No Products in the Cart

Making the call on whether to "gasflasche mieten oder kaufen" (rent or buy gas cylinders) really boils down to your day-to-day operational reality. For facilities that need financial flexibility, guaranteed compliance, and predictable expenses, renting is almost always the smarter path. On the other hand, purchasing makes sense for high-volume, continuous-use scenarios where long-term asset ownership and direct control are the name of the game.

When you're managing cryogenic or industrial gases in specialised environments like biobanks, labs, or industrial plants, the decision to rent or buy cylinders has consequences that ripple out for years. It's about much more than the initial price tag; this choice directly impacts your budget, operational flow, and even your legal responsibilities. Renting essentially turns a hefty capital investment into a manageable, predictable operational cost, neatly bundling maintenance and compliance into one simple package.

When you choose to rent, you're not just getting a cylinder; you're offloading the entire headache of ownership. Forget tracking inspection deadlines, managing repairs, or figuring out what to do with a cylinder at the end of its life. The supplier handles all the safety checks and ensures every unit meets current regulations, which is absolutely critical for keeping your operations smooth and avoiding eye-watering fines. This model gives you peace of mind and lets your team get back to their actual jobs.

Buying, in contrast, puts you in the driver's seat for the cylinder's entire lifecycle. That means footing the bill for the initial purchase, scheduling and paying for periodic TÜV inspections, handling all maintenance, and covering the replacement costs if it fails. While ownership gives you autonomy, it also brings unpredictable expenses and a heavy administrative burden that can really stretch resources, especially for smaller labs or grant-funded projects.

The financial upside of renting is pretty clear. In Germany, for example, renting a liquid gas tank can start from as low as €11.50 per month for a full-service package that includes the tank, inspections, and maintenance. To buy a similar tank outright, you'd be looking at a starting price of €2,360 upfront—and that’s before you spend a single euro on its upkeep. You can learn more about the cost advantages of gas supply rentals right here.

To help with your initial assessment, we’ve put together a table that breaks down the core differences between renting and buying. Think of it as a quick snapshot to see how each approach lines up with your priorities on cost, maintenance, and flexibility.

| Factor | Renting Gas Cylinders | Buying Gas Cylinders |

|---|---|---|

| Upfront Cost | Low (deposit or first rental fee) | High (full purchase price) |

| Maintenance | Included; handled by the supplier | Owner's responsibility and cost |

| Compliance | Guaranteed by the supplier | Owner's legal responsibility |

| Flexibility | High; easily scale up or down | Low; fixed asset investment |

| Total Cost | Predictable operational expense (OpEx) | Unpredictable capital expense (CapEx) |

| Best For | Variable, project-based, or low-volume needs | High-volume, continuous, long-term usage |

This table should give you a solid starting point. As you can see, the "best" option isn't universal; it's entirely dependent on your specific operational context, usage patterns, and long-term strategy.

When you’re weighing up whether to rent or buy a gas cylinder – or as they say in Germany, "gasflasche mieten oder kaufen" – it’s tempting to just compare the initial quotes. But that’s a rookie mistake. A simple price tag misses the complex web of ongoing costs that truly define the expense over the equipment's life. To make a smart financial decision, you have to look at the Total Cost of Ownership (TCO) for buying versus the predictable operational expense of renting.

Buying a gas cylinder might feel like a one-and-done deal, but it’s actually the start of a long-term financial commitment. That initial capital outlay is just the first domino to fall in a long line of expenses that will pile up over the years.

When you buy a cylinder, you’re signing up for the whole package – its entire lifecycle. This means dealing with a series of mandatory, and often unpredictable, expenses that are all too easy to ignore when you’re swiping the company card.

The big one is the recurring technical inspections. In Germany, gas cylinders require periodic safety checks (TÜV inspections). These are non-negotiable and come straight out of your budget. If a cylinder fails, you could be looking at expensive repairs or even being forced to replace it entirely. What was a planned expense suddenly becomes a major financial headache.

But it doesn’t stop at inspections. The financial burden of ownership also includes:

The real financial risk of owning a cylinder lies in its unpredictability. An unexpected equipment failure or a sudden change in safety regulations can instantly turn a depreciating asset into a significant, unbudgeted liability.

Renting completely flips the script. It transforms an unpredictable capital expense into a clear, consistent operational cost. Instead of a large upfront payment followed by a stream of variable bills, you simply pay a fixed periodic fee. This is a game-changer for financial planning, especially for operations like research labs or biobanks that run on tight grants and strict budgets.

That rental fee isn’t just for using the cylinder; it bundles all those lifecycle costs together. The supplier takes on the financial risk of equipment failure and regulatory changes, not you.

Here’s how renting cleans up your finances:

Over a 5 or 10-year period, the financial paths of buying and renting diverge dramatically. Sure, the cumulative rental fees might eventually add up to more than the initial purchase price. But once you factor in the TCO of the purchased cylinder—inspections, maintenance, potential replacements, and your team's administrative time—it often ends up being significantly higher and far less predictable. For any organisation that values budget certainty and operational stability, the rental model offers a clear and compelling financial edge.

In specialised settings like laboratories and biobanks, safety and regulatory compliance aren't just best practices—they are legal imperatives. When you're weighing up whether to rent or buy gas cylinders ("gasflasche mieten oder kaufen"), you're also deciding who carries the significant weight of these responsibilities. The choice you make directly impacts your operational risk, administrative workload, and potential legal liability.

Putting your name on the ownership papers for a gas cylinder means the full burden of compliance lands squarely on your shoulders. You become legally responsible for ensuring every piece of equipment adheres to a complex web of German and EU regulations. This is a substantial undertaking that demands dedicated expertise and meticulous record-keeping.

As the owner, you're accountable for the entire lifecycle of the cylinder, from its first use all the way through to disposal. This means navigating several key regulations that govern pressurised equipment. The moment you purchase a cylinder, you inherit the duty to maintain its safety and compliance indefinitely.

Key responsibilities you take on include:

Dropping the ball on any of these obligations can lead to severe consequences. Non-compliance can result in hefty fines, operational shutdowns ordered by regulatory bodies, and, in the event of an accident, significant legal and financial liability.

Renting gas cylinders, on the other hand, effectively outsources this entire regulatory headache to the supplier. A reputable provider like Cryonos assumes full responsibility for ensuring every cylinder in their fleet is certified, maintained, and fully compliant with all current legislation. This shifts the risk from your organisation to the experts.

When you rent, the supplier manages all the mandatory inspections, tracks certification renewals, and handles the complex logistics of safe transport. Your team is freed from the administrative strain of compliance management, allowing them to concentrate on their core research or production activities. This model provides a robust layer of protection against the risks of non-compliance.

A full-service rental agreement is more than a simple equipment lease; it's a powerful risk mitigation strategy. It ensures that your gas supply infrastructure is managed by specialists who are solely focused on safety and regulatory adherence, safeguarding your operations from potential penalties and disruptions.

This approach is particularly valuable in a fluctuating economic environment. Statistical trends in Germany's energy sector highlight why renting often beats buying for long-term efficiency. Producer prices for gas supply have seen extreme volatility, peaking at 244.80 points in September 2022. While buying locks in an initial cost, renting delegates the ongoing costs of inspections and maintenance—vital under safety rules like VDE 0100-704, effective May 2023. Renting provides a flexible solution that is often more economical than owning a rigid asset.

Ultimately, the decision to rent or buy is also a decision about where you want to allocate your resources and expertise. Choosing to buy means investing not just in an asset, but in the internal capacity to manage its complex safety and regulatory lifecycle. For many organisations, renting offers a more efficient and secure path, ensuring compliance is handled by dedicated professionals while your team focuses on what it does best.

The "gasflasche mieten oder kaufen" debate doesn't have a single right answer. Your best move, both for efficiency and your budget, comes down to one thing: your actual gas consumption pattern. When you align your supply strategy with how your operation really works, you avoid sinking money into cylinders that just sit there or paying extra for flexibility you don’t need.

A university lab with shifting project timelines has completely different needs than a factory with a constant, predictable gas flow. By looking at a few real-world scenarios, you can pinpoint the model that truly fits your workflow and financial setup.

R&D labs and research institutions rarely have a steady rhythm. Gas demand can skyrocket during an intense experimental phase, only to fall to virtually nothing for months at a time. This kind of unpredictability makes buying gas cylinders a risky financial bet.

In this setting, owning cylinders means locking up a chunk of capital in equipment that might go unused for long stretches. This is a real headache for grant-funded organisations, where every euro has to be accounted for. The cylinder quickly turns from an asset into a liability, taking up valuable space and demanding compliance checks while contributing nothing.

Renting is the clear winner here. It gives you the freedom to adjust your gas supply as your projects evolve.

For a two-year research project, renting lets a lab get the gases it needs right away without the burden of long-term ownership. That agility is vital for driving innovation without getting bogged down in asset management.

Clinical labs, fertility clinics, and analytical testing facilities tend to have a much more stable appetite for gas. Their need for liquid nitrogen or carbon dioxide is steady and predictable, driven by daily routines and standard procedures. The volume might not be huge, but the supply has to be rock-solid.

For these users, the choice between renting and buying gets a bit more complicated. Buying outright can look tempting because of the potential long-term savings. But that view often ignores the hidden costs and headaches of ownership, like arranging TÜV inspections or scrambling for an emergency refill when a cylinder runs dry unexpectedly.

A long-term rental contract provides the ideal balance of cost stability and service reliability for consistent, moderate users. It ensures a dependable supply chain managed by experts, eliminating the risk of operational disruptions due to equipment failure or compliance oversights.

A rental agreement with a trusted partner like Cryonos means you get certified, properly maintained cylinders delivered on a set schedule. This model shifts the risks of ownership to the supplier, guaranteeing your critical work is never held up by supply issues. To find the perfect fit, you can look into different sizes, as our guide on 20 kg gas cylinders explains.

In high-volume industrial environments, the numbers tell a different story. For manufacturing plants, welding shops, or large-scale production facilities with a constant, heavy demand for gas, buying cylinders often becomes the smarter financial choice in the long run.

When gas is a fundamental part of the production line running day in and day out, the breakeven point for purchasing arrives much sooner. The large initial investment is balanced out by eliminating monthly rental fees over many years. This model is best for organisations that have the internal resources to manage the entire lifecycle of their cylinder fleet.

This means you need:

For these industrial power users, owning their cylinders offers maximum control and can lead to significant long-term savings—as long as they’re ready to take on the responsibilities that come with it.

When you’re weighing up whether to rent or buy a gas cylinder—“gasflasche mieten oder kaufen,” as the saying goes—it’s easy to focus on the physical tank. But the real value, especially for critical work in biobanks or fertility clinics, isn't just the hardware. It's the entire support system that comes with it. This is the part people often forget, and it can be the difference between a smooth operation and a very expensive shutdown.

Buying a cylinder means you're on your own. You’re not just getting a piece of equipment; you're inheriting its entire lifecycle. And that involves a lot more than just remembering to schedule an inspection now and then.

When that cylinder is yours, you instantly become the project manager for its upkeep. This means finding certified technicians for repairs, chasing down warranty claims (which can be a painfully slow process), and hunting for specific, often hard-to-find, spare parts. If a critical valve gives out, the search for a replacement is on you, and every hour spent on the phone is an hour your work is on hold.

This administrative hassle pulls your skilled people away from what they do best. Instead of focusing on their research or clinical work, they're bogged down in logistics, adding hidden costs that never show up on the initial purchase invoice.

Renting completely flips this script. That rental fee isn't just for the cylinder; it's your ticket into a full-service ecosystem designed to keep things running reliably while taking the load off your shoulders. This support is baked right into the rental agreement.

With a rental partner like Cryonos, you get:

A strong supplier partnership is one of the smartest ways to slash operational downtime. It turns an unpredictable risk into a managed service, ensuring your critical processes are never held up by equipment problems.

The numbers back this up, too. Historical data shows that renting offers far better cost predictability. Gas producer prices have been all over the place, swinging from a low of 44.40 points in March 2000 to a peak of 244.80 in 2022. Buying exposes you to that volatility and depreciation risk.

Renting, on the other hand, shields your budget and often includes vital extras like ADR compliance for transport—a non-negotiable for cell transport units. In fact, service-inclusive rental models can cut the total cost of ownership by 40-60% over a five-year period.

At the end of the day, a rental agreement is about more than just a cylinder. It's a partnership that delivers peace of mind, keeps your operations running, and frees you from administrative headaches. You can learn more about what makes a good partner in our guide on how to choose a cryogenic supplier. This frees up your team to focus completely on their mission, knowing the gas supply is in expert hands.

Deciding between renting and buying a gas cylinder isn't just a financial choice; it's an operational one. It really comes down to a careful look at your own unique needs. To make this a bit easier, we've put together a practical checklist. Running through these questions should give you the clarity you need to decide whether to gasflasche mieten oder kaufen.

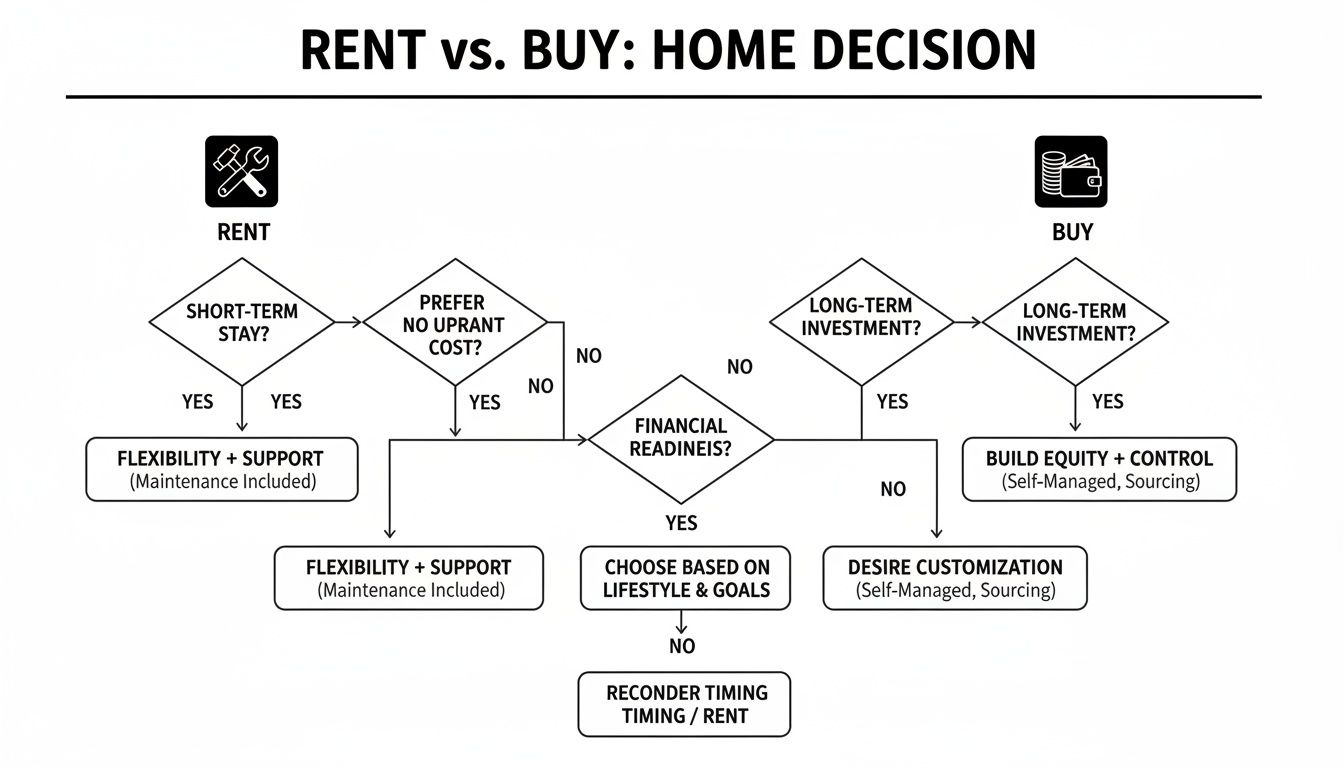

Think of it like a decision tree. This visual breaks down the key questions that will point you toward renting if you value support and maintenance, or toward buying if self-management and direct sourcing are more your style.

Essentially, it connects your operational priorities—whether that’s flexibility for short-term projects or long-term stability—directly to the procurement model that makes the most sense.

First up, let's look at your financial landscape. The answers here often point straight to the most sensible option for your budget.

Next, think about how you actually use gas cylinders day-to-day. Your consumption habits are a huge factor in figuring out the most cost-effective path.

Finally, take an honest look at your team's ability to handle the responsibilities of ownership. This goes beyond just finding a place to store cylinders; it involves real technical and administrative work.

Situational Recommendation: Imagine a research lab running on a two-year grant. They need maximum flexibility and minimal upfront costs. For them, renting is the clear winner. It fits perfectly with project-based funding and unpredictable gas needs. Now, picture a large industrial facility with its own maintenance crew and consistent, high-volume usage. Over a decade, buying will almost certainly prove more economical for them.

By walking through these questions, you can build a clear profile of what your organisation truly needs. This empowers you to make a confident, well-informed decision that supports both your operational and financial goals.

When you get down to the brass tacks of deciding between renting or buying gas cylinders—"gasflasche mieten oder kaufen"—it usually boils down to a handful of specific, practical questions. Let's tackle the most common ones we hear from labs and industrial facilities to help clear the path for your decision.

There’s no magic number for the break-even point on buying a gas cylinder versus renting; it really hinges on how you use it and the total cost you'll incur over its lifetime. For operations with a constant, high-volume demand, purchasing might start to look more economical after about five to seven years, assuming you don’t run into any unexpected, costly repairs.

But the sticker price is just the beginning. To get the full picture, you have to account for the mandatory TÜV inspections (which happen every 10 years here in Germany), routine upkeep, the occasional valve replacement, and the staff hours spent managing compliance paperwork. If your needs are sporadic or tied to specific projects, you might find that the break-even point is always just over the horizon, making renting the smarter financial choice indefinitely.

This is exactly where a good rental agreement shines, especially in critical research or clinical work where downtime isn't an option. Most suppliers, including us at Cryonos, have emergency supply protocols baked right into their service contracts.

What does that look like in practice?

Think of this built-in support as an insurance policy against operational hiccups. It takes the stress of emergency planning off your team and puts it squarely on the supplier, ensuring a critical process never grinds to a halt because a cylinder is empty.

Absolutely. Most suppliers are flexible and offer a clear path for clients to transition from renting to owning their cylinders. This allows your procurement strategy to grow with you. If your gas consumption ramps up and becomes consistently high, buying the very cylinders you’ve been using is often the most logical next move.

The process is usually quite straightforward. It involves a simple purchase agreement where the equipment's value is assessed and the sale is completed. A good supplier will make this transition feel seamless, providing all the necessary paperwork to officially transfer ownership and the associated compliance duties to you.

Once you own your cylinders in Germany, the legal responsibility for a strict set of safety regulations falls to you. The big ones are the Pressure Equipment Directive (PED 2014/68/EU), which dictates the integrity of the equipment, and the ADR regulations, which cover the transport of dangerous goods. As the owner, you are also responsible for making sure periodic TÜV inspections are done on time to keep the cylinders certified for use.

For a reliable supply of state-of-the-art cryogenic and industrial gas solutions, managed with expert support and guaranteed compliance, trust Cryonos GmbH. Explore our comprehensive portfolio of products and services designed for laboratories, biobanks, and industrial users at https://www.cryonos.shop.