No Products in the Cart

Proper Lagerung von Druckgasflaschen isn’t just about ticking boxes on a compliance checklist; it's a fundamental safety protocol. It helps to think of each cylinder not just as a container, but as a concentrated source of energy. Handling that energy—whether it's immense pressure or volatile chemical properties—requires a precise, no-nonsense approach to prevent accidents.

A compressed gas cylinder is far more than a simple metal tank. Mishandle it, and that stored energy can be released in a catastrophic way, turning a standard piece of equipment into a dangerous projectile or the source of a serious chemical incident. The whole point of safe storage is to keep that potential energy under control, protecting your people, your facility, and your operations.

This is particularly critical in Germany, where cylinder-based gas supply is the backbone of so many industries. In fact, cylinders account for 45 percent of Germany's industrial gases market share. This reflects their indispensable role for countless small and medium-sized businesses where on-site production just isn't practical. With such widespread use, it's clear that everyone needs to be on the same page when it comes to safety standards.

The dangers tied to gas cylinders go well beyond just high pressure. A truly safe approach to the Lagerung von Druckgasflaschen needs to account for several different kinds of hazards:

The goal of proper storage is to create a controlled environment that neutralises these risks. It's a system designed to prevent the 'what-ifs'—what if a cylinder falls, what if a valve leaks, what if a fire breaks out nearby?

To manage these risks, German and European authorities have established very clear regulations. The cornerstone in Germany is the TRGS 510 (Technische Regeln für Gefahrstoffe 510), which lays out a detailed framework for storing hazardous materials in portable containers. You can learn more about the specific types of gas found in these cylinders in our detailed guide.

This regulation isn't just a list of arbitrary rules; it's a proven safety blueprint built on decades of real-world experience. It dictates crucial practices like keeping incompatible gases separate, ensuring proper ventilation, and having fire protection measures in place. Following TRGS 510 is the foundation of a solid safety management system, turning legal requirements into practical, life-saving actions on your manufacturing floor, in your laboratory, or at your hospital.

At first glance, the rules for the lagerung von druckgasflaschen (storage of compressed gas cylinders) can look like a complex web of legal jargon. But if you peel back the layers, you’ll find the entire framework is built on a simple, powerful idea: preventing accidents by creating clear, predictable, and safe ways of working.

In Germany, the go-to document for anyone handling pressurised containers is the TRGS 510 (Technische Regeln für Gefahrstoffe 510), or "Technical Rules for Hazardous Substances." This isn't just a friendly set of recommendations; it's the legally binding playbook. It spells out exactly how hazardous materials in movable containers—including every single gas cylinder in your facility—must be stored. Getting to know its core principles isn't just about compliance; it's about keeping your workplace and your people safe.

Think of TRGS 510 as the architect's blueprint for your gas cylinder storage area. It doesn't waste time on vague advice. Instead, it gives you concrete, actionable requirements for everything, from the fire resistance of your storage room walls to the minimum distance you need between different types of gases. Its entire purpose is to tackle the major risks head-on: fire, explosion, dangerous chemical reactions, and asphyxiation.

A central concept in TRGS 510 is risk-based storage. This is a common-sense approach that means the rules scale with the danger. If you're only storing a few small cylinders of an inert gas like argon, the requirements are straightforward. But if you're dealing with large quantities of highly flammable or toxic gases, you'll need to implement much stricter safety measures.

"Compliance with TRGS 510 is not about navigating bureaucracy; it is the practical application of decades of safety knowledge. Every rule, from ventilation rates to segregation distances, is a direct response to a known risk."

This proportional approach makes the system incredibly effective. It ensures the safety measures are always a perfect fit for the potential hazard, making it both robust and practical for operations of any size.

While the full TRGS 510 document is comprehensive, the most critical rules for the lagerung von druckgasflaschen boil down to a few fundamental ideas. If you master these, you're well on your way to a compliant and safe storage plan. These are the absolute non-negotiables.

Segregation of Incompatible Gases: This is probably the single most important rule. You simply cannot store gases that could react dangerously with each other in the same place without very specific safety barriers. The classic example is keeping flammable gases (like hydrogen) far away from oxidising gases (like oxygen). Storing them together is like leaving a can of petrol next to a substance designed to make fires burn hotter and faster. A tiny leak could escalate into a major disaster.

Adequate Ventilation: Proper airflow is essential, especially indoors. A slow, undetected leak can lead to a buildup of flammable gas, displace oxygen in the room, or create a toxic atmosphere. TRGS 510 lays out clear requirements for both natural and mechanical ventilation to prevent this from ever happening. For many indoor storage areas, a technical ventilation system that can perform a set number of air changes per hour is mandatory.

Fire Protection Measures: Your storage area must be built to resist fire. This is especially true for indoor facilities, where walls and doors often need a fire resistance rating of at least 90 minutes (F90). This crucial time buffer ensures that if a fire breaks out elsewhere, the cylinders are shielded from the heat long enough for emergency services to arrive and take control, preventing a catastrophic BLEVE (Boiling Liquid Expanding Vapour Explosion).

Restraint and Security: Every cylinder must be secured so it can't fall over. It’s that simple. A toppled cylinder can smash its valve, instantly releasing its contents at high pressure and turning the heavy steel container into an unpredictable projectile. TRGS 510 mandates the use of chains, straps, brackets, or properly designed racks to keep all cylinders stable and upright.

It’s also crucial to realise that TRGS 510 doesn’t operate in a vacuum. It’s smartly aligned with broader European regulations, most importantly the ADR (Accord européen relatif au transport international des marchandises Dangereuses par Route).

While ADR is primarily about the transport of dangerous goods, its hazard classification and labelling systems are the universal language of safety. When a cylinder is delivered to your site, it’s already carrying ADR-compliant labels that identify its contents and hazards. TRGS 510 takes these same classifications and uses them to dictate the correct storage rules. This brilliant integration creates a seamless chain of safety that runs from the filling plant, along the road, and right into your storage cage.

Moving from regulatory theory to boots-on-the-ground practice is where real safety begins. Designing a dedicated area for gas cylinders isn't about just finding an empty corner; it's about engineering a purpose-built fortress designed to contain and neutralise risks. A well-planned space for the lagerung von druckgasflaschen (storage of compressed gas cylinders) actively prevents incidents before they have a chance to start.

It all starts with a critical look at your site. The location you choose has to act as a protective bubble, isolating the cylinders from potential hazards across your facility. Think of it as choosing high ground in a flood zone—you’re proactively sidestepping the most obvious threats from the very beginning.

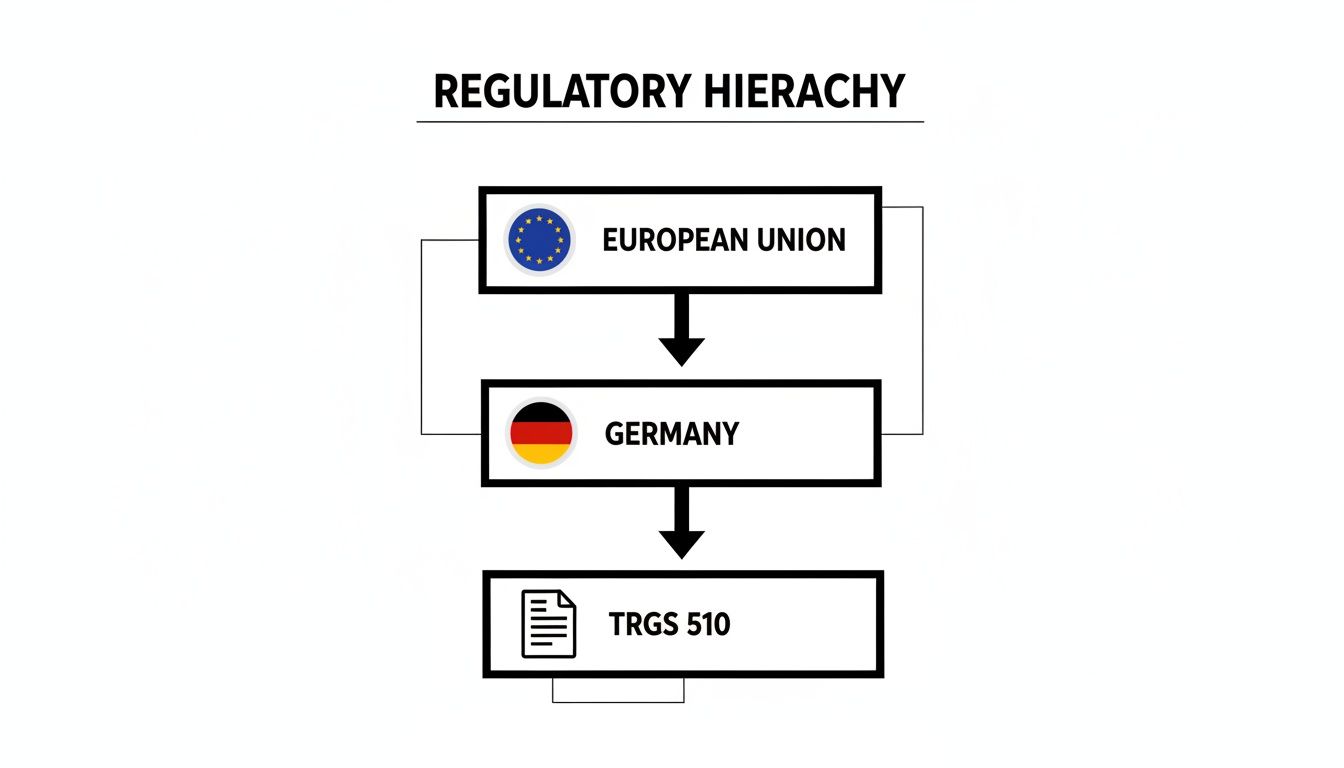

This flowchart maps out the top-down regulatory structure governing gas cylinder storage in Germany, starting from broad EU directives and funnelling down to the specific, practical rules in TRGS 510.

As you can see, while Europe provides the overarching framework, it's Germany’s TRGS 510 that gives you the specific, actionable details you need to implement on-site.

The first rule of real estate applies here with a vengeance: location is everything. An improperly placed storage area introduces constant, unnecessary risk into your daily operations. Your main goal is to keep cylinders far away from anything that could cause them to heat up, catch fire, or take a physical hit.

Key things to look for when choosing a site include:

Your storage area should be a 'low-energy' zone. It needs to be a calm, controlled space, deliberately isolated from the dynamic and potentially hazardous activities happening elsewhere in your facility.

This intentional separation is your first, and arguably most effective, line of defence.

Once you've scouted the perfect spot, it's time to think about the physical structure itself. The design has to tackle ventilation, security, and structural integrity head-on, turning an empty space into a compliant safety installation. Whether you’re building indoors or outdoors, the core principles are the same.

For outdoor storage, a sturdy fenced cage is often enough, as long as it provides shelter from the elements and isn't accessible to the public. The rules for indoor storage, however, are much stricter. The room itself often needs to be built from fire-resistant materials, typically with a rating of F90—meaning it can withstand a fire for at least 90 minutes.

To make sure your setup ticks all the boxes, focus on incorporating these non-negotiable elements. Think of this as a checklist for building your storage fortress, brick by brick.

A perfectly designed storage area is a fantastic starting point, but it's the consistent, daily routines that truly keep incidents at bay. Proper lagerung von druckgasflaschen is an active, ongoing process, not a "set it and forget it" task. The operational habits you build within your team are what transform a compliant space into a genuinely safe one, day in and day out.

Think of it like this: setting up a complex machine correctly is vital, but it’s the daily checks, careful operation, and regular tune-ups that guarantee it runs reliably and doesn't break down. These small, repeated actions are your strongest defence against complacency and unforeseen risks.

One of the simplest yet most effective habits to get into is the 'first-in, first-out' (FIFO) inventory method. This basic principle ensures older cylinders are always used before newer ones. Why does this matter? It prevents cylinders from sitting in storage for so long that they sneak past their mandatory inspection and re-testing dates—a major compliance and safety failure.

Proper handling during transport is another absolute must. Cylinders should never be rolled, dragged, or dropped. Always use a purpose-built cylinder cart or trolley that secures the cylinder while it's being moved. This simple piece of equipment drastically reduces the risk of a cylinder falling and damaging its valve.

And speaking of valves, the valve protection cap must always be securely in place whenever a cylinder isn't in use. This sturdy cap is the cylinder's first line of defence against a catastrophic failure if it gets knocked over. Taking it off should be the very last step before connecting a regulator, and putting it back on should be the first step after disconnecting.

A quick but thorough daily inspection is a powerful way to catch problems before they escalate. This check doesn't need to eat up much time, but it has to be consistent. Train your team to quickly scan for these key signs every day:

A daily five-minute walk-through of your storage area can be the difference between spotting a minor issue, like a loose cap, and facing a major safety incident. It reinforces a culture of vigilance.

While manual logs and paper checklists still work, modern digital tracking systems can take your safety routines to the next level. These systems often use barcodes or RFID tags on each cylinder to completely automate inventory management. This not only makes following the FIFO process effortless but also gives you a real-time overview of your entire stock.

This kind of detailed management is exactly what happens on a much larger scale for national energy security. For example, Germany holds the largest natural gas storage capacity in Central and Western Europe—around 24 billion cubic meters. This massive network depends on precise tracking and government oversight, like the Gas Storage Act, to ensure a stable supply.

Back in your facility, a digital system can automatically flag cylinders that are nearing their test date, alert staff if a cylinder is in the wrong place, or even link up with gas detection monitors. By automating these checks, you turn daily safety from a manual chore into a seamless, data-driven advantage that strengthens compliance and protects your team.

Even with the most robust safety protocols for the lagerung von druckgasflaschen, you have to be prepared for the unexpected. A well-designed emergency response plan isn’t a sign of failure; it's the final, essential layer of a professional safety system.

When an incident happens—whether it's a leak, a fire, or physical damage—your team's reaction in the first few moments can make all the difference. The goal is to shift from reactive panic to a series of clear, pre-planned actions. This plan acts as your team’s muscle memory in a crisis, guiding them through high-stress situations. Without it, even the most knowledgeable staff can make critical mistakes under pressure.

A generic plan just won't cut it. Your response must be tailored to the specific risks your gas cylinders present. Think through the most likely incidents and build clear, step-by-step protocols for each one. This proactive approach ensures your team knows exactly what to do, who to call, and what equipment to grab for different emergencies.

Your plan should absolutely address these core scenarios:

An effective response is impossible without the right tools in the right places. Strategically placed equipment and clearly marked routes are fundamental. You can't afford to waste precious seconds hunting for a fire extinguisher or trying to figure out an escape route.

Make sure your facility is equipped with:

A well-practised response is a fast and effective one. Drills aren't an interruption to work; they are an investment in survival. Running through these scenarios regularly builds the confidence and competence needed to act decisively in a real emergency.

Finally, make sure that Safety Data Sheets (SDS) are kept where your team and first responders can access them instantly. In a crisis, these documents give firefighters and medical personnel the critical information they need on gas properties, hazards, and the right emergency procedures, allowing them to manage the situation safely and effectively.

Standard industrial guidelines for the lagerung von druckgasflaschen lay out essential safety measures—but when you step into biobanks, hospitals or cutting-edge research labs, the stakes rise exponentially. Here, compressed and cryogenic gases aren’t just utilities; they’re lifelines for patient care, critical experiments and irreplaceable sample storage.

That’s why every aspect of your storage strategy must account for purity, traceability and the extreme behaviour of cryogenic fluids. A slip-up in these settings carries more than a compliance penalty—it can jeopardise research outcomes or, worse, human lives.

Cryogenic liquids such as liquid nitrogen (LN₂) sit at –196 °C and offer unrivalled preservation power. But a minor spill releases a vast, invisible gas cloud that can suffocate anyone in its path. Since nitrogen is odourless and colourless, you won’t see or smell the hazard before oxygen levels plummet.

To keep these risks in check, every specialised storage area should include:

Oxygen Depletion Monitors

Continuously track ambient O₂ and trigger alarms if levels fall below 19.5%.

Forced Ventilation Systems

Engineered for a defined number of air-changes per hour to sweep heavier-than-air vapours away from workstations.

Specialised Personal Protective Equipment (PPE)

Thermal gloves, face shields and lab coats designed to prevent severe cold burns from splashes.

In clinical environments, medical gases—from oxygen to anaesthetic blends—are treated as pharmaceuticals. Their chain of custody must mirror that of any drug: one tiny impurity or mix-up can have dire patient-safety implications.

The chain of custody for medical gas is as important as it is for any prescription drug. From the moment it arrives to the point of use, its purity and identity must be guaranteed without fail.

A robust hospital protocol will include:

For a deeper dive, see our guide on the storage of oxygen cylinders.

Research labs handling high-purity, reactive or toxic gases can’t stop at TRGS 510 segregation alone. Often, they install ventilated gas cabinets—sealed enclosures equipped with:

This second layer of containment mirrors national gas-reserve strategies, where security and continuity are paramount. In Germany, for instance, storage levels once dipped to 42 percent capacity before recovering, underlining how even large-scale reserves demand rigorous oversight. Discover more about Germany’s energy supply strategies on economy.ac.

Even when you've got the basics down, specific questions about the correct lagerung von druckgasflaschen always pop up. This part of the guide tackles the most common queries head-on, giving you clear, direct answers to help you sharpen up your safety protocols and stay compliant with German regulations.

Think of this as moving from general knowledge to the nitty-gritty details you can put into practice right away. Getting these specifics right is what separates a good safety plan from a great one.

In Germany, the standard re-testing interval for most compressed gas cylinders is 10 years, which lines up nicely with ADR regulations. But remember, this isn't a one-size-fits-all rule; the exact period can change depending on the gas inside and the cylinder's construction.

You can always find the last inspection date stamped right on the cylinder's shoulder. To keep things simple and safe, your best bet is a strict 'first-in, first-out' (FIFO) inventory system. This approach ensures you use cylinders well before their test dates creep up, avoiding what could become a major safety and compliance headache.

The short answer is almost always no. Mixing different types of gas cylinders is a risky business and is forbidden in most situations. German regulations, particularly the TRGS 510, are very clear about this: you must segregate gases based on their hazard class.

The rule of thumb is simple: if different gases can react dangerously with each other, they need their own space. You would never, for instance, store flammable gases like propane next to oxidisers like oxygen—that's just asking for a fire or an explosion.

While it's often fine to store inert gases like nitrogen and argon together, you have to do your homework first. Always check the Safety Data Sheet (SDS) for each gas and cross-reference it with the TRGS 510 guidelines. It's the only sure way to prevent a hazardous chemical reaction and maintain a compliant lagerung von druckgasflaschen.

Outdoor storage is usually the preferred route, and for good reason. Natural ventilation is incredibly effective at dispersing any potential leaks, which dramatically lowers the risk of a dangerous gas buildup. A proper outdoor storage area needs to be secure, protected from direct sunlight and bad weather, and completely off-limits to the public.

Storing cylinders indoors is a whole different ball game. It brings more challenges, like the need for a robust mechanical ventilation system to ensure enough air changes. The structure itself often needs to be fire-resistant (look for an F90 rating), and you might even need an explosion risk assessment (ATEX). The right choice really comes down to your site's layout and the specific gases you're handling, but no matter which you choose, you must meet all the requirements of TRGS 510.

For state-of-the-art cryogenic storage solutions that meet the highest safety and compliance standards, trust the experts at Cryonos GmbH. Explore our turn-key systems for biobanks, labs, and industrial users at https://www.cryonos.shop.