No Products in the Cart

Welcome to the heart of your underwater world. This guide is all about demystifying sauerstoffflaschen zum tauchen—what most people call scuba tanks or diving cylinders. Right off the bat, let's clear up a huge misconception: while they're often called 'oxygen tanks', for recreational diving, they almost never contain pure oxygen. Instead, they're filled with good old compressed air or a specialised mix like nitrox.

Think of your cylinder like a mountaineer's oxygen supply or an astronaut's life support pack. It’s not just another piece of gear; it’s the one thing that lets you breathe and explore a world where humans simply can't survive on their own. We're going to build your understanding from the ground up, starting with the cylinder's vital role and covering everything you need to know to choose, use, and maintain it safely.

This foundational knowledge is absolutely crucial, especially when you consider how popular diving has become. In Germany alone, the diving community is massive. Recent data shows that 4.71 million people aged 14 and over sometimes go scuba diving, which really underscores the need for reliable equipment and solid safety knowledge. You can actually check out more German diving statistics on Statista.com.

Breathing pure oxygen under the pressure of the deep is a big no-no. It becomes toxic at surprisingly shallow depths, a dangerous condition known as oxygen toxicity that can lead to convulsions and drowning. This is exactly why recreational divers breathe carefully blended gases.

The air we all breathe at the surface is about 21% oxygen and 79% nitrogen. Your standard scuba tank contains this exact same mixture, just squeezed into the cylinder at high pressure. Specialised gas mixes like nitrox have a bit more oxygen (say, 32% or 36%), but they are still nowhere near the 100% mark.

Getting a handle on these gas properties is the very first step toward safe diving. If you want to dive deeper into the science, you might find our article on the properties of oxygen interesting.

To get us all on the same page, here’s a quick rundown of some key terms you'll see when talking about diving cylinders.

| Term | What It Means for a Diver |

|---|---|

| Working Pressure | The maximum pressure the cylinder is designed to hold safely. Typically measured in bar or psi. Don't overfill it! |

| Capacity | The volume of gas the cylinder can hold at its working pressure, usually measured in litres (e.g., 12-litre tank). |

| Hydrostatic Test | A mandatory pressure test performed every few years to check the cylinder's structural integrity. Your tank needs to pass this to be filled. |

| Visual Inspection | An annual check-up (inside and out) for any signs of corrosion, dents, or damage. Think of it as your tank's yearly health check. |

| Nitrox (EANx) | Enriched Air Nitrox. A breathing gas with a higher oxygen percentage (e.g., 32% or 36%) than regular air, allowing for longer bottom times. |

Familiarising yourself with this language will make it much easier to talk with dive professionals and understand your own equipment.

Our goal here is to walk you through the technical details, safety rules, and maintenance habits that turn a simple metal container into a piece of life-sustaining equipment you can trust. By the time you're done, you'll have a real appreciation for the engineering, regulations, and personal responsibility that come with using sauerstoffflaschen zum tauchen.

This knowledge empowers you to:

Treating your scuba tank with the respect it deserves is what ensures every single dive is a safe and unforgettable adventure. Let's get started by looking at what these critical cylinders are actually made of.

When you’re ready to buy your own sauerstoffflaschen zum tauchen, the first big decision on the table is the material. This isn’t just a small detail—it’s a choice that fundamentally shapes how you’ll feel and move underwater. The two main players are steel and aluminium, and each brings a completely different personality to your dive setup.

Think of it like choosing between a classic, rugged leather hiking boot and a modern, lightweight trail runner. Both will get you to the summit, but the experience will be worlds apart. Your final decision will come down to where you dive, your personal style, and what you value most in your gear. Let's get into the practical realities of each.

For many divers, especially those in the colder waters of Europe, steel cylinders are the go-to choice. Their biggest advantage is their inherent negative buoyancy. A steel tank wants to sink, even when it’s nearly empty, and that’s a fantastic trait for a diver.

This means you can often get away with carrying less lead on your weight belt. Imagine shedding two or three kilograms of dead weight—it’s a game-changer for comfort and streamlining in the water. Less weight pulling on your hips reduces strain on your lower back and makes achieving that perfect horizontal trim much easier.

Steel is also incredibly tough. Its robust construction can handle higher pressures, which allows some steel tanks to be physically smaller and more compact than aluminium ones holding the same volume of air. They are true workhorses, built to last for years, but this toughness comes with a critical trade-off.

The Catch with Steel: Rust

Steel's Achilles' heel is its vulnerability to rust, both inside and out. If moisture gets in during a fill or the outer paint gets compromised, corrosion can take hold. Meticulous care—proper rinsing after every dive and ensuring fills come from a source with clean, dry air—is absolutely non-negotiable.

You’ll find aluminium cylinders everywhere, from the rental racks of tropical dive resorts to the boats of divers all over the world. Their most celebrated feature is their fantastic resistance to corrosion, especially in salty marine environments. They are far more forgiving of the inevitable scratches and dings than their steel cousins.

On the boat deck, an aluminium tank is noticeably lighter to haul around, making the pre-dive setup feel a little less like a workout. But this lightweight nature introduces a defining characteristic that every diver using one must learn to manage: a significant buoyancy shift.

As you breathe down the air in an aluminium cylinder, it gets progressively lighter. A tank that was negatively buoyant at the start of your dive can become positively buoyant by the end. This is what causes that "floaty feet" feeling during your safety stop, and it means you have to carry extra lead from the beginning just to counteract this end-of-dive shift.

This change in buoyancy is a critical factor you have to bake into your weighting calculations. It's completely manageable, but it's something you always have to be aware of.

To really see the differences, it helps to put them side-by-side. Think about your own diving habits and what matters most to you as you look over this comparison.

| Characteristic | Steel Cylinders | Aluminium Cylinders |

|---|---|---|

| Buoyancy | Negatively buoyant throughout the dive, often reducing the need for extra weight. | Starts negatively buoyant but can become positive when empty, requiring more weight to compensate. |

| Durability | Extremely tough and resistant to dents and damage from impacts. | Softer metal that is more prone to dings, dents, and scratches. |

| Corrosion | Highly susceptible to rust if moisture is present. Requires diligent care. | Very resistant to corrosion, making it a lower-maintenance choice in saltwater. |

| Weight on Land | Heavier to carry and transport out of the water. | Lighter and easier to handle on the boat or shore. |

| Cost | Generally more expensive upfront due to manufacturing complexity. | Typically more affordable, making it a popular choice for new divers and rental fleets. |

At the end of the day, there's no single "best" material. The right cylinder is the one that fits your needs, your budget, and the kind of diving you love to do. Cold-water divers often swear by steel for its fantastic buoyancy characteristics, while world travellers might prefer the worry-free, corrosion-resistant nature of aluminium. Consider your priorities carefully, and you’ll choose a cylinder that will become a trusted and reliable part of your life support system for years to come.

Now that we’ve covered the materials that make up sauerstoffflaschen zum tauchen, let’s turn our attention to the bit that actually controls your gas supply: the valve. Think of it as the gatekeeper, standing between the high-pressure air in your cylinder and the regulator you breathe from. Getting to grips with how it works is absolutely fundamental to diving safely.

While you might see a few different designs, most valves fall into a simple category called the K-valve. It’s the most common type in recreational diving and works with a straightforward on/off knob, much like a tap. The real difference, and the part that matters most to you as a diver, is how your regulator connects to it.

There are two main systems that dominate the diving world: Yoke and DIN. Each has its own design philosophy and you’ll find them in different parts of the world.

The Yoke system, often called an A-clamp, is what you'll find almost everywhere in North America and popular tropical holiday spots. It’s a simple concept: a clamp on your regulator fits over the top of the cylinder valve and you tighten a screw to hold it in place. A small, black O-ring on the valve face creates the seal.

It’s a bit like a garden hose fitting—easy to connect, widely available, and totally reliable for the pressures used in standard recreational diving, which is typically up to 232 bar. For most holiday divers, the Yoke system is all they’ll ever see or need.

The DIN system, on the other hand, is the standard across Germany and much of Europe. DIN stands for Deutsches Institut für Normung, and its design is quite different. Instead of clamping over the valve, the regulator screws directly into it. This captures the O-ring between the two metal surfaces, creating a much more secure, high-pressure seal. It’s more like an industrial fitting built for serious work.

This robust connection makes DIN the go-to choice for technical divers and anyone using high-pressure steel cylinders (up to 300 bar). The connection is better protected and far less likely to get knocked or accidentally dislodged.

Key Takeaway: While Yoke is user-friendly and widespread, DIN offers a more secure, robust connection that is dominant in Europe and essential for technical diving. Many modern regulators offer convertible fittings, giving you the best of both worlds.

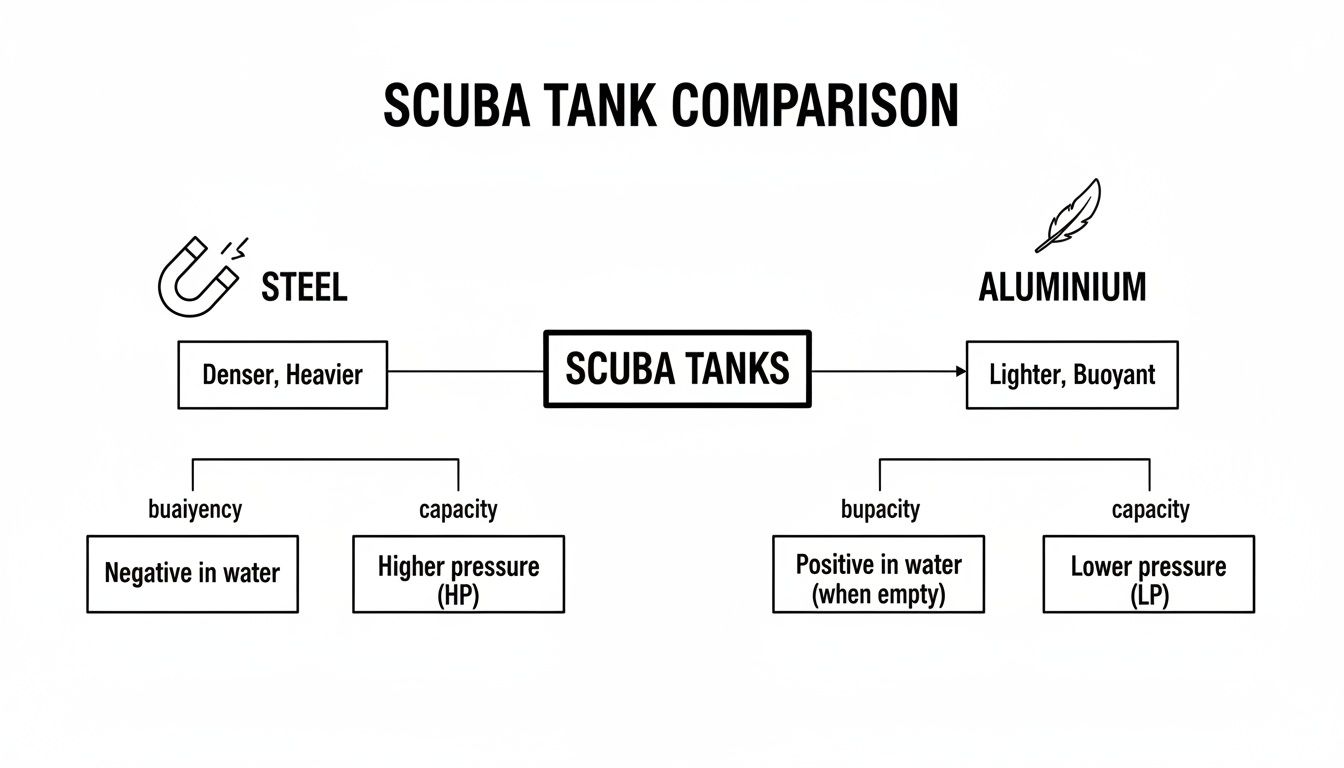

This visual comparison below doesn't show the valves themselves, but it highlights the differences in the cylinders they attach to. The choice between steel (often higher pressure, favouring DIN) and aluminium is a big part of the equation.

As the infographic suggests, steel's higher pressure capacity pairs perfectly with the rugged nature of DIN valves, while aluminium's characteristics make it a great fit for the globally common Yoke system.

Beyond the mechanics of the valve, there's a vital safety procedure that every diver using enriched air nitrox needs to understand: oxygen cleaning. This is easily one of the most misunderstood topics in diving. It has absolutely nothing to do with filling a tank with pure oxygen to breathe.

Oxygen cleaning is a meticulous, specialist servicing procedure. It means a technician completely disassembles the cylinder and valve, then thoroughly cleans every single component to remove any trace of contaminants like dust, oil, or hydrocarbon-based grease.

So, why is this so critical? Standard compressed air naturally contains microscopic oil particles from the filling compressor. In regular air (21% oxygen), these are harmless. But in an oxygen-rich environment, they become an extreme fire hazard.

When a cylinder is filled with gas blends containing more than 40% oxygen, the combination of high O2 concentration and the high pressure of the fill can cause these tiny oil particles to spontaneously ignite. This can lead to a fire or even a violent explosion. Oxygen cleaning simply removes the fuel from this dangerous equation, making the equipment safe for high-oxygen blends.

This isn't just a good idea; it's a non-negotiable safety standard across the entire diving industry. It ensures your gear can handle the unique chemical properties of enriched air, making you a smarter, more responsible, and much safer diver.

Owning a sauerstoffflasche zum tauchen in Germany isn't just about the purchase; it's about taking on a serious responsibility for safety and staying on the right side of the law. These regulations aren't just bureaucratic hoops to jump through. They're a solid framework designed to protect you, your dive buddy, and the staff at the fill station from the catastrophic failure of a high-pressure vessel.

Think of it like the mandatory service schedule for a high-performance car. You wouldn't dream of skipping an oil change or a brake inspection, and the very same logic applies here. Following these standards ensures your cylinder remains a trusted piece of life-support equipment, not a ticking time bomb. Let's walk through the essential checks every cylinder owner needs to know.

With the diving community growing, these safety measures are more critical than ever. The German scuba diving equipment market was recently valued at around USD 265.99 million, with forecasts suggesting it could top USD 400 million in the next decade. More divers mean more cylinders in circulation, which puts a huge emphasis on consistent, regulated testing to keep everyone safe. You can check out more stats on the German scuba market over at deepmarketinsights.com.

The most common check-up your cylinder will get is the visual inspection. You'll often hear it referred to by its German abbreviation, TÜV (Technischer Überwachungsverein), though it's carried out by certified technicians. This is required every single year and is absolutely fundamental to cylinder safety.

Here’s what the technician will do:

If everything checks out, the cylinder gets a sticker with the inspection date, giving it a clean bill of health for another year. This annual once-over is your best defence against internal corrosion, which is a silent threat you’d never spot from the outside.

While the visual inspection looks at the surface, the hydrostatic test gets to the very soul of the cylinder—its structural integrity. In Germany, this intense test is required every five years. It’s designed to see exactly how the cylinder's metal expands and contracts under extreme pressure.

The process involves filling the cylinder with water and submerging it in a sealed, water-filled chamber. The cylinder is then pressurised to a level well beyond its normal working pressure. Technicians measure the amount of water displaced, which tells them precisely how much the cylinder walls expanded.

This expansion has to be within strict, legally defined limits. If it expands too much or doesn't shrink back to its original size, it means the metal has lost its elasticity and is no longer safe. A failed cylinder is condemned on the spot and must be taken out of service for good. Passing this test is non-negotiable if you want to get your tank refilled.

The neck of every sauerstoffflasche zum tauchen is stamped with a series of codes that basically tell its life story. Learning to read these markings is a key part of being a responsible owner.

Getting a handle on these markings and the testing schedule is just as important as knowing your dive tables. It's also just as vital as understanding the rules for moving your gear safely. For more on that, you can learn more about the regulations for transporting gas cylinders in our detailed guide.

Your responsibility for your sauerstoffflasche zum tauchen doesn't end when you leave the dive site. How you handle your cylinder during transport and storage is every bit as critical as your procedures in the water. Getting these day-to-day habits right protects your gear, your vehicle, and everyone around you.

It helps to think of a full scuba cylinder as a store of controlled energy. If it were to fall over and the valve sheared off, that energy would be released instantly, turning the cylinder into a dangerous, uncontrolled projectile. That’s why securing it properly in your vehicle isn't just a suggestion—it's absolutely essential.

The golden rule for transporting any high-pressure cylinder is to stop it from rolling, sliding, or taking a hard knock. The simplest and most stable method is to lay the cylinder down lengthwise in the boot of your car, braced so it cannot move.

Protecting the valve is your number one priority. Some divers use dedicated padded bags for their cylinders, which is a great idea. At a minimum, make sure the valve is positioned away from hard surfaces and use a protective dust cap over the valve opening. For a deeper dive, check out our guide on the importance of a protective cap for your gas cylinder.

Where you store your cylinder between dives can make a huge difference to its lifespan. The aim is to create a stable environment that keeps corrosion at bay and preserves the integrity of the cylinder and its valve.

Always store your cylinder in a cool, dry place away from direct sunlight and big temperature swings. A garage or basement is usually a good spot, as long as it isn't damp. Crucially, the cylinder should be stored standing upright and secured so it can't be knocked over.

Here’s a vital tip: always leave a little bit of pressure in the tank—somewhere around 20 to 30 bar. This small amount of positive pressure ensures that moist, ambient air can't seep inside, which is the main culprit behind internal rust. An empty cylinder is basically an open invitation for corrosion to start.

The sheer scale of diving in Germany underscores why these practices are so important. With roughly 460,000 regular divers, the number of personally owned cylinders is massive. This entire community relies on these established best practices to keep everyone safe.

Finally, a simple but consistent post-dive routine is your best defence against long-term damage, especially after a dip in saltwater.

Building these simple habits into your routine will ensure your sauerstoffflasche zum tauchen remains a reliable and safe piece of life-support equipment for many years of diving.

This guide was designed to give you a solid foundation, breaking down the tech and science behind your most critical piece of gear into concepts you can actually use. Think of it as moving past the "what" and into the "why."

You're no longer just looking at a tank; you see the practical trade-offs between steel and aluminium and how that choice plays out with your weighting and trim underwater. You can now walk into a dive shop and know the difference between a Yoke and a DIN valve, and more importantly, you understand that oxygen cleaning isn't an optional extra—it's a non-negotiable for anyone diving with enriched air.

But understanding the gear is only the first step. The real mark of a competent diver is the commitment to the routines that keep you safe. Adhering to German testing regulations, which means getting that annual visual inspection and the periodic hydrostatic test, isn't just about following rules. It’s a core responsibility. This discipline, combined with proper day-to-day care, is what turns a metal cylinder into a lifeline you can trust.

The big takeaway is simple: your best tools as a diver are knowledge and responsibility. That sauerstoffflaschen zum tauchen on your back is much more than just equipment. It’s your personal life support system, and it demands your full respect and attention.

This is what separates the underwater tourists from the truly skilled divers.

Becoming a confident, safe diver is a journey, not a destination. The best thing you can do now is take what you've learned here and build on it with real-world experience and advice.

Here’s a simple action plan to get you started:

Treat every dive as a new opportunity to learn something and sharpen your skills. When you invest in your own knowledge, you’re ensuring every moment underwater is not just exciting, but fundamentally safe. That commitment doesn't just make you a better diver; it makes you a better, more reliable buddy to everyone you share the water with.

Even when you feel you know your gear inside and out, new questions always seem to pop up. Think of this as your quick-fire round for some of the most common queries we hear about sauerstoffflaschen zum tauchen—those practical, need-to-know details that surface right before a dive.

Absolutely not, and getting this wrong is a serious safety risk. For any gas blend with over 40% oxygen, both the cylinder and its valve must be “oxygen cleaned.” This is an incredibly detailed process that strips out any trace of hydrocarbon contaminants. Why? Because under the high pressures and oxygen levels found in diving, these contaminants can spontaneously combust.

Never, ever fill a standard air-only cylinder with high-percentage nitrox.

This is the classic "how long is a piece of string?" question in diving. The honest answer is: it depends entirely on you and your dive plan. There’s no single number, as several factors are always at play.

To put it in perspective, a diver might get over an hour from a standard 12-litre tank while exploring a shallow 10-metre reef. Take that same tank on a 30-metre dive, and you could be looking at just 20-25 minutes.

The core difference is all about the equipment—or lack thereof. Scuba diving, which stands for Self-Contained Underwater Breathing Apparatus, is built around a sauerstoffflasche zum tauchen. It supplies you with air, letting you stay down and breathe continuously for long periods.

Freediving, sometimes called apnoea diving, is the complete opposite. It’s the raw, unfiltered sport of exploring the ocean on a single breath, with no breathing gear at all.

Freedivers push the limits of human physiology, relying solely on their own lung capacity and adaptations. The current male world record for static apnoea (holding your breath) is a mind-boggling 11 minutes and 35 seconds, set by Stéphane Mifsud. It’s a powerful reminder of what the human body can do when all the gear is stripped away.

That sharp, painful feeling is the direct result of water pressure squeezing your eardrums. As you go deeper, you absolutely have to equalise this pressure. The most common way is the Valsalva manoeuvre: pinch your nostrils and gently blow. You should do this every metre or so on your way down.

If you feel pain and can't equalise, stop. Ascend a little and try again. Never force it. Pushing through the pain is a surefire way to cause a serious ear injury.

At Cryonos GmbH, we build state-of-the-art gas storage and transport solutions designed for ultimate safety and reliability. Whether your needs are industrial or scientific, our equipment is engineered to meet the highest standards. You can explore our full range of compliant, durable cryogenic and gas cylinder solutions at https://www.cryonos.shop.