No Products in the Cart

At its most basic, a tube heat exchanger is a clever device built to pass thermal energy between two or more fluids—all without them ever mixing. Think of these as industrial workhorses, essential for hitting precise temperatures using a system of tubes. Sometimes it's one tube inside another, other times it's a whole bundle packed inside a larger shell, but the goal is always the same: efficient heat transfer.

You've probably experienced the basic principle without even thinking about it. Hold a cold drink on a warm day, and you can feel the heat from your hand moving into the can, warming up your drink. Your hand never touches the liquid, but the heat finds a way. That simple, everyday exchange is the foundation of how tube heat exchangers work.

But in the high-stakes world of cryogenics, this process is ramped up to an entirely different level of importance.

We’re not just talking about cooling a beverage here. We’re talking about maintaining the mind-bogglingly low temperatures needed to liquefy industrial gases, preserve delicate biological samples, or run advanced scientific experiments. In these fields, even tiny temperature swings can spell disaster—leading to costly material loss, ruined samples, or a complete system shutdown. Precise temperature control isn't just a nice-to-have; it's absolutely non-negotiable.

In any cryogenic process, tube heat exchangers are the silent guardians. They are the essential piece of the puzzle that allows for the carefully controlled cooling or warming of substances like liquid nitrogen or helium. This job is absolutely vital across any sector that depends on materials staying stable at temperatures below -150°C.

You can see their indispensable role in action everywhere:

At its heart, cryogenics is the science of extreme cold and its effects on materials. A deep understanding of these principles is key to appreciating why specialised equipment is so vital for safety and efficiency. To explore this topic further, you can learn more about what cryogenics is and why it matters in our detailed guide.

When you get right down to it, these devices are far more than just bits of complex machinery. They are the enabling technology that guarantees reliability and safety in applications where temperature is the single most critical factor. By mastering the flow of thermal energy, tube heat exchangers make the modern world of cryogenics possible and set the stage for the specific designs, materials, and operational principles we’ll dive into next.

While all tube heat exchangers work on the same basic principle of heat transfer, their physical designs are worlds apart, each built to tackle different operational challenges. Not every design is created equal, especially when you're dealing with the brutal temperatures and pressures of cryogenic applications. Getting your head around these variations is key to picking the right tool for the job, whether you're outfitting a massive industrial gas plant or a compact lab freezer.

The world of tube heat exchangers is surprisingly diverse, but a few key designs really stand out for their widespread use and unique perks. Each type strikes a different balance between thermal efficiency, pressure handling, footprint, and how much of a headache it is to maintain.

The shell and tube heat exchanger is probably the most recognisable and widely used design in any industrial setting. Picture a big cylindrical pipe—that's the shell—packed with a whole bundle of smaller tubes. One fluid flows through these little tubes (the "tube side"), while the second fluid flows over and around them inside the larger shell (the "shell side").

The main draw of this setup is its huge surface area for heat transfer, all packed into a pretty tough and scalable unit. By forcing the shell-side fluid across the tube bundle, often with the help of internal plates called baffles, the design kicks up turbulence that seriously boosts thermal transfer. This makes them perfect for jobs that need a lot of heating or cooling power, like liquefying huge volumes of industrial gases.

A key benefit of the shell and tube design is its versatility. By adjusting the number of tubes, their diameter, length, and the flow path, engineers can precisely tailor the exchanger to handle a vast range of pressures, temperatures, and fluid types.

This adaptability makes them the go-to choice for demanding cryogenic processes where reliability and high performance are simply not negotiable.

On the other end of the complexity scale, you have the double pipe heat exchanger, sometimes called a concentric tube exchanger. This is the most basic form you can get: just one smaller tube running inside a larger outer pipe. One fluid zips through the inner tube, and the second flows in the ring-shaped space between the two.

Its dead-simple construction makes it a cheap and cheerful option for smaller-scale applications or those with lower heat transfer needs. Maintenance is also a breeze since everything is easy to get to. However, its limited surface area means it’s just not cut out for high-capacity industrial processes. You'll often spot these in smaller lab setups or pilot plants where simplicity and low cost are the main drivers.

A hairpin heat exchanger is basically a smarter, more compact version of the double-pipe design. It uses one or more U-shaped tubes—the "hairpins"—tucked inside a shell. That U-bend lets you pack a much longer tube length into a smaller physical space, dramatically increasing the surface area for heat transfer compared to a straight double-pipe unit of a similar size.

Hairpin designs offer a great middle ground. They deliver better thermal performance than a basic double-pipe exchanger but are simpler and often cheaper than a big shell and tube unit. Their true counter-current flow design allows for a very close temperature approach, making them highly efficient for specific cryogenic cooling or heating tasks where you're tight on space. For those looking for even more compact alternatives, understanding the differences between tube designs and plate-fin heat exchangers can offer valuable insights.

To help you navigate these choices, the table below breaks down how each design stacks up for cryogenic use.

| Exchanger Type | Best Suited For | Pressure Handling | Thermal Efficiency | Footprint |

|---|---|---|---|---|

| Shell and Tube | High-volume industrial processes, high heat duty applications (e.g., gas liquefaction). | Excellent; can be engineered for very high pressures. | High, enhanced by baffles creating turbulence. | Large, requires significant installation space. |

| Double Pipe | Small-scale, low-duty applications, lab setups, and pilot plants. | Good, but limited by the outer pipe's strength. | Moderate; limited by smaller surface area. | Long and narrow; can be inefficient for space. |

| Hairpin | Medium-duty applications where space is a constraint and high efficiency is needed. | Very good; handles high pressures well. | Very High, due to true counter-current flow. | Compact, fits a long tube length in a small area. |

As you can see, the "best" option really depends on balancing your process demands—like flow rate and pressure—with practical constraints like your budget and available floor space.

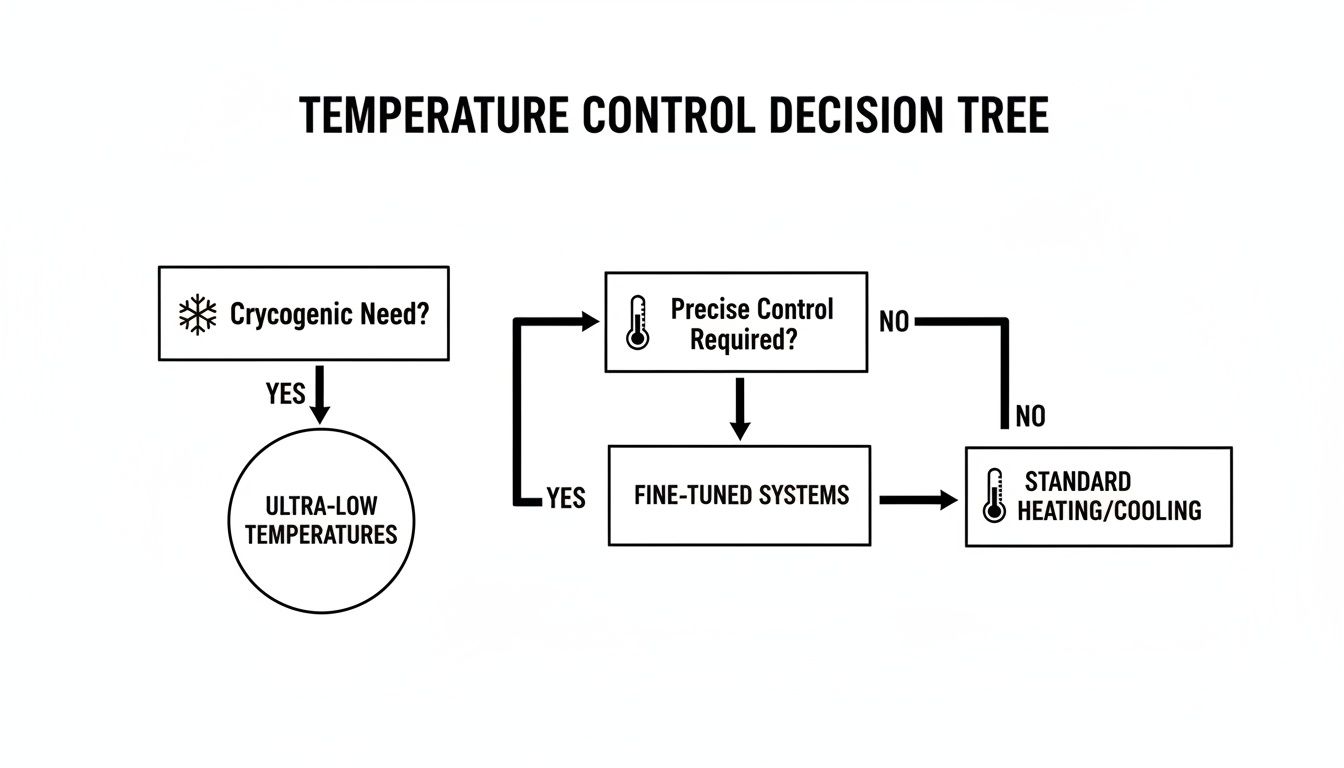

The decision tree below helps visualise how to approach the selection process based on your system's primary requirements for cryogenic control.

This flowchart shows that once a cryogenic need is established, the requirement for precise control becomes a pivotal factor in technology selection.

Each of these tube heat exchanger types has a specific role to play. By getting to know their unique strengths and weaknesses in pressure capacity, thermal stress management, and physical size, you can make a much more informed decision for your cryogenic system.

In the world of cryogenics, the size and thermal performance of a tube heat exchanger aren't just numbers on a spec sheet. They're the very foundation of its efficiency, safety, and running costs.

Get these parameters wrong, and you're left with a system that constantly underperforms, bleeds energy, or fails to hold the critical temperatures your application demands. Proper engineering isn't just a goal here; it's a necessity.

Imagine trying to cool a massive industrial vat of liquid nitrogen with an exchanger built for a small lab dewar. It would be completely overwhelmed, unable to pull heat out fast enough. This leads directly to excessive boil-off, wasting valuable cryogenic liquid and driving up your operational budget. This is exactly why getting to grips with thermal performance is so vital.

Engineers have a specific language for defining and predicting how well a tube heat exchanger will do its job. While the terms might sound a bit academic at first, the concepts behind them are actually quite straightforward. They give us a clear way to measure the efficiency of heat moving between two fluids.

Two of the most critical metrics you'll encounter are:

To put it simply, picture the U-value as the quality of the road heat travels on, and the LMTD as how steep the hill is. For heat to move quickly and efficiently, you need both a smooth, wide road (a high U-value) and a steep hill (a high LMTD).

Grasping these ideas helps make it clear why a seemingly minor design choice can have such a dramatic impact on a system’s overall performance.

Let's bring these concepts to life. Consider a system that needs to keep a large tank of liquid nitrogen (LN2) stable at -196°C. If the tube heat exchanger in the venting system is poorly sized, it will fail to recapture the cold energy from the boil-off gas.

This failure has very real, tangible consequences. If the exchanger is too small, it just doesn't have enough surface area, leading to poor heat transfer. If the fluid flow rates don't match the design, thermal efficiency plummets. Any of these problems mean more LN2 boils away than necessary, leading directly to higher costs and more frequent refills.

But it’s not just about the initial design. Several factors can degrade performance over time.

Ultimately, a correctly sized tube heat exchanger is a finely tuned instrument. It's engineered to balance surface area, material properties, and fluid dynamics to hit peak thermal efficiency for one specific job. This careful calculation is what ensures reliability, minimises waste, and keeps your cryogenic systems running safely and cost-effectively.

When you're building equipment for everyday temperatures, picking a material often comes down to cost versus durability. But when you step into the world of cryogenics, that decision becomes a life-or-death matter of safety and survival. The intense cold can turn tough, ordinary metals into something as fragile as glass, making material selection the single most critical factor in preventing a catastrophic failure.

Think about a standard steel pipe. At room temperature, it's strong and ductile, meaning it can bend and absorb stress without breaking. Now, drop that same pipe into liquid nitrogen. The metal undergoes a complete personality change, becoming incredibly brittle. An impact that would normally just leave a dent could now cause it to shatter.

This phenomenon is known as the ductile-to-brittle transition temperature (DBTT). It’s the tipping point where a material loses its ability to absorb energy and instead fractures on impact. For many common carbon steels, this transition happens at temperatures far warmer than those in cryogenic systems, rendering them totally unsuitable and dangerously unreliable for the job.

To build a reliable tube heat exchanger for cryogenic duty, engineers have to reach for specialised materials that keep their cool—and their toughness—even at bone-chilling temperatures. These materials don't suffer from the same dangerous brittle transition, staying dependable and strong when it matters most.

The top performers in this demanding arena include:

The selection process is always a careful balancing act between mechanical properties, thermal conductivity, and, of course, cost. While steel dominates the broader heat exchanger market, the trend in cryogenics is shifting. In fact, key stats show that nickel alloys are the fastest-growing segment for cryogenic durability. They're prized for their ability to support the ultra-low evaporation rates needed in systems like the AC LIN series used by university researchers and animal breeders.

Beyond brittleness, there's another major challenge on the table: thermal expansion and contraction. As materials cool from room temperature all the way down to cryogenic levels, they shrink. If different parts of a heat exchanger shrink at different rates, it can generate immense internal stress.

This stress can be powerful enough to warp components, break welds, and cause leaks—a critical failure point in any pressurised system. That's why materials with predictable and compatible thermal contraction rates are essential for the long-term integrity of the equipment.

For those working in hospitals, fertility clinics, and advanced research labs, the integrity of cryogenic equipment is everything. The safe storage of biological samples or the stability of a delicate experiment rests entirely on the reliability of every single component.

Choosing a tube heat exchanger built from the right, high-quality materials isn't just an engineering footnote; it's a fundamental requirement for safety and success. Understanding the properties of materials at the extreme temperature of liquid nitrogen is the key to appreciating why this matters so much.

A heat exchanger is never an island; it’s a critical gear in a much larger machine. Choosing the right one and weaving it seamlessly into your cryogenic system is the secret to unlocking top-tier performance, safety, and efficiency. It all starts with knowing where different technologies shine and how to hook them up properly.

While tube-type heat exchangers are the heavyweights in many high-pressure circuits, it helps to size them up against the alternatives to truly appreciate their strengths. A common contender is the plate-and-frame heat exchanger, which relies on a stack of corrugated metal plates to create separate flow channels for the fluids.

These plate designs are incredibly efficient at transferring heat and pack a lot of power into a small footprint. This makes them a great option when space is tight and pressures are on the lower side. The catch? They rely on gaskets, making them vulnerable to leaks—a major risk with the extreme temperature swings and high pressures of cryogenic work. This is exactly where the tough, all-welded body of a tube heat exchanger proves its worth, offering unbeatable durability and safety.

So, how do you decide between a tube design and something else? It’s a classic balancing act of your system's demands. The sheer strength of tube heat exchangers makes them the default choice for any process involving serious pressure or aggressive fluids.

Their dominance in tough industries is undeniable. Germany, for instance, leads the European heat exchanger market, and the workhorse shell-and-tube models—a core type of tube exchanger—command a massive 34.3% of the regional market share. That’s no accident; it’s a direct result of their bulletproof reliability in high-pressure petrochemical and refinery applications. You can dig deeper into these numbers by checking out the full analysis of the European heat exchanger market.

For cryogenic systems, where keeping fluids contained under pressure isn't just a preference but a mandate, the choice becomes pretty clear.

A simple rule of thumb: When pressure, durability, and preventing fluid cross-contamination are at the top of your list, the welded, robust nature of a tube heat exchanger is almost always the right call for long-term peace of mind.

To make things a bit clearer, here’s a quick head-to-head comparison to guide your selection.

The table below gives you a snapshot of how tube heat exchangers stack up against a common alternative, helping you match the technology to the job.

| Technology | Primary Advantage | Pressure Limit | Maintenance | Ideal Application |

|---|---|---|---|---|

| Tube Heat Exchanger | High durability and pressure resistance | Very High | Lower frequency, but can be complex. | High-pressure gas liquefaction, industrial cryogenics. |

| Plate-and-Frame | High thermal efficiency, compact size | Moderate | Easier access for cleaning, but gaskets require regular inspection. | Low-pressure cryogenic cooling, HVAC systems. |

Ultimately, the best choice aligns with the specific pressures, temperatures, and safety requirements of your system.

Once you’ve picked your exchanger, getting it installed correctly is just as important. A successful integration is all about smart planning to maximise its effectiveness and maintain the integrity of your entire system.

By thinking through these factors, engineers and facility managers can confidently build tube heat exchangers into new or existing cryogenic infrastructure. It’s the key to ensuring reliable, safe, and efficient operation for years to come.

When you're dealing with the extreme temperatures and high pressures of cryogenic systems, reliability isn't just a nice-to-have—it's everything. A well-cared-for tube heat exchanger is the backbone of a safe, efficient operation. It's what stands between consistent performance and catastrophic failure. Proactive maintenance isn't just a good idea; it's the only way to ensure longevity and compliance.

At the heart of any solid maintenance programme are regular, systematic inspections. Think of these as routine health checks designed to spot small problems before they grow into major headaches.

Your inspection checklist should always include these key points:

Going beyond just looking, a structured maintenance schedule is what keeps your equipment at peak performance. This means periodic cleaning to blast away any fouling or scale that’s hurting your thermal efficiency. You'd be surprised how much performance can be restored with a good clean. After any major service, pressure testing is also a must to confirm the structural integrity of the tubes and shell.

Working with cryogenic fluids is serious business and demands absolute adherence to safety protocols.

Before a single tool is picked up, the system must be fully isolated, safely depressurised, and purged of any leftover cryogenic liquids or gases. Cutting corners here can lead to devastating consequences, from severe cold burns and asphyxiation to explosive decompression.

To make sure every piece of equipment is built for quality and safety, the entire lifecycle of a tube heat exchanger is governed by strict industry standards. If you're responsible for specifying or managing cryogenic equipment, you need to know these codes.

Two of the most important players in this space are:

Following these standards isn't optional. It’s your guarantee that the equipment meets the highest benchmarks for safety and quality, ensuring it will perform reliably for years to come while keeping you fully compliant with regulations.

When you start working with tube heat exchangers, a few practical questions always pop up about how they run, which design to pick, and what to watch out for. Getting solid answers to these common queries helps build your confidence and makes sure you can manage this critical piece of kit in any cryogenic system. Tackling these points head-on is the best way to sidestep costly mistakes and unexpected downtime.

Let's dive into some of the questions we hear most often, with some straightforward, practical answers to guide you.

The earliest warnings are almost always a drop in thermal performance or an increase in the pressure drop across the exchanger. For instance, if your outlet temperatures just aren't hitting their targets anymore, you know something is wrong on the inside.

In a cryogenic setup, a sudden jump in the evaporation rate from a storage tank is a massive red flag. And don't forget the visual cues—even tiny leaks at the joints or visible corrosion on the outside demand an immediate look. Keeping a close eye on these key performance indicators is your best bet for catching problems before they spiral out of control.

This decision really boils down to one thing: the temperature difference between your two fluids. A fixed tubesheet design is simpler and cheaper, which makes it a great fit when thermal expansion isn't a major concern.

But for cryogenic applications, where you're dealing with huge temperature gaps, a floating head or U-tube design is hands-down the better choice. These designs give the tube bundle room to expand and contract on its own, separate from the shell. This freedom prevents the incredible mechanical stress that would otherwise lead to component failure. For any system where reliability is key, a design that can handle thermal expansion is non-negotiable.

Choosing a design that can handle thermal stress isn't just about efficiency; it's a fundamental safety consideration. An exchanger that fails due to thermal stress can cause catastrophic leaks, posing a significant risk to personnel and the entire facility.

Absolutely not. This is a common and incredibly dangerous misconception. Your average heat exchanger is likely made from carbon steel, which becomes dangerously brittle at cryogenic temperatures. It can literally shatter from a minor impact.

Exchangers built for cryogenic service have to be constructed from specialised materials, like 300-series stainless steel or certain nickel alloys, that stay ductile and strong even when it's freezing. The design itself also has to account for intense thermal stresses and guarantee a completely leak-tight seal. That’s why going to a specialist supplier is critical—it’s about both safety and performance.

For cryogenic systems that demand uncompromising quality and safety, Cryonos GmbH delivers state-of-the-art solutions backed by decades of technical expertise. Explore our range of ADR-licensed and medically certified equipment at https://www.cryonos.shop.