No Products in the Cart

When you're looking to get the right CO2 cylinder, the first thing to figure out is the size you need. In Germany, things are pretty straightforward, as the industry has settled on three main capacities: 2 kg, 6 kg, and 10 kg. Each one strikes a different balance between the amount of gas you get and how easy it is to handle, making them suitable for everything from small-scale lab work to large industrial setups.

Getting into the world of compressed gases means you need to know the standard sizes available. Here in Germany, the market has really honed in on three core multi-use cylinder sizes, which helps keep things consistent between suppliers and makes sure they work with your equipment. This standardisation is a huge deal for keeping operations running smoothly, whether you're dispensing drinks, conducting research, or working on an industrial process.

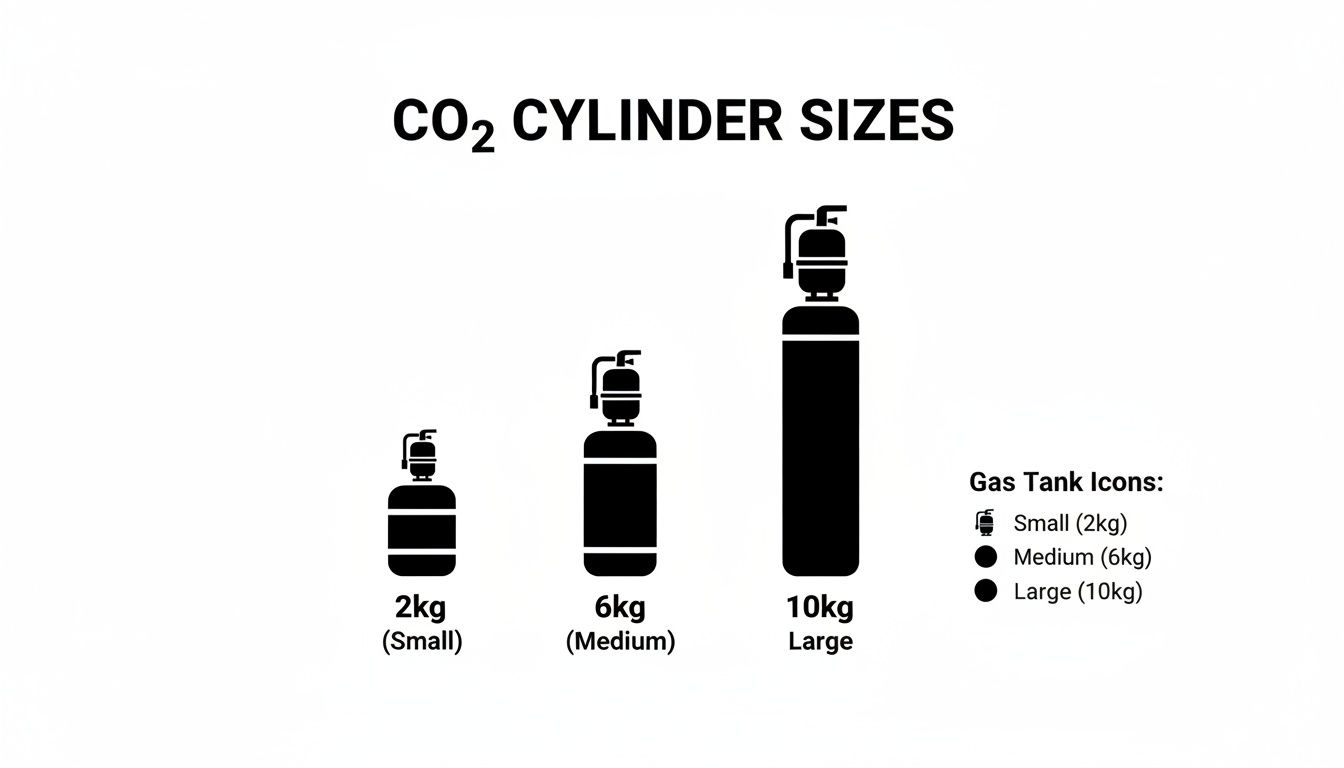

Each size offers its own unique mix of capacity, physical size, and portability. The image below gives you a good sense of the scale for these common cylinders.

As you can see, it's quite a jump from the compact 2 kg bottle to the much larger 10 kg version.

The most common sizes—2 kg, 6 kg, and 10 kg—cover the vast majority of commercial and scientific needs. The German market has standardised these options, so they are consistently manufactured with the same dimensions and valve types.

A versatile 2 kg bottle, for example, is perfect for smaller operations and has enough CO2 to carbonate about 300 litres of beverages. On the other end of the spectrum, a robust 10 kg cylinder can supply enough gas for up to 1,500 litres of carbonated drinks or 2,000 litres of beer, which is why it's a go-to for high-volume businesses.

These cylinders are all built to strict DIN specifications, featuring a unified valve connection (DIN 477 Nr. 6, W 21.8 x 1/14) that guarantees they'll fit standard pressure regulators. This kind of uniformity is essential in fields like biobanking and pharmaceutical labs, where you can't afford to have incompatible equipment. While these are the big three, larger options do exist for more specialised needs. You can learn more about the specifications for a 20 kg gas cylinder in our detailed guide. Getting a handle on these core sizes is the first step to making sure you choose the right gas supply for your work.

To make things even easier, we've put together a quick reference table. This should help you quickly compare the most common CO2 cylinder sizes at a glance and see which one might be the best fit for your space and needs.

| Cylinder Size (kg) | Typical Applications | Approx. Height (cm) | Approx. Diameter (cm) | Approx. Empty Weight (kg) |

|---|---|---|---|---|

| 2 kg | Home brewing, small aquariums, portable beverage | 45 - 50 | 10 - 12 | 4 - 6 |

| 6 kg | Restaurants, bars, medium-sized labs, welding | 60 - 70 | 14 - 16 | 12 - 15 |

| 10 kg | High-volume pubs, breweries, industrial processes | 90 - 100 | 14 - 16 | 18 - 22 |

This table gives you a solid starting point for understanding the physical specifications and what to expect from each cylinder. Always remember to check the exact dimensions with your supplier, as they can vary slightly between manufacturers.

Getting the technical specifications of a CO2 cylinder right is critical. It's about more than just capacity; it's about ensuring the bottle fits your equipment, meets safety standards, and handles your specific operational needs. These details cover precise dimensions, weights, and pressure ratings that influence everything from storage logistics to how you manage refills. This guide breaks down the essential data for the most common CO2 Flaschen Größen (CO2 cylinder sizes).

First things first, you need to understand the different weights involved. Every cylinder has a tare weight (Taregewicht), which is what the empty bottle and valve weigh on their own. The filling weight (Füllgewicht) is the net mass of the CO2 gas packed inside. Add them together, and you get the total weight (Gesamtgewicht) – what the cylinder weighs when it’s completely full.

Why does this matter? For very practical reasons. The most accurate way to check how much gas you have left is to weigh the cylinder and subtract the tare weight. The total weight is also a massive factor for logistics, impacting everything from safe manual handling to transport rules.

The 2 kg cylinder is a go-to for smaller-scale setups where portability and a compact footprint are key. You’ll often find it in home beverage systems, small labs, and aquariums. Its manageable size and weight make it incredibly easy to move around and tuck into tight spaces.

Thanks to its smaller dimensions, you can easily store multiple 2 kg cylinders without eating up much floor space. It’s a flexible way to keep a continuous supply of gas on hand.

Stepping up a notch, the 6 kg cylinder hits a nice balance for medium-demand environments like restaurants, busy bars, and research facilities. It delivers three times the gas of a 2 kg bottle, which dramatically cuts down on how often you need to swap cylinders without becoming a hassle to handle.

This size is often the sweet spot between capacity and manageability, making it a real workhorse in countless commercial settings.

One crucial tip for 6 kg cylinders and larger: always measure your space first. Whether it’s under a counter or inside a gas cabinet, check your available height to make sure the cylinder will actually fit before you buy.

For high-volume operations where a constant, long-lasting gas supply is non-negotiable, the 10 kg cylinder is the industry standard. It’s the top choice for breweries, large venues, industrial welding, and biobanks. While its weight and size demand more careful handling and dedicated storage, the operational uptime it provides for heavy users is simply unmatched.

Knowing these fine details allows you to plan properly, making sure the CO2 Flaschen Größen you choose align perfectly with both your gas consumption needs and the physical layout of your facility.

For a quick and easy comparison, the table below consolidates the key technical data for various common cylinder sizes.

| Filling Weight (kg) | Tare Weight (kg) | Total Weight (kg) | Height (mm) | Diameter (mm) | Water Capacity (L) | Test Pressure (bar) |

|---|---|---|---|---|---|---|

| 0.5 | 1.8 - 2.5 | 2.3 - 3.0 | 350 - 400 | 60 - 70 | 0.75 | 250 |

| 2.0 | 4.5 - 6.0 | 6.5 - 8.0 | 450 - 500 | 110 - 120 | 3.0 | 250 |

| 6.0 | 12.0 - 15.0 | 18.0 - 21.0 | 650 - 750 | 140 - 150 | 8.0 | 250 |

| 10.0 | 18.0 - 22.0 | 28.0 - 32.0 | 900 - 1000 | 140 - 160 | 13.4 | 250 |

| 20.0 | 40.0 - 48.0 | 60.0 - 68.0 | 1200 - 1300 | 200 - 220 | 26.7 | 250 |

| 30.0 | 55.0 - 65.0 | 85.0 - 95.0 | 1400 - 1500 | 220 - 230 | 40.0 | 250 |

This matrix serves as a handy reference for planning installations, calculating transport weights, and ensuring you select the most appropriate cylinder for your application.

Picking the right size CO2 cylinder is only half the job; making sure it connects safely and properly to your gear is just as crucial. The valve is the all-important link between the high-pressure gas locked inside the cylinder and your regulator. Here in Europe, and especially in Germany, this is all governed by strict standards to ensure everything fits perfectly and to head off any dangerous mix-ups between different co2 flaschen größen.

The standard you'll run into almost everywhere is DIN 477 Nr. 6, which you'll also see specified as W 21.8 x 1/14". This code spells out the exact threading and dimensions for CO2 valves, guaranteeing a tight, leak-proof seal. In labs or industrial workshops where gas purity and system safety are top priorities, this isn't just a recommendation—it's a hard rule. Trying to force a non-standard or incorrect valve can lead to a catastrophic failure, wrecking expensive equipment or, worse, causing serious injury.

This image shows you the top of a gas cylinder, zeroing in on the valve and the stamped markings that tell you its technical story. The big takeaway here is that every cylinder carries its vital stats—test pressure, tare weight, and manufacturing date—right on its shoulder. The valve type is a core part of that certified design.

The DIN 477 Nr. 6 connection is an external right-hand thread, engineered specifically for non-flammable, non-toxic gases like carbon dioxide. Its precision design means only the right kind of regulator will attach.

This level of detail is a built-in safety feature. It stops you from accidentally hooking up a CO2 regulator to a system meant for something else, like nitrogen or oxygen, which use their own distinct valve standards. For example, an oxygen cylinder uses a different DIN standard (DIN 477 Nr. 9, G 3/4") to prevent the accidental mixing of gases, which could be explosive.

Valves on CO2 cylinders are almost always made from high-strength brass. It's the material of choice because it’s tough, resists corrosion, and won't create a spark—a critical safety feature when you're dealing with any high-pressure gas.

One of the most important safety elements you'll find in many CO2 valves is a burst disc. It’s a small, single-use pressure relief device. If the pressure inside the cylinder gets too high, perhaps from overfilling or being left in the sun, this disc is designed to rupture and vent the gas safely.

It’s also good practice to give the valve threads a quick look for any damage or cross-threading before you connect a regulator. Damaged threads can mess up the seal, leading to slow leaks that waste gas and could even create an oxygen-deficient atmosphere in a poorly ventilated room.

While connecting your regulator directly to the cylinder is always the safest bet, sometimes an adapter is unavoidable, especially if you're working with equipment from different countries or for very specific jobs. But remember, adding an adapter introduces another potential weak spot in your setup.

If you absolutely have to use one, make sure it’s from a reputable manufacturer and is rated for the correct pressure. After you've installed it, always do a quick leak test with a bit of soapy water solution. No matter what co2 flaschen größen you're using, the number one priority is always maintaining a secure, standardised connection for both safety and performance.

Picking the right cylinder size is a decision that goes straight to the heart of your operational efficiency, costs, and safety. Instead of getting lost in technical specifications, the best way to start is by looking closely at your specific application and what it demands. Think about factors like your gas consumption rate, how much storage space you have, and how often you're willing to change out cylinders.

Matching these real-world needs to the right co2 flaschen größen is what ensures a smooth, uninterrupted workflow. A high-volume, continuous process obviously needs a different supply strategy than an occasional task in a laboratory. This guide breaks down the most common scenarios to help you make a smart decision based on practical requirements, not just numbers on a spec sheet.

Small-scale research labs, cell therapy facilities, and university science departments typically have gas needs that can fluctuate quite a bit. The main challenge here is balancing consumption with often limited space and the need for cylinders that are easy to handle.

In this environment, a 2 kg cylinder is almost always the perfect fit. It’s compact enough to tuck into a safety cabinet or sit next to a piece of equipment, like a CO₂ incubator, without getting in the way. Its lighter weight also means lab personnel can move and replace it without needing specialised equipment, which is a huge plus for minimising downtime during critical experiments. This size is ideal when you have a predictable but not constant need for gas, such as maintaining pH levels in cell cultures.

On the other end of the spectrum, you have large biobanks, cryogenic storage facilities, and pharmaceutical manufacturing plants. These operations have one thing in common: a consistent and high-volume demand for CO₂. It's often used for crucial backup systems for cryogenic freezers or in large-scale cell culture applications where reliability is non-negotiable.

For these demanding jobs, 10 kg cylinders are the industry standard. Trying to get by with smaller cylinders would mean constant changeovers, which drives up labour costs and, more importantly, introduces the risk of supply interruptions. A 10 kg cylinder provides a substantial gas reserve, guaranteeing long periods of smooth, uninterrupted operation.

For mission-critical applications like cryopreservation backup, a common best practice is to connect multiple 10 kg cylinders to an automatic changeover manifold. This setup creates a foolproof, continuous supply, automatically switching to a full cylinder the moment one runs empty—absolutely essential when you're protecting invaluable biological samples.

Industrial welding is another field with very specific gas flow requirements. While CO₂ is often part of a gas mixture (with Argon, for instance), pure CO₂ is still the go-to for certain MAG welding processes. The deciding factor here is the welder's duty cycle—basically, how much time they spend actually laying a bead versus setting up the next job.

A busy fabrication shop with several welding stations running all day will get the most out of 10 kg cylinders. They have the capacity to keep work flowing without constant interruptions for cylinder swaps. However, for a mobile repair rig or a small workshop where welding is more of an occasional task, a 6 kg cylinder offers an excellent compromise. It gives you significantly more gas than a 2 kg bottle but is still much more portable than the hefty 10 kg option, making the 6 kg a versatile workhorse in many industrial settings.

When you're working with pressurised gas cylinders, following safety rules isn't just a good idea—it's an absolute necessity. For CO₂ storage, compliance is non-negotiable, protecting both your staff and your property. The main risk with carbon dioxide isn't fire, but asphyxiation. Getting a solid grip on the physics of gas expansion is the first step to creating a safe environment.

CO₂ gas is heavier than air. If it leaks in an enclosed space, it sinks and pushes out the oxygen, creating a dangerous, low-oxygen zone near the floor. A major leak can quickly turn a room into a death trap. This is precisely why German regulations are so strict about proper ventilation and room size, linking safety directly to the specific co2 flaschen größen you have on-site.

To head off the risk of accidental asphyxiation, German safety authorities have laid out very clear rules for the minimum room size needed to store CO₂ cylinders. The logic is simple: if a cylinder were to leak completely, the CO₂ concentration in the room must not rise to a hazardous level.

German safety regulations, especially from the Berufsgenossenschaft Nahrungsmittel und Gastgewerbe (BGN), give a straightforward formula. The key data point is that 1 kg of liquid CO₂ expands to about 0.51 m³ of gas, and the maximum safe indoor concentration is capped at 3%. For a practical example, storing a single 2 kg cylinder means you need an unfurnished floor area of at least 13.6 square metres. This scales up fast—a 10 kg cylinder requires a room of at least 68 square metres. These numbers assume a standard room height and really highlight why you need a dedicated, properly sized storage area.

What happens if your room isn't big enough? When natural ventilation can't meet these safety thresholds, you have to bring in mechanical systems. The requirements get stricter depending on how much CO₂ you're storing.

These warning systems are your most critical line of defence. They need to be installed by certified pros and regularly maintained to ensure they work in an emergency, often interlocking with ventilation to automatically clear the air.

Beyond just storage, your day-to-day handling procedures are just as important for keeping everyone safe. The sheer weight and high pressure of these cylinders demand respect and proper technique. You can also dive deeper by checking out our article on understanding CO2 cylinder pressure to learn more.

Make sure you always follow these essential rules:

When you're sourcing CO₂, one of the first big decisions is whether to buy your own cylinders (Eigentumsflaschen) or rent them from a supplier (Mietflaschen). This choice directly hits your budget, logistics, and day-to-day flexibility. Each route has its own clear pros and cons, suiting different business needs and gas consumption rates. Figuring out these differences is crucial for choosing the most practical and cost-effective path for your gas supply.

The core distinction really boils down to responsibility. If you own the cylinder, it's all on you—maintenance, mandatory inspections, and finding someone to refill it. Renting, on the other hand, shifts nearly all of those headaches to the gas supplier in exchange for a regular fee.

Buying your own CO₂ cylinders means a bigger upfront investment, but it can save you a significant amount of money in the long run, especially if you have consistent, high-volume needs. The main draw here is freedom. You're not tied to any rental contracts and can choose any gas supplier you like for refills, letting you shop around for the best prices.

But ownership comes with a checklist of duties you can't ignore:

This model is usually the best fit for businesses that want full control over their assets and prefer to avoid the slow burn of ongoing rental fees.

Renting cylinders is a very popular choice for businesses that want lower initial costs and a more "hands-off" way to manage their gas supply. For a daily, monthly, or yearly fee, the gas supplier provides the cylinder, but they retain ownership.

The rental model is all about convenience. Your supplier takes care of all the required TÜV inspections and maintenance as part of the deal. When your cylinder is empty, you just swap it for a full one, which means no waiting around for a refill. This makes logistics much simpler and ensures you always have a reliable supply on hand.

While renting is undeniably convenient, it can get pricey over the long haul compared to owning. The rental fees add up, and eventually, you might find you've paid more than what a new cylinder would have cost. For users with steady, long-term gas needs, it often becomes the less economical choice.

Ultimately, deciding between buying and renting comes down to your operational scale and financial strategy. For a more detailed breakdown, you might find our guide that explores whether to buy or rent gas cylinders useful, as it offers more insights to help you make the right call. It's all about carefully weighing the upfront costs against long-term expenses and maintenance duties to find what works best for you.

When you're working with CO2 cylinders every day, a few practical questions always seem to pop up. Getting your head around the details is the key to managing your gas supply safely and efficiently, no matter which co2 flaschen größen (CO2 cylinder sizes) you're using.

This section tackles some of the most common queries we hear, giving you quick, straightforward answers you can rely on for daily operations.

Figuring out how much gas is left in a CO2 cylinder is a classic problem. Unlike other compressed gases, CO2 is stored as a liquid, so a pressure gauge won't help much. It will consistently read around 57 bar at room temperature as long as there's even a drop of liquid CO2 inside. The needle will only plummet right before the tank is totally empty, giving you virtually no warning.

The only reliable way to know for sure is to weigh it. Every cylinder has its empty weight, or tare weight, stamped right on its shoulder. Just use this simple formula:

(Current Weight of the Cylinder) – (Tare Weight) = Remaining CO2 in kg

It’s a foolproof method. For instance, if you have a 2 kg cylinder with a tare weight of 5.5 kg and it currently weighs 6.5 kg, you've got exactly 1.0 kg of CO2 left.

In Germany, the TÜV inspection is a non-negotiable safety check for all pressurised gas cylinders. This critical inspection makes sure the cylinder is structurally sound and won't fail under pressure. For the vast majority of steel CO2 cylinders, this inspection is legally required every 10 years.

The process involves a pressure test and a meticulous visual check for any signs of corrosion, dents, or other damage. You'll find the date of the last inspection stamped on the cylinder's shoulder. If you own the cylinder (Eigentumsflasche), it's your responsibility to arrange and pay for the TÜV. If you're renting (Mietflasche), the gas supplier takes care of everything.

This is a critical question for anyone in a scientific setting. While beverage-grade CO2 (food-grade E290) is perfectly safe to drink, it's often not pure enough for sensitive lab equipment like a CO₂ incubator. The real difference comes down to purity levels and potential contaminants.

Scientific-grade CO2 typically boasts a much higher purity, often 99.995% or more, and is rigorously tested for trace impurities that could ruin an experiment or damage delicate sensors. Using a lower-grade beverage CO2 could easily compromise the viability of your cell cultures or throw off your results. Always double-check the gas specifications required by your equipment and stick to the right grade.

A cylinder with a riser pipe (or Steigrohr) is specifically designed to dispense liquid CO2, not gas. Inside, a tube runs from the valve all the way down to the bottom of the cylinder, pulling the liquid CO2 from the bottom up.

You'll need one of these for any application that requires rapid, intense cooling or making dry ice, like in cryogenics or some industrial processes. You can usually spot a riser pipe cylinder by a prominent 'T' stamped on its shoulder or a clear label. Trying to draw liquid from a standard cylinder simply won't work, so make sure you've got the right tool for the job.

At Cryonos GmbH, we provide state-of-the-art cryogenic solutions tailored for laboratories, biobanks, and industrial users who demand reliability and precision. Explore our comprehensive portfolio of equipment designed for the safe storage and handling of biological samples and industrial gases at our online shop.