No Products in the Cart

When you hear the phrase CO2 in a tank, it can mean two completely different things. It all depends on the context. In some industries, like beverage carbonation, a tank full of CO2 is exactly what you want. But in the world of cryogenics, finding CO2 in your tank is a sign of serious trouble.

For some, "CO2 in a tank" simply refers to a specialised vessel designed to hold carbon dioxide, either as a compressed gas or a refrigerated liquid for processes like welding or food packaging. These systems are built from the ground up to handle the unique pressures and properties of CO2.

The far more dangerous scenario, however, is when CO2 shows up as an uninvited guest. This happens when it infiltrates tanks built for other substances, especially cryogenic liquids like nitrogen or argon. In these incredibly cold environments, even a tiny amount of CO2 can unleash a cascade of problems.

Think of unwanted CO2 in a cryogenic tank like water getting into your car’s fuel tank. It doesn’t belong there, and even a small amount is enough to cause major engine trouble down the road.

It’s the same principle here. When CO2 from the atmosphere seeps into a liquid nitrogen vessel, it doesn’t just mix in—it instantly freezes solid, forming dry ice.

This phase change from gas to solid is the root of so many operational failures. The tiny dry ice particles build up over time, creating blockages in valves, pipes, and, most critically, safety release mechanisms.

To give you a clearer picture, let's break down the different scenarios where CO2 appears in tank systems.

The table below summarises the main contexts you'll find CO2 in a tank, what state it's in, and the biggest risk it poses in each situation.

| Tank System Context | Role of CO2 | Common State | Primary Risk |

|---|---|---|---|

| Beverage Carbonation | The intended product | Liquid/Gas | Incorrect carbonation levels |

| Industrial Gas Supply | The intended product | Liquid/Gas | Leaks and pressure mismanagement |

| Cryogenic Storage (LN2, Argon) | A dangerous contaminant | Solid (Dry Ice) | System blockages and pressure buildup |

| Bio-Storage/Medical | A harmful impurity | Solid/Gas | Compromised sample integrity |

As you can see, once CO2 becomes a contaminant in a low-temperature system, the risks escalate from a quality issue to a serious safety and operational hazard.

Managing this contamination is non-negotiable for any facility that depends on pure cryogenic gases. The consequences of letting it go unchecked range from expensive equipment damage to catastrophic safety failures. This is particularly true in sensitive fields:

A core part of managing these systems is understanding the specific pressure dynamics at play. To get a better handle on this, you can learn more about CO2 cylinder pressures in our related guide. At the end of the day, controlling CO2 is about protecting your assets, ensuring your operations run smoothly, and keeping everyone safe.

The problem of unwanted CO2 in a tank rarely happens all at once. It’s usually the outcome of small, almost invisible breaches in the system. Just picture your cryogenic tank as a high-tech thermos. If there's even a hairline crack in the seal, outside air will slowly but surely creep in and ruin what's inside.

Carbon dioxide makes up just 0.04% of the air we breathe. That doesn't sound like much, but it’s more than enough to create havoc when it enters an ultra-cold environment like a liquid nitrogen tank. The second that gaseous CO2 from the atmosphere makes contact with the cryogenic liquid, a dramatic change happens.

This isn't a slow mixing process—it's an instant freeze. The CO2 sublimates, going directly from a gas to a solid and forming tiny particles of dry ice. As time goes on, these particles build up, creating a dangerous internal frost that can clog up the works. This is the root cause of most contamination-related equipment failures.

Knowing how the CO2 gets in is the first step to keeping it out. The infiltration usually happens in two ways: through atmospheric leaks or because of mistakes made during handling and refilling. Either one can introduce a steady flow of contaminants into a system that should be perfectly clean.

An atmospheric leak is often the quiet offender. These can pop up in a few places:

Procedural errors during a refill are just as risky and can inject a huge amount of CO2 in a tank in one go.

The single biggest procedural mistake is improper purging. When someone fails to clear the ambient air and moisture from the transfer hoses before connecting them, they are essentially shooting a dose of contaminants straight into the pure liquid nitrogen.

The physics behind this problem is pretty simple, but it's crucial to understand. Liquid nitrogen is incredibly cold, sitting at -196°C (-321°F). Carbon dioxide, on the other hand, freezes at a much warmer temperature of -78.5°C (-109.3°F).

Because of this massive temperature difference, any CO2 gas that gets into the tank’s headspace has zero chance of staying a gas. It solidifies on contact, creating that troublesome dry ice buildup. For a closer look at how dry ice forms, you can check out our guide on the production of dry ice. This accumulation isn't just a bit of frost; it's a solid blockage that can jam safety valves and clog liquid withdrawal lines, creating a serious risk for both the equipment and the people operating it.

When you find unwanted CO2 in a tank, it's far more than a simple quality control problem—it's a serious threat to safety and operations. The real issue isn't the CO2 itself, but how it behaves in the extreme cold of cryogenic systems. This is where theory meets a harsh reality, with consequences that range from expensive downtime to catastrophic equipment failure.

The most immediate risk is a rapid, uncontrolled pressure spike. When solid CO2 (dry ice) that has formed inside a tank starts to warm up, it sublimates—turning directly from a solid back into a gas. This phase change is incredibly powerful; just one kilogramme of dry ice expands to create over 530 litres of CO2 gas.

Picture that expansion happening inside a sealed metal container. The pressure builds with terrifying speed, far faster than the system was ever designed to handle. This can lead to buckled tanks, damaged pipework, and, in the worst-case scenario, a violent rupture.

This rapid gas expansion becomes even more dangerous when the CO2 has formed blockages in critical components. Dry ice is hard and abrasive, and it has a nasty habit of accumulating in the narrow passages of valves and regulators.

A key point of failure is the safety relief valve. This device is the tank's last line of defence against over-pressurisation. If it gets clogged with solid CO2, it simply can’t do its job.

When the safety valve is disabled, the tank becomes a ticking time bomb. With no way to vent the rapidly expanding gas, internal pressure can build until the vessel fails catastrophically, releasing its contents with explosive force.

This isn't just a theoretical risk. Germany's strict safety regulations for cryogenic tanks have evolved in response to real-world incidents. Data from German safety reports showed that improper handling of pressurised gas tanks led to over 150 reported incidents between 2010 and 2020 in the industrial sector. Pressure buildups were a significant factor, with 12% of cases resulting in minor explosions or leaks. For a deeper dive, you can explore more on the hazards of cryogenic liquids.

And while our focus here is on CO2, it’s worth remembering the dangers of other harmful gas contaminants like carbon monoxide to get a broader perspective on contamination risks.

Beyond the immediate physical dangers, CO2 contamination poses a severe threat to the valuable materials stored inside, especially in biobanking and research.

Ultimately, the hidden dangers of CO2 are tied to real-world consequences. Proactive prevention isn't just a best practice—it's absolutely essential for protecting people, equipment, and priceless assets.

It’s one thing to suspect you have CO2 in a tank, but it’s another thing entirely to confirm it and then take safe, decisive action. Ignoring the problem simply isn’t an option. Think of this as your practical playbook for spotting contamination early and rolling out a safe remediation plan, ensuring a manageable issue doesn’t spiral into a critical failure.

The first step is always learning to read the early warning signs. A contaminated tank often drops subtle clues long before a major failure. Operators need to be trained to spot these little indicators during their routine checks, because catching it early is the absolute key to a swift and safe resolution.

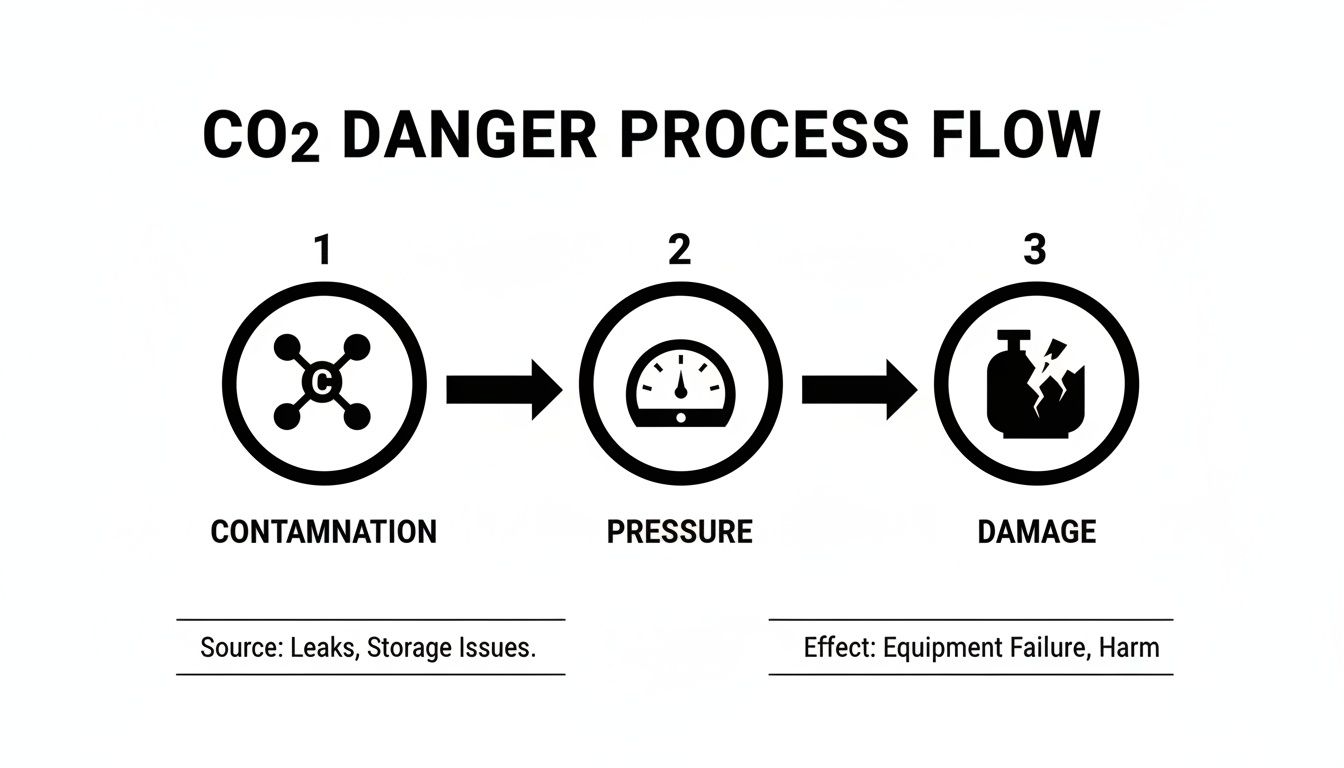

This flowchart maps out how CO2 contamination creates a dangerous chain reaction, starting from the initial breach and leading all the way to potential equipment failure.

As you can see, even a small contamination event can directly cause dangerous pressure spikes and, if left unchecked, lead to severe equipment damage.

Vigilance is your single best tool for detection. Keep a close eye on how your equipment is behaving and be ready to investigate any deviation from its normal operation.

Three main signs point directly to potential CO2 contamination:

Once you’ve confirmed contamination, you have to act methodically. Trying to clear a blockage with brute force—like taking a hammer to a frozen valve—is a recipe for catastrophic failure. Safety must be the guiding principle behind every single action you take.

The core principle of remediation is control. You must safely isolate the tank, manage the internal pressure, and then carefully remove the blockage without causing a sudden, uncontrolled release of gas or pressure.

Here is a quick reference table outlining the essential steps to follow when you suspect CO2 contamination.

| Phase | Action Steps | Key Safety Precaution |

|---|---|---|

| 1. Isolate | Immediately close the main liquid valve. Disconnect the tank from the main supply line. | Prevent further product draw and protect downstream equipment. |

| 2. Depressurise | Slowly and carefully vent pressure from the tank’s headspace through a clear, designated vent path. | Vent gradually to avoid thermal shock or sudden temperature changes. |

| 3. Thaw | Allow the affected components to warm up to ambient temperature naturally. Alternatively, use approved methods like circulating low-pressure, dry nitrogen. | Never use an open flame or direct, intense heat. This can cause a violent rupture. |

| 4. Purge | Once the blockage is cleared, thoroughly purge the entire tank and its pipework with an inert gas like dry nitrogen. | Ensure all residual CO2 and moisture are removed before putting the tank back into service to prevent re-contamination. |

This step-by-step process is designed to be systematic and safe. Attempting shortcuts or skipping steps introduces unnecessary risk.

Following these steps ensures that the CO2 in a tank is removed without endangering your personnel or causing expensive damage to your valuable equipment.

Switching from a reactive, "fix-it-when-it-breaks" mindset to a proactive one is the secret to managing the risks of unwanted CO2 in a tank. A solid prevention strategy is all about disciplined routines and consistent oversight, making sure contamination never gets a foothold. This process starts at the most common point of failure: the refill.

Every single refill has to start with a thorough purge of all transfer lines. It’s a simple step, but it's absolutely critical for removing ambient air and moisture. Skipping it is like injecting CO2 directly into your pure cryogenic liquid. Just as crucial is where your gas comes from—always work with a reputable supplier and insist on certified, high-purity gas to keep contaminants out from the very beginning.

Equipment doesn't last forever. Over time, even the highest quality tank can develop weak spots. That's why diligent preventive maintenance is the core of any strategy to prevent CO2 contamination and protect your system's integrity. It all comes down to regularly scheduled inspections of all your critical components.

Your inspection checklist should zero in on the parts most likely to fail:

A proactive maintenance schedule isn’t just an expense; it’s an investment in safety and operational continuity. Catching a failing seal that costs a few euros to replace can prevent thousands in equipment damage and lost time.

Meticulous records are the backbone of any good prevention plan. Keep a detailed logbook for each tank, noting down every refill, inspection, and pressure reading. This historical data is invaluable, allowing your team to spot tiny deviations from the norm that are often the first red flag of a CO2 in tank issue.

This kind of operational discipline is exactly what allows massive operations to run safely. Take Germany's work with carbon capture and storage (CCS) technology, where managing CO2 in high-pressure tanks is a core competency. In 2019 alone, German-involved projects helped store around 29 million tons of CO2, a figure that highlights the rigorous protocols required.

Ultimately, your team is your best defence. Proper training ensures everyone understands their role in keeping the system clean and safe. When you combine strict procedures with vigilant monitoring and detailed documentation, you build a powerful defence against contamination. For more in-depth strategies, take a look at our guide on how to manage your cryogenic storage. This proactive approach is the bedrock of a safe, reliable, and efficient operation.

Preventing unwanted CO2 in a tank isn't something you do after the fact; it starts long before the first fill. The single most effective strategy is investing in high-quality equipment, engineered from the ground up to guarantee system integrity. Think of your storage vessel as the first and most important line of defence against atmospheric contamination—this makes its design and construction absolutely critical.

Top-tier engineering translates directly into operational safety and reliability. For example, high-performance vacuum insulation isn't just a nice-to-have feature; it's essential for holding those stable cryogenic temperatures. By keeping heat transfer to an absolute minimum, it slashes the risk of internal pressure swings that can stress seals and create tiny pathways for leaks.

High-integrity construction is just as important. Vessels built with robust, high-quality materials and precision welds are simply far less likely to develop the microscopic cracks or weaknesses that let atmospheric gases creep in. This is exactly why choosing certified equipment is so vital.

When you get down to it, premium cryogenic equipment is much more than a container. It’s a meticulously designed system, a secure environment engineered to protect both the valuable contents inside and the people who handle it every day.

At Cryonos, we provide equipment that embodies these principles. Our partnership with Auguste Cryogenics ensures every tank is built to exacting standards, backed by decades of deep technical expertise. When you invest in this level of quality engineering, you're not just buying a tank—you're getting peace of mind and securing your operational continuity by designing the problem of CO2 contamination right out of your workflow.

When you're dealing with cryogenic systems day in and day out, questions are bound to come up. Below, we've tackled some of the most common ones we hear about identifying and handling unwanted CO2 in a tank, giving you clear, straightforward answers to keep your operations safe and running smoothly.

The early warnings of CO2 contamination can be easy to miss if you don't know what you're looking for. Keep an eye out for pressure gauges that won't hold steady or act erratically—that's a classic sign that solid CO2 (dry ice) is sublimating inside the tank, causing pressure swings.

Another big clue is frost showing up in odd places, like on the outside of safety valves or other external components where you wouldn't normally see it. You might also hear strange hissing or popping sounds during a fill, which is the sound of incoming liquid hitting and cracking chunks of dry ice. Any of these signs mean it's time to investigate immediately.

First and foremost, always follow the manufacturer's guidelines for your specific piece of equipment. But as a solid rule of thumb, operators should be doing visual checks every single day. Look for anything out of the ordinary, like weird frost patterns or the sound of a leak.

Consistent monitoring is your best defence. A problem you catch during a daily walk-around is always going to be easier and safer to fix than one that announces itself with a system failure.

Beyond those daily checks, a full, professional inspection should be on the calendar at least once a year, or whatever frequency your supplier recommends. This is non-negotiable for making sure all the critical safety parts are working exactly as they should.

Yes, in most cases, a contaminated tank can be brought back into service. But—and this is a big but—it has to go through a professional and meticulous remediation process first. This is definitely not a task you can rush or cut corners on.

The tank needs a complete, controlled purge and clean-out to get rid of every last trace of CO2 and any moisture that got in. After that, it has to pass a detailed inspection and pressure test to confirm that the contamination event didn't compromise its structural integrity or safety systems.

At Cryonos GmbH, we engineer our cryogenic vessels to prevent contamination right from the start. Take a look at our solutions to secure your operations and protect your valuable assets. Learn more at https://www.cryonos.shop.