No Products in the Cart

The right mag schweißen gas is the invisible force behind every strong, clean weld. It's not just an optional extra; it's the critical component that shields your molten metal from the atmosphere and ultimately dictates the quality of your work.

Think of your shielding gas as a personal bodyguard for the molten weld pool. As you weld, the intense heat creates a vulnerable puddle of liquid metal. The everyday air around us is actually hostile to this process, filled with oxygen and nitrogen that are eager to contaminate the weld.

If these atmospheric gases get in, they cause all sorts of problems, from porosity (tiny, strength-sapping bubbles) to brittleness. The end result is a weak, unreliable joint that nobody wants.

This is where your chosen mag schweißen gas mixture saves the day. It flows from the cylinder, through your torch, and blankets the weld area in an invisible force field. This protective bubble pushes the surrounding air away, giving the molten steel the clean environment it needs to fuse correctly.

But a shielding gas does much more than just protect. The specific blend you're running has a huge impact on how the weld actually behaves and turns out. It's all about controlling the physics of the arc.

Here’s what your gas choice directly influences:

This whole process is a cornerstone of modern manufacturing. In Germany's powerful industrial sector, especially in automotive production, MAG welding is king. Projections show the MIG/MAG segment holding a dominant 38.0% market share in welding machinery in 2025, a testament to its value in high-speed, high-deposition work. You can explore more data on the welding machinery market to see just how significant it is.

Simply put, choosing the correct shielding gas isn't just a minor technical detail—it's the decision that governs the strength, cleanliness, and overall quality of your welds. It’s the difference between a professional, durable result and a failed joint.

Think of your MAG welding gas like a chef's custom spice blend. Just as a chef mixes different spices to get the perfect flavour, a welder blends specific gases to achieve the perfect weld. The two main ingredients in almost every MAG recipe are Argon (Ar) and Carbon Dioxide (CO2), and each one plays a very different, yet critical, role.

Truly understanding these two components is the first major step to mastering the MAG process. The balance between them dictates everything from how the arc behaves to the final weld's strength and look. Let's break down what each gas brings to the party.

Argon is an inert, noble gas that serves as the foundation for most MAG mixes. Picture it as the smooth, steady base of a sauce. Its primary job is to create a stable, consistent electrical arc. Because Argon doesn’t react with the molten metal, it provides a calm, protective bubble for the weld pool to form cleanly.

This stability is what gives you a tidy, visually appealing weld with minimal spatter. A higher percentage of Argon in your mix leads to a smoother transfer of metal from the wire to the workpiece, which is exactly what you want for welding thinner materials where you can't risk blowing through the metal.

If Argon is the smooth base, then Carbon Dioxide (CO2) is the fiery spice that kicks up the heat and intensity. As an "active" gas, CO2 actually reacts in the intense heat of the arc. This reaction splits the CO2 into carbon monoxide and oxygen, a process that pumps a significant amount of extra thermal energy directly into the weld pool.

The result? A hotter, more focused arc that delivers deep, powerful penetration. This is why CO2 is a non-negotiable ingredient when you're welding thicker sections of steel and need to ensure the weld fuses strongly right through the joint.

But using pure CO2 has its trade-offs. While it offers fantastic penetration and is cheap to buy, it also produces a much more violent, less stable arc. This leads to a lot of spatter, which means more time spent on clean-up after the job is done. This is precisely why it’s almost always blended with Argon for MAG applications.

To help visualise these differences, here’s a quick breakdown of what each gas contributes to the welding process.

This table breaks down the primary gases used in MAG welding and their distinct effects on the welding arc and final weld characteristics.

| Gas Component | Primary Function | Effect on Weld Penetration | Effect on Arc Stability | Common Application |

|---|---|---|---|---|

| Argon (Ar) | Inert carrier gas | Low to moderate; creates a wider weld bead | Excellent; produces a smooth, stable arc with low spatter | Base gas for most mixes; ideal for thin materials and achieving a clean finish |

| Carbon Dioxide (CO2) | Active gas; increases heat | High; creates a deep, narrow penetration profile | Lower; can be harsh and produces significant spatter | Mixed with Argon to add penetration for thicker steels; cost-effective |

Understanding these individual roles is the key to creating the right "recipe" for your specific welding job.

Combining Argon and CO2 is where the real control happens. It's a bit like adjusting the heat on a stove.

The German welding equipment market, where arc welding tech like MAG is a cornerstone, pulled in a hefty USD 1,083.6 million in revenue in 2023. Arc welding itself, including MAG, held an impressive 70.14% revenue share that year, a testament to its reliability in major sectors like automotive and machinery manufacturing. You can discover more insights about the German welding market on grandviewresearch.com.

This ability to tweak the gas blend lets a welder fine-tune the arc's characteristics for the task at hand. For instance, a high-Argon mix can achieve "spray transfer," where tiny droplets of molten metal are smoothly sprayed across the arc—perfect for high-speed, clean welds. On the other hand, a mix with more CO2 promotes a "short-circuit transfer," a cooler process much better suited for thin materials and welding out of position.

While Oxygen isn't a primary component in these common mixes, understanding its properties can be useful for more specialised applications. You can learn more about the properties of Oxygen in our detailed article.

Picking the right mag schweißen gas is a lot like choosing the right tool for the job. You wouldn't use a sledgehammer to hang a picture frame, and you definitely shouldn't use a super-hot, high-penetration gas mix on thin sheet metal. Let's move past the textbook theory and get into some practical, real-world advice for welding unalloyed and low-alloy steels, so you can match the gas to your project perfectly.

At the end of the day, it's always a balancing act between penetration, spatter, and cost. Get your head around that trade-off, and you'll be able to choose your gas with confidence. For most jobs, it all boils down to tweaking the Argon to Carbon Dioxide ratio to get the arc performance you're after.

For your everyday welding on mild steel, a versatile mix known as C25 is the industry go-to for a good reason. This blend is 75% Argon and 25% Carbon Dioxide, and it strikes a fantastic balance. The Argon component gives you a stable, smooth arc, while the healthy dose of CO2 provides the deep penetration needed for solid, structural welds.

Think of C25 as the trusty workhorse in your workshop. It's the perfect choice for:

Sure, it throws off a bit more spatter than mixes with more Argon, but its excellent penetration and wallet-friendly price make it the default choice for a huge range of jobs. If you're just getting your MAG station set up, this is a brilliant place to start.

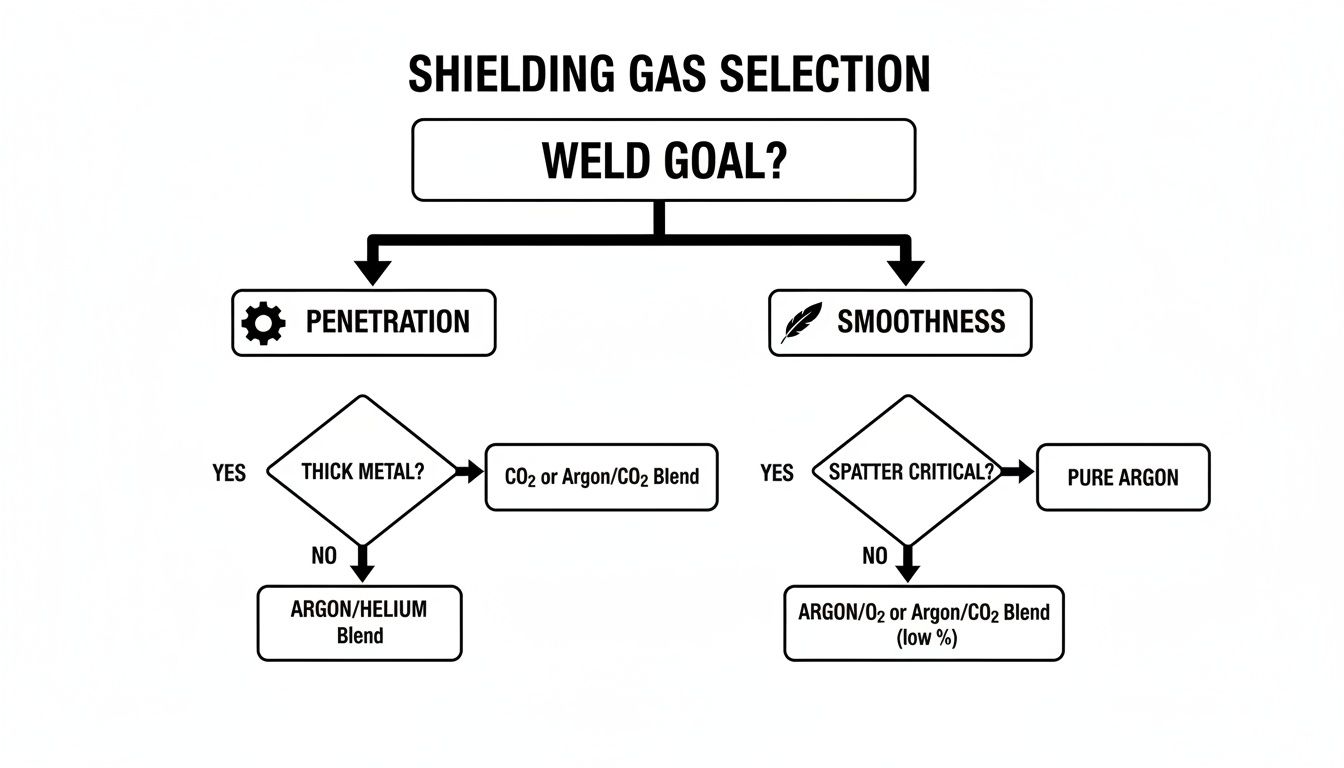

This flowchart helps simplify things, showing how your choice changes based on whether you need a deep, biting weld or a clean, smooth finish.

As you can see, the less spatter you want, the less Carbon Dioxide you need in your mix. Simple as that.

When the job calls for a clean finish with minimal spatter—especially on thinner metals—you'll want a mix with a higher Argon content. Something like C8, which is 92% Argon and 8% Carbon Dioxide, is a much better option when appearance and precision are top priorities.

All that Argon creates an incredibly smooth and stable arc. This stability makes "spray transfer" possible, where tiny molten droplets shoot cleanly across the arc. The result? A very low-spatter weld that looks almost as neat as a TIG weld.

Pro Tip: Reach for a C8 or similar high-Argon mix for automotive bodywork, welding thin sheet metal (under 3 mm), or any project where you want to spend as little time as possible on post-weld clean-up. The gas might cost a little more, but you'll often save that money back in time not spent grinding and finishing.

This level of control is crucial in high-stakes industries. In Germany, MAG welding is a cornerstone of automated manufacturing, with the automatic welding segment set to lead the equipment market all the way through 2033. MIG/MAG processes are expected to grab a 38.0% market share in 2025, proving their worth in high-speed applications for auto giants like Volkswagen and BMW, who together produce 40% of Europe's vehicles. You can learn more about these automotive and industrial welding trends to see how the industry is evolving.

Your choice of mag schweißen gas has a direct impact on the quality, speed, and cost of your work. There’s no single "best" gas—only the best gas for the specific job in front of you. By understanding what Argon and CO2 each bring to the party, you can pick the right blend every time.

To wrap it up, here's a quick checklist to run through:

By asking these simple questions before you strike an arc, you’re moving beyond guesswork. You’re making an informed choice that sets you up for a professional-quality weld, every single time.

Picking the perfect mag schweißen gas blend is only half the job; you’ve got to get it from the cylinder to your torch tip correctly. A proper setup isn't just about getting a good weld—it's about staying safe. Think of it like tuning an instrument before a performance. Get this part right, and you're set up for strong, clean welds free of those annoying gas-related flaws.

This guide will walk you through everything from hooking up your cylinder and setting the right flow rate to doing a quick but crucial leak check.

Your gas regulator is the heart of your delivery system. It takes the incredibly high pressure from inside the cylinder—often over 150 bar—and steps it down to a safe, workable pressure. Getting this wrong by using a faulty regulator or making a poor connection can lead to leaks, broken gear, or much worse.

Follow these simple steps for a solid connection:

A reliable regulator is non-negotiable. If your gauges are busted or inaccurate, you're basically welding blind. You need to know what's happening, so investing in a quality pressure gauge is just common sense for consistent, controlled work.

Even a tiny leak you can't hear is a big problem. It’s a constant drain on your expensive shielding gas, and a significant leak in a small workshop could create a seriously hazardous environment. The easiest and most reliable way to check for leaks is with a bit of soapy water.

Never skip this step. A two-minute leak test can save you hundreds of Euros in wasted gas and prevent major safety risks. It's the cheapest insurance policy in your workshop.

Here’s the drill:

Once you're sure the system is sealed tight, the final step is setting the gas flow rate. This controls the volume of shielding gas covering your weld pool. Too little gas, and you'll get porosity. Too much, and you'll create turbulence that actually pulls in air from the surrounding atmosphere, defeating the whole purpose.

A great starting point is a simple rule of thumb: set the flow rate in litres per minute (LPM) to about 10 times the diameter of your welding wire in millimetres.

For instance:

Remember, this is just a baseline. You'll likely need to tweak it depending on your environment. If you're welding in a draughty spot, you might need to bump it up by 1-2 LPM to compensate. On the other hand, if you're doing fine work in a calm, indoor space, you can probably dial it back a bit to save gas. Always start with the recommended rate and then make small adjustments based on how your welds look and feel.

It’s easy to forget, but your high-pressure gas cylinders are packed with an incredible amount of stored energy. They are the lifeblood of your welding, but they demand respect. If a heavy cylinder gets mishandled, it can instantly turn into an uncontrolled projectile, causing catastrophic damage to your workshop or serious injury.

That’s why establishing and strictly following safety protocols isn't just a suggestion—it's a core responsibility for anyone working with industrial gases. This is about creating a workspace where you can focus on laying down the perfect bead, confident that the fundamental risks are managed. Think of these rules as the bedrock of a professional workshop.

The absolute first rule of cylinder storage: always keep them upright and securely fastened. A falling cylinder can easily snap off a valve, leading to a violent, high-pressure gas release. It’s a scenario you never want to witness firsthand.

To prevent this, make sure every cylinder is chained or strapped to a solid wall, a heavy workbench, or a dedicated cylinder trolley. This simple step is your best defence against them being accidentally knocked over by someone walking past, a forklift, or any other equipment moving through the shop.

The storage area itself is just as important. It needs to be a well-ventilated space, kept far away from intense heat, sparks, or open flames. That means keeping cylinders a safe distance from grinding stations, cutting torches, and any electrical panels that could create an ignition source.

Safety First: Never, ever store gas cylinders in a small, sealed space like a closet. A slow, unnoticed leak could displace the oxygen in the room, creating a deadly atmosphere without any warning.

Moving a heavy, awkward gas cylinder is prime time for an accident. Don't ever try to roll a cylinder on its bottom edge or drag it across the floor. That’s a classic way to lose control and end up with a serious injury.

Always use a proper cylinder trolley designed for the job. These trolleys are built to hold the cylinder securely, providing a stable base that makes moving it both easier and infinitely safer. Make sure the cylinder is properly chained to the trolley before you move an inch.

During transport, the most critical piece of safety gear is the valve protection cap. This heavy-duty steel cap screws over the cylinder valve, and it’s designed to take the hit if the cylinder falls, protecting the delicate brass valve from being sheared off.

Understanding this simple component is key to preventing a true worst-case scenario. To really drive the point home, you can check out our detailed guide on the essential role of a protective cap for your gas cylinder.

Every gas cylinder is covered in labels and markings that provide mission-critical information. These aren't just for the supplier; they're your first line of defence. Take a moment to actually read and understand them.

The label will clearly state the gas inside (like an Argon/CO2 mix), its specific concentration, and provide clear hazard warnings. You'll see pictograms indicating if the gas is flammable, an oxidiser, or under high pressure. Learning to interpret these symbols allows you to understand the risks at a glance and handle the mag schweißen gas with the appropriate care.

Getting a great MAG weld isn't just about striking an arc and laying down a bead. It’s about taking total control over the entire process, and your choice of shielding gas—your mag schweißen gas—is right at the heart of it all. Think of it less as a consumable and more as your most powerful tool for getting perfect, repeatable results.

Throughout this guide, we've walked through the key ideas that separate the pros from the amateurs. We began with the absolute basics: the job of the shielding gas. It's an invisible force field, plain and simple, pushing the atmosphere away from your molten weld pool to stop contamination in its tracks. Nail this one concept, and you've taken the first huge step towards eliminating defects like porosity for good.

Next, we dove into the key ingredients in the bottle: Argon and Carbon Dioxide. We saw how each one brings something different to the party. Argon gives you that smooth, stable arc for a beautiful, clean finish, while CO₂ provides the raw heat needed for deep, solid penetration. Finding the sweet spot between these two is how you create the perfect gas "recipe" for any job, whether you're working on delicate sheet metal or heavy structural steel.

This isn't just academic knowledge. It’s what lets you move from just welding to actively problem-solving on the fly.

When you truly understand how your gas mix affects the arc, you can troubleshoot problems, boost your efficiency, and lay down clean, strong, professional-looking welds every single time.

Finally, we looked at the practical side of things—getting that perfectly mixed gas from the cylinder to the weld pool safely and effectively. From making sure your regulator is securely connected and running a leak test (which is non-negotiable) to dialling in the right flow rate, these steps are the critical link in the chain. A bad setup can ruin the performance of even the best gas mix.

Ultimately, mastering your shielding gas is about gaining complete control. It's the crucial element that ties your skill, your machine, and your materials together, giving you the confidence to produce flawless, professional-grade welds, project after project.

Even after you've got the basics down, there are always a few practical questions that pop up on the workshop floor. Getting straight answers to these common queries is what separates a decent weld from a great one, helping you fine-tune your technique and avoid some classic mistakes. Let's dive into four of the most common questions I hear.

The short answer is yes, you can. Running 100% Carbon Dioxide is definitely an option for welding steel. It's the cheapest gas you can get your hands on, and it delivers some seriously deep penetration, which sounds like a win-win.

But there's always a catch, isn't there? The reality is that pure CO2 creates a much more aggressive and unstable arc. The result? A whole lot of spatter. You might save a few quid on the gas bottle, but you'll pay for it in cleanup time, grinding away all those little metal BBs stuck to your workpiece. For almost every job, mixing in some Argon is the way to go for a smoother, cleaner weld.

Getting your gas flow rate right is absolutely crucial. Think of it like a protective bubble around your molten weld pool. Whether you have too much or too little flow, that bubble bursts, and you're going to have problems.

Flow Rate Too Low: Not enough gas means you don't have a complete shield. The surrounding air, full of oxygen and nitrogen, gets sucked right into the molten metal. This creates a nasty defect called porosity—basically, tiny gas bubbles trapped inside the weld that make it weak and brittle.

Flow Rate Too High: You'd think cranking up the gas would give you more protection, but it does the opposite. Too much pressure creates turbulence at the nozzle. This chaotic flow actually pulls in the surrounding air, causing the exact same porosity you get from having too little gas.

A great starting point is to set your flow rate to 10 times your wire diameter in millimetres. Start there and make small adjustments. It’s the key to a strong, clean weld.

Your regulator is your best friend here. It will have two gauges, and it's important to know what each one is telling you. One shows your working pressure (your flow rate in litres per minute), and the other shows the total pressure left in the cylinder (measured in bar or psi).

The cylinder pressure gauge is your fuel gauge. When you hook up a fresh cylinder, the needle will be way up in the green. As you weld, you'll see that needle slowly creep down. Once it starts dipping into the red zone or getting close to zero, it's time for a swap. Trust me, you don't want to run out mid-pass.

If only it were that simple! While there's no single gas that's perfect for every single scenario, some blends are fantastic all-rounders. A C25 mix (75% Argon / 25% CO2) is the undisputed workhorse of the industry for general mild steel work. It strikes a fantastic balance between a stable arc and good penetration.

That said, the best welders match their gas to the job. If you're working on thin sheet metal or need a flawless finish for an automotive project, a mix with more Argon, like a C8, will give you a much better result than a C25 ever could. Taking a moment to choose the right gas mix really pays off in the final quality of your work.

For all your industrial gas storage and transport needs, from high-pressure cylinders to cryogenic vessels, trust the experts at Cryonos GmbH. Explore our compliant, high-quality solutions for laboratories and industrial users at https://www.cryonos.shop.