No Products in the Cart

When you're faced with a rack of gas cylinders, knowing what's what can feel a little daunting. Thankfully, a simple colour system known as Farbkennzeichnung von Gasflaschen provides an instant safety signal. This system uses specific colours on the cylinder's shoulder to give a rapid visual warning about the contents and any potential hazards—a critical feature in busy labs, industrial sites, or biobanks.

Imagine walking into a storage area and needing to spot a flammable gas from across the room. The colour-coding system for gas cylinders is designed for exactly that. It offers an immediate visual cue about the primary risk a gas poses, long before you’re close enough to read a label.

This isn’t just a helpful suggestion; it’s a standardised safety language. The European standard EN 1089-3 acts as the rulebook, harmonising these colours across many countries. This is crucial for preventing dangerous mix-ups when cylinders cross borders or are used by international teams, and its adoption has dramatically reduced handling errors.

The most important part of the Farbkennzeichnung von Gasflaschen is the cylinder's shoulder—that curved top section. This area is painted a specific colour to flag the main hazard of the gas inside. Think of it as a traffic light for gas safety.

While this system is a powerful safety tool, it’s vital to remember one golden rule.

The label on the cylinder is always the final and definitive authority on its contents. Colours can fade, get obscured by dirt, or even be misinterpreted. The detailed information on the gas label provides the precise chemical identity and safety data you need for secure handling.

Understanding the logic behind these colours is the first step toward building a safer work environment. This guide will decode the system, giving you the confidence to handle, store, and transport cylinders correctly. For a deeper look into the properties of different substances you might encounter, you can learn more about what defines a gas in a cylinder in our related article.

Before we had a unified system, identifying the contents of a gas cylinder was a bit like navigating with a different map in every country. Imagine a cylinder of highly flammable hydrogen, correctly painted red, crossing a border only to end up somewhere that red meant a harmless inert gas. This kind of confusion wasn't just inconvenient; it was incredibly dangerous for anyone handling or transporting gases across Europe.

This chaotic and risky environment was precisely what spurred the creation of the European standard EN 1089-3. The mission was straightforward but absolutely vital: establish a single, harmonised colour code for gas cylinders to drastically improve safety. By standardising the visual cues, the system makes hazard identification faster, more intuitive, and consistent, no matter where the cylinder originally came from.

A common source of confusion when it comes to Farbkennzeichnung von Gasflaschen (the German term for gas cylinder colour-coding) is understanding the difference between the main body of the cylinder and its curved top, known as the shoulder. It's a critical distinction because the EN 1089-3 standard only applies to the colour of the shoulder.

The shoulder's colour is exclusively used to signal the gas's primary hazard—is it flammable, toxic, or an oxidiser? This laser-focused approach ensures that the most critical safety information is always in the same place and presented in a predictable way.

The cylinder's body, on the other hand, is a different story. It’s not regulated by the standard. Gas suppliers are free to paint the body any colour they like, often for branding or to denote specific gas purities. This is why you might see two nitrogen cylinders with the correct green shoulders but completely different bodies—one could be grey and the other black.

This practical distinction drives home a golden rule: the shoulder gives you a quick hazard check, but the label is always the final word on what's actually inside.

Switching an entire continent over to a new system couldn't happen overnight. It required a clear, structured timeline to give industries time to adapt. In Germany, the standardisation of Farbkennzeichnung von Gasflaschen was officially kicked off by a key decree from the Ministry of Transport on 7 January 1999. This set out a phased rollout, mandating that all new cylinders use the EN 1089-3 shoulder colours from 10 August 1999, with a final deadline for full compliance on 30 June 2006.

The results were dramatic. Before the standard, some industrial sites reported handling error rates as high as 15%. After full adoption, that number plummeted to under 2%. You can dig deeper into this safety transformation by looking at industry compliance reports.

To make it easy to spot a compliant cylinder during the transition period, a simple but brilliant marker was introduced.

Seeing that 'N' gives you immediate confidence that the cylinder's colour code is part of the modern, harmonised European safety system. It's a clear sign that you can trust the shoulder colour to tell you the primary hazard at a glance.

Getting to grips with the farbkennzeichnung von gasflaschen, or the colour coding of gas cylinders, is what separates a decent safety protocol from a truly bulletproof one. You don't need to memorise a massive list to understand the shoulder colours defined by EN 1089-3. Instead, think of it as learning a visual language of risk. It’s like a simple colour-coded filing system for hazards—a quick glance tells you the fundamental risk category, making your workplace inherently safer and more efficient.

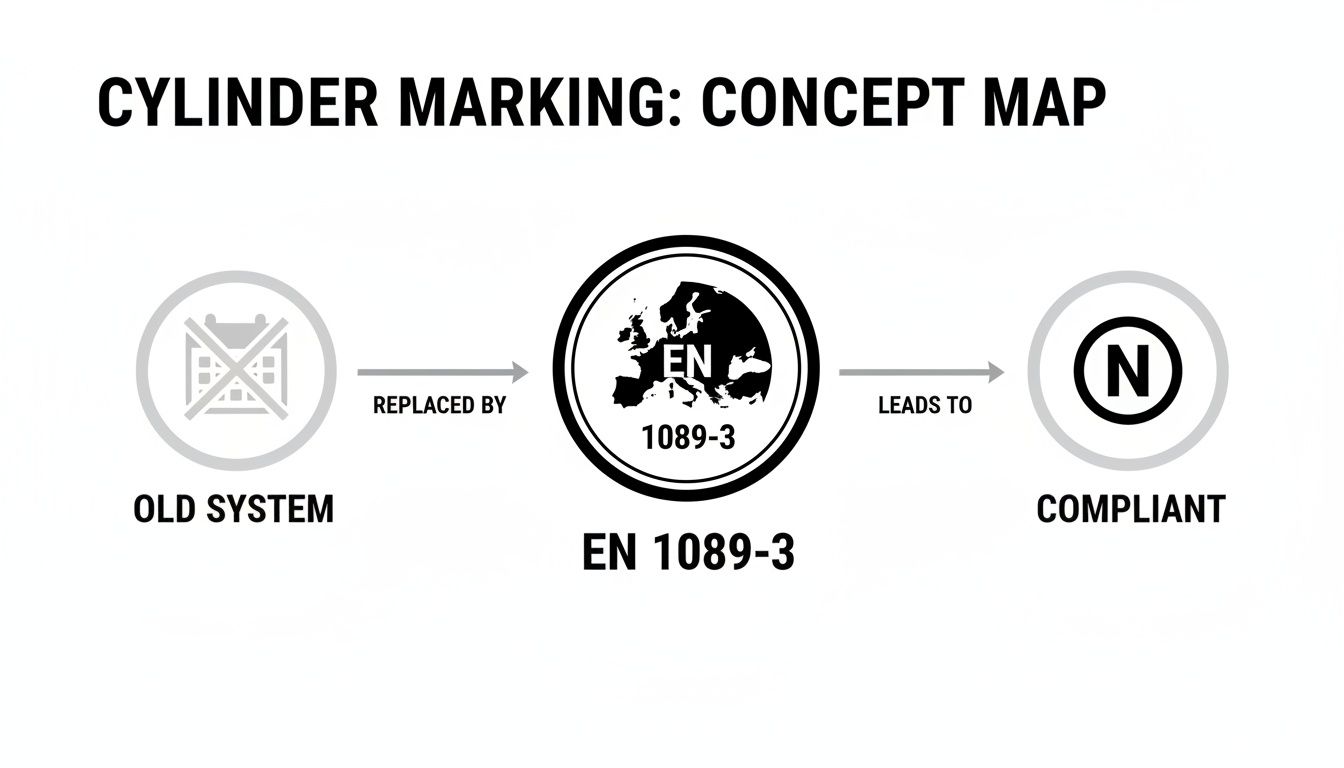

The map below shows the journey from older, often inconsistent marking systems to the harmonised EN 1089-3 standard we use today.

This shift towards a unified system, marked by the 'N' stamp on compliant cylinders, represents a huge step forward for safety across Europe.

This whole system is built around four main hazard groups, and each one gets its own distinct, easy-to-remember colour. By linking each colour to a specific danger, you can instantly see what precautions are needed. Let's break down this powerful safety shorthand.

When you spot a yellow shoulder (RAL 1018), your brain should immediately think "health hazard." This colour tells you the gas inside is either toxic—meaning it's harmful if inhaled, swallowed, or absorbed through the skin—or corrosive, which means it can destroy living tissue and other materials on contact.

These cylinders demand the highest level of care. You should always be working in a well-ventilated space, ideally under a fume hood, and decked out in the right Personal Protective Equipment (PPE). That means gloves and eye protection, minimum.

A red shoulder (RAL 3000) is the universal signal for fire risk. Simple as that. This colour warns that the gas is flammable and can easily ignite if it mixes with an oxidiser (like the air around us) and finds an ignition source, like a spark or an open flame.

The name of the game here is strict environmental control. These cylinders have to be stored well away from any potential ignition sources and, crucially, kept separate from oxidising gases to prevent a truly dangerous situation.

The light blue shoulder (RAL 5012) flags an oxidising gas. Now, these gases aren't flammable on their own, but they act like fuel for a fire. They can dramatically intensify and speed up the combustion of other materials, sometimes to the point of explosion.

This is exactly why separating your gases is so critical. Storing an oxidiser next to a flammable gas is like leaving a box of matches next to a can of petrol—it creates an incredibly high-risk scenario that is completely avoidable with good storage discipline.

Finally, a bright green shoulder (RAL 6018) points to an inert gas. These gases are the quiet ones—they're non-flammable, non-toxic, and non-oxidising under normal circumstances. Their main danger is asphyxiation.

Because they are colourless and odourless, they can silently displace the oxygen in a confined space, leading to suffocation without any warning. This is a massive deal in cryogenic labs where huge volumes of inert gases like liquid nitrogen are used daily. Proper ventilation isn't just a good idea; it's non-negotiable.

For a quick reference, the table below summarises these primary hazard colours.

| Shoulder Colour | Hazard Class | Example Gases | Primary Risk |

|---|---|---|---|

| Yellow | Toxic and/or Corrosive | Ammonia, Chlorine | Health Hazard |

| Red | Flammable | Hydrogen, Acetylene, Propane | Fire/Explosion |

| Light Blue | Oxidising | Oxygen, Nitrous Oxide | Intensifies Fires |

| Bright Green | Inert (Asphyxiant) | Nitrogen, Argon, Helium | Suffocation (in confined spaces) |

Committing these four core colours to memory gives you the power to make a rapid safety check in any environment where gases are used or stored. It’s a fundamental skill for keeping your workplace secure.

The shoulder colour is a brilliant first-glance safety check. It gives you a rapid signal of the primary hazard you’re dealing with. But relying solely on this colour is like judging a book by its cover—a potentially dangerous shortcut.

True, comprehensive safety in gas handling comes from looking at the entire cylinder. You have to understand that the label is always the ultimate source of truth.

Colours can fade over time, get caked with dirt in a busy industrial setting, or even be hidden by a layer of frost in cryogenic applications. In these situations, the farbkennzeichnung von gasflaschen might be misleading or totally unreadable.

The adhesive label, on the other hand, provides the precise, legally required information you need to handle the contents safely. Think of it as the definitive passport for the gas inside.

The most fundamental rule of gas cylinder safety is this: If the label is missing, damaged, or unreadable, do not use the cylinder. Treat its contents as unknown and contact your supplier immediately. Never, ever guess the contents based on colour alone.

This principle is non-negotiable. It’s the very bedrock of safe gas management protocols in any facility, from a university lab to a large-scale biobank.

One of the most common points of confusion crops up when you see two cylinders with the same gas but different body colours. This happens because the EN 1089-3 standard intentionally leaves the cylinder body unregulated. While the shoulder colour signals the hazard, the body is essentially a blank canvas for the gas supplier.

This freedom allows companies to use the body colour for their own internal systems.

This practice just reinforces our core message. The shoulder gives you the hazard class, but only the label can confirm the exact gas, its purity, and any special properties.

Beyond the colours and the main label, the cylinder itself is stamped with permanent markings that tell a crucial story about its history and specifications. These are usually found on the shoulder or neck ring and provide vital safety and compliance information.

Knowing where to look and what these markings mean adds another powerful layer to your safety checks. You’ll typically find several key pieces of information stamped directly into the metal.

Understanding these details empowers you to perform a complete safety check. You’re no longer just looking at a colour; you’re confirming the identity, verifying the cylinder’s integrity, and ensuring it’s fit for service. For more practical advice, explore our guide on selecting the proper protective cap for gas cylinders to safeguard these critical markings and valves.

Knowing the farbkennzeichnung von gasflaschen is a fantastic start, but that knowledge only becomes powerful when you put it into practice. A structured safety program is what turns that information into a real protective shield for your facility, your equipment, and most importantly, your people. It's about building a system where safety becomes second nature, not just a list of rules to remember.

This isn't about wrapping your operations in red tape. It’s about creating clear, repeatable steps that cut down on risk at every point in a gas cylinder's journey through your facility. From the moment it arrives on a truck to the day it goes back, every interaction needs to be guided by solid safety protocols.

The bedrock of any gas safety program is a purpose-built, secure storage area. This can't be just an afterthought or a spare corner in the warehouse; it needs to be a controlled environment designed specifically to prevent accidents. The two biggest priorities? Stability and ventilation.

A good storage area must also account for the specific dangers of the gases inside. That means physically separating incompatible gas types—this is a non-negotiable rule. Keeping flammable gases far away from oxidisers is probably the most critical example of this principle in action.

Here are the key elements of a safe storage area:

An organised storage area does more than just look professional—it actively prevents catastrophic chemical reactions. A physical distance of at least 6 metres (approximately 20 feet) is often recommended between flammable and oxidising gas cylinders, or they should be separated by a fire-resistant wall.

For facilities that handle a lot of oxygen, there are even more specific guidelines to follow. We cover these best practices in detail in our article on the safe storage of oxygen cylinders.

Once your storage is sorted, the focus shifts to how your team interacts with the cylinders day-to-day. Every time someone moves or connects a cylinder, there's a potential risk. Managing that risk comes down to having clear protocols and performing regular checks.

Your safety program needs a systematic visual inspection routine for every single cylinder. This isn't a long process—it should happen quickly upon delivery and again right before use. Train your staff to spot the red flags that signal a cylinder might be unsafe.

A simple but effective inspection checklist should include:

Keeping cylinders upright and secure is just as vital. A cylinder that falls over can easily snap its valve off, turning it into an unguided missile. All cylinders, whether they're in storage or hooked up for use, must be secured upright with chains, straps, or in specially designed racks.

Moving cylinders around your facility brings its own set of challenges. Never, ever roll or drag a cylinder by hand. It's an easy way to cause an injury or damage the cylinder or valve. The only correct way is to use a purpose-built trolley or cart that holds the cylinder securely while it's on the move.

For high-stakes materials, particularly in biobanks and labs working with cryogenics, you need more than just a standard trolley. ADR-compliant transport units, like the specialised equipment offered by Cryonos, are engineered for the secure movement of cryogenic liquids and gases. These units ensure that both your temperature-sensitive samples and high-pressure gases are transported safely, protecting sample integrity and your team throughout the facility. Investing in compliant equipment like this is a true hallmark of a world-class safety program.

Even with a system as clear as the Farbkennzeichnung von Gasflaschen, you’re bound to run into questions during the day-to-day grind. Let's tackle some of the most common ones that pop up in the workplace, giving you quick, practical answers to reinforce safety and help you navigate those tricky moments.

If you come across a cylinder where the label is gone, damaged, or impossible to read, stop. Do not use it, period. It's tempting to guess the contents based on the shoulder colour, but that's a risk you can't afford to take.

Your immediate next step is to mark that cylinder clearly as "Contents Unknown" and move it to a secure, designated quarantine area, well away from your active supply. Then, get on the phone with your gas supplier right away. They'll have a specific protocol for handling and retrieving unidentified cylinders. Using a gas without 100% positive identification can lead to catastrophic accidents, wrecked equipment, or contaminated processes.

Yes, EN 1089-3 sets the foundation, but medical gases operate under their own, much stricter set of rules, like ISO 32.

The most obvious difference you'll see is the cylinder body. Across Europe, medical gas cylinders are typically painted a brilliant white (RAL 9010). This isn't just for show; it's a critical visual cue to separate them from industrial gases. The shoulder colour code still applies—for example, a white shoulder for medical oxygen or a blue one for nitrous oxide—but the white body is the first signal. Always follow the specific medical gas regulations in your region without exception.

Think of the white body as an extra layer of visual safety. It immediately screams "medical use," meaning the cylinder must be handled with the extreme care and precision demanded by healthcare protocols. This simple distinction is vital for preventing mix-ups between industrial and medical-grade gases.

This is a classic question and it gets right to the heart of what EN 1089-3 actually dictates. The standard only mandates the colour of the cylinder's shoulder, which tells you the primary hazard of the gas inside. The colour of the main cylinder body is completely unregulated.

Gas suppliers are free to paint the body of the cylinder however they like. Often, they'll use their corporate colours for branding or use different body colours to signify different purity levels of the same gas. So, it's perfectly normal to see two nitrogen cylinders from different companies side-by-side, both with the correct bright green shoulder (for inert gas), but one might have a grey body and the other a black one. This is exactly why the golden rule is to always trust the label for final identification, using the shoulder colour only as a first-glance hazard check.

At Cryonos GmbH, we know that real safety isn't just about colours and labels—it’s about having robust, compliant equipment you can count on every single day. Our ADR-licensed transport units and cutting-edge storage solutions are built to ensure the secure handling of your most critical materials. See our complete range of cryogenic equipment at https://www.cryonos.shop.