No Products in the Cart

An ISO container tank, more commonly known as an ISO tank, is a purpose-built container designed for hauling bulk liquids, gases, and even powders. It’s essentially a tough, stainless steel cylindrical tank mounted inside a standardised frame, a design that makes it exceptionally safe and efficient for intermodal transport—whether it's moving by road, rail, or sea.

Imagine a highly engineered thermos flask built for a round-the-world trip, and you’re close to understanding an ISO container tank. Its entire purpose is to solve a fundamental logistics puzzle: how do you move huge volumes of sensitive liquids and gases without contamination, loss, or the hassle of constant repackaging? The real genius is in its intermodal design.

The tank itself sits snugly inside a steel frame constructed to the precise dimensions of a standard shipping container. This simple but brilliant idea means it can be handled, stacked, and moved using the exact same port and rail equipment as regular dry cargo boxes. This completely removes the need for risky manual transfers of the product when switching from a truck to a train or a ship.

This seamless hop between different modes of transport is what makes the ISO container tank a true workhorse of modern logistics. For industries where product purity and stability are everything, it brings some major advantages to the table:

For fields like biobanking, pharmaceuticals, and industrial gas supply, this kind of reliability isn't just nice to have—it's essential. An ISO container tank is what guarantees that cryopreserved biological samples or medical-grade liquid oxygen show up in perfect condition.

Nowhere is the importance of this technology more obvious than in Europe’s tightly connected supply chains. Back in 2023, Germany was at the heart of the continent's ISO tank operations, playing a huge part in managing a regional fleet of over 210,000 units. This strong presence highlights Germany's vital role in intermodal logistics. You can find more insights on the European ISO tank market on marketgrowthreports.com.

At first glance, an ISO container tank looks fairly straightforward—it's just a cylinder tucked inside a frame, right? But that simple appearance is deceiving. In reality, it’s a highly sophisticated piece of engineering where every single component is designed for a critical purpose. Getting to know this anatomy is the key to understanding how these tanks can safely move everything from industrial chemicals to ultra-cold cryogenic liquids around the globe.

The whole structure boils down to two main elements working together: the inner vessel that actually holds the cargo, and the outer frame that protects it. This dual-layer approach delivers both structural integrity and incredible operational flexibility, making the ISO container tank a true workhorse of modern logistics.

The core of the whole unit is the inner pressure vessel—the tank itself. This is almost always built from high-grade stainless steel, usually something like grade 316 or 304. The choice is no accident; stainless steel is brilliant at resisting corrosion, which prevents nasty reactions with the cargo and guarantees product purity. For anything medical or food-grade, that’s non-negotiable.

When you're dealing with cryogenic liquids like liquid nitrogen at -196°C, the engineering gets even more impressive. The vessel has to handle extreme thermal stress without turning brittle. Tucked between the inner vessel and an outer shell is an advanced insulation system, often a combination of a vacuum and multiple layers of super-insulating material. This setup minimises heat transfer, which dramatically slows the evaporation of the cryogenic liquid—an absolutely vital feature for long-haul transport.

Wrapped around the vessel is the protective frame, constructed to precise International Organisation for Standardisation (ISO) dimensions. This isn't just some flimsy cage. It's a structural skeleton that allows the tank to be handled, stacked, and moved using standard intermodal equipment anywhere in the world.

This standardised frame is what gives the ISO container tank its unmatched versatility. It has reinforced corner castings that lock tightly onto truck chassis, railcars, and ship cranes, allowing for a smooth transition from road to rail to sea. The frame is built to absorb the shocks and stresses of the journey, effectively shielding the precious inner vessel from any potential harm.

Think of the frame as the tank's exoskeleton. It provides the muscle and bone needed to withstand the rigours of global travel, while the inner vessel acts as the vital organ, focused entirely on protecting its sensitive contents.

Beyond the main vessel and frame, an ISO tank is fitted out with a precise array of valves and fittings, each with a specific job. These components are essentially the tank's control centre, giving operators the ability to load, discharge, and manage the product safely and efficiently.

Some of the key components you’ll always find include:

Every one of these parts is meticulously designed and tested to handle the specific chemical properties of the cargo and the pressures of operation. This intricate system of controls is what makes the ISO container tank more than just a container—it's a highly controlled environment for moving valuable liquids.

Moving an ISO container tank isn't as simple as just loading it onto a truck or a ship, especially when it’s filled with something as sensitive as cryogenic liquids. A whole framework of international and regional rules governs every step of its journey, ensuring safety from start to finish.

Think of these standards not as red tape, but as a universal language of safety. Every handler, operator, and inspector across the globe speaks it. Compliance isn’t optional—it’s the very foundation of safe, legal, and efficient cryogenic logistics. Getting these rules right is key to protecting your cargo, your team, and the public.

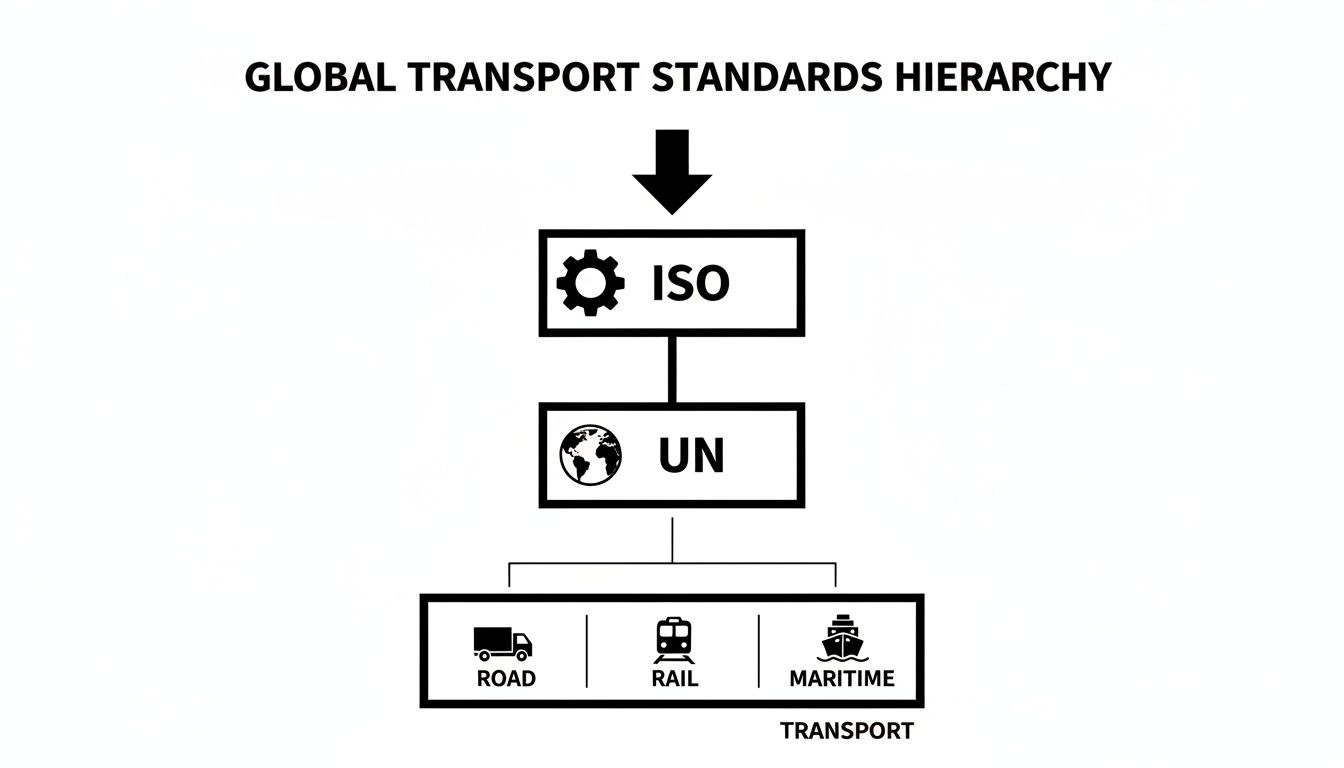

It all starts at the highest level with the International Organisation for Standardisation (ISO). These are the rules that dictate the tank's physical design, what it's made of, how it's built, and how it’s tested. ISO standards guarantee that any tank, no matter where it was made, meets a globally recognised benchmark for strength and reliability.

Working in tandem with ISO are the United Nations' recommendations, specifically the UN Portable Tank Instructions, which you'll see identified by "T-Codes." A T75 code, for instance, is a clear signal that the tank is built for refrigerated liquefied gases like liquid nitrogen. This simple code instantly tells regulators and operators what the tank is designed for and the safety features it must include.

This dual system creates a predictable and robust standard for every ISO container tank that enters the global supply chain. It's the bedrock upon which all other transport rules are built.

Once a tank is certified under ISO and UN guidelines, it then has to play by the rules for each specific mode of transport. For logistics in Europe, this means getting familiar with three critical agreements:

Following these codes is what makes a seamless, legal journey across borders possible. An ADR-compliant shipment can leave a facility in Germany and travel through multiple countries to its destination, with every nation's authorities recognising and trusting its safety certifications.

Germany's influence in the ISO tank world is clear. The 2025 global fleet report shows leading German lessors like TWS Rent-A-Tainer commanding 12,000 units and VTG adding another 4,000. Together, they help account for 84% of the total leasing fleet held by the top 10 lessors. This solidifies Germany's role as a key hub for Cryonos GmbH's cryogenic solutions, making turn-key transport of biological samples and industrial gases a reality. You can find more insights in the global ISO tank fleet in the 2025 report.

To keep operations running smoothly, a solid grasp of broader logistics and warehousing strategies is crucial for managing these specialised containers. And for a closer look at the hardware itself, check out our guide on the different types of ISO tank containers. Ultimately, these regulations are more than just paperwork; they're the practical safety net that makes modern, multi-modal logistics work.

Choosing an ISO container tank isn't a one-size-fits-all situation. These highly specialised containers are classified using a system of UN Portable Tank instructions, better known as "T-Codes." Think of them as a shorthand that instantly tells you what a tank is built to handle and the kind of cargo it can safely carry. Getting to grips with these codes is the first, most crucial step in pairing the right tank with your specific needs.

For fairly straightforward jobs, tanks are grouped by the products they're designed for. T-Codes from T1 to T4, for example, are your go-to for non-hazardous liquids like fruit juices, milk, or vegetable oils. Their design is simpler, focusing more on maintaining product purity and being easy to clean rather than managing extreme pressures or temperatures.

Things get much more serious when the cargo becomes volatile or corrosive. This is where the tank specifications tighten up considerably, and you'll run into classifications like the T11 ISO container tank. The T11 is a real workhorse in the chemical industry, engineered to safely move a huge variety of hazardous materials.

It's built with thicker stainless steel and has much higher pressure ratings compared to its non-hazardous cousins. This robust design is absolutely essential for containing chemicals that might be corrosive, flammable, or toxic, making sure they stay securely sealed from point A to point B. For any organisation transporting industrial chemicals or hazardous precursors, the T11 is often the default, trusted choice.

The T-Code system is like a set of blueprints. A T1 code outlines a basic liquid container. A T11 code details a reinforced structure built for dangerous goods. But a T75? That describes a whole other class of engineering, one designed for the extremes of cryogenics.

When your work involves super-cooled liquids, the conversation shifts entirely to the T75 ISO container tank. This is a highly specialised piece of equipment built for a single, demanding purpose: transporting refrigerated liquefied gases like liquid nitrogen (LN2), argon, oxygen, and liquefied natural gas (LNG) at incredibly low temperatures.

The secret to the T75's performance lies in its sophisticated insulation. It uses a "tank-within-a-tank" design, where the inner vessel holding the cryogenic liquid is separated from the outer shell by a vacuum. This vacuum is an incredibly effective insulator, drastically cutting down on heat transfer from the outside world. This is critical for minimising product loss from evaporation—a process we call "boil-off."

This diagram shows how these tanks fit into the global logistics framework, all governed by a strict hierarchy of standards.

As you can see, ISO standards define the container's physical construction, UN codes classify its use, and specific transport regulations like ADR (road), RID (rail), and IMDG (maritime) govern its movement across the globe.

To make sense of the common codes you'll encounter, here’s a quick-reference table matching UN T-Codes to their primary applications, especially for specialised and cryogenic liquids.

| UN T-Code | Primary Use Case | Example Cargo | Key Feature |

|---|---|---|---|

| T1–T4 | Non-hazardous food-grade & industrial liquids | Fruit juice, milk, vegetable oils, non-haz chemicals | Simple design, focused on purity and ease of cleaning. |

| T11 | General-purpose hazardous chemical transport | Solvents, acids, resins, industrial chemicals | Reinforced stainless steel, higher pressure rating. |

| T14 | Highly hazardous or corrosive chemicals | Concentrated acids, toxic substances | Thicker shell, higher test pressure than T11. |

| T50 | Liquefied gases under pressure (non-refrigerated) | LPG (Propane, Butane), anhydrous ammonia | High-pressure vessel designed for ambient temperatures. |

| T75 | Cryogenic & refrigerated liquefied gases | Liquid Nitrogen (LN2), LNG, Liquid Oxygen (LOX) | Vacuum-insulated "tank-within-a-tank" design. |

This matrix helps clarify that the jump from a T11 to a T75 isn't just an upgrade; it's a move to a completely different type of engineering designed for a unique set of physical challenges.

The incredible capabilities of the T75 translate directly into its use across some of the world's most critical industries. Every application hinges on the tank's ability to maintain extreme cold and manage pressure reliably over long distances.

In every one of these scenarios, the T75 is far more than just a container. It's a vital piece of infrastructure that guarantees the integrity, purity, and availability of critical materials. Choosing the right tank—whether it’s a T11 for chemicals or a T75 for cryogenics—is absolutely fundamental to operational success and safety.

Choosing the right ISO container tank isn't as simple as just picking a size. It’s a detailed process where every decision can impact the safety, efficiency, and—most importantly—the integrity of your valuable cargo. Get this choice right from the start, and you'll prevent costly mistakes and ensure your sensitive materials arrive in perfect condition.

The entire selection process really boils down to one fundamental question: what, exactly, are you transporting? The unique chemical and physical properties of your product will guide almost every other choice you make, from the tank’s material composition to its pressure rating and valve setup.

First on the list is product compatibility. The tank's inner vessel has to be built from a material, usually a specific grade of stainless steel, that won't react with or be corroded by your cargo. For anyone in the pharmaceutical and biobanking sectors, this is absolutely non-negotiable for maintaining product purity.

Next, you have to think about the operating conditions your product requires. This comes down to two key metrics:

For cryogenic applications, there's an often-overlooked but critical factor: the Net Evaporation Rate (NER), sometimes called the boil-off rate. A lower NER means the tank’s insulation is more effective, which preserves more of your product over time and can extend the maximum journey duration.

Once you’ve nailed down the technical specs, the next hurdle is navigating the regulations. The ISO container tank you choose must hold the correct certifications for both the product it's carrying and the routes it will travel. For instance, any tank moving hazardous materials by road in Europe absolutely must be ADR-compliant.

Failing to check these certifications can get your shipment stopped cold at a border, leading to serious delays and potential fines. A trustworthy provider will always supply a tank that meets all the necessary ISO, UN, ADR, RID, and IMDG standards for your specific job. Making the right choice upfront is key, and to help you navigate this complex area, we've outlined some common pitfalls to avoid when you buy a cryogenic container to avoid mistakes.

To make a truly informed decision, you need to ask providers specific, targeted questions that go beyond the basics. This is how you effectively compare your options and make sure the tank you lease or buy is a perfect fit for your operational workflow.

Here’s a checklist of essential questions to ask any potential ISO container tank supplier:

By carefully working through these critical criteria—from product compatibility and performance metrics to regulatory compliance and operational features—you can confidently select the ideal ISO container tank that protects your assets and streamlines your logistics.

An ISO container tank is an incredibly robust piece of engineering, but its safety and reliability depend entirely on diligent handling and consistent maintenance. This isn't just about ticking boxes for regulatory compliance; it's about fostering a powerful safety culture that protects your team, your valuable cargo, and the public.

From the routine checks before a journey begins to the mandatory inspections years down the line, every single step plays a vital role. It all adds up to ensure an incident-free journey from start to finish.

Proactive safety begins long before the tank is even filled. A thorough pre-trip inspection is your first line of defence against potential issues. This can't be just a quick glance-over; it has to be a systematic check of all critical components. Operators need to verify that every valve is working correctly and is in the proper position, that safety placards are clean and clearly visible, and that the tank's frame and vessel show no signs of damage or stress.

Proper loading and unloading protocols are fundamental. Rushing these procedures is a frequent and avoidable cause of accidents, so it's absolutely essential that all personnel involved are fully trained on the specific characteristics of the cargo, especially when dealing with cryogenic liquids like liquid nitrogen.

The use of appropriate Personal Protective Equipment (PPE) is completely non-negotiable. This always includes:

These safety measures are critical for preventing cold burns and other serious injuries. For a deeper dive, exploring the foundational rules for safe work with cryogenic liquids can give your team more detailed insights and actionable steps. Implementing these best practices for safety and maintenance also significantly reduces operational risks, a concept closely aligned with effective loss control strategies that aim to cut risks and save money.

Beyond the daily checks, every ISO container tank is subject to a strict, legally mandated inspection schedule to keep its transport certification valid. These tests are critical for verifying the tank's structural integrity and confirming it continues to meet international safety standards. There are two main inspection milestones operators must follow.

Think of these inspections as a comprehensive health check-up for the tank. Just as a person needs regular medical exams to catch problems early, an ISO tank requires these rigorous tests to confirm it remains fit for the demanding task of transporting hazardous or sensitive materials.

The two key inspections are:

The 2.5-Year Intermediate Inspection: This test focuses on the tank's operational and safety equipment. Inspectors will check the condition of all valves, gaskets, and pressure relief devices to ensure they are functioning as they should. The tank also undergoes a leakproofness test, where it is filled with air or an inert gas and pressurised to confirm there are absolutely no leaks.

The 5-Year Periodic Inspection: This is a much more intensive examination. In addition to repeating all the checks from the 2.5-year test, the 5-year inspection involves a hydrostatic pressure test. Here, the tank is filled with water and pressurised to 150% of its maximum allowable working pressure. This process rigorously tests the strength and integrity of the vessel's welds and overall structure, providing definitive proof that it can safely handle its designated cargo.

Sticking to this inspection schedule isn't just a regulatory hurdle—it's the ultimate assurance that your ISO container tank is safe, compliant, and ready for service.

Working with cryogenic logistics, especially for the first time, naturally brings up a few questions. To help clear things up, we've put together answers to some of the most common queries we hear about ISO container tanks, particularly from those in biobanking, medical labs, and industrial gas transport. Think of this as a practical guide that builds on everything we've covered so far.

The "holding time" is simply how long a tank can keep its contents properly chilled before it needs to vent off excess pressure. This isn't a single, fixed number; it really depends on the tank's size, the quality of its insulation, what specific cryogen is inside, and even the outside weather.

A well-maintained T75 cryogenic ISO container tank can typically hold its temperature for anywhere from 30 to over 100 days. The high-end models with superior vacuum insulation are engineered specifically to push that timeframe to the maximum. This is absolutely critical for long-distance transport or when you're using the tank for temporary storage on-site and need to guarantee product integrity.

This is a firm no—using the same tank for different products is strongly advised against and, in many cases, outright prohibited. This is especially true when you're dealing with anything sensitive or hazardous. For pharmaceuticals, biological samples, or food-grade products, the risk of cross-contamination is huge. Even the smallest trace of a previous cargo could ruin an entire batch.

When it comes to cryogenic gases, tanks are almost always dedicated to a single product, whether it's nitrogen, oxygen, or argon. This isn't just a suggestion; it's an essential safety measure to prevent dangerous chemical reactions and to maintain the absolute purity required for medical and scientific work. Dedicated use is the industry standard for a reason: it guarantees safety and compliance.

Yes, almost always. If you're moving an ISO container tank by road and its contents are classified as hazardous materials under the ADR agreement, you will need special permits. Getting this right involves a few different layers of compliance.

The truck itself has to be ADR-compliant, and the driver must hold a valid ADR licence for the exact class of goods they are hauling. On top of that, the tank must be up-to-date on all its mandatory periodic inspections. This is where a specialised logistics partner becomes invaluable—they handle all the necessary permits to ensure every part of the journey is legal, safe, and seamless across European borders.

For state-of-the-art cryogenic solutions that guarantee safety and compliance, trust Cryonos GmbH. We provide turn-key transport and storage equipment designed for the most sensitive materials. Explore our reliable cryogenic systems at https://www.cryonos.shop.