No Products in the Cart

Think of the ISO container code as the universal license plate for the world of shipping. This standardised system, known officially as ISO 6346, is what gives every single container its own unique identity, making the intricate dance of global trade possible. It’s the secret language that allows businesses to track, manage, and verify their assets anywhere on the planet.

At its core, the ISO container code is the bedrock of modern logistics. Imagine trying to keep track of millions of identical-looking steel boxes crisscrossing oceans and continents without a shared system. It would be pure chaos. This code provides a simple but incredibly effective way to identify a container's owner, its unique unit number, and even verify that the code itself is correct.

This standardisation is absolutely critical in fields where there's no room for error. Take specialised cryogenic transport, for instance. When a container is carrying sensitive biological samples or industrial gases, the code is a guarantee that it can be tracked flawlessly from origin to destination. For anyone managing valuable or hazardous goods in transit, understanding this code isn't just helpful—it's essential.

The system's importance is clear when you look at the numbers. The global market for ISO containers is set to grow significantly, projected to hit 1,832.4 thousand units by 2032. This isn't just a random statistic; it shows a massive, increasing reliance on standardised logistics worldwide. Fortune Business Insights offers more detail on these market trends if you're curious.

So, what makes it so indispensable? A few key advantages stand out:

The image below gives you a real-world look at an ISO 6346 code on a container, showing how the owner code, serial number, and other markings come together.

This simple string of letters and numbers forms a unique, verifiable identity that is absolutely vital for keeping global trade and logistics moving smoothly.

At first glance, a code like CRYU 123456 7 on the side of a container might seem like a random jumble of letters and numbers. But in reality, it’s a highly logical system where every single character tells a story about the container it's attached to.

Think of it less like a password and more like a sentence that reveals the container’s identity, its purpose, and its legitimacy. Knowing how to read this code is a fundamental skill in logistics, allowing you to instantly verify who owns a container and confirm you’re dealing with the right piece of equipment. Let's break it down into its four distinct parts.

To make this clear, here’s a quick overview of what each component in an ISO 6346 code represents.

| Component | Format | Description |

|---|---|---|

| Owner Code |

AAA (3 letters) |

A unique prefix identifying the company that owns or operates the container. This code must be registered with the BIC. |

| Category Identifier |

A (1 letter) |

A single letter indicating the type of equipment. U is for freight containers, J for related equipment, and Z for chassis. |

| Serial Number |

123456 (6 digits) |

A unique six-digit number assigned by the owner to distinguish this container from all others in their fleet. |

| Check Digit |

1 (1 digit) |

A single digit calculated from all the previous letters and numbers. It's used to validate the entire code and prevent errors. |

Each of these elements plays a critical role in global transport and inventory management, ensuring every container can be accurately tracked from origin to destination.

The first three letters—CRY in our example—make up the owner code. This is a unique identifier assigned to the company that owns or operates the container. To make sure no two companies accidentally use the same prefix, every owner code has to be officially registered with the Bureau International des Containers (BIC) in Paris.

You’ll see common codes like MSK for Maersk or HLC for Hapag-Lloyd on standard shipping containers. For a specialised company like Cryonos GmbH, a custom code like CRY immediately signals that the container belongs to our dedicated fleet.

Right after the owner code, you'll find a single letter. This is the equipment category identifier, and it tells you exactly what kind of equipment you're looking at.

There are three main categories you’ll run into:

In our example CRYU, the 'U' confirms this is a standard freight container, even if it's a specialised type like a cryogenic tank. Only codes ending in 'U' are officially recognised for intercontinental transport under the ISO 6346 standard.

The final two parts of the code work hand-in-hand. They give the container its unique identity and provide a clever, built-in way to check for errors.

The serial number is the sequence of six digits that follows the letters—123456 in our example. This number is unique to that specific container within the owner’s fleet. No two containers from the same owner can ever share the same serial number, ensuring every single unit has a distinct identity.

The final, standalone number is the check digit (

7in our example). This single digit is the code’s self-verification tool. It’s calculated using a specific mathematical formula based on all the preceding letters and numbers.

If just one character is typed incorrectly into a logistics system, the calculated check digit won't match the one printed on the container. This simple but brilliant feature instantly flags the mistake, preventing costly errors like sending the wrong container or losing track of a valuable asset. We’ll get into exactly how that calculation works in the next section.

That final digit tacked onto the end of an ISO container code isn’t just a random number; it’s a cleverly designed security feature. Think of it as an automatic spell-checker for the logistics world, built to catch costly data entry mistakes before they spiral into bigger problems.

When you understand how this check digit is calculated, you gain the power to verify any container's code on the spot. It’s a quick way to confirm that the number you’re looking at is legitimate and not just a typo on a shipping manifest.

While there are plenty of online calculators that can do the maths for you in a second, learning the manual process is surprisingly straightforward. It turns what looks like a complicated formula into a simple, step-by-step check. This skill is invaluable when you’re troubleshooting discrepancies or doing on-site inspections.

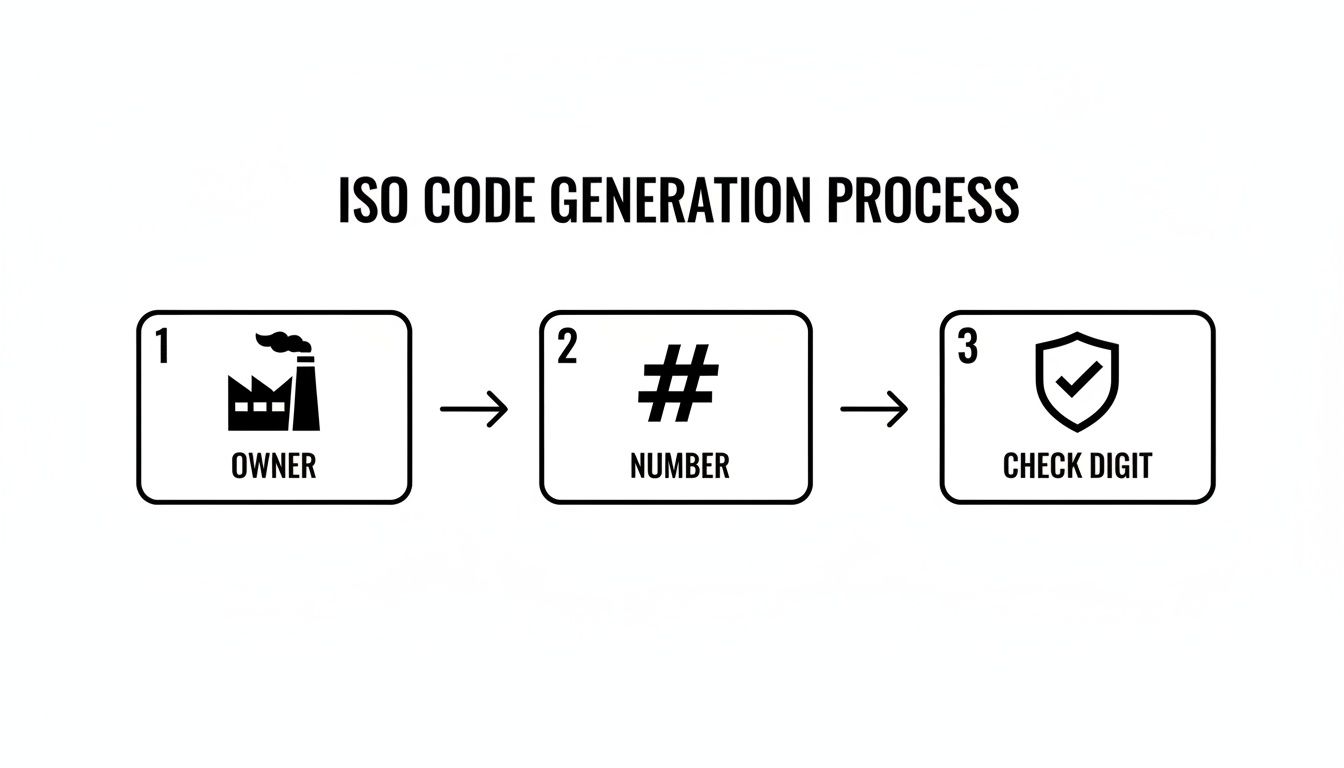

This diagram breaks down how each piece—from the owner code to the serial number—comes together to generate the final, verifiable identifier.

This entire workflow highlights the systematic nature of the ISO 6346 standard. Each part logically builds on the last to create a unique code that anyone in the supply chain can trust.

The calculation itself follows a precise four-step algorithm. Let’s walk through it using our example code, CRYU 123456.

Convert Letters to Numbers: First, we assign a numerical value to each of the four letters in the owner code. The system starts with 'A' = 10, 'B' = 12, 'C' = 13, and so on, deliberately skipping any number that is a multiple of 11. For our code CRYU, the corresponding values are 13, 29, 32, and 32.

Apply Positional Multipliers: Next, each of the first 10 characters (the four new numbers for the letters and the six serial digits) is multiplied by a power of 2. The first character gets multiplied by 2⁰, the second by 2¹, the third by 2², and so on, all the way up to 2⁹ for the tenth character.

Sum the Results: Now, simply add all those weighted values from the previous step together. This will give you one large total.

Find the Final Digit: Take that total sum and divide it by 11. The remainder from this division is your check digit. There's one small exception: if the remainder happens to be 10, the check digit becomes 0.

Key Takeaway: The check digit is the direct result of a modulo 11 calculation performed on the first 10 characters of the code. If the digit you calculate doesn't match the one printed on the container, you know there’s an error somewhere in the code.

This standardised system is the backbone of Germany's incredibly efficient logistics network. In fact, within the country's shipping container market, ISO containers are utterly dominant, making up a staggering 98.31% of the total revenue share in 2020. This uniformity is crucial for companies like Cryonos GmbH, which depend on ISO tank containers for safely transporting sensitive cryogenic materials, as it guarantees seamless tracking and integration across different systems. You can discover more insights about Germany's container market and its rapid growth.

Beyond the main ID number, every ISO container has a second, equally important code that tells you its physical story at a glance. This four-character marking, known as the size and type code, is logistics shorthand. It gives you the vital statistics—dimensions and purpose—without you ever having to pull out a measuring tape.

Getting a handle on this code, whether it’s 22G1 or 45G1, is absolutely essential for the practical, day-to-day grind of logistics planning. It's how you make sure the right container is picked for the right cargo, that it will actually fit on the truck or train, and that it can be handled safely at every single stop. Let's break down how to read this critical piece of the puzzle.

The first two characters in this four-part code are all about dimensions. Think of them as a quick, standardised way to identify the container's length and height—two factors that are non-negotiable for loading, stacking, and transport.

2 means you’re looking at a 20-foot container, while a 4 tells you it's a 40-footer. Simple.2 usually points to a standard height of 8 feet 6 inches. See a 5? That’s a 'high cube' container, standing taller at 9 feet 6 inches.So, when you spot a code starting with 45, you know instantly it's a 40-foot high cube container, giving you that much more vertical packing room. This simple two-digit system cuts out the guesswork and helps avoid costly mistakes, like trying to squeeze a high cube under a low bridge.

This is exactly why the ISO 6346 standard is so brilliant. It boils down complex physical specs into a simple, universal language that works seamlessly across ships, trains, and trucks.

While the first two digits define the size of the box, the last two characters tell you what it’s built for. This two-character type code is what helps match the container to the cargo's specific needs, whether you're shipping general goods, perishable items, or bulk liquids.

The system uses a letter for the general category, followed by a number for more specific details.

Here are a few of the most common ones you'll see:

G1 (General Purpose): This is your standard dry freight container, the workhorse of global shipping. The G1 specifically means it has passive vents up top.R1 (Refrigerated): This code marks a 'reefer'—a mechanically refrigerated and heated container. It's essential for anything temperature-sensitive, from pharmaceuticals to fresh produce.T1 (Tank Container): This identifies a tank container designed for non-dangerous liquids. Think food-grade oils or other non-hazardous materials.Put it all together, and a code like 45G1 paints a complete picture: a 40-foot, high-cube, general-purpose dry container. This immediate clarity is the bedrock of efficient and safe global logistics.

In high-stakes industries, an ISO container code is so much more than a simple string of letters and numbers; it’s a non-negotiable link in the chain of safety, compliance, and custody. When you're dealing with cryogenic liquids or hazardous materials, this standardised system provides the very bedrock of trust and traceability that every single shipment depends on.

Imagine a container carrying irreplaceable biological samples for a biobank, or one filled with volatile industrial gases. There is absolutely zero room for error. The unique ISO code guarantees an unbroken, verifiable chain of custody from the moment it leaves the facility to its final destination. This is how you know the correct, certified, and compliant container is being used for its specific—and often dangerous—purpose.

The connection between the ISO 6346 standard and regulatory frameworks like ADR (the European Agreement concerning the International Carriage of Dangerous Goods by Road) is both direct and critical. ADR transport rules demand precise identification and documentation for any hazardous materials on the move, and the ISO code is the primary tool that makes this possible.

An accurate code allows authorities, handlers, and even emergency responders to instantly identify the container's owner and contents by cross-referencing it with shipping manifests. This immediate clarity is fundamental to managing risk and is often a prerequisite for getting and keeping the regulatory approval to transport such goods. Without this standardised identifier, proving compliance becomes a nearly impossible task.

A verified ISO container code acts as a declaration of conformity. It signals to everyone in the supply chain that the container meets international standards for safety, construction, and identification. This is especially vital for specialised equipment like the ISO tank containers used in cryogenic logistics.

This level of standardisation is also what enables seamless multimodal transport—that smooth transition of a container from a ship to a train to a truck. Take inland waterway transport in Germany, for example. It's a critical piece of the European logistics network, with the country accounting for 21.2% of empty container movements at the EU level in 2023. The universal language of the ISO container code, where German-registered units bear the 'DE' designation, is what ensures this complex dance works flawlessly. You can see more on how container standardisation supports European logistics on the Eurostat website.

This capability is a game-changer for organisations that need reliable, compliant transport for sensitive materials. For any business that relies on precise and safe logistics, the ISO code isn't just a label. It's an essential operational asset that underpins the entire transport process, ensuring safety and integrity every step of the way. You can learn more about the role of specialised containers in our detailed guide on ISO tank containers.

Understanding the theory behind the ISO container code is one thing, but putting it to work in your daily logistics is where you really start to see the benefits. When you integrate these codes properly, you’ll see a dramatic jump in accuracy, faster turnaround times, and a sharp drop in those costly human errors.

Fortunately, making this happen is more straightforward than you might think. The whole system, from instant online verifications to registering your own fleet, is built for the real world. Let’s break down how you can make the ISO code work for you.

One of the best tools you have is the official Bureau International des Containers (BIC) database. It's a free online resource that lets you instantly verify any container's owner code. If a container shows up at your facility, a quick check can confirm who it belongs to, adding a crucial layer of security and validation to your receiving process.

And if your business runs its own fleet of containers? Registering your unique owner code is a must. The BIC registration process guarantees your prefix is one-of-a-kind, protecting your brand and making your assets instantly recognisable anywhere on the globe.

Integrating ISO codes is about transforming a simple marking into an active tool for inventory control. By digitising this information, you create a single source of truth for every asset, eliminating guesswork and manual tracking.

Manual data entry is the root of so many logistical headaches. A single mistyped number can send a container to the wrong continent or make it disappear from your system entirely. This is where a little bit of tech makes a huge difference.

By building the ISO container code into your warehouse management system (WMS) or inventory software, you can automate tracking with some pretty basic tools.

This simple approach helps clean up your receiving, dispatching, and auditing procedures for all your critical equipment. For a deeper dive into how these containers are used in specialised fields, check out our guide on the versatility of the ISO container tank.

Got questions about ISO 6346? You're not alone. Here are some quick, straightforward answers to the most common queries we hear from clients navigating the world of shipping containers.

Think of the size and type code as a container's vital statistics, boiled down to four characters like 45G1. The first two characters give you the physical dimensions. The first number tells you its length, and the second tells you its height and width.

The last two characters define what kind of container it is. Is it a standard general-purpose dry container? A reefer for temperature-sensitive goods? Or maybe a specialised tank container for liquids? This code tells you at a glance.

Nope, country codes are completely optional under the ISO 6346 standard. When a company chooses to use one, it's a two-letter code that follows the main identification number, like DE for Germany.

It’s a common misconception, but this code doesn't tell you where the container was made or who owns it now. It only indicates the country where the owner's code is registered with the BIC.

An ISO container code is more than a label; it’s a universal language for global logistics. It ensures that every container has a unique, verifiable identity that is understood at every port, terminal, and border crossing worldwide.

A container without a valid ISO 6346 marking can throw a real spanner in the works. These are often called "Shipper-Owned Containers" (SOCs), and they are a common source of operational headaches, from triggering errors in logistics software to causing frustrating customs delays.

To keep things moving, terminals might assign a placeholder code like "XXXX" to process these units. While it solves an immediate problem, it often creates a bigger one down the line, leading to data mismatches and even potential penalties at ports and borders.

For state-of-the-art cryogenic solutions that meet the highest international standards, trust Cryonos GmbH. Explore our compliant and reliable transport and storage options at https://www.cryonos.shop.