No Products in the Cart

At its heart, a reciprocating piston compressor works a lot like a simple bicycle pump. Think of it as a positive displacement machine: it uses a piston moving back and forth inside a cylinder to shrink a gas's volume, which in turn ramps up its pressure. This straightforward, powerful mechanism is why it’s a real workhorse in any industry needing high-pressure gas.

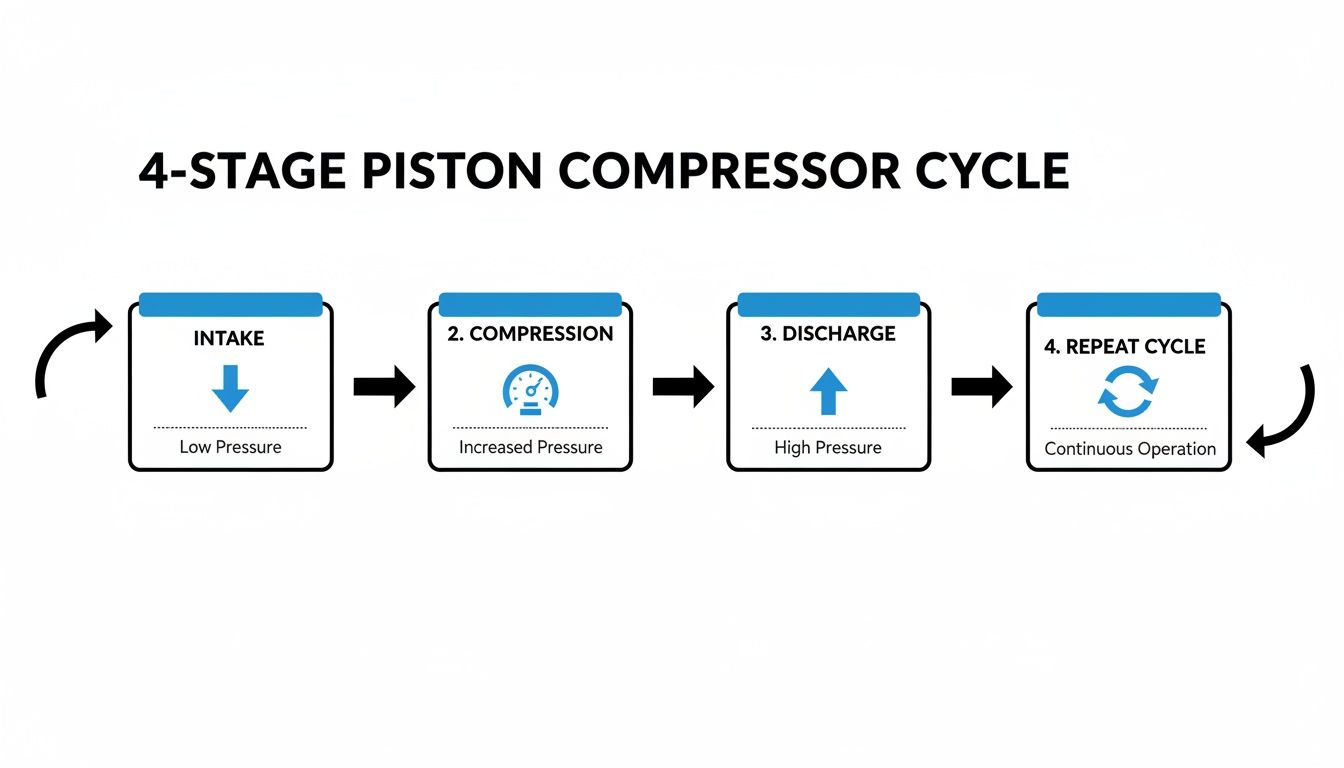

To really get a feel for how these compressors work, it helps to break their constant motion down into a simple, four-stage cycle. It’s a remarkably efficient process that takes low-pressure gas and turns it into a high-pressure powerhouse, ready for everything from heavy industrial manufacturing to specialised lab work.

The whole show centres on the movement of a piston, which is driven by a crankshaft to create the pressure changes inside a sealed cylinder.

The mechanical process is just a sequence of perfectly timed events, repeating with every single rotation of the crankshaft. Each step has a specific job: preparing, compressing, and then sending the gas on its way.

This diagram brings the four-stage cycle to life, showing exactly how gas flows through the compressor from start to finish.

You can see how the piston's simple back-and-forth motion translates directly into a powerful pressurisation cycle. Let’s walk through what’s happening at each step:

Intake Stroke: The cycle kicks off as the piston moves down, creating a vacuum inside the cylinder. This pressure drop pulls the inlet valve open, letting low-pressure gas rush in to fill the chamber.

Compression Stroke: Once the cylinder is full, the piston changes direction and starts moving up. This movement forces the inlet valve shut and squeezes the gas into a smaller space, causing its pressure and temperature to climb dramatically.

Discharge Stroke: As the piston nears the top, the gas pressure inside the cylinder becomes greater than the pressure in the discharge line. This forces the discharge valve open, and the now highly pressurised gas is pushed out of the cylinder and into the system or a storage tank.

The real genius of this design is its raw power and simplicity. By converting rotational motion into a direct, linear force, a reciprocating piston compressor can hit pressures that other types of compressors just can't touch.

Finally, a tiny bit of gas is always left behind in the small "clearance volume" at the top of the cylinder. When the piston starts its next intake stroke, this trapped gas expands, the pressure drops, and the inlet valve opens once again to restart the whole cycle. It's this steady, mechanical rhythm that makes the reciprocating piston compressor such a vital tool for so many critical jobs.

While the basic idea of a piston pushing gas in a cylinder is simple, the world of reciprocating piston compressors is surprisingly diverse. Not all of them are built the same. Engineers have tweaked the fundamental design over the years to hit specific targets for pressure, flow rate, and gas purity.

Figuring out these differences is crucial for picking the right machine. What works for a small workshop's air tools is completely different from what’s needed in a high-tech cryogenic lab. Let's break down the main design forks you'll encounter.

The first big split in design comes down to a simple question: how many times is the gas squeezed? This leads us to single-stage and multi-stage compressors.

A single-stage compressor is the most straightforward design you can get. Gas gets pulled into a cylinder, a single piston compresses it in one stroke, and then it's pushed out. This direct approach is perfect for applications that don't need massive pressure, generally topping out around 10 bar (150 PSI).

But there’s a catch: compressing gas creates a lot of heat. When you need really high pressures, trying to do it all in one go is like trying to run a marathon at a full sprint. It’s incredibly inefficient and puts a huge amount of thermal stress on the machine's parts. This is where multi-stage compressors shine.

Instead of one big squeeze, a multi-stage machine compresses the gas in steps. After the first stage, the hot, pressurised gas is routed through a heat exchanger called an intercooler. This crucial step cools the gas down, making it denser and much easier to compress in the next stage. By repeating this compress-and-cool cycle, these machines can reach extremely high pressures far more efficiently and safely than any single-stage model could hope to.

Another critical dividing line is lubrication. How the moving parts inside the compressor stay friction-free has a massive impact on the purity of the gas that comes out the other end.

Oil-lubricated compressors are the traditional workhorses. They use oil to keep the cylinder walls, pistons, and bearings running smoothly. This method is effective and the machines are often cheaper upfront. The downside? Tiny, microscopic oil particles will always find their way into the compressed gas stream. For many industrial jobs, this isn't a problem, but for highly sensitive applications, it's a non-starter.

That’s why oil-free compressors are absolutely essential in certain fields. These models are engineered differently, using materials with self-lubricating properties like specialised polymer piston rings and permanently sealed bearings. This clever design completely isolates the compression chamber from any lubricant.

For industries like medical, food and beverage, electronics, or cryogenics, gas purity isn't just a preference—it's a strict requirement. An oil-free reciprocating piston compressor guarantees that the output gas is 100% free of oil contamination, protecting delicate processes and valuable end products.

The demand for pure, uncontaminated gas is also growing in new energy sectors. Take the production of green hydrogen, for example, where processes depend on absolute purity. You can learn more by checking out our guide on how green hydrogen is made.

Finally, compressor designs can be split by how they use the piston's movement.

To make these distinctions easier to grasp, it helps to see them side-by-side. The table below summarises the key characteristics of each design, highlighting where they fit best.

| Compressor Type | Pressure Range | Key Advantage | Common Applications |

|---|---|---|---|

| Single-Stage | Low (up to 10 bar) | Simplicity, lower initial cost | Workshops, general pneumatic tools |

| Multi-Stage | High to Very High | Higher efficiency, better cooling | High-pressure gas filling, cryogenics |

| Oil-Lubricated | Varies | Durability, cost-effective | Heavy industry, manufacturing |

| Oil-Free | Varies | Absolute gas purity | Medical, food processing, laboratories |

| Double-Acting | Medium to High | Higher flow rate and efficiency | Large-scale industrial gas processing |

Each design presents a unique balance of cost, performance, and purity. This incredible adaptability is what makes the reciprocating piston compressor such an enduring and versatile machine, with the right configuration available for nearly any job.

To really get a feel for a reciprocating piston compressor, you have to look past the basic mechanics and dig into the numbers and materials that define its capabilities. These aren't just technical specifications on a data sheet; they're the real-world factors that decide if a compressor is right for the job, how efficiently it will run, and ultimately, how long it will last.

Getting a handle on these details is what separates a decent equipment choice from a great one. It’s about knowing exactly what you're getting and why it's been built the way it is.

When you're sizing up a compressor, three numbers tell most of the story: flow rate, pressure, and efficiency. Each one gives you a vital piece of the performance puzzle.

Flow Rate (CFM/LPM): This is all about volume. Measured in Cubic Feet per Minute or Litres per Minute, it tells you how much gas the compressor can push out. A bigger flow rate means it can power more tools at once or fill a storage tank in less time.

Pressure (PSI/bar): This is the force behind the flow. Measured in Pounds per Square Inch or bar, it tells you how forcefully that gas is being delivered. Reciprocating piston compressors are known for their muscle here—they can hit exceptionally high pressures, making them indispensable for specialised jobs.

Volumetric Efficiency: This is a subtle but critical metric. It’s a reality check, comparing the actual amount of gas the compressor discharges with the theoretical volume the piston displaces. No compressor is 100% efficient because a tiny bit of "clearance volume" is always left at the top of the cylinder. The higher the volumetric efficiency, the less energy you're wasting.

Here’s a simple way to think about it: a compressor with high pressure but low flow is like a thin, powerful jet of water. One with high flow but low pressure is more like a slow, wide river. The key is matching both to your application to build an effective system.

The legendary durability of a reciprocating piston compressor is no accident. It’s the direct result of carefully choosing materials that can stand up to incredible stress and heat, day in and day out. What each part is made of is absolutely critical for a long service life, especially when you're dealing with different gases.

This kind of thoughtful engineering is a hallmark of industrial machinery across Europe, a region that dominates the global market. The European market for these compressors recently hit USD 8,600.0 million, making up nearly 90% of the worldwide total. Germany's market leadership, valued at USD 2,000.0 million, is backed by strong industrial bases in Italy and Spain, highlighting a continent-wide dedication to top-tier compression technology. You can dive deeper into these market dynamics in this detailed industry report.

The choice of materials directly affects how well a compressor can handle everything from simple inert gases like nitrogen to more challenging or high-purity media.

These material choices are the foundation of the compressor’s reliability, making sure every component can do its job under immense pressure for thousands of hours.

While the mechanics are fascinating, you really start to appreciate the power of a reciprocating piston compressor when you see it at work. These machines aren't just pieces of hardware; they are the engines driving progress in some of the most demanding scientific and industrial fields imaginable. Their knack for delivering extremely high pressures with unwavering reliability makes them non-negotiable for applications where failure simply isn't an option.

Nowhere is this more true than in cryogenics—the science of the ultra-cold. In this world, precision and purity are everything.

If you want to create cryogenic fluids like liquid nitrogen (LN2) or liquid helium, you have to cool gases down to incredibly low temperatures until they finally condense. This entire process relies on complex liquefaction cycles, and right at the heart of these systems, you'll almost always find a reciprocating piston compressor.

These compressors handle the critical first step: squeezing gases like nitrogen or helium to the extreme pressures needed to even begin the cooling journey. This highly pressurised gas then flows through a series of specialised heat exchangers and expansion stages, causing its temperature to plummet. Without that initial high-pressure kick from a piston compressor, liquefaction would be far less efficient, if not completely impossible. This process relies heavily on components built for extreme thermal performance, and you can learn more about the technology behind a plate-fin heat exchanger to see how these systems fit together.

The ability to generate pressures exceeding 200 bar (3000 PSI) is what makes the reciprocating design so essential for liquefying gases. It provides the brute force needed to push gas molecules close enough together for them to change phase at cryogenic temperatures.

Another vital job in cryogenics is managing "boil-off" gas. As cryogenic liquids sit in storage tanks, they naturally warm up and evaporate a little over time. This creates gas that builds up pressure inside the vessel. A reciprocating piston compressor is brought in to capture this valuable boil-off, re-compress it, and either turn it back into a liquid or send it off for other uses. It’s a smart way to prevent waste and keep storage conditions safe.

Beyond the deep freeze of cryogenics, these compressors are workhorses in countless laboratories and industrial plants where high-pressure, high-purity gases are the lifeblood of daily operations. Their tough design, especially the oil-free models, makes them a perfect match for sensitive processes.

High-Pressure Cylinder Filling: Gas supply companies depend on reciprocating compressors to fill cylinders with nitrogen, oxygen, and argon to pressures of 200-300 bar. This is a classic application that perfectly demonstrates their raw power and reliability in continuous-duty work.

Gas Chromatography and Research: In analytical labs, sophisticated instruments like gas chromatographs need a perfectly steady supply of high-purity carrier gases (like helium or nitrogen) at very precise pressures. Oil-free piston compressors deliver the clean, stable gas flow required for accurate and repeatable scientific results.

Semiconductor and Pharmaceutical Manufacturing: In these ultra-clean environments, the tiniest impurity can ruin an entire product batch worth millions. Oil-free reciprocating compressors are trusted to supply clean dry air (CDA) and process gases, making sure that everything from microchips to medicines remains completely contaminant-free.

The importance of this technology is clear when you look at its market footprint, especially in Europe's industrial hubs. For instance, Germany's reciprocating compressor market was valued at USD 294.28 million and is expected to climb to USD 491.1 million by 2035. This growth speaks to the sustained demand from advanced manufacturing centres in regions like North Rhine-Westphalia and Bavaria.

From biobanks that preserve biological samples in liquid nitrogen to industrial plants that cut steel with high-pressure oxygen, the reciprocating piston compressor is the unseen hero making it all possible.

Picking the right reciprocating piston compressor isn’t just another purchase; it's a major decision that echoes through your operational efficiency, reliability, and long-term costs. A smart investment means looking past the initial price tag and really digging into how a machine’s capabilities match your specific needs. It's a systematic process, but getting it right from the start saves a lot of headaches down the road.

The first move is always a thorough needs analysis. Before you even think about comparing models, you need a crystal-clear picture of your operational parameters. This foundation is crucial. It stops you from overspending on a beast of a compressor you don't need or, even worse, getting stuck with a unit that can't keep up when the pressure is on.

Let's start with the basics: pressure and flow rate. These are the two non-negotiable metrics for any compressor. Get these numbers wrong, and your equipment simply won't run correctly or efficiently.

Pressure (PSI/bar): First, figure out the maximum pressure your application demands. It’s wise to add a small buffer to account for pressure drops in your piping, but don’t go overboard. Generating unnecessarily high pressure is a massive waste of energy and money.

Flow Rate (CFM/LPM): Next, calculate the total volume of compressed gas needed to run everything at once—all your tools and processes. This is your peak demand. Your compressor absolutely must be able to meet this peak flow to avoid frustrating performance dips.

What kind of gas are you compressing? This is a critical question. You can’t just use a standard air compressor for reactive or high-purity gases. The materials and design might not be compatible, which could lead to contamination or even serious safety hazards.

Think about whether you're working with inert gases like nitrogen, flammable ones like hydrogen, or something corrosive. The compressor’s construction materials have to withstand the specific gas without degrading over time.

For applications in medical, food, or cryogenic fields, any hint of contamination is a deal-breaker. In these cases, an oil-free reciprocating piston compressor is the only real choice to guarantee absolute gas purity. This is especially true for delicate processes like those in our advanced liquid nitrogen generator systems, where purity is everything.

Where and how the compressor will be used also has a huge say in your final choice. Factors like its duty cycle and the surrounding ambient conditions play a massive role in the machine's performance and lifespan.

A compressor's duty cycle is the percentage of time it can run versus its total cycle time. A unit with a 50% duty cycle should only run for five minutes out of every ten. Mismatching the duty cycle to your needs is a common cause of premature equipment failure.

You also need to consider the temperature of the installation site. Hot environments can put a serious strain on the cooling system, while extreme cold can mess with lubricants and make start-ups difficult. No matter the climate, proper ventilation is essential to prevent overheating and ensure your reciprocating piston compressor has a long, productive life.

This careful approach to selection mirrors broader trends across the industry, where efficiency and specialised technology are becoming more important than ever. The global market, valued at USD 5.72 billion, is set to climb to USD 8.56 billion by 2034, largely thanks to industrial modernisation. Europe, in particular, is seeing major growth as tough regulations push industries toward more advanced, low-emission, and oil-free technologies. You can find more insights on these global market trends on Cognitive Market Research.

A reciprocating piston compressor is a serious investment in power and reliability, but its long-term performance comes down to proper installation and consistent upkeep. Getting these fundamentals right from day one is how you guarantee peak efficiency, stretch the machine’s service life, and keep your workspace safe. Skipping these steps, on the other hand, is the fastest route to expensive downtime and parts failing well before their time.

Proper installation starts from the ground up—literally. These compressors generate a fair bit of vibration thanks to the constant back-and-forth motion of the pistons, making a solid, level foundation non-negotiable. A dedicated concrete pad is usually the best bet; it soaks up vibrations and stops the machine from "walking" over time, which puts a huge strain on pipes and connections.

Where you put it matters just as much. A compressor needs to breathe, so good ventilation is absolutely critical for managing heat. An overheated compressor is an inefficient one, and it won't last long. You'll also want to plan your pipework to keep bends and long runs to a minimum, as these are notorious for causing pressure drops between the compressor and your tools.

Once your compressor is set up correctly, a proactive maintenance schedule is your best friend for ensuring its longevity. Don't think of it as a chore—it’s a simple health check for your equipment. A structured routine helps you spot small issues before they snowball into major, wallet-draining problems.

A smart approach is to break tasks down into daily, weekly, and monthly checks. This keeps the process from feeling overwhelming and ensures nothing gets missed.

Daily Checks: These are quick, five-minute visual inspections. Glance at the oil level (for lubricated models), drain any moisture from the receiver tank, and just listen. Any strange new noises or vibrations are early warnings of trouble.

Weekly Checks: Time for a slightly closer look. Pop open the air filters to check for dirt; clean or replace them if they're clogged. This is also a good time to check all the fittings and hoses for air leaks—a massive, and common, source of wasted energy.

Monthly Checks: Now we get a bit more hands-on. Check the belt tension to make sure you're getting efficient power transfer from the motor. Test the safety relief valve to confirm it's working, and give the cooling fins on the cylinder and intercooler a good clean to maintain optimal heat transfer.

Proactive maintenance is always, always cheaper than reactive repair. Keeping a simple logbook to jot down checks and findings creates an invaluable health record for the machine, making any future troubleshooting a whole lot easier.

Even with the best maintenance plan, things can still go wrong. Knowing how to quickly diagnose and fix common problems will save you a world of time and money. Here’s a quick-reference guide to help you figure out what’s going on with your reciprocating piston compressor.

| Symptom | Potential Cause | Recommended Action |

|---|---|---|

| Low Discharge Pressure | Clogged intake filter or leaking gaskets/hoses. | Clean or replace the air filter. Check all connections for leaks with soapy water. |

| Excessive Noise/Vibration | Loose mounting bolts or worn piston rings/bearings. | Tighten all anchor bolts. Schedule a service to inspect internal wear components. |

| Compressor Overheating | Poor ventilation, low oil level, or dirty cooling fins. | Improve airflow around the unit, top up the oil, and thoroughly clean all cooling surfaces. |

| Moisture in Air Lines | Malfunctioning air dryer or infrequent tank draining. | Drain the receiver tank daily. If you have an air dryer, inspect and service it. |

Following these best practices for installation and maintenance ensures your reciprocating piston compressor runs like a top, delivering the reliable, high-pressure performance your critical applications depend on.

Diving into the world of compressor technology always brings up a few questions. Below, we've tackled some of the most common queries we get about choosing, running, and caring for a reciprocating piston compressor.

Our aim is to give you the practical knowledge you need to feel confident with your equipment. These insights should help you make smarter decisions, whether you're trying to solve a problem or spec'ing out a new system.

Consistent servicing is the key to a long, reliable life for your compressor. While the perfect maintenance schedule really depends on how hard you run the machine and its working environment, a basic calendar is a great place to start.

For machines under constant, heavy load, a quick daily check is a must. For everything else, a more structured approach works best:

The main difference comes down to how many times the air gets squeezed. A single-stage compressor does the job in one go, compressing the air once before pushing it into the storage tank. These typically hit pressures around 10 bar (150 PSI) and are simpler and more budget-friendly for less demanding tasks.

On the other hand, a two-stage (or multi-stage) compressor works a bit harder. It compresses the air in a first cylinder, cools it down with an intercooler, and then sends that pre-compressed air to a second, smaller cylinder to be squeezed again. This two-step process is much more efficient and allows the machine to reach significantly higher pressures, often climbing past 15 bar (220 PSI). This makes it the go-to choice for serious industrial and specialist jobs.

The intercooling step is the secret sauce for multi-stage efficiency. By cooling the air between compressions, it becomes denser, meaning it takes less energy to squeeze it to the final high pressure.

That all depends on the compressor's duty cycle. Think of the duty cycle as the percentage of time a machine can safely run within a specific period before it needs a break to cool down. For instance, a compressor with a 75% duty cycle can run for about 45 minutes out of every hour without overheating.

Many of the smaller, consumer-grade reciprocating piston compressors you might see are built for intermittent work, with duty cycles of 50% or even less. Industrial-grade models, however, are a different beast entirely. They're constructed with heavy-duty components and better cooling systems, allowing for 100% continuous duty in the toughest environments. Always, always check the manufacturer's specs to avoid pushing your machine too hard and causing premature failure.

For state-of-the-art cryogenic solutions and expert advice on compressors for industrial gas applications, trust Cryonos GmbH. Explore our compliant, high-performance equipment at https://www.cryonos.shop.