand is only growing. Germany's compressed gas market, valued at USD 291.4 million, is expected to climb to USD 379.2 million by 2030. While nitrogen currently holds the biggest slice of the pie, oxygen is set for the fastest growth, thanks to its critical role in healthcare, manufacturing, and research. You can dig deeper into these trends by exploring the German compressed gas market outlook.

The key takeaway is simple: the main hazard is the pressure. A damaged valve or a weakened cylinder wall can cause a sudden, violent release of energy.

A full, standard-sized gas cylinder contains enough stored energy to propel it through a brick wall. This is why securing cylinders is a non-negotiable safety rule.

Now, let's flip the script. Instead of squeezing a gas, imagine chilling it to incredibly low temperatures until it condenses into a liquid. Welcome to the world of cryogenics. Substances like liquid nitrogen, oxygen, and argon are stored at temperatures colder than -150°C (-238°F).

Here, the hazards are completely different. First, there's the extreme cold itself, which can cause severe frostbite on contact. Second, and just as critical, is their massive expansion ratio. When a cryogenic liquid warms up and turns back into a gas (a process called boiling), it expands to hundreds of times its liquid volume.

A single litre of liquid nitrogen, for instance, will boil off to become nearly 700 litres of nitrogen gas. If this happens in a poorly ventilated room, it can rapidly displace the oxygen in the air, creating a life-threatening asphyxiation hazard without any warning—the gas is invisible and has no smell.

This is exactly why you'll never find cryogenic liquids in a standard high-pressure cylinder. They require special, vacuum-insulated containers called dewars or cryogenic vessels. These are engineered to minimise heat transfer and safely vent the small amount of gas that naturally boils off. This isn't just a matter of preference; it’s a critical safety requirement rooted in physics. A standard steel cylinder would quickly and catastrophically rupture from the pressure build-up.

To make these differences crystal clear, here’s a quick side-by-side comparison.

This table breaks down the key characteristics of each storage method, from the physical state and pressure to the primary hazards and typical applications.

| Characteristic | Compressed Gas | Cryogenic Liquid |

|---|---|---|

| Physical State | Always a gas inside the cylinder | A super-cooled, dense liquid |

| Storage Pressure | Very high (e.g., 200+ bar / 3,000+ psi) | Low pressure, designed to vent |

| Storage Temperature | Ambient (room temperature) | Extremely cold (below -150°C / -238°F) |

| Primary Hazards | High pressure (projectile risk), chemical properties | Extreme cold (frostbite), rapid expansion (asphyxiation) |

| Container Type | High-pressure steel or aluminium cylinder | Insulated dewar or cryogenic vessel |

| Common Examples | Gaseous Nitrogen, Oxygen, Argon, Helium, Hydrogen | Liquid Nitrogen (LN₂), Liquid Oxygen (LOX), Liquid Argon |

Ultimately, choosing between a compressed gas and a cryogenic liquid comes down to the application's needs for volume, purity, and flow rate. While the underlying substance might be the same (like nitrogen), how it's stored changes everything.

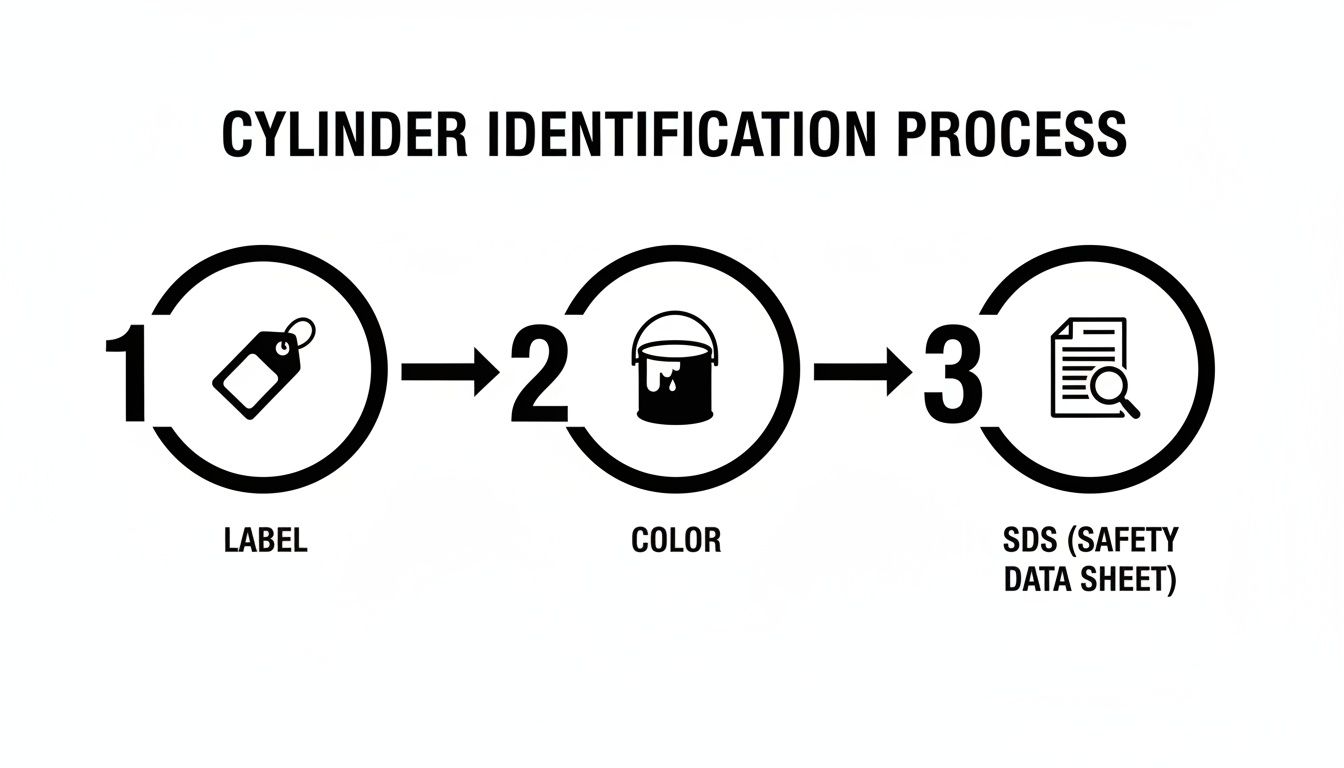

When you’re faced with a gas cylinder, knowing what’s inside isn't just a box-ticking exercise—it’s the most critical first step for safety. Think of it as a puzzle with three main pieces: the cylinder label, the colour code, and the Safety Data Sheet (SDS). While all three give you clues, only one tells the full, authoritative story.

Understanding how to read these identifiers quickly and correctly allows everyone, from a new technician to a seasoned facility manager, to make smart, immediate decisions. This is the bedrock skill for preventing accidents and treating every gas cylinder with the respect it demands.

First things first: always trust the label. The colour of the cylinder can be a useful hint, but the label is the definitive, legally required statement of what’s inside. No guesswork allowed.

A standard gas cylinder label is jam-packed with vital information, all designed to be understood in a moment. While the layout might differ slightly between suppliers, they all have to include specific core elements under regulations like the Globally Harmonized System (GHS).

Here’s what you need to look for:

Treat the label as the final word. If a cylinder has no label, or if it's so damaged you can't read it, don't use it. It should be marked "contents unknown" and sent straight back to the supplier.

Cylinder colours offer a quick visual reference for the type of gas inside. Standards like EN 1089-3 in Europe assign specific colours to the cylinder's shoulder (the curved top part) to signal the primary hazard.

For example, a bright green shoulder often points to an inert gas like Argon, while a red shoulder is a clear warning of a flammable gas like hydrogen. This system is great for a quick risk assessment from a distance, but it comes with a huge catch.

Crucial Safety Note: Never rely solely on cylinder colours for identification. Standards can vary by region and even by supplier, and older cylinders might not follow the latest codes. The label is the only identifier you can bet your safety on.

The growing demand for all kinds of gases, especially in liquid form, just makes clear safety standards even more important. Germany's liquid gas cylinder (LGC) market, for instance, is ballooning thanks to high safety standards and quality control. With Europe's LGC market projected to jump from USD 5.1 billion to USD 9.5 billion in the next decade, consistent identification is non-negotiable. You can read the full research on the European LGC market trends.

If the label is the headline, the Safety Data Sheet (SDS)—which you might know by its older name, Material Safety Data Sheet (MSDS)—is the complete article. This document is your most detailed guide to understanding absolutely everything about the gas you're handling. Your supplier is legally required to provide one for every hazardous substance they sell you.

An SDS is typically broken down into 16 standardised sections, giving you the full picture on:

Make sure your SDS library is organised and easy for the whole team to access. Before anyone works with a new gas, reading its SDS should be a mandatory step. It gives your team the knowledge to handle materials safely, act decisively in an emergency, and stay fully compliant with regulations.

Knowing what's inside a gas cylinder is just the starting line; how you handle it day-to-day is what truly prevents accidents. Translating safety theory into clear, daily habits is absolutely essential for protecting your people, your equipment, and the surrounding environment. This means adopting a systematic approach to every single interaction with a cylinder, from the moment it arrives on-site to its final connection.

Let’s break this down into three core areas: handling, storage, and transport. Each stage presents its own unique risks and demands specific, non-negotiable procedures. Mastering these practices will shift your safety culture from a set of rules on a page into a series of ingrained, effective habits that minimise risk at every turn.

This simple flowchart lays out the crucial first steps for identifying a cylinder's contents and any associated hazards before you even think about moving it.

As the graphic shows, while colour codes and safety data sheets are vital, the cylinder's label is always your first and most critical source of information.

A gas cylinder is an awkward object. Its weight and shape make it tough, and potentially dangerous, to move without the right gear and technique. A large steel cylinder can easily weigh over 70 kg, and dropping it could shear off the valve, leading to a violent, high-pressure gas release. The golden rule of handling is to maintain control at all times.

Never, ever roll, drag, or slide a cylinder, not even for a short distance. This can damage the cylinder walls and creates a huge risk of losing your grip on it.

Here are the non-negotiables for safe handling:

Proper storage is about much more than just tucking cylinders out of the way. It’s about creating a safe, controlled environment that prevents common hazards like tipping, unauthorised access, and dangerous chemical reactions. A well-organised storage area is a cornerstone of any facility's safety programme.

Cylinders must always be secured to stop them from falling. A toppling cylinder can easily snap its valve, turning it into a dangerous, uncontrolled projectile weighing tens of kilos.

The most fundamental rule of storage is to secure every single cylinder. Use chains, brackets, or a designated storage rack to fasten them to a solid structure like a wall.

On top of that, a clear system for separating different types of cylinders is crucial for preventing dangerous situations from developing.

Moving a gas in cylinder, whether across a large facility or out on public roads, brings a whole new set of risks and regulatory headaches. The focus here is on making sure cylinders are completely secured against movement and that all legal transport rules are followed to the letter. This isn't just about avoiding fines; it’s about preventing a potential disaster on the road.

In Germany and across Europe, the transport of dangerous goods is governed by the ADR (Accord Dangereux Routier) agreement. Following these regulations isn't optional—it's mandatory. For a closer look at the specific requirements, you might find our guide on the transport of gas cylinders helpful.

The German gas cylinder market is growing fast and is projected to hit 515.80 million USD by 2032 with a compound annual growth rate of 8.91%. This growth reflects the country's intense focus on high-quality engineering and safety, especially in the chemical and industrial sectors where strict TÜV certifications are the norm. You can explore more insights on the German gas cylinder market on databridgemarketresearch.com. This growth just highlights how important it is to use compliant and safe equipment.

To pull all these best practices together, here’s a quick-reference table. Think of it as your go-to checklist for ensuring safety at every stage of a cylinder's life in your facility.

| Safety Area | Key Action | Rationale |

|---|---|---|

| Handling | Always use a designated cylinder trolley with securing chains. | Prevents dropping a heavy cylinder, which could damage the valve and cause a high-pressure leak. |

| Wear correct PPE (safety glasses, gloves, steel-toed boots). | Protects against impact injuries and potential contact with hazardous materials. | |

| Keep the valve cap on securely during movement. | The valve assembly is the most vulnerable point; the cap protects it from impact damage. | |

| Never lift a cylinder by its valve or cap. | This can cause catastrophic failure of the valve, leading to an uncontrolled release of gas. | |

| Storage | Secure every cylinder upright with chains or brackets. | A falling cylinder can become a projectile if its valve shears off. |

| Separate incompatible gases (e.g., flammables and oxidisers). | Prevents dangerous chemical reactions or fires in case of a leak. | |

| Designate and clearly mark areas for "Full" and "Empty" cylinders. | Avoids confusion, prevents accidental use of empty cylinders, and simplifies inventory. | |

| Ensure storage area is well-ventilated and away from heat. | Reduces the risk of gas accumulation and prevents pressure build-up from heat exposure. | |

| Transport | Securely fasten cylinders in the vehicle to prevent any movement. | Prevents cylinders from tipping or rolling during transit, which could lead to damage or leaks. |

| Follow all ADR (Accord Dangereux Routier) regulations. | Ensures legal compliance and public safety when transporting hazardous materials on public roads. |

Following this checklist consistently helps build a strong safety culture, where correct procedures become second nature rather than a chore. It’s the small, daily habits that prevent major incidents.

Picking the right container for a gas in a cylinder is just as critical as the procedures you use to handle it. A vessel that’s perfect for one job might be inefficient or even outright dangerous for another. This isn't about generic advice; it's about a careful look at your specific needs, whether you're running a long-term biobank, an industrial fabrication shop, or a high-purity research lab.

Get this choice wrong, and you could be looking at wasted product, compromised sample integrity, or unnecessary safety risks. The goal is simple: match the container's design and capabilities directly to what your application demands.

A few critical factors should steer your decision. Thinking through each one will help you zero in on the ideal vessel, ensuring both safety and peak performance for your work.

Required Volume and Usage Rate: How much gas do you need, and how fast will you go through it? For low-volume, occasional use, a standard high-pressure cylinder is usually fine. But for high-volume, continuous work, a liquid cylinder or a micro-bulk system will be far more efficient.

Purity Levels: Does your work demand ultra-high purity gas? Speciality gas applications, like those in analytical chemistry or semiconductor manufacturing, need cylinders that are specially prepared and treated to stop any contamination in its tracks.

Flow Rate and Pressure: What flow rate and pressure does your equipment need to run properly? A standard cylinder might not keep up with the high flow rates needed for some industrial processes. In that case, a liquid cylinder with its own built-in vaporiser is a much better bet.

Portability: Do you need to move your gas source around the facility often? Small, lightweight aluminium cylinders or portable liquid nitrogen dewars offer the best mobility for tasks that aren’t tied to one spot.

Considering these variables helps you avoid the common trap of choosing a vessel based on price alone—a decision that often ends up costing much more in the long run.

Let's see how these factors play out in the real world. The right choice becomes obvious when you compare the unique needs of different professional settings.

A university research lab running daily experiments will likely value portability and ease of use above all else. For them, a small, portable liquid nitrogen dewar is perfect for topping up equipment or snap-freezing samples at various workstations. Its non-pressurised design and convenience are ideal for low-volume, hands-on tasks.

On the other hand, a biobank responsible for the long-term storage of priceless biological samples has completely different priorities. Here, the absolute integrity of the samples and minimising product loss are non-negotiable. This facility would invest in a specialised, low-evaporation cryogenic freezer built for stability over months, or even years.

The choice isn't just about holding a gas; it's about supporting a critical function. An industrial fabrication workshop using argon for welding needs a high-capacity, high-flow solution. A large liquid cylinder or a micro-bulk tank can supply a steady, uninterrupted flow of gas, preventing the costly downtime that comes with constantly swapping out smaller high-pressure cylinders.

For a deeper dive into the technical specifications and designs available, our guide on what you should know about cryogenic vessels offers valuable insights to inform your selection process.

To make the decision a bit easier, here’s a quick comparison of common container types and where they shine. This table shows how different designs are tailored to specific jobs, helping you match your needs to the right technology.

| Vessel Type | Primary Use Case | Key Advantages | Best For |

|---|---|---|---|

| High-Pressure Cylinder | Low- to medium-volume gas supply | Widely available, suitable for various gases | Labs, small workshops, intermittent use |

| Liquid Cylinder (Dewar) | High-volume, high-flow gas supply | High capacity in a compact footprint, continuous flow | Welding, laser cutting, purging systems |

| Portable Dewar | Transport and dispensing of liquid cryogens | Lightweight, easy to handle, non-pressurised | Research labs, medical clinics, dermatology |

| Cryogenic Freezer | Long-term static storage of samples | Extremely low evaporation, high sample security | Biobanks, cell therapy labs, research archives |

Ultimately, investing a little time to choose the correct vessel is an investment in your own success. It ensures you have a reliable, safe, and efficient supply of the gas in a cylinder you depend on, letting you focus on your core work without worrying about your gas management system.

Hopefully, this guide has given you a solid foundation for managing your gas cylinder systems safely and effectively. We’ve walked through everything from identifying different gas types and setting up secure handling protocols to making sure you have the right equipment for the job. If there's one thing to take away, it's this: expertise and diligence are what keep things safe and compliant, no matter the application.

But knowing the rules is just the start. True gas management means having a reliable partner who genuinely understands the tiny details of your work. We don't just sell state-of-the-art equipment; we bring decades of hands-on technical experience to the table, and we're committed to helping you succeed for the long haul.

It’s one thing to have a safe workplace on paper, but applying that knowledge correctly is what makes it secure in practice. Whether you’re setting up a new laboratory, fine-tuning an industrial process, or establishing a biobank, the right support can make all the difference. We see our role as bridging that gap between understanding the theory and implementing the perfect, practical solution.

We believe that superior equipment is only half the equation. The other half is expert guidance, responsive service, and a partnership built on trust. Our goal is to ensure your operations are not only compliant but also as efficient and secure as possible.

This means we do more than just send you a product catalogue. It means we listen to your specific challenges and offer solutions that are practical, durable, and a perfect fit for what you need to do every day.

Every application has its own set of rules, from the required purity of the gas to the environmental conditions of the storage area. We specialise in creating systems that meet these precise, and often unique, demands.

Here's what our commitment looks like in practice:

If you’re ready to take your gas management strategy to the next level, get in touch with our experts today. Let's work together to find a solution that gives you complete peace of mind and keeps your operations running smoothly.

Even with a solid grasp of the principles, practical questions always pop up during the day-to-day grind. This section is designed to give you direct, no-nonsense answers to some of the most common queries we hear about handling gas cylinders.

Think of it as your go-to guide for those moments when you need a quick, reliable solution.

To stay in service safely, every gas cylinder needs to be periodically inspected and re-tested by a qualified technician. How often this happens depends on what the cylinder is made of, what’s inside it, and national regulations, like those from TÜV here in Germany.

As a general rule of thumb, standard steel cylinders for common industrial gases like nitrogen or argon usually need a check-up every 5 to 10 years. That said, the interval can be much shorter if the cylinder is holding corrosive or unstable gases.

The definitive answer is always stamped right onto the shoulder of the cylinder. Look for the markings that show the date of the last inspection and, crucially, when the next one is due. For specialised cryogenic vessels, it's absolutely vital to stick to the manufacturer’s recommended maintenance schedule to make sure the vacuum integrity and safety relief devices are all working as they should.

Although they are both vacuum-insulated vessels built to hold cryogenic liquids, they serve very different purposes. It all boils down to their primary job: are they for temporary storage or for providing a continuous supply of gas?

A Dewar: This is typically a non-pressurised, open-mouthed container you'd use for short-term storage or for moving smaller amounts of liquid nitrogen. Picture a high-tech thermos flask—perfect for grabbing some liquid for immediate use in the lab.

A Liquid Cylinder: This is a bigger, pressurised vessel specifically designed to supply gas. It has internal vaporisers that turn the cryogenic liquid back into a gas at a controlled, steady pressure. This makes it a fantastic portable, high-capacity alternative to a whole bank of high-pressure gas cylinders, ideal for any job that needs a constant, reliable flow.

If you think you have a leaking cylinder, how you react in the next few moments is critical for everyone's safety. Don't even think about trying to fix the valve or the cylinder yourself. Your number one priority is to isolate the hazard and get the right people involved.

First, and only if it’s safe to do so, move the cylinder to a well-ventilated area outside, well away from any potential ignition sources like sparks or open flames.

The gas itself dictates what you do next. If you're dealing with flammable, toxic, or corrosive gases, evacuate the immediate area and trigger your facility's emergency response plan. This should always include notifying your emergency team and the gas supplier.

For inert gases like nitrogen or argon, the main risk in an enclosed space is asphyxiation due to oxygen displacement. Make sure the area is completely ventilated before anyone goes back in. In any and every situation, your first port of call should be the gas’s Safety Data Sheet (SDS), which gives you specific, detailed emergency instructions for that exact substance.

At Cryonos GmbH, we don't just supply equipment; we provide the expertise to ensure your gas management systems are safe, compliant, and perfectly matched to your work. Explore our state-of-the-art cryogenic solutions at https://www.cryonos.shop and partner with a team dedicated to your success.