No Products in the Cart

So, you're wondering if you can transport gas cylinders lying down, or as they say in German, "darf man gasflaschen liegend transportieren"? The short answer is yes, but it comes with a very big "but". It's only permissible under specific, strictly controlled conditions.

While keeping gas cylinders upright is always the safest and best practice, sometimes laying them down is your only option. The real key isn't whether you can, but whether you're doing it correctly and safely according to regulations.

Before we get into the how, it’s crucial to understand the why. This isn't just about following rules for the sake of it; it's about actively managing the serious risks that come with pressurised gas. In Europe, the main rulebook for this is the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR).

These aren't just bureaucratic hoops to jump through. They are a critical safety net. Think of an upright cylinder as a stable, predictable package. The moment you lay it on its side, the physics change completely. New hazards pop up, and you have to be ready to handle them.

Whether you can transport a cylinder horizontally boils down to a few critical questions. Each one is designed to tackle a specific risk, from a snapped valve to an uncontrolled gas leak. Before you even think about this method, you have to check these boxes:

The whole point of the ADR rules is to minimise risk. Laying a cylinder down increases that risk, which means your safety measures have to be even better to compensate.

Basically, getting the green light for horizontal transport depends entirely on you putting extra safety measures in place. It's a trade-off. For a deeper dive into general safety rules, you can learn more about transporting gas cylinders in a car in our complete guide. Cutting corners here isn't just a violation; it puts you and everyone around you in real danger.

To make sense of the differences, it helps to see the requirements side-by-side. While standing a cylinder up is the go-to method, laying it down introduces a new set of challenges that you must be prepared to handle.

| Consideration | Upright Transport (Preferred Method) | Horizontal Transport (Conditional Method) |

|---|---|---|

| Stability | Naturally more stable, lower centre of gravity when secured correctly. | Prone to rolling and shifting; requires robust blocking and strapping. |

| Valve Risk | Valve is less exposed to direct impact from the side. | Increased risk of valve shearing; a protective cap is absolutely mandatory. |

| Pressure Relief | Pressure relief devices (if present) are designed to function correctly in the upright position. | May not function as intended, especially with liquefied gases, potentially venting liquid instead of vapour. |

| Internal Contents | Ideal for all gas types, including those with liquid phases or internal components (like Acetylene). | Prohibited for certain gases (e.g., Acetylene). Can be problematic for liquefied gases. |

| Securing Method | Typically secured in racks, pallets, or strapped individually against a bulkhead. | Must be chocked to prevent rolling and secured lengthwise to prevent sliding. |

| General Recommendation | Always the first and safest choice. | Only when upright is not possible and all ADR conditions are met. |

Ultimately, the choice isn't just about what fits in your vehicle. It's a calculated decision based on safety, regulations, and the specific nature of the gas you're handling. When in doubt, always default to the upright position.

When you find yourself asking, "darf man gasflaschen liegend transportieren?" (can you transport gas cylinders lying down?), the answer isn't a simple yes or no. Instead, it’s wrapped up in a set of rules designed not to make your life difficult, but to prevent disasters. These regulations are the essential safety net for handling pressurised goods.

The main framework you’ll encounter across Europe is the ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road), which sets the baseline for safety. But Germany doesn't just adopt the ADR; it adds its own specific requirements on top, creating a two-layered system of compliance.

Think of it like this: the ADR is the international highway code, while German regulations are the local speed limits and traffic rules you have to follow once you’re in the country. Ignoring either can lead to hefty penalties and, far more importantly, create serious safety hazards. This isn’t just for big industrial suppliers, either. It applies to anyone moving gas cylinders for work, from a lab transporting cryogenic samples to a welder with gas tanks in their van.

One of the most unique parts of German transport law is its points-based system. No, this isn't about traffic tickets—it’s about calculating risk. Every type of dangerous good gets a point value per kilogram, and the total score for your load determines which rules you need to follow.

This system is actually quite practical. It creates a clear threshold, offering flexibility for smaller loads and distinguishing between someone moving a single cylinder and a lorry packed to the brim.

The magic number to remember is 1,000 points. If your total load stays below this limit, you can operate under a much simpler set of rules. This is commonly known as the "1,000-Punkte-Regel."

For most common gases, the maths is simple. The regulations state that new and used gases are typically valued at 1 point per kilogram. This allows you to transport up to 1,000 kilograms under these simplified rules without needing a special dangerous goods licence or vehicle markings.

However, some gases are considered higher risk. Certain reuse gases (like UN 3162) are valued at 50 points per kilogram, which dramatically lowers the maximum amount you can carry to just 20 kilograms.

Crossing that 1,000-point threshold is a game-changer. You’re no longer in the low-risk category. Instead, you're now in the world of fully regulated dangerous goods transport, and a much stricter set of requirements kicks in immediately.

Once you exceed the limit, you'll need:

Knowing which side of this line you're on is absolutely crucial for staying compliant. It's the difference between a routine delivery and a highly regulated, specialised operation. For a deeper dive into these rules, check out our complete guide on gas cylinder transport regulations.

Following the rules is one thing, but truly understanding the immense power locked inside a gas cylinder is another entirely. We need to move past just ticking boxes on a checklist and get to grips with what actually happens when transporting pressurised gas goes wrong. The dangers aren't just theoretical lines in a manual; they’re rooted in physics and can have devastating, real-world consequences.

Think of a gas cylinder less like a simple container and more like a rocket waiting for a launch signal. Under normal circumstances, it's perfectly stable and safe. But careless handling during transport can instantly turn all that stored potential energy into kinetic energy with explosive force. This is precisely why the question of whether you can transport gas cylinders lying down (darf man gasflaschen liegend transportieren) demands such a careful, detailed answer.

One of the most immediate and frightening dangers is the cylinder itself becoming a projectile. In a sudden stop, a sharp swerve, or a collision, an unsecured cylinder gains a terrifying amount of momentum. A standard 11 kg propane cylinder, when full, weighs over 21 kg. Imagine that much weight smashing through a vehicle’s bulkhead or flying from a truck bed – it's a lethal threat to anyone in its path.

Just as dangerous is the risk to the valve assembly. If a cylinder rolls and slams into a hard surface, or if another heavy object strikes it, the relatively soft brass valve can be sheared clean off.

This is what’s known as "rocketing." The instant, violent release of high-pressure gas launches the cylinder with enough force to punch through concrete walls. It effectively becomes an unguided missile.

This terrifying scenario is exactly why valve protection caps aren't optional extras. They are a non-negotiable piece of safety equipment, your first and most vital line of defence against catastrophic valve failure during a bumpy ride.

For cylinders filled with liquefied gases like propane or CO₂, laying them down creates a unique and often misunderstood risk. These cylinders are built with a pressure relief valve (PRV) positioned in the vapour space at the top. This is a critical safety feature, designed to vent excess gas pressure if the cylinder gets too hot.

When the cylinder is on its side, however, the liquid inside can slosh up against the PRV. If the valve activates, it will vent liquid instead of gas. This is a huge problem. Liquid propane, for instance, expands to 270 times its volume as it turns back into a gas at atmospheric pressure. This can trigger a cascade of dangerous events:

Ultimately, the key is to shift your mindset from simply following rules to actively preventing risk. Every cylinder you move contains a significant amount of potential energy. Treating it with the respect it commands is the only way to ensure the safety of yourself and everyone around you.

When you can't transport a cylinder upright, figuring out the right way to do it lying down becomes a game of following the rules—and for good reason. Sticking to a clear, methodical process isn't just about ticking boxes for compliance; it's about actively managing the very real risks that come with the territory.

This checklist breaks down the essential steps you need to take. Think of it as a pre-flight check for your cargo. Each step is designed to prevent a specific failure, whether it's the cylinder rolling loose after a sudden stop or the valve getting smashed in an impact. Skipping even one of these can compromise the whole setup.

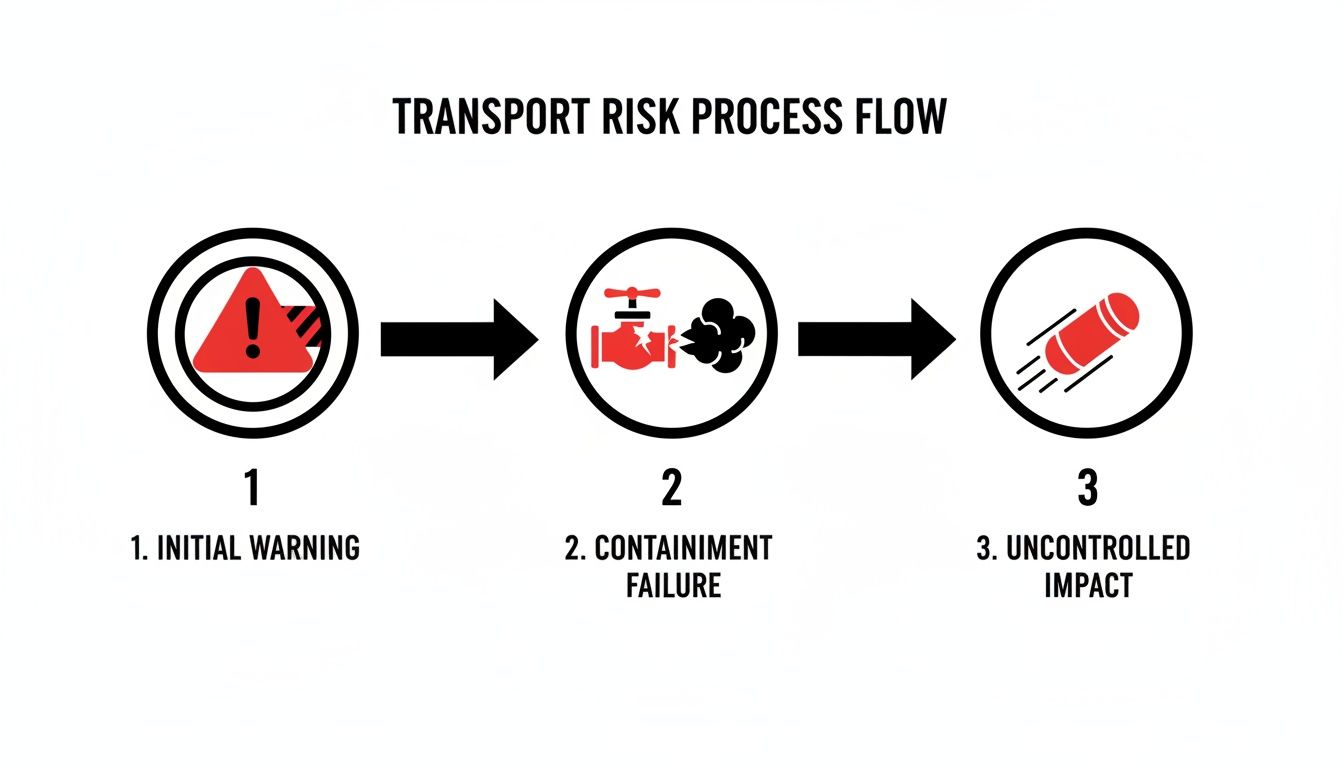

The flowchart below shows just how quickly things can go wrong when a cylinder isn't properly secured for horizontal transport.

As you can see, a simple mistake like not securing the load properly can escalate fast, turning the cylinder into a high-speed projectile. It's a chain reaction you want no part of.

To make this easier to follow, here’s a quick-reference table outlining the key safety checks.

| Safety Check | Action Required | Reason |

|---|---|---|

| Immobilise Cylinder | Use chocks to prevent rolling and brace the cylinder against a solid bulkhead to stop sliding. | Eliminates side-to-side and front-to-back movement during transit, which is the primary cause of accidents. |

| Secure with Straps | Fasten with at least two heavy-duty, rated ratchet straps until the cylinder is completely immobile. | Ensures the cylinder remains fixed in place even under the extreme forces of a collision or emergency stop. |

| Protect the Valve | Screw the valve protection cap on securely until it is hand-tight. | The valve is the weakest point. The cap is designed to absorb impact and prevent a catastrophic gas release. |

| Check Orientation | Position the cylinder so the pressure relief device is facing upwards (12 o'clock position). | If the valve activates, this orientation ensures gas vents instead of liquid, which is far more dangerous. |

| Ensure Ventilation | Keep windows slightly open or run the vehicle’s ventilation system, especially in enclosed vans. | Prevents the build-up of flammable or asphyxiating gases from even a minor, undetected leak. |

Let's break these points down a bit more.

Your absolute number one priority is to eliminate all movement. A gas cylinder isn’t just heavy cargo; it's unstable cargo that will shift if you give it an inch. An unsecured cylinder in a moving vehicle is a disaster waiting to happen.

Your securing strategy needs a few layers of defence:

Crucial Tip: Never, ever rely on simple ropes or bungee cords. They stretch and snap under the incredible forces generated by a sudden stop. They're completely useless for this job. Only use certified, high-tension securing equipment designed for heavy loads.

The valve is the most fragile part of a gas cylinder. A sharp knock can shear it right off, causing a violent, uncontrolled release of high-pressure gas. Protecting it isn't optional.

Always make sure the valve protection cap is screwed on tightly. This sturdy metal or composite cap is built specifically to take a hit and shield the valve from damage. For a deeper dive into why these caps are so vital, check out our guide on the importance of protective caps for gas cylinders. Give it a good hand-tighten before you set off.

Getting the orientation right is also key. When you can, position the cylinder so that the pressure relief valve is pointing straight up, at the 12 o'clock position. This is a small detail that makes a big difference, as it helps prevent liquid from venting if the valve ever activates.

Finally, make sure your vehicle has plenty of ventilation. This is non-negotiable if you're transporting cylinders inside an enclosed space like a van. Even a tiny leak can fill the space with a dangerous amount of gas. Crack the windows open or keep the fan running to maintain a steady airflow and stop any flammable or asphyxiating atmospheres from building up.

It’s a common but critical mistake to think all gas cylinders can be handled the same way. The truth is, the gas inside the cylinder dictates the rules, making a one-size-fits-all approach not just inefficient, but downright dangerous. The answer to the question "darf man gasflaschen liegend transportieren" (can you transport gas cylinders lying down) changes entirely depending on what’s in the bottle.

Every type of gas comes with its own set of hazards. Inert gases like nitrogen or argon, for instance, pose a serious asphyxiation risk if they leak into a confined space. Flammable gases like propane or hydrogen, on the other hand, carry the obvious threat of fire or explosion. And then you have oxidising agents like oxygen, which can turn a small, manageable fire into a raging inferno.

Liquefied gases such as propane (LPG) and carbon dioxide (CO₂) add a whole other layer of complexity, especially when laid on their side. These cylinders contain the gas in both a liquid and a vapour state. The crucial safety device, the pressure relief valve (PRV), is specifically designed to sit in the vapour space at the top when the cylinder is standing upright.

If you transport one of these cylinders horizontally, you run the risk of the liquid sloshing up against the PRV. Should the valve activate to release excess pressure, it will vent liquid instead of vapour. This is a far more hazardous situation. The liquid instantly expands into a huge cloud of gas, which can freeze the valve open and cause a massive, uncontrolled release.

A core principle of safe transport is ensuring safety systems work as designed. Horizontal transport of liquefied gas can directly compromise the function of the pressure relief valve, turning a safety feature into a point of failure.

This is exactly why, if horizontal transport is absolutely unavoidable for these gases, the cylinder must be positioned with the PRV at the 12 o’clock position. It's a non-negotiable step to keep the liquid phase away from this vital safety component.

While many gases have rules with exceptions, a few have an absolute ban on being transported lying down. The most famous example here is acetylene.

Acetylene isn't just compressed into a cylinder. It's dissolved in a solvent (usually acetone) held within a porous, sponge-like material that fills the entire container. This complex internal structure is what keeps the highly unstable acetylene gas safe.

If you lay an acetylene cylinder on its side, the solvent can pool away from the porous mass. This creates dangerous voids filled with pure, gaseous acetylene, which can decompose explosively from even a small shock or change in pressure.

The first and most important step in safe transport is knowing the specific gas you're dealing with. Before you load a single cylinder, always check the transport requirements for that particular gas.

Safely transporting gas cylinders isn't just about straps and valve caps; it's about successfully navigating Germany's wider world of road regulations. The journey from your facility to its destination is shaped by rules that have little to do with the gas itself but everything to do with your vehicle and the route you’ve chosen. This adds a completely different dimension to the question of whether cylinders can be transported lying down (darf man gasflaschen liegend transportieren), because full compliance goes way beyond the cargo bay.

Environmental protection is a huge factor in German logistics today. Many cities have established Low Emission Zones (LEZs), known locally as Umweltzonen, to combat air pollution. These zones restrict access for any vehicle that doesn't meet specific emissions standards, which can throw a major spanner in the works for your delivery routes and schedules. Planning a transport run now means you have to first check if your vehicle is even allowed to enter certain parts of a city.

This push for higher environmental standards has very real financial consequences for transport companies. On top of the LEZs, Germany has rolled out CO₂-based tolls for heavy goods vehicles on federal motorways. This means that older, less efficient vehicles not only face potential access restrictions but also cost more to operate for every single kilometre they travel. Choosing the right vehicle for the job has become a delicate balancing act between safety compliance, payload capacity, and emissions performance.

And these aren't just suggestions; German air quality regulations have serious legal teeth. The targets set by the LEZs are designed to slash particulate matter pollution, and the courts have repeatedly backed the right of cities to enforce these rules. A landmark 2018 decision by Germany's Federal Administrative Court even gave local authorities the green light to implement diesel bans, a measure Hamburg quickly put into practice. You can learn more about the impact of these air quality rulings on the logistics sector.

This holistic view is crucial for businesses like those served by Cryonos. A laboratory planning a shipment of cryogenic gases must consider not only ADR rules but also whether their logistics partner's fleet can legally and cost-effectively navigate the planned route.

Ultimately, modern gas transport is a game of total compliance. You have to master the fine details of securing each cylinder while also solving the much larger logistical puzzle of environmental zones, toll systems, and vehicle standards. A successful delivery hinges on getting both parts of the equation right, ensuring your cargo arrives safely, legally, and efficiently.

Even when you know the rules, real-world questions pop up the moment you’re ready to load a cylinder. To clear up any lingering doubts and reinforce what we've covered, here are some straightforward answers to the most common scenarios people face.

When you’re moving small quantities for personal use, you’re usually exempt from the full, heavy-duty ADR regulations. That said, safety is still your number one job. The short answer to "darf man gasflaschen liegend transportieren" (can you transport gas cylinders lying down) in this case is yes, but with some strict conditions.

The cylinder must be absolutely immobile. Wedge it, strap it, do whatever it takes to ensure it cannot roll or slide around. Just as important, the valve must be shut tight and the protective cap or collar needs to be securely in place. You also need good ventilation, so cracking a window open is always a good idea. Even though it's allowed, keeping the cylinder upright is always the safer bet to stop liquid propane from interfering with the pressure relief valve.

If you're moving cylinders for business, don't assume that staying under the 1,000-point ADR threshold means you can skip the paperwork. You can't. You are still required to have a transport document with you at all times.

This isn't just red tape; it's a critical safety document. It must clearly state:

On top of that, your vehicle must have at least one suitable fire extinguisher on board. The moment you go over that 1,000-point limit, you're in a different league. Full ADR compliance kicks in, meaning a certified driver, orange placards on your vehicle, and a whole lot more safety equipment and documentation.

The most dangerous mistake is not a complex technical error, but a simple failure of the basics. Neglecting to secure the cylinder properly is the single greatest risk, as it turns a heavy, stable object into an unpredictable and potentially lethal projectile in an emergency.

Without a shadow of a doubt, failing to properly secure the cylinder is the most critical and hazardous mistake you can make. An unsecured cylinder can roll violently or become a missile during a sudden stop, potentially leading to a catastrophic valve failure. It’s a terrifyingly simple error with devastating consequences.

Running a close second is forgetting the valve protection cap. Think of this cap as the cylinder's helmet. It’s the primary defence against the valve being sheared off in an impact, which would turn the cylinder into an uncontrollable rocket. Always use robust, rated securing gear like high-tension ratchet straps and chocks to lock the cylinder down. These two simple steps are completely non-negotiable for safe transport.

For all your cryogenic storage and transport needs, from ADR-compliant vessels to essential safety accessories, Cryonos GmbH provides state-of-the-art, reliable solutions. Explore our product range and ensure your operations are safe and efficient at https://www.cryonos.shop.