No Products in the Cart

Wolfram Inertgas Schweißen is what we call Tungsten Inert Gas (TIG) welding in German. It’s a highly precise arc welding process, famous for creating exceptionally clean, strong joints. The secret lies in its use of a non-consumable tungsten electrode to generate the weld, giving the welder incredible control and top-quality results, especially on thinner metals.

Imagine performing surgery on metal. That’s the kind of precision you get with Wolfram Inertgas Schweißen. It's less about raw power and more about finesse, which makes it the go-to method for any job where perfection is the only option. What really sets it apart from other welding methods is that the electrode creating the arc isn't consumed during the process.

This core element—a durable tungsten electrode—sparks a highly stable and focused electric arc between its tip and the workpiece. The intense heat from this arc melts the base metals, allowing them to fuse together. At the same time, a constant flow of inert gas bathes the molten weld pool, acting as a vital protective shield.

This shield is the "Inertgas" part of the name, and it's absolutely critical for a successful weld. We use gases like argon or helium because they are chemically inactive. Their job is to push away atmospheric oxygen and nitrogen, which would otherwise contaminate the molten metal and introduce defects like porosity or brittleness. This protective bubble ensures the finished weld is pure and strong.

You can dive deeper into how different gases influence the final weld in our guide on welding shielding gases.

Unlike MIG welding, where filler wire is fed automatically through the torch, TIG welding puts the operator in complete command. The welder holds the torch in one hand to manage the arc and manually feeds a separate filler rod into the weld pool with the other.

This two-handed technique is what separates TIG welding from other processes. It provides independent control over the heat input from the arc and the amount of filler material added, enabling the creation of flawless, aesthetically pleasing weld beads.

This high degree of control allows for incredibly precise work on a huge range of materials, including:

It’s this combination of precision and control that makes Wolfram Inertgas Schweißen the premier method for creating welds that are as strong as they are visually perfect.

To get the kind of precision Wolfram‑Inertgas Schweißen is famous for, you absolutely need the right gear. A proper TIG setup is much more than just a torch and a power cord; it’s a complete system where every single piece has a critical job to do. Understanding how these parts work together is the first real step toward mastering the craft.

The heart of the entire operation is the power source. Think of it as the brain, controlling the electrical current that strikes and maintains the arc. These machines aren't one-size-fits-all, and the type you choose determines which metals you can work with.

Picking the wrong power source won't just give you a sloppy weld—it might not create a weld at all. It's a foundational choice.

The most common TIG welders you'll encounter are Direct Current (DC), Alternating Current (AC), or versatile machines that offer both (AC/DC). Each has a specific role to play.

Your power source dictates your capabilities, so matching the machine to your most common projects is the first big decision. Next up is the tool you'll actually hold in your hand: the TIG torch.

The TIG torch is far more than a simple handle. It’s a precision instrument designed to deliver current to the electrode while bathing the weld in a protective cloud of shielding gas. Its main components work in harmony to produce a stable, controlled arc.

The collet is a small but mighty component that grips the tungsten electrode, holding it firmly inside the torch. The ceramic cup (or nozzle) slides over the collet and does the vital job of directing the shielding gas evenly over the weld area. Finally, the back cap screws onto the rear of the torch, sealing it and helping to secure the electrode.

Each part of the torch must be correctly sized for the tungsten electrode you are using. A mismatch can lead to poor gas coverage, an unstable arc, and ultimately, a contaminated weld.

The tungsten electrode is the real star of the Wolfram‑Inertgas Schweißen show. This is the non-consumable element that carries the welding current and forms the arc. Tungsten is used because of its mind-bogglingly high melting point of 3,422°C, which lets it endure the arc's intense heat without melting into the weld pool.

These electrodes are alloyed with different oxides to enhance their performance, and they are colour-coded to make your life easier. Choosing the right one is absolutely critical for arc stability and the quality of your finished weld.

The colour on the tip of a tungsten electrode isn't just for show—it tells you exactly what it's designed for. This quick guide breaks down the most common types.

| Electrode Type (ISO/AWS) | Colour Code | Primary Application | Arc Characteristics |

|---|---|---|---|

| Pure Tungsten (WP) | Green | Aluminium & Magnesium (AC welding) | Good arc stability for AC |

| 2% Thoriated (WT20) | Red | DC welding on steel & stainless steel | Excellent arc starting, high current |

| 2% Ceriated (WC20) | Grey | All-purpose for AC/DC, good at low amperages | Good arc starting, stable at low current |

| 1.5% Lanthanated (WL15) | Gold | Excellent all-purpose for both AC and DC welding | Versatile, easy arc starting, very stable |

Today, many welders are moving towards Lanthanated (gold) electrodes as a great all-around choice. They perform brilliantly on both AC and DC and are a non-radioactive alternative to the traditional thoriated electrodes.

The final key consumable is the shielding gas. As the name Wolfram Inertgas Schweißen suggests, an inert gas is essential to shield the molten weld pool from oxygen, nitrogen, and other troublemakers in the atmosphere. The two most common gases for the job are Argon and Helium.

Argon is the undisputed champion of TIG welding gases. It’s heavier than air, which allows it to provide excellent shielding coverage, and it promotes a characteristically stable and smooth arc. For a deeper dive into gas selection, check out our TIG welding gas guide.

Helium is sometimes mixed with Argon to produce a hotter arc. This extra heat allows for faster travel speeds and deeper penetration on thick materials, especially aluminium. For the vast majority of TIG applications, however, pure Argon is the standard, offering the perfect balance of performance and cost.

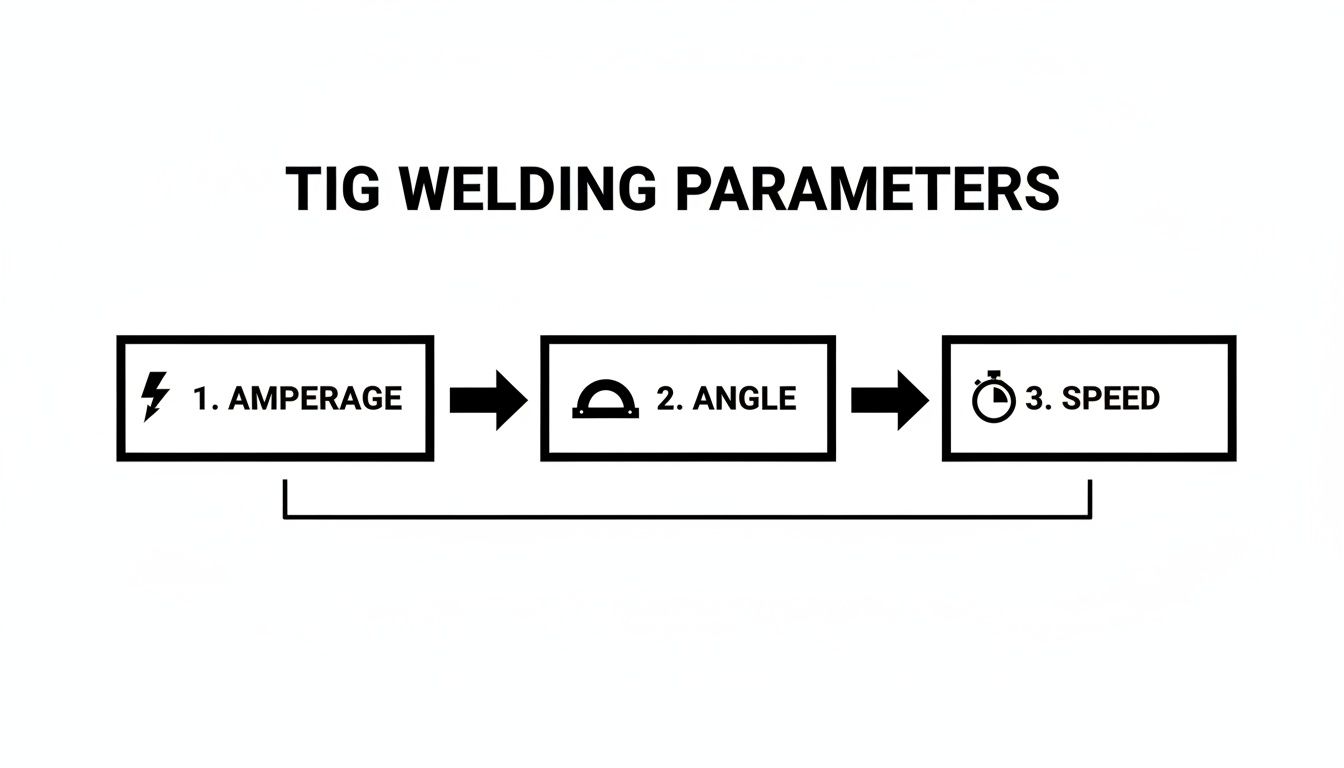

With the right equipment laid out, the real work begins. This is where the science of Wolfram-Inertgas-Schweißen meets the art of the human hand. A perfect weld isn’t the result of one magic setting; it’s a delicate balance of multiple variables, each one directly impacting the final quality. Think of it like conducting an orchestra—amperage, travel speed, torch angle, and gas flow must all work in perfect harmony.

Nailing these parameters is what separates an amateur weld from a professional one. Even a slight miscalculation can lead to defects, a weak joint, or just a plain messy finish. Let's break down each critical variable so you can gain the control needed to produce strong, clean, and visually flawless welds every time.

Amperage is simply the measure of electrical current flowing through the arc, and it’s your main dial for controlling heat. The basic rule is straightforward: more amperage means more heat and deeper penetration. The real skill is matching the amperage to the thickness of the material you’re working with.

A great starting point is the old rule of thumb: one amp for every thousandth of an inch (0.025 mm) of material thickness. So, for a piece of steel that's 1/8-inch (3.2 mm) thick, you'd start around 125 amps. This is just a guideline, of course. Things like the type of joint and the metal’s conductivity will require you to adjust from there.

Once your amperage is set, the next two variables you control in real-time are your arc length and travel speed. These two are deeply connected and demand a steady, practised hand.

Arc length is the distance between the tip of your tungsten electrode and the workpiece. For the best control, you want to keep this distance tight and consistent—roughly the same as the diameter of the electrode itself. A short arc concentrates the heat, giving you better penetration and a narrower, more manageable weld bead.

Travel speed is all about how quickly you move the torch along the joint. This directly shapes the bead's width and reinforcement. Move too slowly, and you’ll pump too much heat into the metal, creating a wide, flat bead and increasing the risk of burn-through. On the flip side, moving too fast leaves a narrow, convex bead that looks "ropey" and suffers from poor penetration.

The goal is to find a rhythm. Your travel speed should be perfectly synchronised with the way the weld pool is forming, creating that classic, uniform pattern of overlapping ripples. That consistency is the true hallmark of a skilled TIG welder.

How you hold the torch and feed the filler rod is crucial for directing the arc and ensuring the metals fuse properly. The standard approach is to hold the torch at a 15 to 20-degree angle, pushing it away from the weld you've just laid down. This "push" angle gives you a clear view of the weld pool and makes sure the shielding gas effectively covers the molten metal just ahead of the arc.

Adding filler material is a dance of coordination. The rod should be held at a low angle, maybe 15 degrees or so, and gently dabbed into the leading edge of the molten pool. A critical detail: never pull the filler rod out of the shielding gas envelope. Doing so will introduce contaminants from the air straight into your weld. The motion should be fluid and constant: advance the torch, dab the rod, advance, dab.

Setting the correct shielding gas flow rate is a final, critical step. You need enough inert gas to protect the weld pool from atmospheric contamination, but not so much that you create turbulence. For argon, a common flow rate is between 10 to 15 litres per minute (L/min).

Too little gas won't provide enough shielding, leading to defects like porosity (tiny holes in the weld). Too much flow is just as bad; it can cause turbulence that actually pulls in air from the surrounding atmosphere, contaminating the weld. The size of your ceramic cup also plays a part—larger cups need a bit more gas to provide the same coverage.

This intense focus on gas shielding has deep roots. In Germany, the Wolfram-Inertgas-Schweißen (WIG) process was first used with shielding gas in the early 1940s, with argon quickly becoming the preferred choice for its stability. By 1945, German companies were using WIG to create high-quality seams in stainless steel pipes, achieving penetration depths of 4-6 mm in a single pass without any filler metal—a 30% efficiency improvement over older methods. You can find more on the history behind these TIG welding developments on Fronius.com.

For those ready to take their skills to the next level, understanding pulse welding is a must. Pulsed TIG isn't a constant stream of energy; instead, it alternates between a high peak amperage and a low background amperage. This technique gives you incredible control over heat input, making it perfect for welding very thin materials without distortion.

By controlling the frequency and duration of these pulses, you can fine-tune the heat to an amazing degree. This allows you to produce strong, beautiful welds on materials that would be nearly impossible to handle with standard DC TIG.

The sheer precision of Wolfram Inertgas Schweißen makes it so much more than just another way to join metal; it's a fundamental fabrication process for industries where failure is simply not an option. In these high-stakes environments, the integrity of a single weld can mean the difference between mission success and catastrophic failure. That’s why the clean, strong, and spatter-free nature of TIG welding makes it the go-to choice for the most demanding jobs.

From the upper atmosphere to sterile operating rooms, you'll find the results of this meticulous process. Its ability to create flawless joints in exotic and high-performance alloys is what truly sets it apart from faster, less controlled welding methods.

This diagram shows the core parameters—amperage, torch angle, and travel speed—that a skilled welder must constantly balance to achieve such high-quality results.

Mastering the interplay between these three variables is the key. It's how a welder unlocks the full potential of TIG for the most critical industrial applications.

In aerospace, every single component carries immense responsibility. TIG welding is used extensively to build parts from high-strength, lightweight materials like titanium, aluminium, and nickel-based superalloys. These metals are notoriously tricky to work with, but the precise heat control of the TIG process minimises the risk of defects that could compromise structural integrity.

The applications here are incredibly varied and absolutely critical:

The perfectly smooth finish of a TIG weld also reduces stress concentrations, a vital factor in preventing metal fatigue over a component's long service life.

In industries where hygiene is everything, the surface of a weld is just as important as its strength. The food, beverage, and pharmaceutical sectors rely on Wolfram Inertgas Schweißen to create the smooth, non-porous, and crevice-free welds needed for sanitary piping and processing equipment.

The real advantage of a TIG weld in these settings is its incredibly smooth profile. This prevents bacteria from getting a foothold and allows for effective clean-in-place (CIP) and sterilise-in-place (SIP) procedures, which is essential for ensuring product purity and safety.

Rough or porous welds left by other methods would quickly become breeding grounds for contaminants. For this reason, TIG welding on stainless steel tubing, tanks, and vessels is the undisputed industry standard for maintaining sterile conditions and meeting strict regulatory demands.

The world of motorsport is a relentless chase for performance, where every gram of weight and every ounce of strength makes a difference. TIG welding is the preferred method for fabricating custom components that are both incredibly light and exceptionally durable.

From custom exhaust systems made from thin-wall stainless steel or titanium to roll cages and suspension components, the precision of TIG allows fabricators to get maximum strength with minimum material. This fine-tuned control is essential when you're working with advanced alloys designed to shave seconds off lap times. This same precision is also found in high-end automotive restoration, where visually perfect welds on body panels are a true mark of craftsmanship.

In the nuclear industry, the integrity of a weld is directly tied to safety. Components inside nuclear reactors, like pressure vessels and piping systems, have to contain radioactive materials under immense pressure and high temperatures for decades.

TIG welding is mandated for many of these critical joints because of its ability to produce welds of the highest purity and quality, completely free of defects like porosity or inclusions. The process also allows for thorough inspection using non-destructive testing (NDT) methods, verifying that every single weld meets the sector's exceptionally stringent safety standards. The reliability of Wolfram Inertgas Schweißen is fundamental to the safe operation of power plants all over the world.

Laying down a technically perfect weld bead is a mark of true skill. But the real measure of professional Wolfram Inertgas Schweißen is executing that weld safely and knowing how to verify its quality. In high-stakes fields like ours, ensuring personal safety and the structural integrity of your work isn't just a good idea—it's completely non-negotiable.

This means gearing up correctly before you even think about striking an arc. It also means knowing how to inspect your work for hidden flaws that could compromise everything. Every TIG welder must treat safety as the absolute top priority. The process itself involves some serious hazards, from intense heat and powerful electrical currents to harmful radiation and fumes. Without the right precautions, these risks can lead to severe, long-term health problems.

Your Personal Protective Equipment (PPE) is your first and most critical line of defence. For TIG welding, this involves more than just a standard pair of gloves; you need specific gear designed for the unique challenges of the process.

Knowing the theory is one thing, but putting it into practice is what counts. Digging into the essential personal protective equipment requirements will give you a much deeper appreciation for how this gear keeps you safe on the job. And don't forget about proper ventilation—especially when working with materials like aluminium or stainless steel—to clear out the harmful fumes and ozone gas created by the arc. Gas cylinder safety is also paramount; our article on the importance of a protective cap for gas cylinders is a great resource.

Once the welding is done and you've packed up safely, the focus shifts to quality control. A weld that looks clean on the surface can still hide critical flaws that weaken the joint. Learning to spot these defects and understand what causes them is the key to producing work you can trust.

A good TIG weld should be uniform, with a consistent ripple pattern and no visible imperfections. Of course, things don't always go that smoothly.

A weld is only as strong as its weakest point. Identifying and correcting defects like porosity or tungsten inclusions is not just about aesthetics; it is fundamental to the structural integrity and safety of the final product.

To help you troubleshoot your own work, we've put together a guide to some of the most common issues you'll encounter in Wolfram Inertgas Schweißen.

This table is a great starting point for diagnosing issues with your welds. By understanding the root causes, you can adjust your technique and setup to prevent them from happening again.

| Defect | Potential Cause(s) | Preventive Solution |

|---|---|---|

| Porosity | Inadequate gas shielding, contaminated base metal or filler rod, excessive arc length. | Increase gas flow rate, clean materials thoroughly, maintain a tight arc length. |

| Tungsten Inclusions | Dipping the tungsten electrode into the weld pool, excessive amperage causing tungsten to melt. | Practise steady torch control, use the correct amperage for the material thickness. |

| Undercut | Excessive amperage, incorrect torch angle, or moving too quickly. | Reduce welding current, maintain a proper torch angle (15-20 degrees), slow down travel speed. |

| Lack of Fusion | Insufficient heat input, travelling too fast, incorrect joint preparation. | Increase amperage, slow travel speed, ensure the joint is clean and correctly bevelled. |

By proactively watching for these issues and knowing how to fix them, you can dramatically improve the quality and reliability of every single weld you produce.

The traditional craft of Wolfram Inertgas Schweißen is undergoing a massive shift. What was once purely a manual art form is now evolving into a precise, data-driven science, thanks to the principles of Industry 4.0.

This transformation is all about plugging digital technology directly into the welding process. Smart manufacturing is completely reshaping what's possible, turning the welder’s torch from a simple tool into an intelligent device that’s part of a much larger production ecosystem.

Now, we can monitor and record every critical parameter in real time. Think about it: a system where voltage, amperage, gas flow, and travel speed are constantly tracked and fine-tuned. This ensures absolute consistency, whether you're on the first weld or the thousandth. It takes the guesswork out of the equation, guaranteeing every joint is made to exact specifications.

The pay-off is a huge leap in quality, a massive drop in defects, better efficiency across the board, and complete traceability for every single component.

Robotics are playing an ever-bigger role in TIG welding, especially in industries that need high volumes and flawless repeatability. A perfect example is the manufacturing of electric vehicle (EV) battery packs.

Each EV battery pack requires thousands of small, incredibly precise, and structurally vital welds. Frankly, manual welding just can't keep up with the speed or consistency demanded at this scale.

Automated TIG systems, on the other hand, can lay down perfect welds 24/7 without getting tired or making mistakes. This guarantees that every single battery connection is secure, reliable, and meets the tough safety standards of the automotive world.

When you combine the natural precision of the TIG process with the relentless accuracy of robotics, manufacturers can hit levels of productivity and quality control that were previously out of reach. This is what's cementing TIG's place in the future of advanced fabrication.

Digitalisation is the engine driving TIG welding's potential in modern manufacturing. Here in Germany, a world leader in smart manufacturing, we're already seeing the impact firsthand.

Companies have been pioneering real-time process controls since 2020, propelling the entire industry forward. By meticulously recording voltage, current, and arc length, they're achieving 100% measurable welds and an incredible 99.5% process reliability.

Data from German trials shows these smart systems slash variability by 35% while maintaining arc stability at 98% over long, 10-metre seams—a must-have for demanding jobs like EV battery production. You can dive deeper into these TIG welding innovations on wolfram-industrie.de. This data-first approach means every weld isn't just completed; it's documented, verified, and optimised.

Even after you get the hang of the equipment and the basic techniques, you’ll always run into new questions on the workshop floor. It’s just the nature of Wolfram Inertgas Schweißen. This section tackles some of the most common queries we hear, with clear, straightforward answers to help you solve problems and build your confidence.

Think of this as a quick reference guide. We'll dive into a few of the topics that come up again and again.

The single biggest advantage of TIG welding is superior precision and control. While a MIG setup is certainly faster for laying down a lot of metal, TIG gives the welder total command over the heat input and the addition of filler material. They are two separate actions.

This separation is the key to producing incredibly clean, high-quality welds with virtually no spatter. It’s exactly why TIG is the go-to process for delicate work on thin materials, tricky joints, and any job where the final appearance is non-negotiable—think aerospace components or custom automotive fabrication.

For welding stainless steel, 100% pure Argon is the undisputed industry standard. It’s the right choice for the overwhelming majority of jobs. Argon gives you excellent arc stability, helps clean the surface as you weld, and leaves a bright, clean, and aesthetically pleasing bead.

In some very specific situations, like welding extremely thick sections of stainless, a fabricator might use an Argon/Helium mix. Adding helium makes the arc hotter, which can boost your travel speed and penetration. But for general-purpose work and anything requiring high precision, pure Argon is the most reliable way to get top-quality results, every time.

Pure Argon is the go-to because it's heavier than air, forming a dense, protective blanket over the weld pool. This shield is crucial for keeping atmospheric contaminants out, which is essential for preserving the corrosion-resistant properties of stainless steel.

Tungsten contamination is probably the number one frustration for welders new to the TIG process. The most common culprit? Accidentally touching the electrode tip to the molten weld pool or the filler rod. Just a brief dip is enough to foul the tungsten and make your arc unstable and hard to control.

Other common causes include:

The fix is all about discipline and technique. Focus on keeping a steady hand and a consistent arc length. Before you strike an arc, always double-check that your gas flow rate is correct for the job and that you’ve set an adequate post-flow time.

For all your industrial gas handling and storage needs, from high-purity argon for welding to complex cryogenic solutions, Cryonos GmbH delivers state-of-the-art equipment with unmatched reliability. Explore our comprehensive portfolio of vessels and safety gear at https://www.cryonos.shop.