No Products in the Cart

Ever tried to grab a handful of frozen berries, only to find you’ve got a solid, icy brick? That’s where the magic of IQF comes in. At its heart, IQF stands for ‘Individually Quick Frozen,’ a process engineered to freeze small items separately, so every single piece stays loose and ready to use.

The idea behind IQF is simple but incredibly effective. Instead of freezing a big batch of food all at once, the IQF process gives each item—whether it's a pea, a shrimp, or a delicate biological sample—its own personal, ultra-fast freezing treatment.

This rapid chill is the secret sauce. By dropping the temperature in minutes instead of hours, it stops large, damaging ice crystals from forming. Those crystals are what ruin the texture and structure of conventionally frozen products. With IQF, the item's cellular integrity, flavour, and nutrients are locked in with remarkable precision.

IQF has completely changed the game, especially in the food industry. Here in Germany, the technology is a cornerstone of the frozen food market. Since the early 2000s, there’s been a massive shift away from old-school plate freezers towards advanced cryogenic IQF tunnels.

By 2022, Germany's frozen food consumption hit about 47 kg per capita annually. More than half of all the frozen vegetables and berries you see in the supermarket are now processed using IQF. This move is a direct response to what people want: high-quality frozen goods that don’t clump together. In fact, IQF's market share has more than doubled since the mid-1990s. The global demand for these systems is growing, as detailed in a market report from Reanin.

This lightning-fast freezing relies on cryogenic gases like liquid nitrogen, a core principle in the field of cryogenics. To get a better handle on the science, take a look at our guide on what cryogenics is and how it works.

To really see the difference, it helps to put the two methods side-by-side. Traditional freezing has its place, but for preserving individual quality, IQF operates on another level entirely.

| Feature | IQF (Individually Quick Frozen) | Conventional Freezing (Block/Plate) |

|---|---|---|

| Process Speed | Extremely fast (minutes) | Slow (hours) |

| Product Form | Free-flowing, separate pieces | Solid blocks or clumps of product |

| Ice Crystal Formation | Tiny, micro-crystals that cause minimal damage | Large ice crystals that rupture cell walls |

| Quality Preservation | Excellent preservation of texture, flavour, and nutritional value | Significant degradation of texture and flavour upon thawing |

| Ideal For | Small, delicate items: berries, peas, shrimp, individual cell vials | Bulk items: large cuts of meat, fish fillets, concentrated juices |

Essentially, the choice comes down to what you’re trying to protect. If preserving the integrity of each individual piece is the goal, IQF is the clear winner.

While IQF got its start in the kitchen, its applications now reach far beyond it. The same principle that keeps a raspberry perfectly formed is just as vital for preserving sensitive biological materials. This has made it a crucial tool for:

At its heart, IQF technology is about control. It offers precise, individualised preservation that protects quality at a microscopic level, whether for a blueberry or a delicate cell sample.

This is where having the right cryogenic infrastructure is non-negotiable. The IQF process creates a superior frozen product, but that quality has to be maintained through storage and transport. At Cryonos GmbH, we provide the complete cryogenic chain—from long-term storage freezers to secure transport dewars—to make sure the benefits of IQF are protected every step of the way.

To really get why IQF individually quick frozen technology is such a big deal, you have to think small—microscopically small. The whole game comes down to one thing: ice.

When you freeze something slowly, like in your freezer at home, the water inside forms big, jagged ice crystals. Picture them as tiny, sharp daggers. As these crystals grow, they tear right through the delicate cell walls of whatever you're freezing, whether it's a piece of fruit or a critical biological sample.

That kind of cellular damage is permanent. When you eventually thaw the product, those ruptured cells can't hold their structure or moisture anymore. The result? Mushy textures, lost flavour, and a major drop in quality. For biological materials, this destruction means the cells are no longer viable, making the sample completely useless.

IQF flips the script by relying on pure speed. Instead of taking hours, the freezing process is over in a matter of minutes. Techniques like fluidised-bed freezers blast each individual item with cryogenic gas, suspending them in the air and freezing them from all sides at once.

This extreme drop in temperature forces water molecules to solidify almost instantly. They have no time to line up and form those big, destructive crystals. Instead, they create tiny, uniform micro-crystals. Think less like daggers and more like minuscule, smooth needles.

These micro-crystals are so small that they form inside the cells without bursting through the walls. That’s the secret. By keeping the cellular integrity intact, IQF preserves the product perfectly, locking in all its original moisture, nutrients, and texture.

By controlling the size of ice crystals, IQF technology effectively pauses the product in time, preserving its original state at a cellular level. It’s not just freezing; it’s high-precision cryopreservation applied on a larger scale.

This core principle is what makes IQF so effective for everything from food production to advanced scientific work. The same process that keeps a pea firm and tasty also protects the viability of a cell line—something absolutely essential in modern research and therapeutics. For anyone working with cell-based therapies, mastering these preservation methods is key. We cover this in more detail in our guide on how to store cell lines for cell-based therapies.

To really drive the point home, let's look at how the speed of freezing directly affects the final quality. This table paints a clear picture of the difference.

| Freezing Method | Freezing Speed | Ice Crystal Size | Impact on Cell Walls | Resulting Product Quality |

|---|---|---|---|---|

| Conventional Freezer | Slow (Hours) | Large, Jagged | Severe Puncturing and Rupturing | Mushy, Loss of Moisture and Flavour |

| IQF Technology | Rapid (Minutes) | Tiny, Micro | Minimal Intrusion, Walls Remain Intact | Firm Texture, Original Quality Retained |

At the end of the day, the IQF individually quick frozen process is a clever application of physics. By manipulating how quickly heat is removed, it changes the very structure of the ice that forms inside a product. This ensures that when it’s thawed, it's remarkably close to its original, fresh state. This protection at the cellular level is what sets IQF apart and makes it the gold standard for quality preservation.

So, we've covered the complex science and what happens at a cellular level. But what does IQF individually quick frozen technology actually mean for your day-to-day operations? The benefits aren't just theoretical—they translate into very real gains in quality, efficiency, and your bottom line, whether you're in a food production facility or a scientific lab.

We can break down the practical impact of IQF into three key areas. First, the incredible quality it preserves, which is about much more than just taste. Second, how much easier it makes products to handle and use. And finally, the improved safety that comes baked into the process.

The first thing you notice with IQF is the stunning quality. Because the freezing happens so fast, those large, destructive ice crystals never get a chance to form. This means the original structure of each item stays almost perfectly intact. For a food producer, a frozen raspberry holds its delicate shape, and a pea still has that satisfying pop when you cook it.

This structural integrity is the key to everything else:

In scientific settings, this level of quality is absolutely critical. For a biobank, the viability of a cell line is everything. The gentle freeze of IQF ensures cell membranes aren't ruptured, leading to a much higher percentage of cells that are viable and functional when thawed—a non-negotiable for research and therapeutic applications.

One of the simplest yet most powerful advantages of IQF is that every single piece is frozen separately. This free-flowing nature is a game-changer for anyone concerned with efficiency and waste. No more hacking away at a giant frozen block just to get a small amount.

Think about a commercial kitchen producing ready-to-eat meals. With IQF peas, a machine can dispense precisely 100 grams into every container, time after time. This eliminates ingredient waste and guarantees a consistent product. That kind of portion control is a huge operational win, saving money and streamlining the entire production line.

The true power of IQF lies in its practicality. It transforms frozen products from rigid, inconvenient blocks into granular, easy-to-use ingredients, boosting efficiency and dramatically cutting down on waste.

The same logic holds true in the lab. A researcher might only need one or two vials from a batch of 50 cryopreserved samples. Because they were frozen individually, they can grab exactly what they need without compromising the rest of the stock by putting it through a damaging thaw-refreeze cycle. This protects the integrity and value of the entire sample inventory.

Speed isn't just about quality; it's about safety, too. The rapid temperature drop in the IQF individually quick frozen process sends products through the "danger zone" (roughly 5°C to 60°C) so quickly that microbial growth is stopped in its tracks. Bacteria, yeasts, and moulds have almost no time to multiply, which means a safer, more stable product with a longer shelf life.

And because you don't need preservatives to maintain quality, IQF helps create a cleaner label for food products. The preservation is physical, not chemical—a major plus for today's health-conscious consumers. This rapid halt to microbial activity also means a lower risk of spoilage along the supply chain, ensuring the product that gets to the end-user is just as safe as the day it was frozen.

Choosing the right preservation technique is a massive decision for any operation, whether you're in food production or biomedical research. Not all freezing methods are created equal, and your choice directly impacts everything from the quality of your final product to your operational costs. To really understand where IQF (Individually Quick Frozen) technology shines, we need to put it side-by-side with the more traditional approaches.

Older methods like block and plate freezing certainly have their place. They work on a fundamentally different principle, treating a large quantity of product as a single, solid unit. This can be a cost-effective way to handle robust, lower-value items where the integrity of individual pieces isn't the top priority.

But for delicate products—think berries, shrimp, or sensitive cell lines—this bulk approach is a non-starter. The slow freezing process and the inevitable clumping cause significant cellular damage, destroying the very qualities you were trying to preserve in the first place.

To make the best choice for your needs, a direct comparison is essential. Let’s break these methods down across the metrics that truly matter: speed, quality, and the operational realities of running the equipment.

Here's a closer look at how IQF stacks up against plate and block freezing. This table offers an in-depth analysis of different freezing methods across key performance and economic indicators relevant to both scientific and industrial users.

| Parameter | IQF (Cryogenic) | Plate Freezing | Block Freezing (Slow) |

|---|---|---|---|

| Freezing Speed | Extremely fast, often wrapping up in just a few minutes. | Moderate, typically needing several hours to freeze products solid. | Very slow. This can take many hours, or even days, for large blocks. |

| Impact on Product Quality | Minimal cell damage, preserving texture, flavour, and viability perfectly. | Moderate cell damage due to the formation of medium-sized ice crystals. | Severe cell damage, leading to poor texture and significant moisture loss. |

| Energy Consumption | High during operation because of the cryogenic gases, but it's a very fast process. | Moderate and consistent, relying on direct contact with cold plates. | Lower but prolonged, requiring sustained energy over a much longer time. |

| Equipment Costs | A high initial investment for specialised tunnels or spiral freezers. | A moderate investment for standard industrial plate freezers. | A low initial cost, often just using basic cold room infrastructure. |

This comparison makes one thing crystal clear: these methods are not interchangeable. Block freezing is a blunt instrument; IQF is a precision tool. While the initial investment in IQF technology is higher, it pays for itself through superior product quality, drastically reduced waste, and far better usability down the line.

The decision isn't just about freezing a product; it's about what state you need that product to be in after thawing. For applications demanding high quality and individual piece integrity, IQF is often the only viable choice.

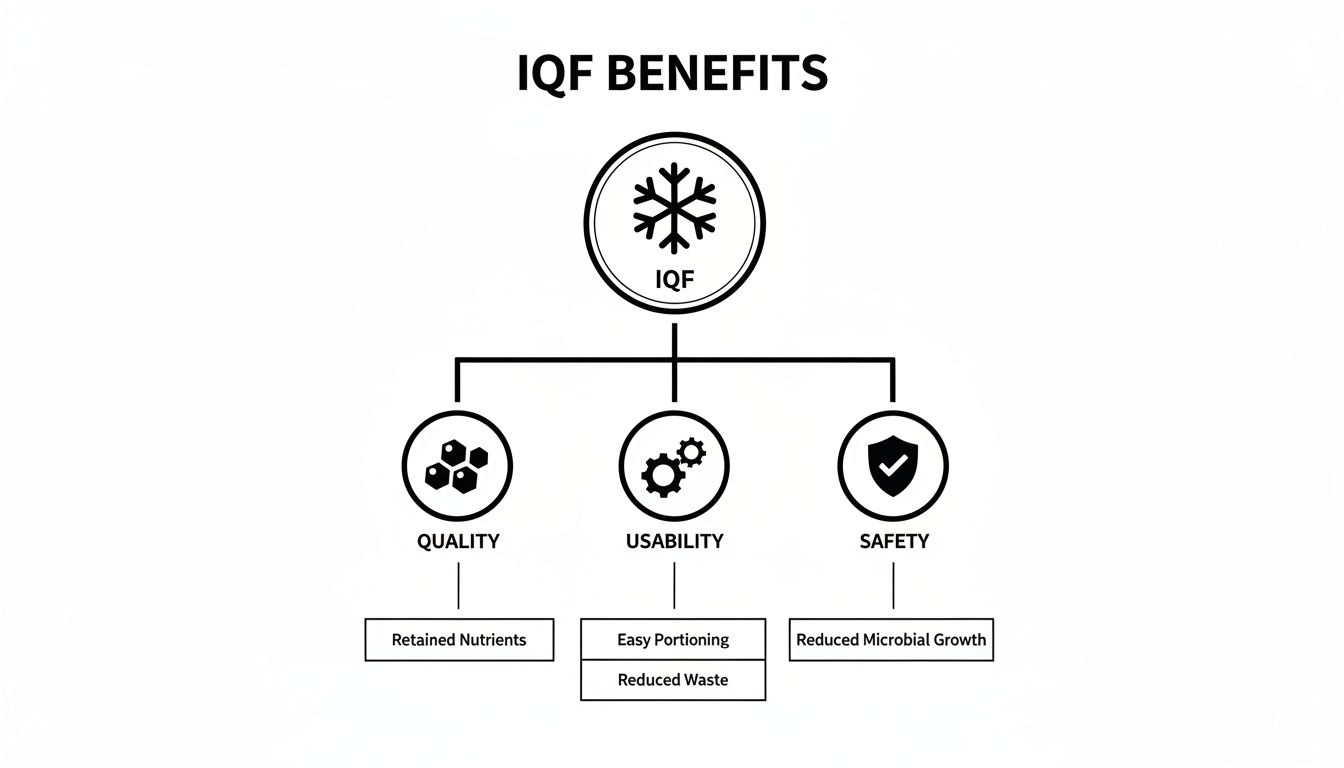

This diagram breaks down the main benefits you get from the IQF method.

As you can see, the core advantages of IQF (Individually Quick Frozen) technology branch out into superior quality, enhanced usability, and improved safety. Every single one of these benefits comes directly from the rapid, individualised freezing process that defines IQF.

Ultimately, the best freezing method is the one that lines up perfectly with your specific goals. If you're processing bulk fish for canning, block freezing might be perfectly fine. But if you’re freezing individual cell cultures for therapeutic use, preserving viability is everything, making an IQF-style rapid freeze absolutely essential.

Of course, once your product is frozen, maintaining that quality requires an unbroken cold chain supported by reliable equipment. The storage phase is just as critical as the initial freeze. To explore options for dependable long-term preservation, you can find more information in our guide about the role of the ultralow temperature freezer in modern laboratories and biobanks. By matching the right freezing technology with robust storage solutions, you ensure the integrity of your valuable products from start to finish.

Achieving that perfect, rapid freeze with IQF individually quick frozen technology is an incredible first step. But all that precision and care can be undone in a heartbeat if the cold chain breaks. The moment your perfectly frozen product leaves the IQF tunnel, a new and equally critical phase begins: long-term storage and secure transport.

This is exactly where Cryonos fits into your workflow. While we don't build the initial freezing systems, we deliver the rock-solid cryogenic infrastructure that protects your valuable assets for everything that comes next. Our solutions are engineered to bridge the gap between that initial freeze and the final use, ensuring the integrity you worked so hard to achieve is maintained flawlessly.

Think of it like this: the IQF process forges a high-quality product, and Cryonos builds the vault to protect it. Without a secure vault, even the most precious materials are at risk. We provide that security through specialised storage and transport solutions designed for the real-world rigours of the modern cold chain.

Once your biological samples or other sensitive materials are individually quick frozen, they need an environment of absolute stability. Even tiny temperature fluctuations over time can degrade quality, reduce cell viability, and completely compromise research outcomes. This is where our AC FREEZER series provides the ultimate safeguard.

These advanced cryogenic freezers are built to maintain ultra-low temperatures with unwavering consistency. They create the ideal conditions for storing IQF-processed samples for months or even years, effectively locking in their quality. By preventing the slow degradation that can happen in less reliable storage, the AC FREEZER series ensures your materials remain in the exact state they were in right after the freeze.

This long-term stability is crucial for:

By integrating our cryogenic storage into your workflow, you create a seamless transition from the IQF process to secure, long-term preservation. This organises your operations and takes the risk of sample loss off the table.

The success of an IQF workflow isn't just measured by the quality of the initial freeze, but by the ability to maintain that quality throughout the product's entire lifecycle. A robust cold chain is non-negotiable.

A cold chain is only as strong as its weakest link, and transport between facilities is often the most vulnerable stage. Moving highly sensitive, cryogenically preserved materials requires more than just a cold box; it demands specialised vessels that meet strict regulatory standards for both safety and performance.

Cryonos tackles this challenge head-on with our ADR-licensed transport vessels. The European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) sets tough requirements for transporting hazardous materials, including cryogenic liquids. Our vessels aren't just compliant; they're engineered for maximum security and thermal efficiency on the move.

This means you can shift your valuable IQF-processed samples between your lab, a collaborator’s facility, or a long-term storage biobank with complete confidence. The risk of temperature spikes or containment failure is minimised, protecting your assets, the public, and the personnel handling them. This integration of compliant transport solutions is fundamental to a truly complete and secure IQF individually quick frozen workflow.

A complete workflow organises every step to protect product integrity. It starts with the initial freeze and extends through every stage of handling, storage, and movement, creating an unbroken chain of quality control. Cryonos provides the critical hardware to make that chain a reality.

Achieving that perfect IQF individually quick frozen quality is a massive step forward, but it's really just the start of the journey. To get the full value from that investment, you have to get just as serious about everything that happens after the freeze. One slip-up in storage or a single mistake in handling can wipe out all the benefits, compromising everything from cellular viability in a biological sample to the safety and texture of food.

Making IQF technology work for you means extending that same level of precision well beyond the freezer. It’s all about building a disciplined approach to the entire cold chain, putting robust quality checks in place, and having a solid plan for when things go wrong. Without these practices locked down, your product’s integrity is always on the line.

The goal is a seamless workflow where quality is an obsession from start to finish. From the second an item leaves the freezer until it arrives at its final destination, every stage demands meticulous care to protect the value you worked so hard to create.

If there's one golden rule in post-IQF management, it’s this: protect the cold chain at all costs. An unbroken cold chain is your non-negotiable promise that a product has stayed within its required temperature range, end to end. Any deviation—often called a "temperature excursion"—is a disaster waiting to happen. It can trigger recrystallisation, which ruins texture and fatally damages sensitive cells.

Getting this right comes down to two things: the right tech and the right procedures.

An IQF product is only as good as the cold chain that protects it. Maintaining unwavering temperature stability is the most fundamental operational responsibility.

You can’t manage what you don’t measure. Regular quality control checks are the only way to be sure your IQF process and handling protocols are consistently hitting the mark. Think of these tests as a critical feedback loop, helping you spot and fix any small drifts in your process before they snowball into major failures.

The exact tests you run will depend on what you’re freezing. For instance:

Finally, managing risk means playing by the rules. When transporting biological materials or other goods classified as hazardous, using ADR-compliant vessels isn’t optional; it's mandatory. This ensures the safety of everyone handling the shipment and the general public, but it also secures your valuable assets while they’re on the move. By blending rigorous testing with strict adherence to safety regulations, you build a resilient operation that guarantees quality all the way down the line.

It’s natural to have questions when you’re looking at a process as advanced as IQF individually quick frozen technology. We get it. To help out, we've put together some quick, straightforward answers to the questions we hear most often.

Think of this as your go-to guide for the core principles. Whether you're weighing IQF against older methods or figuring out how it fits into a modern lab workflow, you'll find the clarity you need right here.

The real difference is what happens to each individual item you’re freezing. With regular freezing, a whole batch of product gets treated like one big block, freezing slowly and clumping together. This solid mass makes getting a single portion next to impossible and, more importantly, it’s a clear sign that large, damaging ice crystals have torn through the product’s structure, ruining its texture and quality.

IQF, on the other hand, freezes every single item on its own—and does it almost instantly. This rapid-fire process keeps the unique shape and integrity of every piece, whether it’s a pea or a delicate cell vial. What you get is a free-flowing product with virtually no cellular damage, making it the hands-down winner whenever quality and usability are top priorities.

Yes, absolutely. In fact, the core principle of IQF—freezing so fast that large ice crystals can't form—is the very foundation of good cryopreservation. It's perfectly suited for maintaining the viability of cell cultures, tissues, and other sensitive biologicals because it keeps cell walls from being punctured and destroyed.

For scientific work, you're not just preserving something; you're trying to keep it viable. The ultra-fast freeze you get with IQF is non-negotiable for making sure cells are still functional and intact when they’re thawed. It’s a vital tool for both research and therapeutics.

Of course, once the initial freeze is done, the long-term health of those samples is all about stable storage. That's why pairing an IQF process with reliable cryogenic freezers is so critical for protecting your investment.

Cryonos provides the essential infrastructure for everything that happens after your materials come out of the IQF freezer. Our job starts the second that rapid-freeze process ends, making sure the incredible quality you’ve just achieved is maintained perfectly over time and across any distance.

We do this with two key pieces of the puzzle:

Simply put, Cryonos is here to protect the integrity of your IQF-processed products for their entire journey.

Ensure the quality achieved with IQF technology is preserved from the freezer to its final destination. Explore our complete range of cryogenic storage and transport solutions at Cryonos GmbH by visiting https://www.cryonos.shop.