No Products in the Cart

Natural gas fueling stations are facilities that dispense natural gas for vehicles designed to run on this cleaner fuel. They come in two main flavours: Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG). Think of them as the modern equivalent of a petrol station, but built for a more cost-effective energy source that’s quickly gaining ground in the transport world.

As industries and governments hunt for cleaner alternatives to traditional diesel and petrol, natural gas has stepped up as a reliable and practical bridge fuel. It offers a solid way to slash emissions and bring down operational costs, especially for heavy-duty vehicle fleets. Natural gas fueling stations are the backbone of this transition, creating a network that supports everything from city buses to long-haul lorries.

This expanding infrastructure isn't just a niche market; it's a major global trend. Projections show the natural gas fueling station industry is on track to hit a value of $5.8 billion by 2030, growing at a compound annual rate of 7.60%. This growth reflects a clear recognition that natural gas is a vital part of the energy puzzle for commercial transport. You can dig deeper into these market dynamics in this detailed report on the natural gas fueling station market.

The rise of these specialised stations isn't happening by accident. It's driven by a few key factors that deliver real benefits to both fleet operators and the environment.

Here’s what’s behind the push:

At its core, a natural gas fueling station represents a strategic investment in efficiency and sustainability. It empowers fleet managers to meet stricter environmental regulations while simultaneously improving their bottom line.

This guide will walk you through everything you need to know about this essential infrastructure. We’ll explore the different types of stations, how they work, the critical components involved—like the specialised CNG fuel tanks—and what it takes financially to build your own. Whether you're a fleet manager, an investor, or just curious about clean energy, you’ll find a clear roadmap here.

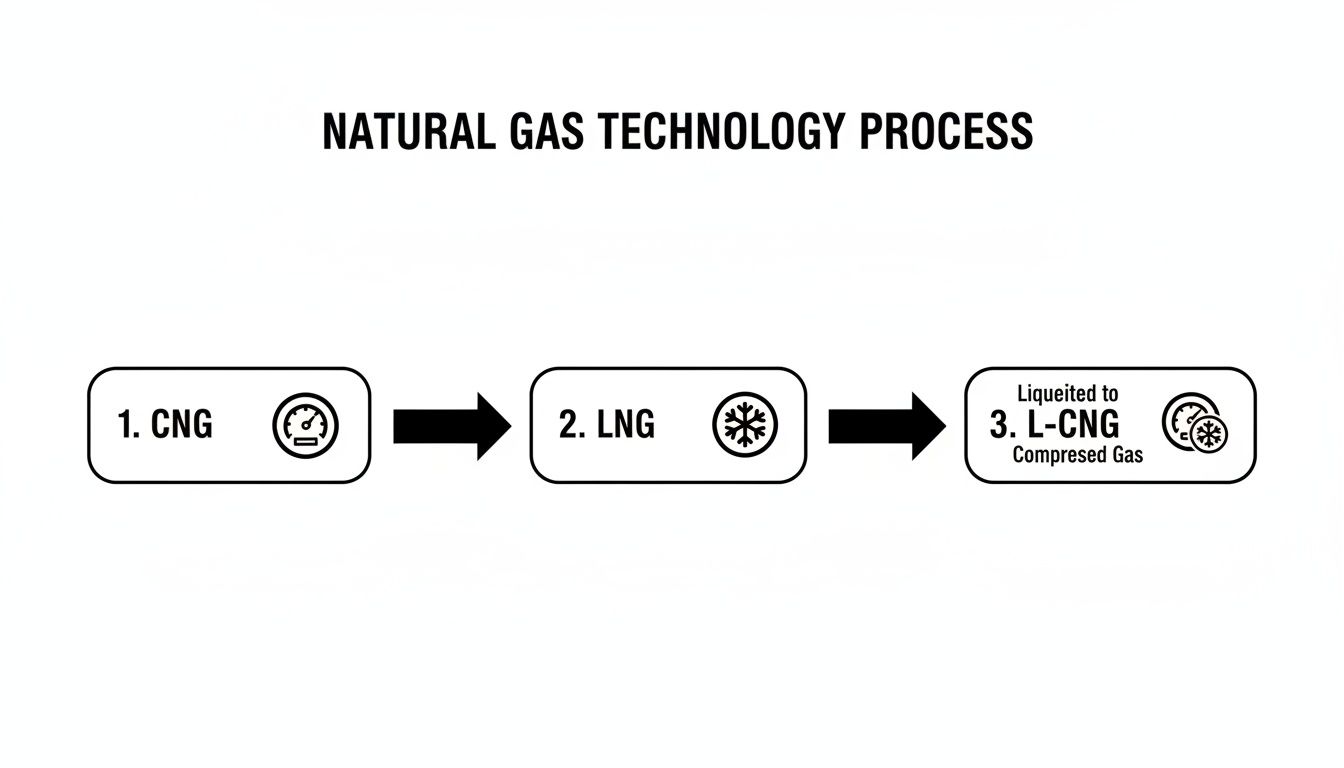

When you hear “natural gas fuelling station,” it’s easy to picture just one kind of setup. But the reality is a bit more nuanced. The technology actually comes in three main flavours: Compressed Natural Gas (CNG), Liquefied Natural Gas (LNG), and a clever hybrid known as L-CNG.

Each one is engineered for very different jobs, and picking the right one boils down to the specific vehicles you’re serving and how they operate day-to-day.

Think of it as different ways to pack the same amount of energy into a fuel tank. The fundamental difference is the physical state of the gas—is it a highly pressurised gas or a super-chilled liquid? This single distinction shapes everything, from how much fuel you can store and how fast you can refuel, to the overall complexity of the station itself.

Compressed Natural Gas (CNG) is the most straightforward of the bunch. Picture a scuba tank, but for a lorry or a bus. The process is simple: natural gas is drawn from a standard utility pipeline, cleaned up, and then squeezed to incredibly high pressures—usually between 3,000 and 3,600 pounds per square inch (psi).

This pressurised gas is then held in tough, high-strength cylinders, both at the station and on the vehicle. Because the gas is simply compressed, CNG stations are mechanically simpler than their cryogenic cousins. This makes them a perfect fit for return-to-base fleets that run predictable, shorter routes and can refuel overnight.

For urban and regional fleets, CNG is often the ideal choice. A fleet of waste management trucks, for instance, completes its daily city routes and reliably returns to a central depot each night. In that scenario, the range limitations of CNG become a non-issue.

Liquefied Natural Gas (LNG) technology takes a completely different path. Instead of pressure, it uses extreme cold. An LNG station employs a cryogenic process to chill natural gas down to a frigid -162°C (-260°F). At that temperature, the gas transforms into a clear, colourless liquid.

This cooling process is like shrinking a huge balloon down to the size of a small marble. The liquefaction shrinks the gas's volume by a factor of over 600. This incredible energy density is the trump card for LNG.

By turning gas into a liquid, LNG packs far more fuel into the same amount of space. This makes it the go-to solution for heavy-duty vehicles that need to travel long distances without sacrificing payload for bulky fuel tanks.

LNG is stored in large, vacuum-insulated cryogenic tanks that act like giant thermoses, keeping the fuel cold and stable. This is why LNG is the fuel of choice for long-haul lorries and even maritime vessels that need to cover hundreds or thousands of miles before their next stop.

So, what happens if a site needs to service both long-haul trucks running on LNG and local delivery vans on CNG? That’s where L-CNG (Liquefied to Compressed Natural Gas) stations come in, offering a versatile, all-in-one solution.

An L-CNG station masterfully combines the best of both worlds. It takes advantage of the high storage density of LNG while providing the dispensing flexibility of CNG. The process is quite ingenious. The station receives and stores natural gas in its most compact form—as a liquid in cryogenic tanks.

When a vehicle needs fuel, the station can dispense LNG directly to heavy-duty trucks. At the same time, it can use a cryogenic pump and a vaporiser to carefully warm a portion of the LNG, turning it back into a gas, which is then compressed for CNG vehicles.

This dual-fuel capability makes L-CNG stations incredibly flexible. They can serve a diverse mix of vehicles from a single footprint, creating a one-stop shop for mixed fleets. This adaptability is critical for public-access natural gas fueling stations that want to serve the broadest possible market. It’s a smart, future-proof investment that can evolve as a region's fleet composition changes over time.

Pulling up to a natural gas dispenser might feel familiar, but what happens behind the scenes is a world away from your typical petrol station. It's a sophisticated process, whether that involves squeezing natural gas to incredible pressures or chilling it to cryogenic temperatures. The goal is always the same: to safely and efficiently get the fuel from the pipeline into a vehicle's tank.

For any station, the journey starts with natural gas arriving from a local utility pipeline—the very same kind that supplies homes and businesses. This raw gas isn't quite ready for a vehicle, though. It first needs to be purified and prepared to meet strict quality standards before it's ready for the next step: compression or liquefaction.

This flowchart maps out the distinct paths natural gas takes to become a vehicle fuel, depending on the station type.

As you can see, CNG is all about pressure, LNG is all about cold, and L-CNG smartly combines both to offer a more versatile solution.

At a Compressed Natural Gas (CNG) station, the compressor is the undisputed powerhouse. Once the incoming gas is dried and filtered, it’s fed into a multi-stage compressor that acts like a massive engine, systematically squeezing the gas. This powerful process boosts its pressure from a modest 60 psi in the pipeline all the way up to an immense 4,500 psi.

This highly pressurised gas is then directed into a series of large, robust cylinders called a cascade storage system. The cascade is cleverly designed to fill vehicles as quickly as possible. Imagine a series of water tanks at different heights; the highest-pressure tank is used first for a rapid initial fill, with the others following in sequence to top off the vehicle's tank to its target pressure of 3,600 psi.

When a driver hooks up the dispenser nozzle, the system releases the stored CNG. The whole experience feels much like using a standard pump and takes just 3 to 5 minutes for a typical vehicle.

Liquefied Natural Gas (LNG) stations work on a completely different principle: temperature, not pressure. These sites receive natural gas that has already been turned into a liquid at a large, central production plant and is delivered by cryogenic tanker trucks. The core of any LNG station is its storage system.

The LNG is carefully offloaded into a giant, vacuum-insulated storage tank. This piece of equipment is basically a massive thermos, expertly engineered to keep the fuel at its incredibly cold temperature of -162°C.

This cryogenic storage is the technological backbone of any LNG or L-CNG operation. Its ability to minimise heat transfer and control the boil-off rate—the slow evaporation of LNG back into a gas—is critical for safety, efficiency, and profitability.

Fuelling an LNG vehicle is a specialised process. A driver connects a cryogenic hose and nozzle to transfer the super-cooled liquid from the storage tank directly into the vehicle's own insulated fuel tank. Due to the extreme temperatures, this requires personal protective equipment (PPE), like cryogenic gloves and face shields. Even so, a heavy-duty truck can be completely refuelled in about 5 to 10 minutes.

The growth in this area is hard to ignore. The LNG filling stations market, valued at USD 1.7 billion in 2025, is projected to double to USD 3.4 billion by 2035. This expansion, representing an 8.3% compound annual growth rate, highlights just how much demand for LNG is rising in the heavy transport sector. You can find more detail on this market acceleration in this comprehensive LNG filling stations market report.

An L-CNG station cleverly merges both approaches to serve a wider variety of vehicles. It stores fuel in its densest form—as liquid LNG—but can dispense it as either LNG or CNG.

Here’s how it works:

This dual-fuel capability makes L-CNG a highly flexible and efficient model, especially for public natural gas fueling stations that need to cater to diverse vehicle fleets.

For any LNG or L-CNG natural gas fuelling station, the cryogenic storage system is the undisputed heart of the entire operation. This isn’t just a simple tank; it’s a piece of high-performance engineering designed to manage one of nature’s most extreme states. The whole point of liquefying natural gas is to shrink its volume, which requires keeping it at an incredibly frigid -162°C (-260°F).

Maintaining this temperature isn't optional—it's the fundamental principle that makes LNG viable for heavy-duty transport. If the temperature creeps up even slightly, the liquid starts turning back into a gas, a process known as "boil-off." This is where the design of the storage vessel becomes absolutely critical for both the safety and profitability of the fuelling station.

Think of an LNG storage tank less like a container and more like a giant, industrial-grade thermos. Its sole purpose is to isolate the super-cooled liquid inside from the warmth of the outside world. This is achieved through a clever design known as a vacuum-insulated vessel.

At its core, this technology uses a tank-within-a-tank structure. There's an inner vessel built from materials that can handle cryogenic temperatures without becoming brittle, and a tough outer vessel. The real magic happens in the space between these two layers.

All the air is pumped out of this gap, creating a powerful vacuum. A vacuum is a fantastic insulator because it contains very few molecules to transfer heat from the outside in. This design dramatically slows down the rate at which the LNG warms up and evaporates.

The performance of a cryogenic tank is measured by its Boil-Off Rate (BOR). A low BOR indicates a highly efficient, well-insulated tank that minimises fuel loss, protecting the station operator’s investment and ensuring more product is available for sale.

This rate is a crucial metric for any natural gas fuelling station operator. A high BOR means lost revenue, as fuel literally disappears into thin air. Investing in superior cryogenic equipment with a guaranteed low BOR is one of the most important financial decisions in a station's development.

Working with a substance as cold as LNG demands strict adherence to safety protocols. At these temperatures, the liquid can cause severe freeze burns to exposed skin in seconds and make conventional materials like carbon steel as fragile as glass.

Safe handling is a non-negotiable part of daily operations. Personnel must be thoroughly trained and equipped with the right gear.

Key safety measures include:

By understanding the technical demands of cryogenic storage and the importance of safe handling, station operators can make informed decisions. Choosing high-quality, reliable equipment is foundational to the entire project. To explore more about the versatility of this technology, you can learn more about the role of an ISO container tank in modern logistics. This foundational choice ensures operational efficiency, safety, and long-term success for any LNG or L-CNG project.

Building a natural gas fuelling station is about much more than just bolting together compressors and cryogenic tanks. Before a single vehicle can pull up to the dispenser, you have to navigate a complex maze of safety regulations and permitting procedures. This isn't just red tape; it's a meticulous process designed to protect the public, the environment, and the people who will run the station.

Think of these requirements as layers of protection, each one designed to prevent, detect, and control any potential hazard. From engineering standards to operational protocols, every piece of the puzzle must fit perfectly. This robust system ensures that both compressed and liquefied natural gas are handled safely at every step.

Any modern natural gas fuelling station comes equipped with a suite of automated safety systems. These are the unsung heroes of the facility, working around the clock to monitor conditions and react instantly if something goes wrong.

Here are the key players:

These systems don't work in isolation. For instance, a detected methane leak wouldn't just sound an alarm—it could also automatically activate the ESD system, securing the site long before a situation has a chance to escalate. For a deeper dive into safety measures during transit, our guide on the safe transport of gas cylinders offers some valuable insights.

The road from an idea on a blueprint to a fully functioning station is paved with permits. This journey is intentionally thorough, involving multiple agencies at local, regional, and even national levels. It’s the official process that guarantees a station is built correctly, located responsibly, and operated safely from day one.

The permitting process isn't a bureaucratic hurdle; it's a critical quality assurance check. It validates that a station’s design, construction, and operational plans meet the highest safety and environmental standards established by law.

This process typically kicks off with site selection. This phase involves detailed environmental impact assessments to check everything from soil conditions to proximity to residential areas and local zoning laws. Once a site is approved, developers submit detailed engineering plans for review, followed by construction permits and a series of final inspections before getting the green light to operate. Each step is a checkpoint to ensure full compliance.

The table below outlines the typical lifecycle for bringing a natural gas fueling station project to life, highlighting the key stages from initial concept to the first day of operation.

| Phase | Key Activities | Primary Consideration |

|---|---|---|

| 1. Feasibility & Site Selection | Market analysis, financial modeling, environmental impact assessment, securing land rights. | Is the project viable and is the location suitable and compliant with zoning? |

| 2. Design & Engineering | Detailed station layout, equipment specification, safety system design, HAZOP studies. | Does the design meet all regulatory codes and operational requirements? |

| 3. Permitting & Approvals | Submitting applications to local, regional, and national authorities for all necessary permits. | Ensuring all legal and environmental requirements are met before construction. |

| 4. Procurement & Construction | Ordering major equipment (tanks, compressors), civil works, mechanical and electrical installation. | Adherence to engineering plans and construction safety standards. |

| 5. Commissioning & Training | System testing, safety drills, operational training for staff, final inspections by authorities. | Is the station functioning correctly and are personnel prepared to operate it safely? |

| 6. Operation & Maintenance | Routine fuelling operations, scheduled maintenance checks, ongoing compliance monitoring. | Ensuring long-term safety, reliability, and efficiency of the station. |

This structured approach ensures that every detail is accounted for, leading to a safe and successful launch.

A great real-world example is Germany, which has become Europe's leading market for natural gas fuelling infrastructure, especially for LNG. This success story is built on one of the world's most stringent regulatory frameworks. Major operators like Liqvis, which recently opened its eleventh LNG station, thrive by meeting—and often exceeding—these high standards. This rigorous approach actually simplifies compliance in the long run. Partnering with experienced suppliers who provide certified, compliant hardware isn't just a good idea; it's the surest path to getting your project across the finish line.

Before you can break ground on a new natural gas fuelling station, you need to have the numbers nailed down. It’s about more than just the price of the hardware; you need a solid grasp of the core economics driving the business. A strong, predictable return depends entirely on a detailed breakdown of what it will cost to build the station and what it will cost to run it day-to-day. Getting this right is everything.

The financial journey really boils down to two key areas. First up are your Capital Expenditures (CapEx). Think of these as all the one-time, upfront costs you'll incur to get the station built and ready for its first customer. It's the big initial investment.

Then you have your Operational Expenditures (OpEx). These are the recurring, day-in, day-out costs of keeping the lights on and the gas flowing safely and efficiently. This is where your long-term profitability is won or lost.

CapEx is, without a doubt, the biggest cheque you’ll write at the start of the project. The final figure can swing wildly depending on the type of station you're building (CNG vs. LNG), its overall capacity, and even its location.

A few major items make up the bulk of your CapEx:

Once you’re up and running, the game shifts to managing your OpEx. These costs are directly tied to how much fuel you sell and how efficiently your equipment operates. The lower you can keep your OpEx, the healthier your profit margins will be.

Your main operational costs will include:

So, when do you start making money? The return on investment (ROI) for a natural gas fuelling station is driven by a few make-or-break factors. The single most important one is the price spread—the difference in price between natural gas and traditional diesel. The wider that gap, the more money your customers save, and the better your margins.

The entire business model is built on this simple fact: you must consistently offer natural gas at a lower price per energy equivalent than diesel. This is what attracts and keeps fleet customers, who watch their fuel budget like a hawk.

Beyond price, fuelling volume is everything. A station on a busy transport corridor or one serving a few dedicated fleets will hit its profit targets far quicker than a site with low traffic. Smart operators also hunt for government grants and tax incentives, which can seriously cut down the initial CapEx hit and dramatically shorten the timeline to a positive ROI.

This is why choosing high-efficiency, low-maintenance equipment from the very beginning isn't just a technical decision—it's a financial one. Investing in reliable technology means less downtime, fewer repair bills, and fewer long-term headaches. It’s a direct path to a healthier bottom line and the sustained success of your station.

As fleet managers and investors start looking at cleaner fuels, a lot of practical questions come up. Making the switch to natural gas is a big step, and understanding the day-to-day realities of running these vehicles is the key to feeling confident in the technology. Here, we'll tackle some of the most common queries with clear, straightforward answers.

Our goal is to pull back the curtain on the whole experience, addressing everything from refueling times to the fundamental safety of the fuel itself. These insights should help you see just how smoothly natural gas vehicles can fit into modern logistics and transport operations.

One of the first questions we always get is about downtime at the pump. The good news is that refueling times for natural gas vehicles are very much in line with their diesel or petrol cousins, so fleet efficiency isn't compromised.

This quick turnaround makes both CNG and LNG practical, competitive options for commercial fleets where every minute counts towards the bottom line.

Natural gas has an excellent and well-documented safety record, which comes down to its physical properties and the robust engineering of modern fueling systems. In many respects, it actually presents fewer risks than liquid fuels.

Because CNG is lighter than air, it simply dissipates up into the atmosphere if a leak ever occurs. This is a huge advantage over petrol or diesel, which pool on the ground and create a lingering fire hazard. On top of that, the fuel tanks on both CNG and LNG vehicles are built to be incredibly tough, undergoing far more rigorous impact and safety testing than standard fuel tanks.

All modern natural gas fueling stations are built with layers of advanced safety systems, including automatic shut-off valves and highly sensitive methane detectors. These features are designed to stop potential incidents before they can even start, ensuring a secure environment for everyone.

The main difference between these two fuels is where they come from, not what they're made of. Chemically, they are virtually identical—both are mostly methane and can be used in the exact same vehicles and fueling infrastructure without any changes.

Conventional LNG is a fossil fuel, extracted from underground reserves. Bio-LNG, on the other hand, also known as Liquefied Biomethane (LBM), is a renewable fuel. It's produced by capturing methane from organic waste sources like agricultural residue, landfill gas, or even food scraps.

This process essentially turns a powerful greenhouse gas into a clean, carbon-neutral vehicle fuel. The best part? Fueling stations designed for LNG are 100% compatible with Bio-LNG. This offers a simple and direct path for fleets to achieve even bigger decarbonisation goals without a single new investment in equipment.

For any project involving cryogenic gases, having the right storage and handling equipment is essential for safety and efficiency. Cryonos GmbH is your turn-key supplier for state-of-the-art cryogenic solutions, offering everything from storage vessels to transport units. Discover our full range of certified equipment and expert services at https://www.cryonos.shop.