No Products in the Cart

A Schutzkappe für Gasflaschen is, quite simply, the helmet for a high-pressure gas cylinder. It’s a dedicated safety device with one critical job: to shield the valve assembly—by far the most fragile and sensitive part of the cylinder—from any impacts that could lead to a catastrophic failure.

It helps to think of a high-pressure gas cylinder as a source of contained, high-potential energy. The valve is what gives you control over that energy, but it's also the cylinder’s Achilles' heel. An unprotected valve is dangerously exposed to damage if the cylinder is dropped, knocked over, or hit during transport.

A direct impact can shear the valve right off, instantly releasing the highly compressed contents. This turns the heavy steel cylinder into an unguided projectile with enough force to smash through concrete walls, presenting an unimaginable risk to your team and facility. The Schutzkappe für Gasflaschen is engineered specifically to absorb and deflect these kinds of impacts, keeping that danger contained.

But it's not just about guarding against heavy impacts. These caps are also designed to prevent the valve handle from being accidentally opened during routine handling and storage. This is absolutely essential in busy environments like industrial workshops, biobanks, or labs where cylinders are constantly being moved around.

Here in Germany, using a protective cap isn't just a recommendation—it's a strict legal requirement for transport and storage. Regulations demand that every gas bottle must have its valve securely closed and a compliant cap fitted whenever it's not in use. Failing to do so can lead to serious fines during an inspection, a point often emphasised in German gas supplier guidelines.

A Schutzkappe is a simple device, but it serves multiple crucial safety roles in any setting that uses compressed gases. Below, we've broken down its core functions and the real-world benefits they provide.

| Core Functions of a Gas Cylinder Protective Cap |

| :--- | :--- | :--- |

| Protective Function | Specific Risk Prevented | Operational Benefit |

| Impact Shielding | The valve assembly being sheared off or damaged by a fall or collision. | Prevents catastrophic, uncontrolled gas release and the "rocket effect." |

| Accidental Opening Prevention | The valve handle being unintentionally turned by contact with other objects. | Stops dangerous leaks during transport, handling, and storage. |

| Contamination Guard | Dust, moisture, and debris entering the sensitive valve outlet. | Ensures a clean, reliable connection when attaching regulators. |

| Regulatory Adherence | Violating transport laws like the ADR and German safety regulations. | Avoids legal penalties, operational downtime, and liability issues. |

Ultimately, a properly fitted valve cap is doing a lot more than just covering the valve; it’s an active safety component that mitigates multiple points of failure.

For any facility managing cryogenic liquids or high-pressure industrial gases, using a valve cap is a non-negotiable part of a robust safety protocol. It’s an inexpensive piece of hardware that prevents high-consequence, high-cost accidents. To get a better sense of what these cylinders contain, feel free to explore our article on the properties of gas in cylinders.

To really get a handle on the schutzkappe für gasflaschen, you need to understand the rules that govern them. It's easy to see these standards as just red tape, but they're actually a carefully crafted safety net, built on decades of engineering experience and real-world incident analysis. They exist to make sure every single cap performs exactly as it should under pressure—both literally and figuratively.

The whole framework really starts with transport regulations. The big one here is the ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road). This is the cornerstone of gas cylinder safety across Europe. It mandates that any gas cylinder travelling on public roads must have a protective cap that shields the valve from any potential impact.

Beyond just getting from A to B safely, specific technical standards dictate what a valve cap is made of and how it's built. These are the blueprints that guarantee a cap can take a hit. Two of the most important ones you'll come across are:

When you buy a cap that meets these standards, you have peace of mind knowing it’s been put through its paces to do its one crucial job: protect the valve. A huge part of this is standardised threading, with the W80x1/11" being the most common interface for technical gas cylinders in Germany and across Europe. This ensures a snug, secure fit every time.

Think of it this way: The legal and technical rules form a complete safety system. The ADR gives the legal "why" for transport, while standards like ISO 11117 provide the engineering "how," proving the equipment is up to the task.

While the ADR is king of the road, specific German regulations take over once the cylinders are inside your facility. These rules are especially strict, and for good reason—they're designed to prevent accidents in enclosed spaces.

For instance, German regulations are very clear about the indoor storage of propane cylinders. Guidelines from major suppliers like Tyczka Energy state that a residential apartment can't have more than two 16 kg propane bottles. Only one is allowed per room, and they are completely forbidden in bedrooms. Each one has to be fitted with a schutzkappe für gasflaschen to contain the risk, which is critical when you consider that gaseous propane expands to 260 times its liquid volume.

It's the same story for high-pressure gases. Suppliers like Linde Gas confirm that all their high-pressure cylinders, including those used in Cryonos' AC LAC XL series, must have their valve caps on whenever they aren't actively in use. This prevents any accidental manipulation of a valve holding back pressures that can hit 200-300 bar.

These local rules really drive home the point that the valve cap is a vital part of the entire safety lifecycle, from the delivery truck to its spot in your storage area. For a closer look at the transport side of things, check out our guide on gas cylinder transport regulations. Having this knowledge helps you shift from simply following the rules to proactively managing risk in your day-to-day operations.

Picking the right schutzkappe für gasflaschen isn’t just a matter of finding one that fits. It’s about matching the cap’s material and design to the real-world risks of your work. The choice you make has a direct line to the level of protection you get, making this a critical decision for any lab, biobank, or industrial site handling compressed gases.

Your two main options will almost always be galvanised steel or some form of high-density plastic.

Think of it like this: you wouldn’t wear a simple plastic bicycle helmet for professional motorsport. It just doesn’t offer the right kind of protection. The same logic applies here. Steel caps are the undisputed gold standard for high-pressure industrial and cryogenic gases—things like the liquid nitrogen in biobanks or pure argon in advanced labs. Their ability to take a serious hit is non-negotiable when a sheared-off valve could lead to catastrophe.

Plastic caps, on the other hand, have their place. They’re lighter and won’t corrode, which is why you see them on lower-pressure cylinders like those for propane. While perfectly fine for that job, they just don't have the raw strength to shield a valve from the kind of high-energy impact that could happen during transport or in a busy industrial setting.

For nearly all industrial and scientific work, galvanised steel is the go-to choice for a schutzkappe für gasflaschen. It’s not just a chunk of metal; its entire construction is engineered to meet tough safety standards.

German standardisation is a huge help here, ensuring caps and cylinders actually work together, especially for the technical gases we handle at Cryonos GmbH. For instance, common specs call for W80x1/11" threading and galvanised steel, following standards like ISO 11117 and EN 962 for all technical gases from oxygen to CO2. These rules ensure that a cap weighing around 0.45 kg gives you reliable protection across a whole family of cylinders. For a closer look at these specs, you can explore product examples on Gasprofi.de.

Beyond the material, the design itself is vital. You’ll notice that most caps have small holes in them. These aren't just for show; they’re a critical safety feature to stop pressure from building up where it shouldn't.

Imagine a tiny, slow leak from the valve packing. A non-vented cap would trap that escaping gas. Over time, the cap itself could become pressurised, effectively turning it into a dangerous projectile the moment someone tries to unscrew it. Vented designs let that gas escape harmlessly.

For any work with cryogenic gases where thermal expansion is a real thing, or in any high-pressure situation, a vented steel schutzkappe für gasflaschen is an absolute must. Non-vented caps are really only for very specific, low-risk uses where the main worry is keeping contaminants out, not letting pressure out. Always double-check which design is right for your gas and your environment.

A protective cap is only as good as its fit. Even the most robust schutzkappe für gasflaschen is completely useless if it’s loose, cross-threaded, or forced onto the wrong cylinder. Getting this simple procedure right isn't just best practice; it's a fundamental pillar of gas safety that stops accidents before they ever get a chance to happen.

Think of it as a methodical, non-negotiable part of your routine. Before you even reach for the cap, your first move should always be to double-check that the cylinder valve is fully and securely closed. Trying to install a protective cap on an open valve is a recipe for disaster.

Once you've confirmed the valve is shut tight, you're ready for a quick pre-installation check. This simple step ensures you have the right gear for the right cylinder.

Before you twist that cap on, take a few seconds to run through a quick compatibility check. It’s a tiny investment of time that pays huge dividends in safety and prevents costly damage to your cylinders and caps.

To make it even easier, here's a quick checklist to run through before every installation.

| Verification Step | What to Check | Common Standard |

|---|---|---|

| Thread Inspection | Look for dirt, debris, rust, or visible damage (cross-threading, stripping) on both the cap and the cylinder neck ring. | N/A |

| Thread Standard Match | Ensure the cap's thread specification matches the cylinder's. The threads must be identical. | W80 x 1/11" (for most DE technical gases) |

| Cap Integrity | Visually inspect the cap itself for significant cracks, deep dents, or structural deformities. | N/A |

This process confirms you're working with safe, compatible equipment. If anything looks off, don't proceed. Grab a different cap.

A damaged cap provides a false sense of security. Its structural integrity is shot, meaning it could easily fail to protect the valve during an impact. If you find a damaged cap, it must be replaced immediately—no exceptions.

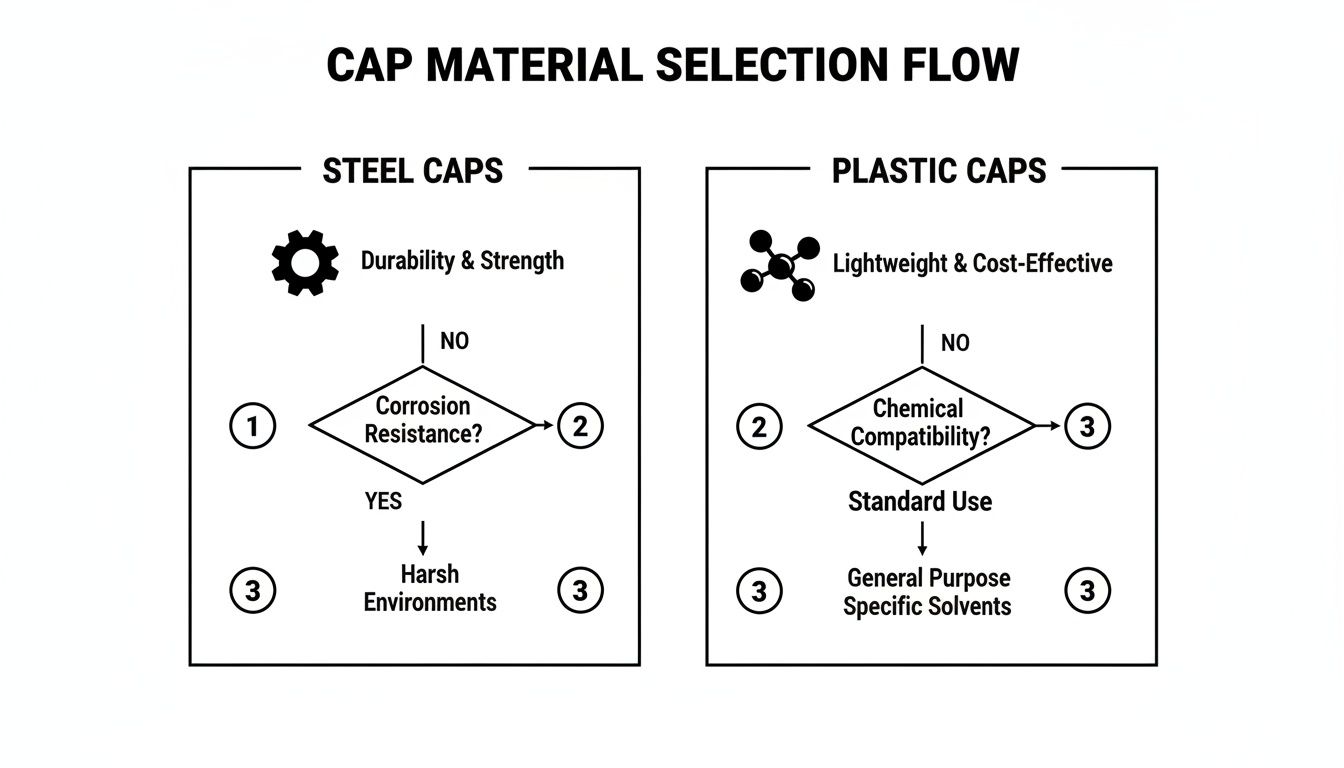

The material of the cap plays a huge role in its durability and suitability for your specific environment, as this flowchart shows.

As you can see, steel is the go-to choice for high-pressure, high-risk industrial settings where toughness is paramount, while plastic is typically reserved for lower-risk applications.

With your checks done, the installation itself is refreshingly simple. Carefully align the threads of the cap with the cylinder's neck ring, making sure it's sitting level and not at an angle.

Start turning the cap clockwise by hand. It should spin on smoothly with zero resistance. If you feel it binding or catching, stop right away. Back it off, check the alignment again, and restart. Trying to force it is the fastest way to ruin the threads.

Keep turning the schutzkappe für gasflaschen by hand until it’s snug and firm. That's it—job done.

Now for the most critical part: Never use a wrench, pipe, or any other tool to tighten a protective cap. These caps are engineered to be hand-tightened only. Using a tool creates way too much torque, which can easily strip the threads on both the cap and the cylinder itself, rendering both completely unsafe. A good, firm hand turn is all you need for a secure fit.

Popping a schutzkappe für gasflaschen on is a great first step, but real safety comes from keeping a watchful eye on it over time. Think of it less as a one-time task and more as a continuous process. Integrating a simple, routine inspection into your workflow is the best way to make sure your caps are delivering the protection you rely on, month after month.

This regular check doesn’t have to be some drawn-out procedure. It’s a quick visual scan you can do every single time you handle a cylinder. When it becomes second nature, you’ll be spotting potential problems long before they have a chance to become genuine hazards in your facility.

A good, thorough look-over takes only a few seconds. Before you screw a cap on, or just after you take one off, pause for a moment to check for any obvious signs of wear, tear, or damage. These are the red flags that tell you a cap's structural integrity might be on the line.

Zero in on these four critical areas:

If you spot any of these issues, the next step is simple and absolute.

A damaged Schutzkappe is a compromised Schutzkappe. It offers a false sense of security and must be taken out of service and replaced immediately. Never attempt to repair or continue using a cap that shows signs of significant damage.

How you store your caps is just as important as how you inspect them. A protective cap left rolling around on the floor is just waiting to be run over, kicked, or have its threads filled with dirt and grime.

To avoid this, set up a specific, clean, and dry spot to store caps when their cylinders are hooked up and in use. This simple habit keeps them in prime condition, so they're always ready to be re-installed. For more on this, our guide on the correct storage of oxygen cylinders offers some great insights that apply to all compressed gas cylinders.

Choosing the right schutzkappe für gasflaschen isn’t just a one-off purchase; it’s a critical piece of a much larger safety puzzle. This is especially true in demanding environments like biobanks, labs, and industrial gas facilities.

A high-quality cap is more than just a piece of hardware. Think of it as the foundation of your commitment to keeping your people and your facility safe, day in and day out, while also meeting strict regulations.

At Cryonos, this is a world we know inside and out. We don’t just sell products; we deliver complete safety ecosystems built on decades of real-world experience.

When you work with us, you're getting a partnership grounded in deep technical knowledge and a genuine commitment to your facility's long-term security. That means you can count on us for:

Choosing Cryonos means you're not just buying a product. You're gaining a partner dedicated to helping you build a safer, more compliant workplace from the ground up.

Let our team help you find the precise safety equipment for your cryogenic vessels and gas cylinders. Together, we can strengthen your safety protocols and protect your most valuable assets—your people and your research.

When it comes to gas cylinder safety, a few common questions always pop up. Let's clear the air and walk through the specifics of the schutzkappe für gasflaschen so you can be sure you're operating safely and staying on the right side of the regulations.

Yes, for the most part. In Germany and under the European ADR transport regulations, a protective valve cap is mandatory for nearly all gas cylinders during transport and while in storage. This isn't just a suggestion; it's a legal requirement that covers a huge range of industrial, medical, and common gases like propane.

Running a cylinder without a proper cap is a serious safety violation and can get you hit with significant fines during an inspection. The only real exception is when a cylinder is securely connected to an apparatus within a fixed, stable installation.

Sizing is all about the thread on the cylinder's neck ring, not the physical size of the bottle itself. Get the thread right, and you've got the right fit.

Luckily, standardisation makes this pretty straightforward. The vast majority of technical gas cylinders you'll encounter in Germany and across Europe use a W80 x 1/11" thread.

To be absolutely sure, it's always best to confirm this specification with your gas supplier or check the cylinder’s documentation. Trying to force a cap with the wrong thread size is a recipe for disaster—it will either be too loose to offer any real protection or you'll end up damaging the cylinder's threads.

Absolutely not. You should never, ever use a wrench, pipe, or any other tool to tighten a schutzkappe für gasflaschen. These caps are designed to be secured by hand, and only by hand.

Using a tool applies far too much force (torque), which can easily strip the threads on both the cap and the much more expensive cylinder neck ring. This kind of damage makes the cap unsafe, a nightmare to remove, and compromises the integrity of the cylinder itself. A firm, snug turn by hand is all it takes for a secure and safe fit.

If a protective cap shows any real signs of damage, take it out of service and replace it immediately. A compromised cap is a major safety hazard, plain and simple.

Keep an eye out for these clear warning signs:

A damaged cap can't be trusted to do its job in a collision. Using one just creates a false sense of security and puts your people and your facility at risk. Don't hesitate—just discard and replace it.

At Cryonos GmbH, we don't just supply parts; we provide a complete ecosystem of safety solutions for demanding lab and industrial environments. From ADR-licensed transport to expert technical support, we make sure you have the right accessories to operate safely and stay compliant. Find the correct safety equipment for your cryogenic vessels and gas cylinders today.