No Products in the Cart

Every strong, clean weld depends on an invisible but absolutely essential partner: the right gas zum schweißen, or welding gas. This gas wraps the molten weld pool in a protective bubble, shielding it from nasty atmospheric contaminants that would otherwise ruin the joint. Getting your head around its role is the very first step toward producing professional-quality work.

Think of welding gas like a surgeon working in a sterile theatre. Just as a surgeon keeps an incision clean to prevent infection, the right gas prevents the weld from getting contaminated. The moment you strike an arc, the metal becomes molten and incredibly reactive with the air around it—especially with oxygen and nitrogen.

Without that protective shield, these atmospheric gases rush straight into the molten pool and cause disastrous defects. You end up with things like porosity (tiny gas bubbles trapped inside the weld) and brittleness, both of which completely compromise the joint's structural integrity. The result is a weak, ugly weld that's guaranteed to fail under pressure.

Depending on the process you're using, welding gas plays one of two fundamentally different—but equally important—roles. This distinction is the key to picking the right gas for your job.

Demand for both types of processes remains strong across Germany's industrial sector. While arc welding has been the mainstay for years, market analysis suggests that oxy-fuel welding—a process entirely dependent on gases like acetylene and oxygen—is projected to be the fastest-growing segment from 2025 to 2030. You can dig into more data on the German welding products market over at Grand View Research.

It helps to think of shielding gas as a bodyguard for the molten metal. It stands guard, pushing away any harmful outside influences until the weld has solidified and can defend itself.

To make this easier to remember, here's a quick breakdown of the primary functions for different gas categories.

| Gas Category | Primary Function | Common Welding Processes | Example Gas |

|---|---|---|---|

| Inert Gases | Act purely as a shield; do not react with the weld | TIG, MIG (non-ferrous) | Argon, Helium |

| Active Gases | React with the weld pool to improve arc stability and bead | MIG (steels) | Carbon Dioxide |

| Gas Mixes | Combine properties for optimised performance | MIG (various metals) | Argon/CO2 mix |

| Fuel Gases | Combust with oxygen to create a high-temperature flame | Oxy-fuel welding/cutting | Acetylene |

This table provides a quick reference, but remember that the ideal choice always depends on the specific material and application.

Ultimately, choosing a gas zum schweißen isn't just a minor technical detail; it’s fundamental to your project's success. The right gas or mix influences everything—arc stability, penetration depth, weld bead appearance, and the final mechanical properties of the joint.

Getting it wrong leads to wasted materials, time-consuming rework, and, in the worst-case scenario, dangerous structural failures. By understanding these core principles, you're in a much better position to make informed decisions that lead to consistent, high-quality welds every single time.

When you're picking a shielding gas, your choices boil down to two families: inert and active. Getting the difference between them is a bit like understanding the difference between a referee and a player in a football match. One stays on the sidelines, protecting the integrity of the game, while the other gets right in there to influence the outcome. This is a crucial distinction, as it completely dictates which gas you can use for which metal and welding process.

Inert gases are the quiet bodyguards of the welding world. They do their job without getting chemically involved in what's happening in the weld. Their entire purpose is to create a pure, stable bubble around the molten metal, shielding it from the oxygen, nitrogen, and moisture in the air that would otherwise poison the weld and ruin the joint. Think of it as creating a perfectly clean room for the metal to fuse properly.

The two inert gases you'll see most often are Argon and Helium. As noble gases, they're chemically stable and don't react with other elements. This quality is non-negotiable when you're welding non-ferrous metals like aluminium, magnesium, and copper, or reactive metals such as titanium.

Because these gases don’t react, they are absolutely essential for processes where purity is everything. In TIG welding, for example, even a tiny amount of active gas would instantly contaminate and destroy the non-consumable tungsten electrode, bringing your work to a screeching halt.

Active gases, on the other hand, are brought in specifically to participate. They're chosen for their ability to react with the weld pool in controlled, helpful ways. While they still shield the weld, their real value is in how their chemical reactions improve the arc and the final bead shape. This makes them indispensable for welding ferrous metals like carbon and stainless steels.

The most common active gas is **Carbon Dioxide (CO₂) **. You can use 100% CO₂ for short-arc MIG welding on steel, and it's a great, low-cost option that offers deep penetration. The trade-off is often a more violent, spattery arc compared to what you get from a mixed gas. Oxygen (O₂) is another active gas sometimes added in small amounts to mixes to make the weld pool more fluid and "wet out" better.

The real magic happens when you blend inert and active gases. A simple mix of Argon and Carbon Dioxide can turn a sputtering, messy arc into a smooth, stable, and controllable one, dramatically improving weld quality on steel.

These blends have become the industry standard for most MIG welding on steel. By adding a small percentage of an active gas like CO₂ to a mostly inert gas like Argon, welders gain precise control over the arc. For instance, a common 75% Argon / 25% CO₂ mix strikes a fantastic balance of arc stability, deep penetration, and minimal spatter, making it incredibly versatile for mild steel. The active CO₂ helps stabilise the arc, while the inert Argon base provides excellent shielding and a smooth transfer of metal from the wire to the joint. This synergy is exactly why choosing the right gas mix is every bit as important as setting your voltage and wire speed.

Knowing the difference between inert and active gases is a great start, but now it's time to put that theory to work in the shop. Picking the right gas zum schweißen is a hands-on decision that directly controls your arc stability, weld penetration, and the final look and strength of the bead.

Every welding process and metal has an ideal gas partner. Making the right match is what turns a frustrating, messy job into a smooth, clean, and controlled operation.

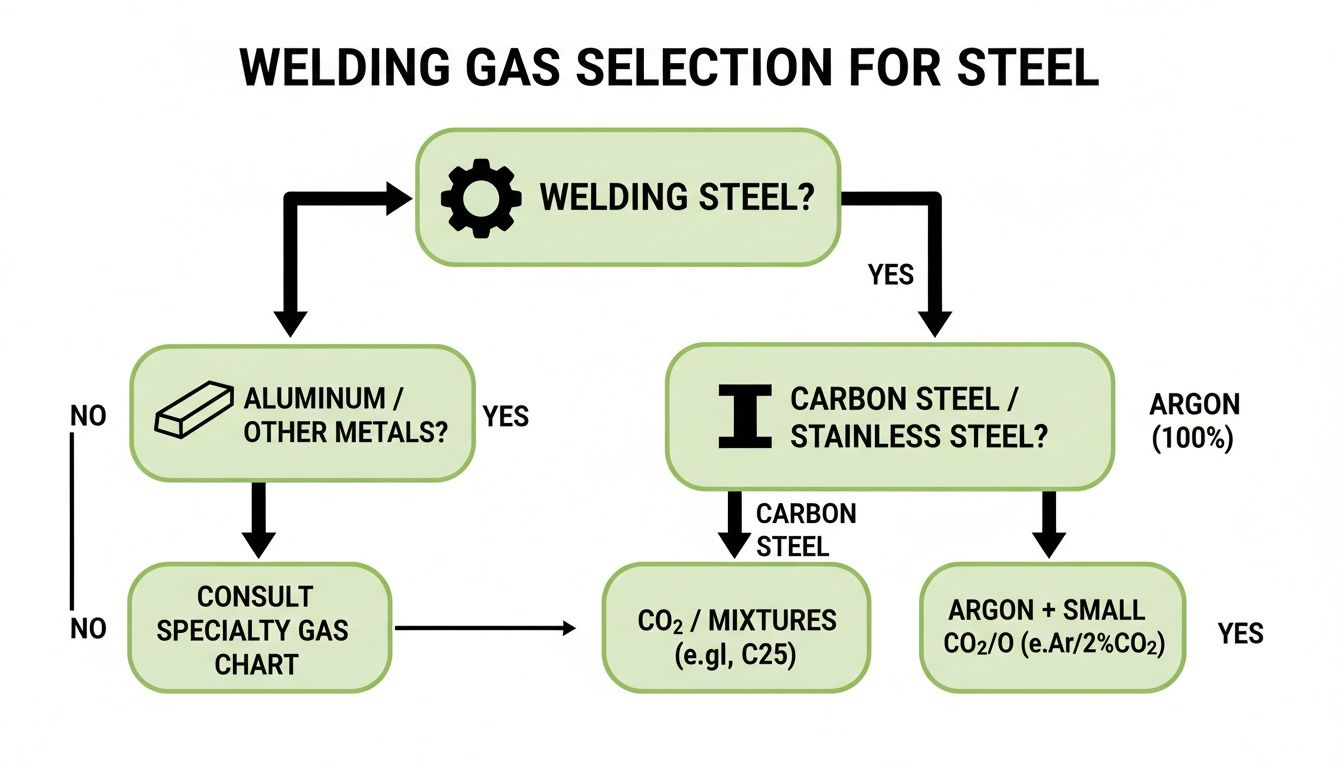

This decision-making process helps clarify which gas is best suited for your specific metal.

This flowchart offers a clear path for choosing your welding gas, whether you’re working with common steels or other metals like aluminium.

For Metal Inert Gas (MIG) welding, your choice of gas is dictated almost entirely by the metal you're joining. The process is famously versatile, but that flexibility comes from picking the perfect gas blend for the job at hand.

Tungsten Inert Gas (TIG) welding is all about precision and creating beautiful, clean welds. This is only possible because it relies on completely pure inert gases. The non-consumable tungsten electrode is incredibly sensitive; any active gas would cause it to oxidise and burn up in an instant.

When it comes to TIG welding, think purity above all else. Pure Argon is the workhorse for over 95% of all TIG applications, covering everything from steel and stainless steel to thin-gauge aluminium. Its superb shielding properties and arc stability make it the most reliable choice out there.

The main exception, much like with MIG welding, is when you’re tackling thick aluminium or copper. In these cases, adding Helium to the Argon creates a much hotter arc. This extra punch is needed to overcome the high thermal conductivity of these metals and ensure you get deep, consistent penetration. For a deeper dive on this, check out our comprehensive guide on TIG welding gas.

To make things even clearer, here’s a quick-reference table to guide your gas selection for the most common welding jobs.

| Welding Process | Material | Recommended Gas | Key Benefits |

|---|---|---|---|

| MIG | Mild Steel | 75% Argon / 25% CO₂ | Excellent balance of arc stability, minimal spatter, and good penetration. |

| MIG | Stainless Steel | Argon + 1-2% CO₂ or O₂ | Maintains corrosion resistance, stable arc, and improves bead appearance. |

| MIG | Aluminium | 100% Argon | Provides necessary cleaning action and a stable arc for a clean weld. |

| TIG | All Steels, Aluminium | 100% Argon (High Purity) | The standard for clean, precise welds; protects the tungsten electrode. |

| TIG | Thick Aluminium (>6mm) | Argon / Helium Mix | Increases arc heat for better penetration on highly conductive materials. |

This table serves as a solid starting point, but always remember to fine-tune your flow rates and settings based on your specific machine and the thickness of the material you’re working on.

Oxy-fuel processes are in a league of their own. Here, the gas isn't just for shielding—it's the fuel for the fire. This method works by combining pure Oxygen with a fuel gas to create an incredibly hot flame, capable of melting or slicing right through metal.

The most common fuel gas is Acetylene. When mixed with Oxygen, it produces one of the hottest commercially available flames, making it perfect for welding, brazing, and cutting steel. While other fuel gases like propane can be used, they burn at lower temperatures and are typically reserved for heating or cutting, not for structural welding.

Working with any gas zum schweißen means you’re handling high-pressure cylinders that demand your full respect. Think of them not as simple containers, but as vessels holding immense potential energy. A dropped or poorly handled cylinder can quickly become an uncontrolled projectile, capable of causing serious injuries and significant property damage. That's why a culture of safety isn't just a nice-to-have—it's the bedrock of any professional workshop.

The single most critical rule is to always keep cylinders upright and securely fastened. A falling cylinder is one of the most common—and preventable—causes of workshop accidents. Whether it's in use or in storage, every cylinder should be anchored with a sturdy chain or strap to a wall, welding cart, or a purpose-built rack. Never, ever leave one free-standing.

Safe handling is a routine that needs to become second nature. It’s all about moving these cylinders with care and purpose, recognising the potential hazards with every step you take.

Think of a cylinder valve like the ignition on a car; you wouldn't leave it exposed to accidental bumps. The cap is its essential shield.

Where you store your gas cylinders is just as important as how you move them. A designated storage area should be organised to prevent accidents and meet all safety standards. This means it needs to be a well-ventilated space, well away from high-traffic areas, exits, and any sources of ignition like sparks, flames, or extreme heat.

Segregating different types of gases is also crucial. Flammable gases like acetylene must be stored separately from oxidisers like oxygen. A fire-resistant partition wall is often required to keep a safe distance between them, which is typically a minimum of 6 metres (about 20 feet) unless a proper barrier is in place.

Always remember the "First In, First Out" (FIFO) principle for your cylinder stock. This simple practice ensures you use older cylinders first, preventing any from sitting in storage for too long.

On top of that, it's vital to keep full and empty cylinders separate to avoid any mix-ups. Clearly marking storage areas for "Full" and "Empty" helps streamline your workflow and stops someone from accidentally hooking up an empty tank in the middle of a critical weld.

Ensuring safety isn't just about good workshop habits; it's a legal requirement. In Germany and across Europe, strict regulations govern the handling and transport of dangerous goods, which includes welding gas cylinders. The European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) is one of the key frameworks. If you're involved in moving a gas zum schweißen, understanding these rules is non-negotiable. For a deeper dive, check out our guide on transporting gas cylinders according to regulations.

Every cylinder comes with a label and a corresponding Safety Data Sheet (SDS). This document provides vital information on the specific hazards of the gas, first-aid measures, and handling precautions. Taking the time to read and understand this information is a non-negotiable part of workshop safety.

Picking a supplier for your gas zum schweißen is one of those strategic moves that defines your workshop’s efficiency, costs, and the quality of your work. It’s less about chasing the cheapest price per cylinder and more about forging a solid partnership. Whether you’re running a huge industrial operation or a small specialist lab, the right supplier delivers more than just gas—they deliver peace of mind and support.

First and foremost, think about the consistency of their supply chain. Running out of gas halfway through a critical job means instant downtime, blown deadlines, and unhappy clients. A truly dependable supplier has their logistics dialed in, ensuring you get what you need, right when you need it. This simple reliability prevents the kind of costly hiccups that can derail an entire project.

When you start looking around, you have to look past the price tag and see what else they bring to the table. A great partner adds real value with their expertise and flexibility, tailoring what they offer to fit your specific scale and technical demands.

Here are a few key things to dig into:

For high-volume operations, making the switch from individual cylinders to a bulk storage system can be a game-changer for efficiency. Cryogenic tanks, for instance, store gas as a liquid, giving you a continuous supply that eliminates the constant labour and safety risks of swapping heavy cylinders. This approach slashes handling time and can lead to major cost savings in the long run.

The needs of a weekend hobbyist and a massive fabrication plant couldn't be more different, and a good supplier understands that instinctively. The scale of your operation dictates the smartest, most cost-effective way to manage your gas supply.

For smaller workshops, labs, or hobbyists, the game is all about precision and getting good value. The goal is to find a supplier with a wide range of cylinder sizes and purity grades. This lets you buy only what you need, cutting down on waste and making sure you have the exact gas spec for high-precision work, like TIG welding specialty alloys. You can learn more about what to look for in local gas options by checking out our guide on finding Linde gas in your area.

A strategic gas supplier acts as an extension of your team. Their reliability directly impacts your productivity, and their technical expertise can help you solve complex welding challenges, improve quality, and even reduce long-term operational costs.

To make a truly informed decision, it pays to have a clear set of questions ready. You should treat this process like you’re interviewing a critical business partner—because you are.

Questions to Ask a Potential Gas Supplier:

By asking these questions, you’re setting yourself up to choose a supplier who doesn't just sell quality gas zum schweißen, but who also backs your business with the reliability and consistency you need to produce outstanding work.

The world of welding gases is anything but static. As engineering demands get tougher and materials become more advanced, the gas zum schweißen we rely on has to evolve right alongside them. These developments are all about squeezing out more performance, bolstering safety, and making the entire supply chain—from the production plant right to the welder's torch—run smoother.

The constant push for stronger, lighter materials in sectors like automotive and aerospace has given us a whole new class of high-strength alloys. The thing is, these cutting-edge metals often demand equally advanced gas blends to get the job done right. Researchers are always tinkering with multi-component gas mixtures that go far beyond your standard Argon/CO₂ combo.

These aren't just random concoctions; they're precisely engineered blends designed to fine-tune the arc, cut down on nasty fume generation, and actually improve the metallurgical properties of the finished weld. For instance, adding just a tiny amount of a specific gas can dramatically clean up the bead appearance and slash post-weld clean-up time on exotic alloys.

One of the biggest game-changers in how we manage welding gas supply has been cryogenic technology. This whole process is reshaping how large-scale industrial operations get and store the gases they absolutely depend on. The core idea is to cool gases like Argon, Oxygen, and Nitrogen to incredibly low temperatures, which turns them into liquids.

Moving and storing gases in their liquid state is a massive leap forward for a few key reasons:

For any workshop or factory with a high gas consumption, the answer is often an on-site cryogenic tank, sometimes called a micro-bulk or bulk tank. It's basically a giant, super-insulated thermos that holds the liquefied gas. As you need it, the liquid is converted back into a gas and piped directly to your welding stations.

Think of a cryogenic tank as having your own private gas reservoir right outside your workshop. It provides a continuous, reliable supply, ending the logistical nightmare of managing cylinder inventory, tracking rentals, and worrying about running out mid-production.

This setup guarantees a constant supply pressure and purity, which is critical for consistent weld quality from the first arc of the day to the very last. Companies like Cryonos specialise in these state-of-the-art cryogenic transport and storage solutions, providing the infrastructure that allows industrial users to fully benefit from a safer, more cost-effective, and uninterrupted supply of their essential gas zum schweißen. It's a significant step forward in operational productivity.

Even when you've got the basics down, real-world questions always pop up on the shop floor. Let's tackle some of the most common queries about using gas zum schweißen and give you clear, straightforward answers to help you work safer and smarter.

In most cases, no—and it's a crucial difference to understand. TIG welding is all about precision and absolutely requires a 100% inert gas, like pure Argon. The whole point is to shield the non-consumable tungsten electrode from the air; any active gas would instantly burn it up and ruin your weld.

MIG welding steel, on the other hand, actually needs an active gas component like CO₂ to get a stable arc and good penetration. While you can use pure Argon for MIG welding non-ferrous metals like aluminium, the gases needed for welding steel are fundamentally different for each process.

Your best friend here is the high-pressure gauge on your regulator. I'm talking about the one that reads the pressure inside the cylinder, not the one showing your flow rate. As you work, you'll see the pressure on that gauge steadily drop.

It's time for a fresh cylinder once that needle dips into the red zone, which usually starts around 35 bar (about 500 psi). Trying to weld below this pressure is asking for trouble; your gas flow will become unreliable, leading straight to porosity and weak, ugly welds.

Trying to run a MIG or TIG bead without any shielding gas is a recipe for instant disaster. The second you strike an arc, the molten weld pool gets hit with all the oxygen and nitrogen in the atmosphere, causing immediate and catastrophic contamination.

Without its protective gas shield, the weld pool becomes a porous, brittle, and blackened mess. This defect, sometimes called "sugaring," creates a weld with absolutely zero structural integrity. It will crack under the slightest bit of stress.

You can store cylinders in a home garage, but you have to be extremely disciplined about safety. First, the area must be incredibly well-ventilated. Any potential gas leak needs a clear escape route to prevent a build-up that could lead to an asphyxiation or fire risk.

Crucially, every cylinder must be stored upright and securely chained to a wall or another solid structure to ensure it can't be knocked over. You also need to keep them well away from any source of heat, sparks, or flammable materials. When in doubt, always check your local regulations before storing high-pressure gas cylinders in any residential space.

For industrial operations that can't afford the downtime or safety risks of managing individual cylinders, Cryonos GmbH provides cutting-edge cryogenic storage and transport solutions. We take the logistical headache out of maintaining a consistent, safe supply of welding gases. See how our systems can help at https://www.cryonos.shop.