No Products in the Cart

When you need industrial gases for your operations, finding a reliable "Linde Gas in meiner Nähe" is the first—and most important—step. The smartest move is to use the official Linde Gas distributor locator. This simple action connects you with certified suppliers, guaranteeing you get authentic products that meet Germany's tough safety and quality standards.

It’s the best way to safeguard your processes and your team from the very real risks that come with unauthorised resellers.

Starting your search for a local Linde gas supplier isn't just about finding the closest pin on a map. It’s about building a relationship with a provider who understands product integrity and regulatory compliance inside and out. Trust me, sourcing from unverified channels can lead to massive headaches, from receiving impure gases that damage expensive equipment to, in the worst-case scenario, creating serious safety hazards.

Sticking to official channels is non-negotiable. An authorised Linde distributor has been trained, audited, and properly equipped to handle industrial gases safely. It’s your peace of mind that you're getting exactly what you paid for, whether that's high-purity argon for welding or medical-grade oxygen.

These official partners provide:

Linde plc isn't a newcomer. Founded right here in Germany by Carl von Linde way back in 1879, it has grown into the world's largest industrial gas supplier by market share and revenue. That long history, with deep roots in Germany, speaks volumes about their expertise and reliability in the field.

To get started on the right foot, follow these initial actions to quickly and safely find a certified Linde gas supplier in your area.

| Action | Why It's Important | Tool or Resource |

|---|---|---|

| Use the Official Locator | Ensures you're contacting a certified, audited, and compliant distributor, not a third-party reseller. | The official Linde Gas distributor search tool on their website. |

| Verify Certifications | Confirms the supplier is trained to handle and transport hazardous materials according to ADR and local laws. | Ask the distributor for their certification documents. |

| Confirm Gas Purity Specs | Guarantees the product meets the specific purity levels required for your application, preventing equipment damage. | Check the product data sheet or ask for a certificate of analysis. |

Following these steps sets a solid foundation for a safe and reliable supply chain.

Your supplier is your first line of defence in maintaining a safe work environment. Choosing a certified distributor means you're not just buying a product; you're investing in a system of safety, quality control, and expert support that protects your entire operation.

For more specialised needs, like getting liquid nitrogen for private use, knowing the specific purchasing requirements is just as important. For more details on that process, feel free to explore our guide on how private individuals can purchase liquid nitrogen.

Ultimately, finding the right supplier is the crucial first step that influences everything that follows, from placing an order to handling the materials safely on-site.

Alright, let's get practical. The most reliable way to find an authorised supplier is to go straight to the source: Linde’s official online tools. This isn't just a map—it's a smart filter designed to connect you with the right partner for your specific gas needs. It’s all about precision.

Imagine you're running a fabrication workshop in Munich and you're down to your last cylinder of a specific CORGON® welding gas mixture. A quick search for "Linde Gas in meiner nähe" will likely pull up a messy list of hardware stores and unverified resellers. Using the official locator, however, lets you bypass all that noise from the get-go.

The real magic of the locator is in its filters. You aren't just looking for any supplier; you need one that stocks the exact gas you use and offers services that fit your workflow.

Here’s how to drill down and find what you need:

For our Munich workshop, you’d filter for "Welding Gases" and maybe "Cylinder Collection" if you plan on picking it up. Just like that, you’ve turned a long, generic list into a handful of qualified partners guaranteed to have what you're looking for.

Once the locator gives you a few options, the final step is a quick visit to their websites. An authorised distributor’s online presence usually has tell-tale signs of their legitimacy and official partnership with Linde. This little bit of due diligence helps you steer clear of rogue sellers who might be using the Linde name without permission.

A professional and transparent website is a huge green flag. It tells you they’re invested in their business and in giving customers clear, accurate information—a hallmark of any genuine Linde partner.

Keep an eye out for these key elements to confirm you're dealing with a legitimate distributor:

By taking this methodical approach—using the official locator, applying the right filters, and giving their website a quick once-over—you can confidently find the right supplier. It’s the difference between finding just any "Linde Gas in meiner nähe" and finding the perfect one for your business.

Once you've shortlisted a few potential suppliers for "Linde Gas in meiner Nähe," your work isn't quite finished. Finding the closest distributor is one thing, but confirming they operate with the highest safety and compliance standards is another game entirely. This verification step is absolutely critical—it protects your business from legal risks, operational disruptions, and serious safety incidents.

Think of it this way: when you partner with a gas supplier, you're not just buying a product. You are entrusting them with a vital part of your operational safety chain. A non-compliant supplier can quickly become a significant liability, and it’s your responsibility to do your homework before any contracts are signed or cylinders are delivered.

When you're vetting a potential distributor, certain certifications are non-negotiable. These aren't just fancy badges for their website; they are proof that the supplier adheres to internationally recognised standards for quality management and operational safety.

Here are the main credentials to ask about:

Don’t just take their word for it. Ask to see the actual certificates. Any reputable supplier will have no problem providing them.

This is perhaps the single most important check you can make. The Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) governs how hazardous materials are transported across Europe. Industrial gases, especially those under high pressure or in cryogenic liquid form, fall squarely into this category.

A supplier’s failure to comply with ADR regulations isn't just their problem—it can become your problem, too. If an incident occurs with a non-compliant delivery to your site, your business could face serious legal scrutiny and liability.

Ask a potential supplier direct questions about their transport protocols. Do their drivers hold the necessary ADR training certificates? Are their vehicles properly placarded and equipped with the required safety equipment? In Germany, the industrial gases market's growth is heavily driven by demand in heavy manufacturing sectors like steel, chemicals, and automotive, with Linde plc playing a critical role. This high volume of transport makes strict adherence to safety regulations paramount. You can learn more about the European industrial gases market dynamics on marknteladvisors.com.

Beyond formal certifications, your conversations with a potential supplier should give you a clear sense of their real-world commitment to safety.

Here is a practical checklist of questions to guide that discussion:

The quality of their answers will reveal a lot about their operational maturity. This process actually mirrors many of the critical considerations you must make when sourcing specialised cryogenic equipment. For some extra insights, check out our guide on the five things to keep in mind while choosing a cryogenic supplier. Taking this thorough approach ensures every link in your supply chain is as secure as it can be.

Getting the right type of gas is only half the battle. The container it arrives in is just as critical for safety, efficiency, and the performance of your application. It’s a common mistake to overlook this, but a mismatch between the gas, its cylinder, and your equipment can lead to expensive errors or, even worse, a serious safety incident.

This is far more than just picking a cylinder size. It’s a technical decision. Think about it: a research lab needing ultra-high purity (UHP) nitrogen for a sensitive gas chromatograph has completely different requirements from a construction site that uses industrial-grade oxygen for cutting steel. The lab needs a specific purity grade, probably with a special valve to stop any contamination. The construction site, on the other hand, needs a tough, high-capacity cylinder that can handle a bit of rough treatment.

Understanding this difference is what separates a smooth operation from a potential headache when you’re looking for "Linde Gas in meiner nähe".

Every gas cylinder is covered in crucial information. Learning to read it isn't just good practice; it's a fundamental safety skill. The label and markings tell you everything—what’s inside, the pressure, and all the specs. It should always be your first point of reference.

Just as important are the valve connections. Here in Germany, and across most of Europe, these connections are standardised under DIN 477. This isn't just for convenience; it's a built-in safety feature. The system is smartly designed to make it physically impossible to connect a regulator for an inert gas like argon to a cylinder of a flammable gas like hydrogen. Each gas family has its own unique thread type, preventing dangerous mix-ups.

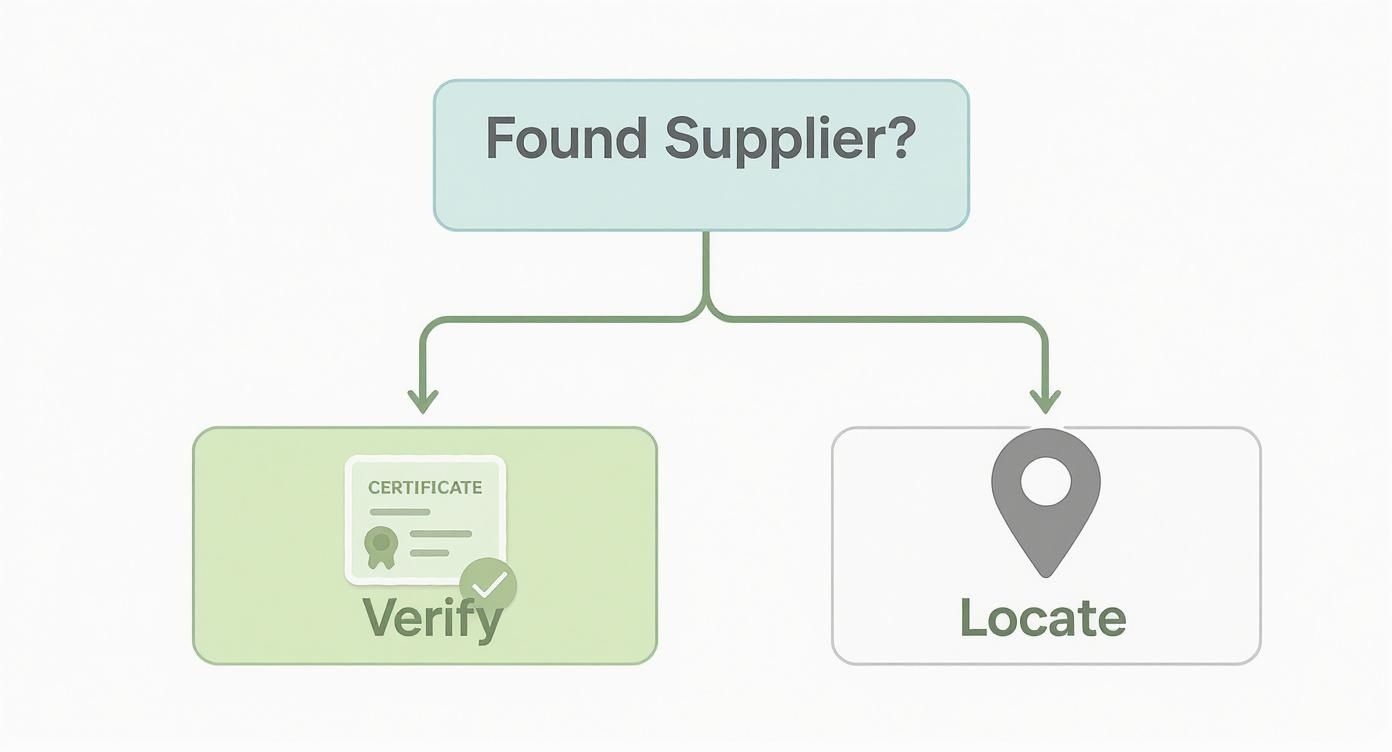

This flowchart breaks down the basic path for checking your supplier, which is the first step in making sure you get the right, compliant equipment.

It really is that simple to start: either you've found someone and need to verify them, or you're still in the process of locating a certified distributor.

The moment the delivery truck arrives, the responsibility shifts to you. Before the driver even thinks about leaving, get into the habit of doing a quick visual check of the cylinders.

What are you looking for? It's pretty straightforward:

Once you’ve signed for the delivery, safe handling becomes the priority. Always—and I mean always—use a proper trolley to move cylinders, even if it’s just a few metres. Never roll, drag, or let them drop.

Storing cylinders correctly is one of those non-negotiable workshop safety rules. They must be secured upright with a chain or strap, kept in a well-ventilated area, and positioned well away from heat sources or incompatible materials. This one simple habit prevents the vast majority of cylinder-related accidents.

Thinking about the whole process—from matching the gas to the right container to implementing strict handling protocols—creates a closed loop of safety. It protects your team, your equipment, and your entire operation, turning the simple task of ordering gas into a professional, deliberate process.

You’ve found a verified supplier and figured out the exact gas and container you need. Great. Now comes the part where small details make a big difference: placing the order and getting ready for the delivery truck to arrive.

This stage is all about clear communication. A simple mix-up—getting the wrong gas grade or an unexpected delivery time—can throw a wrench in your entire operation. You need to be crystal clear to prevent any headaches down the line.

Don't just ask for "argon." Be specific: "I need a 50-litre cylinder of Argon 5.0, and I need it delivered next Tuesday between 9 AM and 12 PM." That level of detail leaves no room for error and ensures you get exactly what your process requires. It's the difference between smooth sailing and the frustrating discovery that you’ve received industrial-grade gas when your sensitive lab equipment needed high-purity stuff.

Before you hit "confirm," take a minute to look past the price of the gas itself. You also need to understand the cylinder rental agreement. Suppliers often have daily, monthly, or yearly contracts, so you'll want to pick the one that makes the most sense for how often you'll be using the gas.

It’s also a good time to sort out the admin side of things. Confirm their payment options and ask about setting up a business account if you plan to order regularly. Getting this sorted now will save you a ton of time on future orders.

Setting clear expectations right from the beginning is the key to a good long-term supplier relationship. This isn't just about a one-off purchase; it's about building a supply chain you can count on.

Your job isn’t done once the order is placed. Getting your facility ready for the delivery is just as important, and it’s a critical safety step. The delivery driver needs a clear, safe path to your designated storage area.

That means no stray pallets, equipment, or parked vehicles blocking the way. Put yourself in the driver's shoes for a moment. Can their truck get to your site easily? Is there a flat, stable spot for them to unload what are often very heavy cylinders? A little prep work makes their job safer and your delivery quicker.

The storage area itself needs to be good to go. It must be well-ventilated and kept far away from any heat sources or flammable materials. Have your chains or securing straps ready so you can secure the new cylinders the moment they arrive.

Proper handling is governed by strict rules. We cover these in detail in our guide on the regulations for transporting gas cylinders, and following those same safety protocols on-site is non-negotiable.

Even with the best plan, you’re bound to have questions when managing your gas supply. Finding "Linde Gas in meiner nähe" is the first step, but the practical side of things—handling cylinders, sending them back, and transport—is just as critical for a safe, smooth workflow. Let's dig into some of the most common questions we hear.

When it comes to gas cylinders, safety is non-negotiable. Always keep them stored upright in a secure, well-ventilated space, well away from heat sources or anything flammable. One of the simplest yet most vital precautions is to chain them to a wall or a proper rack to stop them from tipping over, a surprisingly common cause of accidents.

When you need to move them, even just across the room, use a purpose-built trolley. Don't ever try to roll or drag them. And finally, make sure those valve caps are screwed on tight whenever a cylinder isn't in use. It protects the most fragile part of the whole setup.

It’s worth remembering that different gases have their own specific needs. For instance, oxidisers like oxygen must be kept separate from flammable gases like acetylene. Always refer to the Safety Data Sheet (SDS) for the detailed, product-specific rules.

Getting empty cylinders back to the supplier promptly is the key to keeping rental fees down and your workspace clear. The process itself is pretty simple, but it's all in the details.

First off, close the cylinder valve completely. Even if you think it's empty, there can still be residual pressure. Once the valve is shut, screw the protective cap back on securely. Then, just get in touch with your local Linde distributor to either arrange a pickup or check their drop-off times and procedures.

It’s always a good habit to keep your paperwork in order. Hang onto your delivery notes and return confirmations to make sure your account is accurate and avoid any surprise billing issues. Most importantly, never try to refill a cylinder yourself or toss it out with regular waste.

Picking up cylinders yourself is often an option, but you absolutely have to follow the rules for transporting dangerous goods, known as the ADR regulations. Your vehicle has to be up to the task—usually an open truck or a van with good ventilation. Cylinders always need to be secured upright during the journey so they can't shift or fall.

Your distributor will give you specific instructions based on what type and how much gas you're collecting. For bigger orders or the more hazardous gases, using the distributor's professional, ADR-compliant delivery service is always the safest and most legally sound bet.

For state-of-the-art cryogenic storage and transport solutions that meet the highest safety and compliance standards, including ADR-licensed transport, Cryonos GmbH offers a comprehensive portfolio of reliable equipment. Explore our range of cryogenic vessels and accessories at https://www.cryonos.shop.