No Products in the Cart

A good Schlauch für Gasflaschen is so much more than a simple tube. It's the critical safety link between a high-pressure energy source and your application. In demanding environments like biobanks, laboratories, and industrial plants, this connection is everything—equipment failure simply isn't an option.

Think of your gas hose as the first line of defence against a catastrophic failure. Even a small mismatch in material, an incorrect pressure rating, or a poorly seated fitting can spiral into dangerous leaks, explosions, and costly downtime. For those of us in highly specialised fields, the consequences can be even more severe, potentially ruining irreplaceable research samples or derailing critical manufacturing processes.

This guide isn't about reciting basic specs from a catalogue. We're going to dig into the real-world factors that actually matter. We'll look at the subtleties of material compatibility for specific gases, why precise pressure and temperature ratings are crucial, and how to select the right fittings to guarantee a secure, leak-free connection every single time.

In Germany, the reliance on top-tier components is woven into the industrial fabric. Gas cylinders are by far the dominant supply method in the country's industrial gases sector, commanding a massive 45% market share. This highlights just how vital they are for delivering essential gases like oxygen, nitrogen, and argon to a huge range of users, from biobanks to pharmaceutical labs.

This preference for portable cylinders is especially strong among small and medium-sized businesses, such as cell therapy clinics, where building an on-site gas production facility would be financially out of reach.

Connecting the technical details to your specific needs is what keeps operations safe and efficient. For example, a hose intended for cryogenic liquid nitrogen in a biobank has completely different requirements from one used for welding gases in a fabrication shop. Of course, safety doesn't stop with the hose. If you handle cylinders regularly, you might find our guide on the proper use of a protective cap for gas cylinders helpful—it's another essential piece of the safety puzzle.

Choosing the right gas hose isn’t an expense; it’s a foundational investment in operational excellence and personnel safety. Cutting corners here introduces unnecessary risk into environments where precision and reliability are everything.

At the end of the day, understanding and selecting the correct Schlauch für Gasflaschen is a non-negotiable part of running a responsible operation. It protects your team, your assets, and the integrity of your work.

Choosing the right material for your Schlauch für Gasflaschen isn't just a matter of performance—it's one of the most fundamental safety decisions you'll make. The wrong choice can lead to chemical degradation, embrittlement, and, in the worst-case scenario, a catastrophic failure.

Every gas has its own chemical personality, and the hose material has to be completely inert to it. This is non-negotiable. A seemingly small mismatch can contaminate a high-purity gas in a lab or, even worse, spring a dangerous leak of flammable gas on an industrial site. Let's dig into the common materials and where they really shine.

When you're up against high pressures or chemically aggressive gases, stainless steel is the gold standard for a reason. Its rigid, non-porous structure is incredibly resistant to permeation. That makes it the perfect choice for containing slippery gases like hydrogen or helium that would otherwise find their way through softer materials.

On top of that, its natural corrosion resistance is a lifesaver for gases like ammonia or chlorine, which would chew through rubber or plastic hoses in no time. The sheer strength of stainless steel also means it can handle the serious pressures you find in many industrial gas cylinders without breaking a sweat.

In any lab or pharmaceutical setting, gas purity is everything. This is where Polytetrafluoroethylene (PTFE), better known by its brand name Teflon, becomes indispensable. Its incredibly smooth, non-reactive surface ensures the hose doesn't leach any contaminants into the gas stream.

That makes PTFE the go-to material for:

The goal isn't just to move gas from point A to point B; it's to deliver it in the exact state your application needs. For any sensitive process, a PTFE-lined hose is your best bet for maintaining that integrity.

Out in the industrial world, rubber and Polyvinyl Chloride (PVC) hoses are the real workhorses. They're flexible, durable, and don't break the bank. This reality is clearly reflected in the German hose market, a sector that generated a massive 1,772.9 million USD in revenue, with a huge portion dedicated to the 'Schläuche für Gasflaschen' used everywhere.

Rubber hoses command the largest segment with a 40.93% share, valued for their toughness in demanding jobs from cryogenic transport to everyday gas handling.

But you have to know your rubber. Different formulations are engineered for specific gas families:

PVC hoses are often your most economical pick and are fine for low-pressure air lines or some inert gases. Just be aware they can get brittle in the cold and are generally not as tough as their rubber or stainless steel counterparts.

The material of the inner tube is just one part of the story. The hose's overall construction is what really determines its performance, especially when it comes to pressure and flexibility. A critical piece of this puzzle is the reinforcement layer—usually a braid of metal or textile.

Braiding: A braided layer, often stainless steel or a synthetic fibre, is tucked between the inner tube and the outer cover. This is what gives the hose its muscle, allowing it to contain high pressures without ballooning or bursting. A double-braided hose, for example, can handle far more pressure than a single-braided one.

Outer Cover: The outer layer is the hose's first line of defence against the outside world. It protects against abrasion, UV light, and chemical splashes. If you know a hose is going to be dragged across a workshop floor, choosing one with an extra-tough cover is a simple way to extend its working life.

For extremely specialised work, like handling liquid nitrogen, the hose needs unique cryogenic properties to withstand the intense cold without shattering. For these challenging biobank or lab environments, exploring a purpose-built cryogenic transfer hose isn't just an option—it's essential for safety and reliability.

Technical specs can look intimidating, but when you're dealing with a Schlauch für Gasflaschen (gas cylinder hose), understanding pressure ratings and fittings isn't just good practice—it's absolutely essential for safety. A mismatch here isn't a small mistake; it's a serious accident waiting to happen. Let's break down these critical details into plain language.

The terminology around pressure can be confusing, but it really comes down to two key terms you have to know: working pressure and burst pressure. It helps to think of it like the specs for a car. Working pressure is the safe, legal speed you drive every day. Burst pressure is the theoretical top speed the engine could hit right before it blows apart. You'd never drive at that limit, and the same logic applies here.

The Maximum Allowable Working Pressure (MAWP), which most of us just call working pressure, is the highest pressure a hose is built to handle safely and continuously under normal use. This is the number that should guide your selection, period.

On the other hand, burst pressure is a value that only comes from destructive lab testing. It’s the literal point where the hose will rupture. To ensure a solid margin of safety, industry standards demand that a hose's minimum burst pressure is at least three or four times higher than its MAWP. This buffer is there for a reason—it accounts for unexpected pressure surges and the natural wear-and-tear on materials over time.

A classic rookie mistake is glancing at the burst pressure and thinking you have a massive safety margin to play with. You don't. The only number that matters for your setup is the MAWP. Make sure your hose's MAWP is comfortably higher than the maximum pressure your system will ever see.

If you want to dig a bit deeper into how pressure behaves inside the cylinder itself, our article on understanding CO2 cylinder pressure is a great resource that builds on this topic.

Once you've nailed down the pressure rating, the next challenge is getting a perfect, leak-free connection. In Europe, and especially in Germany, you’ll run into a few standard fitting types. Each one is designed for a specific purpose, and they are definitely not interchangeable.

Here are the main players you need to be able to spot:

Getting the fitting right is non-negotiable. Trying to force a BSP fitting onto a DIN valve, for instance, won't just fail to seal—it will likely damage the threads on both parts, creating a permanent safety hazard. Always double-check the fitting on your cylinder and your equipment before you even think about picking up a wrench.

Making a secure connection goes beyond just matching thread types. You also have to understand how the fitting actually creates its seal. Some rely on a precise metal-to-metal contact, while others use a soft gasket or an O-ring.

This detail tells you whether to reach for thread sealant or not.

Finally, a quick word on materials. When you connect different metals, like a brass fitting to a stainless steel hose, you introduce the risk of galvanic corrosion, particularly in damp environments. While it's sometimes unavoidable, being aware of it means you know to inspect those connection points more often for any signs of trouble.

Moving from theory to the workshop floor is where safety protocols truly matter. A proper installation of your schlauch für gasflaschen isn't just about linking two points; it's a careful procedure that guarantees gas purity and, more importantly, the safety of everyone in the vicinity. Even the most robust, high-quality hose can become a serious hazard if it’s not installed correctly.

Before you even begin to connect your new hose, give it a thorough pre-installation check. Run your eyes and hands over it from end to end. You're looking for any damage that might have happened in transit—dents in the fittings, kinks along the hose body, or any scuffs on the outer cover. A compromised hose should never be connected. Period.

Once you're ready to connect the hose, the goal is a tight, leak-free seal without over-stressing the components. This is where a common and critical mistake often happens: using just one wrench. Attempting to tighten a fitting with a single wrench can twist the entire hose assembly or, worse, damage the delicate swivels and seals hidden inside the fitting.

The professional approach always involves two wrenches. Use one wrench (the "backup" wrench) to hold the hose fitting completely still. Use the second wrench to turn the nut onto the cylinder or equipment port. This simple technique isolates all the tightening force on the nut itself, preventing any damaging torque from being transferred to the hose. It’s the key to protecting the hose's integrity and ensuring the fitting seats perfectly.

While it's easy to think "tighter is better," over-tightening is just as dangerous as leaving a connection too loose. It can strip threads and crush seals, creating the perfect spot for a future leak. If the manufacturer provides torque specifications for the connection, grab a torque wrench and follow them exactly. It takes all the guesswork out of the equation and guarantees a perfect seal every time.

With the hose installed, the final, non-negotiable step is a leak test. This is your last line of defence to catch a potentially dangerous issue before the system is put into service. And no, a quick sniff test doesn't count.

The industry-standard method is to use an approved, non-corrosive leak detection solution. These fluids are specifically designed to create obvious bubbles at the site of even the smallest leak, and they won't harm brass, steel, or other common fitting materials.

To run the test properly:

A common shortcut is using soapy water, but this can be a costly mistake. Many household soaps contain chlorides or ammonia, which can cause corrosion and stress cracking on brass fittings over time. Always invest in a proper leak detection fluid designed for the job.

If you find a leak, the first step is to close the cylinder valve. Safely depressurise the hose, then carefully retighten the connection. Once that's done, repeat the entire leak test. Do not operate any equipment until you get a completely bubble-free result.

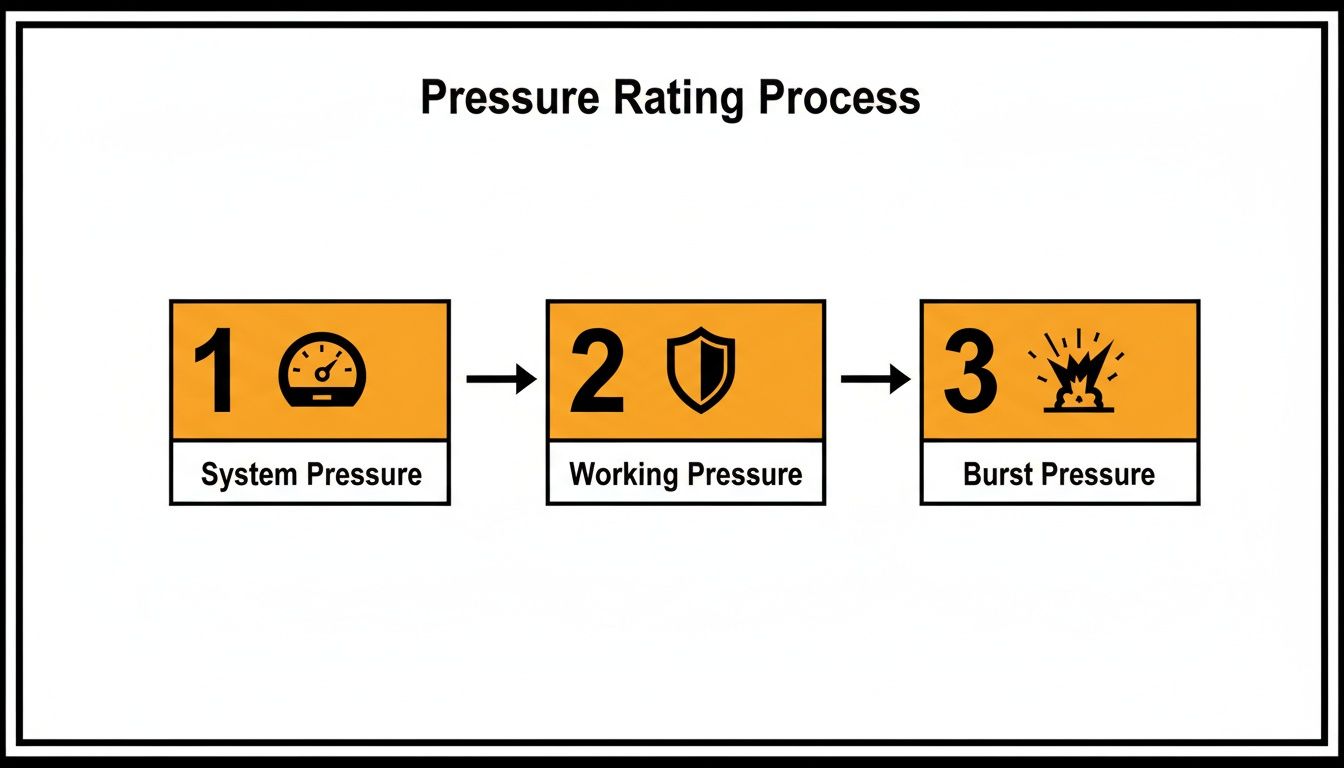

The following diagram breaks down the hierarchy of pressure ratings, which ensures your system's safety margin is always respected.

This visual shows that your system's operating pressure must always stay safely below the hose's designated working pressure, which in turn is set significantly lower than its ultimate burst pressure.

Even the highest-quality schlauch für gasflaschen has a limited lifespan. Treating hose management as a core safety procedure—not just a box-ticking exercise—is crucial for preventing accidents and keeping your operations running smoothly. A disciplined inspection schedule is your single best defence against degradation before it becomes a critical failure.

This proactive mindset is a cornerstone of Germany’s world-class industrial sector. The country's industrial hose assembly market, which is vital for gas cylinder operations, makes up a massive 28.9% of Europe's 6.2 billion USD market. That leadership is built on a foundation of precision and safety, something you can learn more about at futuremarketinsights.com.

Getting into a routine of regular visual checks should be second nature. A quick once-over before each use is smart, but you'll also want to schedule a more thorough examination monthly or quarterly, depending on how heavily the hose is used and the environment it’s in.

When you inspect, you’re on the hunt for specific signs of trouble. Run a gloved hand along the entire length of the hose, paying extra attention to the areas near the fittings where stress tends to concentrate.

Here’s what you’re looking for:

Every reputable gas hose is stamped with a manufacturing date. This isn't just for traceability; it’s a critical piece of data for its service life. Materials like rubber and elastomers degrade over time simply from exposure to oxygen, ozone, and temperature changes—even if the hose just sits on a shelf.

Adhering to the manufacturer's recommended replacement schedule is non-negotiable. A common rule of thumb for standard rubber industrial gas hoses is to replace them every five years, but you must always default to the manufacturer's specific guidance.

Think of that date stamp as an expiration date. Pushing a hose beyond its intended service life is a gamble you can't afford to take. When you install a new hose, document the date and set a clear, unmissable reminder for its replacement.

How you store your hoses when they're not in use has a direct impact on how long they last. It isn't complicated, but it does require a bit of thought. The main goal is to shield the hose from environmental factors that speed up the ageing process.

To get the most out of your equipment, always store hoses in a location that is:

By treating your gas hoses with this level of professional care, you're not just creating a safer work environment. You're also reducing your total cost of ownership through fewer unexpected failures and longer, more predictable service life.

Even when you've got a handle on the right materials and how to hook everything up, questions about your schlauch für gasflaschen are bound to pop up in the day-to-day grind. We get a lot of queries from professionals in labs, workshops, and industrial sites, so we’ve put together some answers for the most common ones.

The goal here is to be direct and clear, reinforcing those critical safety principles. Getting these details right isn't just about ticking a compliance box; it's about building a culture of safety where everyone on the team feels confident and capable around high-pressure gas systems.

Let's get into some of the questions that really matter.

There’s no single, one-size-fits-all answer here, but a good rule of thumb in the industry is to replace standard rubber hoses every 5 years. This applies even if the hose looks perfectly fine on the outside. Materials break down over time due to environmental exposure, and that five-year mark is a smart, conservative safety buffer.

However, treat this as a general guideline only. The manufacturer's specific recommendations are what you really need to follow. They’ve tested their products and know their expected lifespan. Always look for the manufacturing date stamped right on the hose or its fittings and use that as day one of its service life.

Of course, some situations call for immediate replacement, no matter how old the hose is. If you see any of the following, that hose needs to be taken out of service right away:

In regulated lab or industrial settings, sticking to these replacement schedules is a non-negotiable part of keeping everyone safe and staying compliant.

Let me be absolutely clear: no. Using the same hose for different types of gases is an incredibly dangerous shortcut that you just can't afford to take. The two big risks are material incompatibility and cross-contamination.

Think about it: a hose made for an inert gas like nitrogen or argon could be eaten away from the inside out if you suddenly run an oxidising gas like oxygen or a corrosive one like ammonia through it. The liner just isn't built for that kind of chemical assault.

The most catastrophic risk is an explosion. If a hose was previously used for a hydrocarbon-based fuel gas, residual oils could remain inside. If that same hose is then connected to a pure oxygen cylinder, the high-pressure oxygen can ignite those oils, causing a violent and potentially fatal reaction.

Best practice is unwavering on this. You must dedicate specific hoses to specific gases or, at the very least, to compatible gas families (e.g., one set for inert gases, another for fuel gases). Always label your hoses clearly to prevent any deadly mix-ups.

If you catch that distinct odour of a gas like propane or acetylene, you need to act immediately and deliberately. Your first priority is to get rid of any potential ignition sources.

Follow this safety protocol—no exceptions:

If the leak is large, if you can't shut the valve, or if you feel unsafe for any reason, get everyone out of the area immediately. From a safe distance, call your facility's emergency response team, your gas supplier, or the local fire brigade.

Absolutely not. You should never try to repair a damaged gas hose. There's no safe way to patch or mend a hose that's designed to hold back high-pressure gas. Wrapping it with tape, slapping on some sealant, or using clamps just creates a new weak spot that is practically guaranteed to fail under pressure.

The only safe and correct response for a hose that's damaged, leaking, or compromised in any way is to take it out of service immediately. Replace it with a brand-new, correctly rated assembly. When you're dealing with the massive amount of energy stored in a gas cylinder, there are no safe shortcuts.

At Cryonos GmbH, we know that safety and reliability are everything in your line of work. From cryogenic storage to gas handling equipment, our solutions are built to meet the highest standards for performance and compliance. Explore our complete range of state-of-the-art cryogenic and gas management solutions by visiting our shop.