No Products in the Cart

When you hear "CO2," your mind probably jumps to greenhouse gases and climate change. It's often cast as the villain in environmental discussions. But what if I told you that in the world of refrigeration, CO2 is actually one of the good guys?

We’re talking about using carbon dioxide (R744) as a refrigerant, cycling it within a closed loop to move heat from one place to another. It's a technology that’s rapidly becoming the backbone of future-proof cooling and freezing, especially for critical applications.

For decades, the refrigeration industry relied on synthetic refrigerants, many of which turned out to be incredibly damaging to the environment. Now, strict regulations like the EU F-Gas Regulation are phasing them out for good, forcing industries—from supermarkets to cutting-edge labs and biobanks—to find a better way forward.

This regulatory push has put CO2 as a refrigerant squarely in the spotlight. Think of its role in a closed refrigeration system like a renewable energy source. You're taking a natural substance and using it over and over in a contained, circular process that prevents environmental harm. Instead of being released into the atmosphere, the CO2 is simply recirculated to do its job: absorbing and releasing heat with remarkable efficiency.

The main driver is simple: we have to. The F-Gas Regulation is designed to slash emissions from fluorinated greenhouse gases, the very chemicals that have dominated refrigeration for years. Many common HFCs (hydrofluorocarbons) have a Global Warming Potential (GWP) thousands of times higher than CO2, making them a serious contributor to climate change.

CO2, on the other hand, has a GWP of just 1. This isn't just low; it's the baseline. It’s the benchmark against which all other refrigerants are measured, making it the ideal solution for meeting tough regulations without sacrificing performance.

This regulatory pressure means that anyone investing in new cooling systems today needs a solution that won’t become obsolete tomorrow. Choosing CO2 as a refrigerant isn't just about ticking a compliance box; it's a smart, strategic move. It secures your operations against future bans, lowers long-term running costs, and ends the reliance on synthetic chemicals that are only going to get more expensive and harder to find.

The advantages are clear:

This sets the stage for understanding how forward-thinking cryogenic systems are built on this technology—creating solutions that are not only compliant but truly resilient for the challenges ahead.

To really get your head around why CO2 is such a game-changer as a refrigerant, you have to look past how your typical fridge works. Those standard systems are all about a simple cycle: a refrigerant turns from a liquid to a gas (evaporation) to absorb heat, and then back to a liquid (condensation) to release it. Easy enough.

But CO2 plays by a different set of rules. It has a remarkably low critical point—just 31°C and 73.8 bar. Go above that temperature and pressure, and CO2 stops behaving like a normal gas or liquid. It doesn't condense; instead, it becomes a supercritical fluid, a unique state of matter that's dense like a liquid but flows like a gas.

A transcritical CO2 system is engineered specifically to harness this weird-but-wonderful property. Instead of a condenser, it features a gas cooler. In this part of the cycle, the high-pressure CO2 doesn't liquefy. It simply cools down while remaining in its supercritical state, which allows it to shed a massive amount of heat with incredible efficiency. It’s a bit like a high-pressure water system that can transfer huge amounts of energy without ever boiling. That’s the core principle.

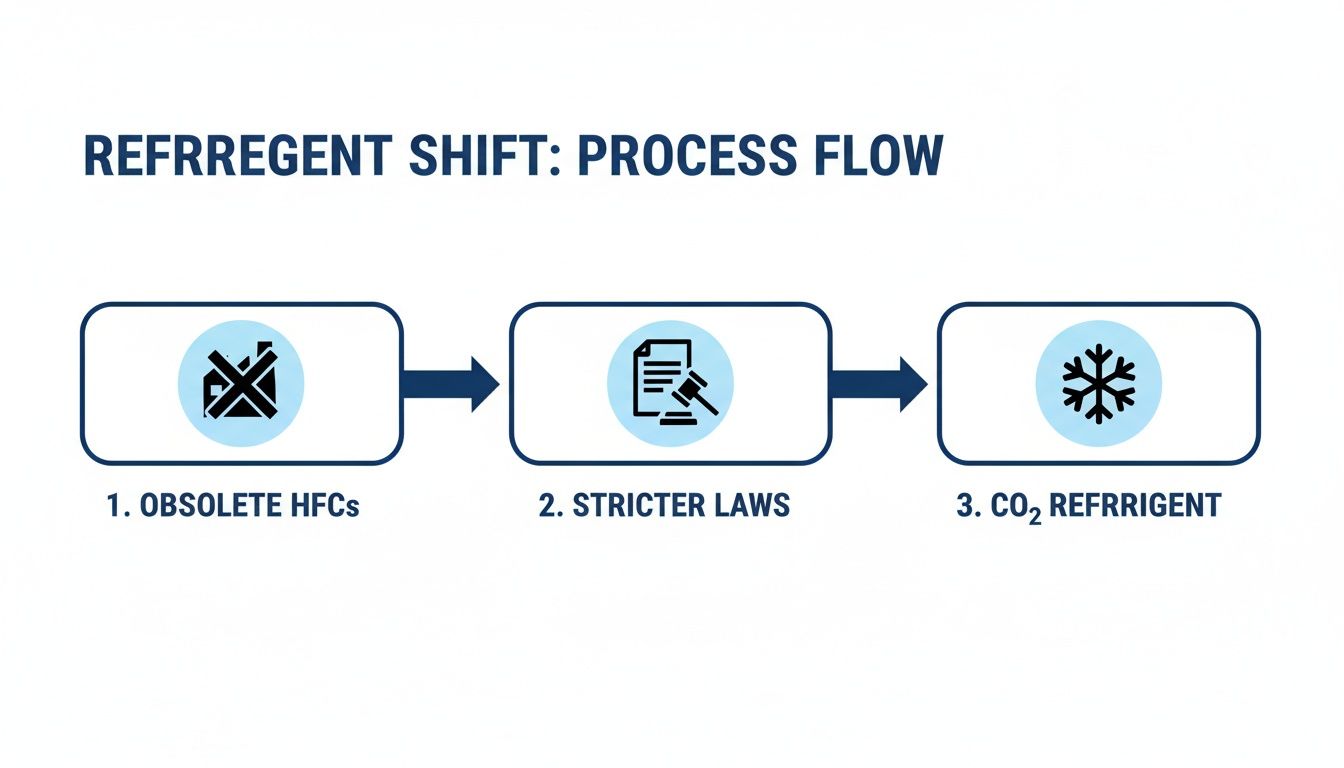

This process chart gives a bird's-eye view of the wider industry shift that's pushing CO2 refrigeration into the spotlight.

As you can see, there’s a clear path leading away from outdated HFCs and straight towards natural refrigerants like CO2, a move driven largely by stricter environmental laws.

The whole process can be broken down into four distinct stages, each handled by specialised components tough enough to manage the extreme conditions CO2 demands.

The cycle's unique ability to work so well above its critical point makes CO2 an incredibly powerful tool for applications that need pinpoint temperature control. For Cryonos GmbH’s clients, this translates to rock-solid, reliable cooling for sensitive storage freezers and transport cylinders. Germany's greenhouse gas emissions fell by 3.4% in 2023, a reduction helped in part by refrigeration efficiencies where CO2 systems can slash energy use by 20% compared to alternatives.

The performance of both the heat rejection and absorption phases hinges almost entirely on the design of the heat exchangers. If you want to dive a bit deeper, understanding how a plate-fin heat exchanger works will give you great insight into how these systems are fine-tuned for maximum efficiency. Every single component, from the high-pressure valves down to the robust piping, is engineered to guarantee safety and reliability under pressures that would be unthinkable in conventional systems.

Deciding to use CO2 as a refrigerant isn't just about ticking a regulatory box. It's a strategic move that delivers powerful advantages for your facility's environmental footprint, operational performance, and long-term financial health. For labs, biobanks, and industrial operations, the benefits really boil down to three core pillars.

The most obvious win is on the environmental front. With a Global Warming Potential (GWP) of 1 and an Ozone Depletion Potential (ODP) of zero, CO2 is about as clean as it gets. This isn't just a minor improvement; it’s a night-and-day difference compared to the high-GWP hydrofluorocarbons (HFCs) being aggressively phased out, ensuring your systems are future-proof for decades.

Beyond its green credentials, CO2 is a powerhouse performer. Transcritical systems are engineered for incredible energy efficiency, particularly when the outside air is cool. CO2 also has a high volumetric cooling capacity, meaning it’s exceptionally good at absorbing and moving heat.

This property has a direct impact on system design. It allows engineers to use smaller, more compact components like pipes and compressors compared to systems running on legacy refrigerants. If you’re working with tight space constraints, that’s a huge plus.

But one of the biggest operational perks of CO2 systems is their knack for heat reclamation. The high-grade heat that gets rejected in the gas cooler isn't just wasted; it can be captured and put to good use for other facility needs, such as:

This clever integration turns what was once just a refrigeration system into a combined cooling and heating solution, taking a serious bite out of a facility's total energy bill and carbon footprint.

Sure, the initial investment for a CO2 system can be higher, but you have to look at the total cost of ownership to see the full picture. The long-term financial case is compelling. For starters, the refrigerant itself—R744—is an inexpensive and widely available industrial byproduct. It's worlds cheaper than proprietary synthetic refrigerants, whose prices are set to skyrocket as regulations squeeze supply.

Here's a comparison of how CO2 stacks up against the refrigerants it's replacing.

This table provides a quick look at the key properties and impacts of CO2 compared to common HFC and the newer HFO refrigerants.

| Property | CO2 (R744) | HFCs (e.g., R404A) | HFOs (e.g., R1234yf) |

|---|---|---|---|

| GWP | 1 (Baseline) | 3,922 (Very High) | <1 (Very Low) |

| ODP | 0 | 0 | 0 |

| Flammability | Non-flammable (A1) | Non-flammable (A1) | Mildly flammable (A2L) |

| Toxicity | Low (A1), asphyxiant at high concentrations | Low (A1) | Low (A1) |

| Operating Pressure | Very high (transcritical) | Moderate | Low to moderate |

| Cost | Low and stable | High and volatile | Very high |

While HFOs offer a low GWP, their mild flammability and high cost present different challenges. CO2 hits a sweet spot with its non-flammability, rock-bottom GWP, and low cost, making it a robust long-term choice despite its high operating pressures.

The energy savings also add up quickly, translating directly into lower electricity bills. In colder climates, like those common during Germany’s winters, high-pressure CO2 systems have proven to be 30-40% more energy-efficient than HFC cascade systems. It's no surprise that by 2024, the refrigeration segment claimed 96% of the USD 4,995 million transcritical CO2 market, a boom driven by mandates like the EU's F-Gas ban on virgin HFCs with a GWP over 2,500. You can dig deeper into these economic drivers and emission trends to see where things are headed. Find out more about the factors influencing Germany's CO2 emissions.

Choosing CO2 is not just a green choice; it's a strategic move to future-proof your operations. It protects your facility from volatile refrigerant prices, avoids costly retrofits down the line, and positions your organisation as a leader in sustainable practices.

Ultimately, adopting CO2 als Kältemittel means building resilient, efficient, and cost-effective infrastructure. It aligns your operational needs with pressing environmental goals, turning your cooling systems from a potential liability into a valuable, long-term asset.

In the world of life sciences, precision isn’t just a nice-to-have; it’s everything. The integrity of priceless biological samples, whether they’re cell lines or specimens from a clinical trial, hinges on an absolutely stable, unbroken cold chain. This is where using CO2 als Kältemittel stops being theoretical and becomes a critical, real-world solution for modern labs and biobanks.

These high-stakes environments need consistent and rock-solid ultra-low temperature (ULT) storage. Old-school HFC-based systems are becoming a real headache due to regulations phasing them out, creating an urgent need for a reliable replacement. CO2 refrigeration, especially in a cascade setup, has stepped up as a far better option. In these systems, CO2 efficiently handles the high-temperature stage, working with another refrigerant to hit temperatures as low as -80°C with incredible stability.

That stability and efficiency directly protect sensitive materials. Beyond just ULT freezers, this technology is vital for a whole range of life science applications, each with its own strict temperature demands.

You'll find it in places like:

The bottom line in all these settings is the guarantee of an unbroken cold chain. For things like cell transport media or vital research samples, even a small temperature change can ruin years of work or spoil a therapeutic product. CO2 systems have the muscle to ensure compliance and protect these critical assets.

Think of biobanks as the libraries of modern medicine, holding millions of biological samples that are the foundation for new research and personalised treatments. The move towards CO2 als Kältemittel in this field is picking up speed, driven by its ability to offer long-term, stable, and energy-efficient storage.

The high cooling capacity of CO2 means temperatures bounce back quickly after a freezer door is opened—which happens all the time in a busy lab. This keeps temperature excursions to a minimum, protecting samples from harm. On top of that, the lower running costs from better energy efficiency and cheap refrigerant make CO2 a smart financial decision for facilities that need to plan their budgets decades out.

By choosing CO2, biobanks aren't just going green; they're investing in the long-term security and integrity of their priceless collections. It makes CO2 als Kältemittel a truly essential tool for the future of science.

Working with CO2 als Kältemittel means getting comfortable with its most notable trait: high operating pressures. While that might sound a bit intimidating at first, it's a challenge that modern engineering has completely sorted. This isn't a system you can cobble together with standard parts; it requires robust, specialised components built to handle pressures that can top 120 bar—a world away from what traditional HFC systems are designed for.

That requirement naturally extends to the people working on these systems. A technician trained on conventional refrigeration can't just jump onto a transcritical CO2 unit and expect to know the ropes. Proper installation and maintenance demand specific training and certification to understand the unique high-pressure environment and its safety protocols. This ensures every single component, from the pipes to the valves, is installed and maintained for safe, leak-free performance.

Modern CO2 systems are not experimental setups. They are mature, field-proven technologies engineered from the ground up with multiple layers of safety, making them exceptionally reliable.

Here are the key safety mechanisms you'll find:

The industry hasn't just managed these high pressures; it has turned a potential challenge into a performance advantage. The rigorous engineering needed for CO2 systems has resulted in exceptionally durable and dependable equipment built to last.

What’s more, the initial performance hurdles in warmer climates have been cleared. Early transcritical systems struggled a bit with efficiency when ambient temperatures rose above CO2's critical point. But with the introduction of technologies like ejectors and parallel compression, performance has improved dramatically. These innovations recover expansion energy that would otherwise be lost, giving the system a major efficiency boost in high-temperature conditions. It’s a perfect example of how the industry has matured, delivering solutions that are not just safe but highly efficient across all sorts of operating environments.

The move toward using CO2 als Kältemittel (CO2 as a refrigerant) across Germany isn't just a nod to environmentalism. It’s a sharp business move, driven by a powerful mix of tough regulations and plain old economic sense.

At the heart of this shift is the EU F-Gas Regulation. This isn't a gentle suggestion; it's an aggressive phase-out of the high-GWP hydrofluorocarbons (HFCs) that have dominated the industry for years. This legislative muscle is forcing businesses to find a reliable, future-proof alternative, and CO2 is stepping up as the most logical, compliant choice.

This regulatory pressure has kicked the market into high gear. In Germany, the appetite for transcritical CO2 systems has exploded, hitting a market revenue of USD 4,995.0 million in 2024. And it’s not slowing down. Projections show that number climbing to an incredible USD 11,384.2 million by 2030, all thanks to the national push for natural refrigerants. You can dig into more of the data on this rapid market expansion on Grandview Research.

Avoiding outright bans is one thing, but there are some compelling financial reasons pushing this change forward. German climate goals and ever-increasing carbon taxes are making the old HFCs more and more expensive to buy, use, and maintain. Choosing a CO2 system now is like an insurance policy against those climbing costs and the risk of future penalties.

When a facility chooses CO2, it's not just "going green." It's making a hard-nosed investment in efficient, compliant infrastructure that will stay relevant and cost-effective for decades. It's about future-proofing the entire operation from regulatory surprises and market shocks.

The German government often helps sweeten the pot, too. Various incentive programmes are available to help businesses cover the initial cost of switching to more environmentally friendly tech. This support can significantly lower the barrier to entry, making the move to CO2 a smart financial play right from the start.

It's this perfect storm of regulatory, economic, and operational advantages that explains why the adoption of CO2 als Kältemittel is happening so fast. It offers a clear, stable path forward. This decision also has knock-on effects for other parts of the business; for instance, understanding the regulations for transporting gas cylinders becomes essential for managing refrigerant logistics safely and legally.

Switching to a new technology always brings up questions. Here, we've tackled some of the most common queries we hear from lab managers and procurement specialists who are looking into CO2 refrigeration for the first time.

Yes, they are exceptionally safe—when they are designed and installed by certified professionals who know what they're doing. These aren't your standard cooling systems. They're built with incredibly robust components specifically to handle the higher pressures of CO2, and they come layered with safety features like pressure relief valves.

A key point to remember is that CO2 is non-flammable and non-toxic in low concentrations. This often makes it a much lower-risk choice compared to alternatives like ammonia, which can be toxic. The entire safety equation hinges on partnering with experts who live and breathe the specific installation and maintenance protocols for using CO2 als Kältemittel.

Looking at the upfront invoice, yes, the initial equipment cost can be higher. This is simply because the high-pressure components are more specialised and rugged. But that's only one part of the story.

When you look at the total cost of ownership over the system's life, the picture flips completely. CO2 systems typically come out far ahead. This is thanks to some serious energy savings, the rock-bottom cost of CO2 refrigerant itself, and the huge benefit of dodging future carbon taxes or the expensive retrofits that HFC systems will inevitably face. Think of it as a long-term investment that pays you back in both efficiency and regulatory peace of mind.

One thing to get straight from the start: you can't just "drop-in" CO2 to replace an old HFC refrigerant. The operating pressures and hardware are fundamentally different. Moving to a full CO2 als Kältemittel system means a complete, planned replacement.

The best first step is always to talk with a refrigeration expert. They can run the numbers for your specific facility and map out the most cost-effective path forward.

For state-of-the-art cryogenic solutions that ensure safety and compliance, trust the experts at Cryonos GmbH. Explore our compliant, high-performance systems for your laboratory or biobank at our online shop.