No Products in the Cart

In Germany, the Gasflasche 20 kg is more than just a container; it's a workhorse. This specific size is fundamental across industries, reliably supplying essential gases like nitrogen, oxygen, and argon. It hits the perfect sweet spot between providing enough gas for serious work and being manageable enough to move around, making it a go-to for everyone from high-tech biobanks to heavy manufacturing plants.

When you think about what powers German industry, massive machines and complex production lines probably come to mind. But often, the real enabler is something much simpler: the humble gas cylinder. The 20 kg size, in particular, has become the standard for countless operations, acting as a portable power pack for both science and production.

It's best to see this cylinder not just as a tank, but as a critical tool. It’s the silent partner in a pharmaceutical lab creating a sterile environment, the steady hand in a welding workshop shielding a perfect seam, and the lifeblood for cryogenic freezers preserving invaluable samples. Its importance is hard to overstate.

There's a good reason the 20 kg cylinder is so popular. It’s the ideal compromise. You get enough gas to handle substantial tasks without constant interruptions, yet it’s still light enough for one person to manage safely with the right trolley. In fast-paced environments where flexibility is key, that balance is everything.

Sure, a larger cylinder holds more gas, but it quickly becomes a logistical nightmare, often needing a forklift to move. A smaller one is easier to carry but needs swapping out so frequently that it disrupts workflow. The 20 kg format just works, giving you continuity without the hassle.

You can see just how versatile the 20 kg gas cylinder is by looking at where it's used. Its impact is felt every day across Germany's core economic sectors:

In Germany's thriving industrial gases market—set to be worth €2.7 billion in 2025—the 20 kg gas cylinder is the undisputed leader. It accounts for an estimated 45% of the total supply mode market share, a figure that truly underscores its indispensable role.

This isn't just a trend; it's a testament to the cylinder's proven reliability. The data shows just how deeply the Gasflasche 20 kg is woven into the nation's economic fabric. For a deeper dive, you can explore more data on the German industrial gases market and see the scale for yourself.

Here at Cryonos GmbH, we build our cryogenic storage and transport solutions around these dependable cylinders. They are a core component of our systems, designed to give our clients in biobanking, research, and industry a secure, efficient, and trustworthy gas supply.

At first glance, a Gasflasche 20 kg might seem like just another steel container, but the markings stamped onto its shoulder tell a detailed story. Learning to decode these specifications is vital for safe and efficient work, whether you're in a high-tech biobank or a busy industrial workshop.

Think of these markings as the cylinder's technical passport. They provide all the essential information you need in a single glance, helping you move beyond seeing a simple container to truly understanding the tool in your hands. It’s about knowing the difference between the cylinder's empty weight and the gas inside, and grasping what its pressure rating really means for your work.

One of the most fundamental concepts to get your head around is the difference between tare weight and net weight. It’s a simple idea. Imagine a glass of water: the tare weight is just the weight of the empty glass, while the net weight is the weight of the water inside it. The total weight is simply both combined.

This exact principle applies to a 20 kg gas cylinder:

A cylinder’s pressure rating, typically 200 bar or 300 bar, is another critical piece of information. A great way to think about it is like the 'inflation level' of a car tyre. A higher pressure rating doesn't make the cylinder physically bigger, but it dictates how much gas can be safely compressed inside.

A 300 bar cylinder can hold a lot more gas than a 200 bar cylinder of the same size, which means longer run times and fewer changeovers for you. But, it also means you absolutely need regulators and equipment specifically designed to handle that higher pressure. Choosing the right pressure rating is a key decision that directly impacts both your operational efficiency and your safety protocols.

The Gasflasche 20 kg remains a true workhorse in Germany's industrial gas sector, aligning perfectly with Cryonos GmbH's expertise in cryogenic storage and transport for biobanks and biotech firms. According to recent industry analysis, this sector is made up of 42 businesses expected to generate €2.7 billion in 2025. Cylinders dominate 45% of supply modes, all within a market that has seen a 5.6% CAGR growth over the past five years. Discover more insights into the German industrial gas manufacturing industry from IBISWorld.

This market data really drives home the central role these cylinders play, making a clear understanding of their properties more important than ever. Of course, the choice of gas inside a 20 kg gas cylinder is just as vital as the cylinder itself. Different gases have unique properties that make them perfect for very specific jobs.

The table below gives a quick comparison of three common industrial gases you'll find in these cylinders, outlining what they are and where they're used in the sectors we serve at Cryonos.

| Gas Type | Chemical Formula | Typical Pressure (bar) | Primary Application (e.g., Labs, Industry) | Key Safety Consideration |

|---|---|---|---|---|

| Nitrogen | N₂ | 200 or 300 | Cryopreservation in biobanks, inerting atmospheres in labs, food packaging | Asphyxiation risk in enclosed spaces; handle in well-ventilated areas. |

| Oxygen | O₂ | 200 or 300 | Medical applications, steel cutting, welding, wastewater treatment | Highly reactive; acts as a powerful oxidant and accelerates combustion. |

| Argon | Ar | 200 or 300 | Shielding gas for TIG/MIG welding, creating inert atmospheres for electronics | Denser than air, posing an asphyxiation risk by displacing oxygen at low levels. |

As you can see, each gas comes with its own set of safety considerations directly tied to its chemical properties. This is why matching the right gas to the right application—and handling it correctly—is absolutely non-negotiable.

The valve on a Gasflasche 20 kg is the gatekeeper standing between you and the high-pressure gas inside. Treating it with anything less than total precision is simply not an option. For anyone working in a lab, clinic, or industrial setting, mastering the proper handling of valves, regulators, and connections is a fundamental skill.

Think of gas fittings like a unique key for a specific lock. An oxygen cylinder has a connection that will only fit an oxygen regulator, while an argon cylinder has a completely different one. This design, governed by standards like DIN 477-1, is a critical safety feature built right in. It physically stops you from accidentally connecting a regulator meant for an inert gas to an oxygen cylinder—a mistake that could have catastrophic consequences due to material incompatibility.

Before you connect anything, it helps to know what you're looking at. A typical valve on a 20 kg gas cylinder has several key parts, and each one has a specific job to do.

Connecting a pressure regulator is a routine task, but it demands your full attention every single time. Rushing through this process is one of the most common causes of leaks and accidents.

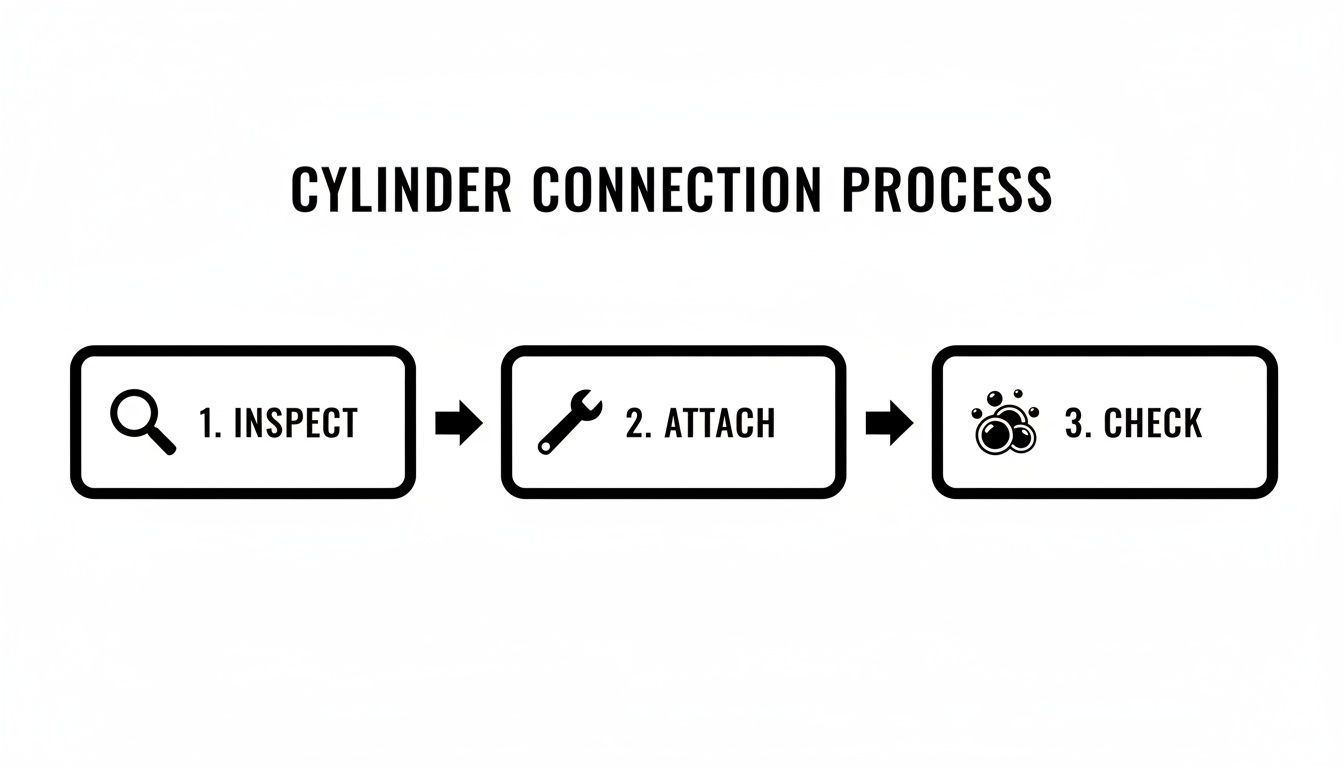

Follow these steps carefully to ensure a secure, leak-free seal:

A common mistake is using PTFE tape or other sealants on high-pressure gas connections. These fittings are engineered to create a precise metal-to-metal seal. Adding tape can interfere with this seal, increasing the risk of a leak rather than preventing one.

Once the regulator is connected, the final and most important step is to check your work. Open the main cylinder valve slowly and listen carefully for any hissing sounds. Next, apply a leak detection solution to the connection point. If you see bubbles forming, you have a leak. Immediately close the valve, depressurise the system, and go through the connection process again. This simple check takes just a moment, but it’s your best defence against a dangerous gas leak.

Properly storing a Gasflasche 20 kg isn't just about ticking boxes on a checklist; it's about understanding the physics at play. When you really get the 'why' behind each safety rule, you shift from simply following instructions to actively creating a safe work environment. It's a science, where every step is designed to neutralise a potential hazard before it even has a chance to materialise.

A huge factor here is heat. When a gas cylinder gets warm, the pressure inside ramps up—a lot. Think of it like a vigorously shaken can of fizzy drink. While cylinders are built tough, placing them near heat sources like radiators, furnaces, or even in direct, intense sunlight is an unnecessary gamble.

The best spot for your 20 kg gas cylinder is always a well-ventilated area, tucked away from busy walkways and any possible ignition sources. Good airflow is non-negotiable. It stops any leaking gas from building up, which is especially critical for gases heavier than air that can settle in low-lying areas.

Always store cylinders standing upright. If you lay a cylinder on its side, the liquefied gas can seep into the pressure relief valve, which is only meant to handle gas. This could cause the valve to fail in an emergency, leading to a very dangerous situation.

On top of that, you absolutely must secure cylinders to stop them from falling over. A simple chain or a sturdy strap fixed to a wall does the job perfectly. A toppling cylinder can easily smash its valve, triggering a powerful, uncontrolled release of high-pressure gas that can turn it into a projectile.

The most important safety mechanism for a gas cylinder is the cylinder itself. Designed and tested to the highest quality standards, they are extremely safe. The safety valve is an added layer of protection for the highly unlikely worst-case scenario.

This built-in safety means you can have confidence in the equipment, but only if you treat it with the respect it commands. Following these fundamental storage rules is the first, most important step toward operational safety.

You can't just store all gases side-by-side. One of the golden rules of cylinder storage is to keep incompatible gases apart. For example, oxidisers like oxygen must never be stored near flammable gases. You need a physical barrier, like a firewall, or at least a significant distance between them. This simple step prevents a minor incident from escalating into a dangerous chemical reaction. For more specific advice, our guide on the storage of oxygen cylinders goes into much greater detail.

Handling these cylinders also means gearing up with the right Personal Protective Equipment (PPE). The bare minimum includes:

If you ever suspect a leak, your first moves are crucial. If you hear a hissing sound or smell gas (for those with an added odour), shut the cylinder valve immediately, but only if it's safe to do so. Get everyone out of the area and make sure it's thoroughly ventilated before doing anything else. Never try to fix a leaky valve yourself—that’s a job strictly for trained professionals.

The best way to prevent leaks in the first place is to follow a clear, simple connection process every single time. This infographic breaks down the three essential steps for making a safe and secure connection.

This visual guide is a great reminder that a methodical approach—inspecting the gear, attaching it correctly, and then checking for leaks—is the cornerstone of safe handling.

Moving a pressurised Gasflasche 20 kg from point A to point B isn’t just a simple delivery run. It’s a process that’s tightly regulated by international laws for a very good reason: public safety. These aren't just bureaucratic hurdles; they are critical safeguards when dealing with potentially hazardous materials on our roads.

The cornerstone of these regulations is the ADR treaty, which is short for the European Agreement concerning the International Carriage of Dangerous Goods by Road. Think of the ADR as the definitive rulebook for transporting everything from flammable liquids to compressed gases across Europe.

For any business that handles or moves gas cylinders, sticking to ADR rules isn’t optional—it’s mandatory. This framework spells out everything, from how cylinders must be chained down in a vehicle to the specific training drivers need and the exact labels that have to be on every cylinder.

At first glance, the ADR framework can seem intimidating, but its core principles are logical and built around one thing: minimising risk during transit. When it comes to a 20 kg gas cylinder, this means specific rules for the vehicle, the driver, and the cylinders themselves.

There's a concept within ADR called "limited quantities," which can sometimes offer exemptions from the toughest rules for smaller loads. But for any kind of industrial-scale transport, full compliance is the only way to operate safely and legally. This is where leaning on professional expertise, like ours at Cryonos, becomes so important. For a deeper dive, you can read our detailed guide on the transport of gas cylinders.

Some of the key vehicle and driver requirements under ADR include:

The labels and markings stamped on a gas cylinder's shoulder are like its passport. They provide instant, universally understood information about what's inside and the hazards that come with it. For anyone in logistics or handling, knowing how to read these labels is a fundamental skill.

The most obvious feature is the hazard diamond, a colour-coded symbol that tells you the main risk in a split second. A green diamond, for example, means it's a non-flammable, non-toxic gas, while a bright red diamond is a clear warning of flammability.

Every gas also gets a four-digit UN Number, which is a universal identifier recognised all over the world. For instance, compressed nitrogen is UN 1066, and compressed oxygen is UN 1072. This number tells emergency services exactly what they’re dealing with, no guesswork involved.

Together, the shoulder colour, hazard diamond, and UN number give you a complete safety profile for every single 20 kg gas cylinder.

Germany's industrial gases market is projected to hit USD 4.25 billion by 2025, and the versatile Gasflasche 20 kg plays a huge role, making up a massive 45% share of the cylinder supply. This just goes to show how vital they are for Cryonos GmbH’s clients, from hospitals to major industrial suppliers. Oxygen, which holds a 35% market share, is essential for producing 37.23 million tons of steel and pushing forward with clean hydrogen energy.

The table below is a quick reference for some of the most common gases you'll find being moved in these cylinders.

This table breaks down the essential ADR labelling information for gases frequently used in laboratory and industrial settings, helping logistics managers ensure full compliance.

| Gas Type | UN Number | Primary Hazard Class (Diamond) | Description of Hazard |

|---|---|---|---|

| Nitrogen | UN 1066 | Class 2.2 (Green Diamond) | Non-flammable, non-toxic gas. The primary risk is asphyxiation from oxygen displacement. |

| Oxygen | UN 1072 | Class 2.2 & 5.1 (Green & Yellow) | Non-flammable, but a powerful oxidiser. It intensely accelerates combustion of other materials. |

| Argon | UN 1006 | Class 2.2 (Green Diamond) | Non-flammable, non-toxic gas. As it's heavier than air, it poses an asphyxiation risk. |

| Carbon Dioxide | UN 1013 | Class 2.2 (Green Diamond) | Non-flammable, non-toxic gas. High concentrations can cause asphyxiation by displacing oxygen. |

| Hydrogen | UN 1049 | Class 2.1 (Red Diamond) | Extremely flammable gas. Poses a significant fire and explosion risk. |

Getting transport and labelling laws right is non-negotiable. It’s what keeps your team, the public, and your valuable materials safe. At Cryonos, our ADR-compliant transport services are built on this very foundation of rigorous safety and deep regulatory knowledge.

Getting to grips with the technical specs, safety rules, and transport laws for a Gasflasche 20 kg is the first step towards a safe, efficient setup. But let's be honest, a single cylinder is rarely the whole story. It's usually just one piece of a much larger puzzle. The real magic happens when you integrate that reliable gas source into a complete, turn-key system designed to protect what matters most. That’s where we come in. At Cryonos GmbH, we think beyond individual products to deliver comprehensive cryogenic systems.

We don’t see a 20 kg gas cylinder as just a standalone item. We see it as the vital power source for your advanced equipment. Our solutions are designed from the ground up to work together seamlessly. For example, our systems often pair high-pressure gas cylinders with our state-of-the-art cryogenic vessels, ensuring you get consistent, reliable performance for long-term storage or transport.

Our expertise is in creating systems where every single component works in harmony. Take our AC LIN transport vessels and the larger AC LAC XL series. These units are engineered for the safe, ADR-compliant transport of cryogenic liquids like liquid nitrogen. In many setups, a Gasflasche 20 kg works right alongside these vessels to maintain pressure and ensure a steady supply, safeguarding priceless biological samples while they’re on the move.

This integrated approach means you're not just buying a piece of equipment; you're investing in a fully verified system that guarantees performance from end to end. We make sure the regulators, vessels, and gas supply are perfectly matched for peak efficiency and safety. This completely removes the guesswork and the risk of running into compatibility problems down the road.

Working with Cryonos gives you more than just top-tier hardware. We deliver real, long-term value that directly boosts your operational uptime and gives you total peace of mind. Our commitment to quality isn't just a slogan—it's reflected in the concrete benefits our clients see every day, built on decades of specialised experience in the field.

Here's what that looks like in practice:

Choosing Cryonos means choosing a partner who is genuinely dedicated to the integrity of your work. Our goal is to provide the peace of mind that comes from knowing your cryogenic infrastructure is robust, efficient, and backed by people who know the science inside and out.

Ultimately, it’s all about creating an environment where you can focus on what you do best—whether it's research, patient care, or production—without ever having to worry about the reliability of your cryogenic storage and gas supply. Our turn-key solutions, which include the dependable Gasflasche 20 kg, are designed to deliver exactly that.

Even after you've got the technical details down, practical questions always pop up when you're working with a Gasflasche 20 kg. This section tackles some of the most common queries we hear, giving you clear, straightforward answers to help you handle your cylinders with confidence.

Think of it like a car's MOT – it's a mandatory safety check. In Germany, these inspections, known as wiederkehrende Prüfung (recurring tests), are required by law for any high-pressure equipment like a 20 kg gas cylinder.

For most standard steel cylinders filled with common gases like nitrogen or argon, this inspection is due every 10 years. You don't have to guess, either. The date of the last check and the due date for the next one are stamped right onto the cylinder's shoulder. A quick glance tells you everything you need to know about its compliance status.

Let me be blunt: absolutely not. Filling high-pressure gas cylinders is a highly regulated, specialised job that should only ever be done by authorised gas suppliers. Trying to decant gas from one cylinder to another without professional equipment and training is incredibly dangerous.

Gas suppliers have a meticulous process. They ensure cylinders are filled to the precise weight and pressure and run safety checks while they're at it. Your job is simple: just return your empty cylinder to a certified supplier and get a safe, professionally filled replacement.

There's a common myth that a nearly empty cylinder is safer in the sun than a full one. That's just not true. The amount of gas inside doesn't change the basic rules of physics or safety. Proper handling and storage are what matter, full or empty.

A hissing sound, a strange smell (if an odourant is used), or frost forming around the valve are all red flags for a potential leak. What you do next is critical.

At Cryonos GmbH, we don’t just sell equipment; we provide the expertise that keeps your operations running safely and efficiently. See how our integrated cryogenic solutions can support your work. Learn more at Cryonos.